K-WANG

Watlow PPC-2000 Controller

Watlow PPC-2000 Controller

PPC-2000 User's Guide "is a user manual for modular programmable process control systems launched by Watlow. It supports 48 PID control loops or 8 adaptive control+24 PID control (a total of 32 loops), with rich I/O interfaces (up to 128 analog inputs, 288 digital I/O, 48 analog outputs), supports multiple sensors such as thermocouples and RTDs, and is configured and monitored with ANAWIN3 HMI software. LogicPro software supports logic programming and provides advanced functions such as RS-232/RS-485 communication, adaptive control, and cascade control. The warranty period is 3 years, and it needs to be used in conjunction with external safety devices. The manual covers the entire process of installation, operation, settings, and troubleshooting.

Core specification parameters

1. Control ability

Basic control: Supports On/Off, P, PI, PID control, with built-in Autotune function

Optional configuration: ① 48 channel conventional PID control; ② 8-channel adaptive control+24 channel PID control (a total of 32 channels)

Adaptive Control: Only 1-8 channels are supported, and adaptive mode, system delay (1-600 seconds), and set gain (5 selectable levels) can be set

2. I/O interface parameters

Key parameters of interface type

Up to 128 analog inputs are supported, including thermocouples (J/K/T/B/S/R, etc.), RTDs (100 Ω platinum resistors), 0-20mA/4-20mA currents, and -10V~10V voltages

The maximum number of digital I/O channels is 288, and the processor module comes with 48 channels (24 channels can be configured). The expansion module supports 16/32 input/output channels

Up to 48 analog outputs, supporting 0-5V/0-10V/1-5V voltage and 0-20mA/4-20mA current, expandable through SDAC module

Counter input up to 17 channels, supports 0-10kHz frequency, 16 bit counting range

3. Communication and Power Supply

Communication parameters: RS-232 (maximum 50 feet), RS-485 (maximum 6000 feet), baud rate 9600/19200, Modbus RTU protocol

Power specification: PPC-IPS-2 input frequency 47-440Hz, peak output 9A@5Vdc The 6A@24Vdc Module operating voltage 12-28Vdc

Installation Guide

1. Module installation requirements

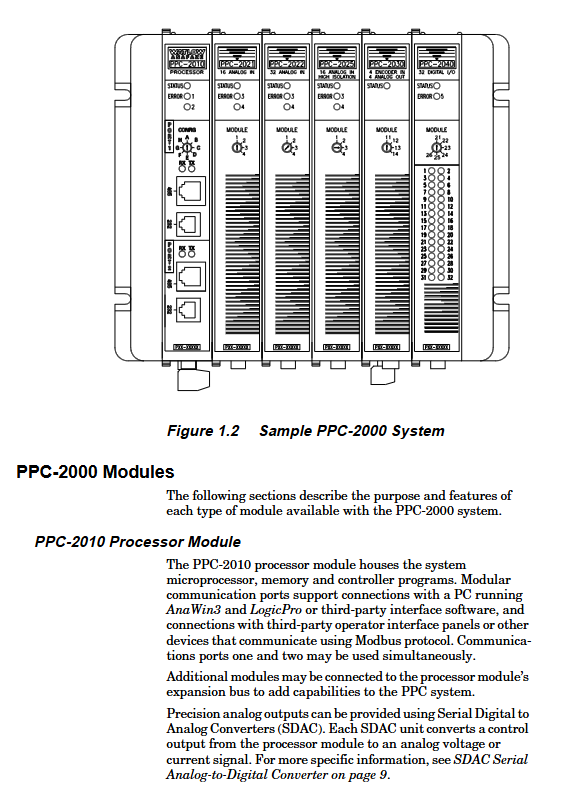

Core modules: PPC-2010 processor (48 digital I/O channels, 2 serial ports), PPC-202x analog input module (16/32 channels), PPC-2030 encoder input+analog output module, etc

Installation method: DIN rail or panel installation, unique module address (rotary switch setting, 1-64)

Space requirements: Each module should reserve heat dissipation space, PPC-IPS-2 should be installed vertically, and the minimum ventilation space should be 2.5 inches

2. Wiring specifications

Wire gauge requirements: 20-22 AWG shielded wire for analog signals, 24 AWG wire for digital signals, and 12-24 AWG wire for power supply

Shielding treatment: The shielding layer is grounded at one end (controller side) to avoid grounding loops

Sensor wiring: The positive and negative poles of the thermocouple correspond correctly. For 3-wire RTDs, attention should be paid to compensating for lead resistance. Current sensors should be connected in series with matching resistors

3. Environment and Safety

Working environment: temperature 0-60 ℃, storage temperature -20-70 ℃, humidity 10-95%, non condensing, altitude up to 2000 meters

Safety protection: Pollution level 2 (IEC 664), independent power-off switch needs to be installed to avoid live operation

Software operation and function settings

1. ANAWIN3 software operation

Core functions: Configure input types, linear scaling, channel parameters (PV source, output target, PID parameters), alarm settings

Display modes: bar chart, single loop, scanning, alarm display, supporting real-time monitoring of process variables (PV) and set values (SP)

Adaptive control settings: Only channels 1-8 are available, and the "Adaptive" control type needs to be enabled in the software to configure system delay and set gain

2. Core Function Configuration

Control parameter settings

PID parameters: proportional band (PB), integration time (TI 0-6000 seconds), differentiation time (TD 0-255 seconds)

Output settings: Time proportional period (1-255 seconds), DZC mode (SSR only), SDAC extended output

Adaptive parameters: Adaptive mode (Adapt/Reset/Hold), system delay (automatic detection or manual setting within 1-600 seconds)

Advanced control functions

Cascade control: The main channel output serves as the set value for the slave channel, supporting coordinated hot/cold output

Ratio control: from channel setting value=main channel PV x ratio+offset, supports range limitation

Process variable retransmission: Convert PV signals into 4-20mA analog signals and output them to recorders and other devices

Logic programming: LogicPro supports the IEC1131-3 standard, with 7 types of logic instructions and 42 types of application instructions. The program is stored in Flash

3. Alarm settings

Alarm types: high/low process alarm, high/low deviation alarm, sensor fault alarm (disconnection/short circuit)

Alarm parameters: alarm dead zone (0-255), delay time (0-100 seconds), supports "Alarm" (confirmation required) and "Control" (no confirmation required) modes

Output configuration: Any number of outputs can be assigned as alarm outputs, supporting multiple alarms sharing one output

Troubleshooting and Maintenance

1. Common troubleshooting

Key points for troubleshooting fault phenomena

Communication failure: Verify the consistency of baud rate/address/protocol, check the RS-485 wiring (A/B wires are not reversed), and confirm the terminal resistance (120 Ω)

Check for abnormal PV readings, sensor type settings, wiring polarity, input filtering parameters, and troubleshoot grounding loops or electromagnetic interference

Alarm misoperation triggers adjustment of alarm dead zone and delay time, checks sensor signal stability, calibrates input offset

Confirm that the channel control mode (Auto) and output target configuration are correct when there is no response from the output. Check the load power supply and wiring

2. Maintenance points

Firmware update: Replace via Flash chip, ANAWIN3 backup configuration is required before update

Battery replacement: The replacement of the processor module battery (Duracell DL2032) requires a power outage to avoid parameter loss

Regular calibration: analog input/output channel calibration, sensor regular inspection (thermocouple aging, RTD lead resistance)

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923