K-WANG

WATLOW MLS Controller

WATLOW MLS Controller

MLS User's Guide "is a modular PID controller user manual released by Watlow Anfaze in 1995. It covers 16/32 loop independent control functions, supports direct connection of various sensors such as thermocouples and RTDs, and has core features such as RS-232/RS-485 serial communication, SDAC analog output, and multi job storage. It provides a one-year product warranty and needs to be used with external safety devices. The manual details the entire process of installation, operation, setting, PID tuning, and troubleshooting, and is suitable for precise control of industrial temperature, pressure, and other parameters.

Core specification parameters

Enter relevant information

Analog input: 16 channels (AIM-16 module) or 32 channels (AIM-32 module) differential input, sampling rate 16 loops/second

Sensor support: thermocouple (J/K/T/B/S/R, range -450~3210 ° F), RTD (3 ranges, RTD1: -100~300 ° C), current (0-10mA/4-20mA), voltage (-10~60mV, expandable to 0-25V)

Resolution: 0.02% (>12 bits), Accuracy: 0.1% (at 25 ° C)

Input filtering: Low pass filtering (0-255 scan period) to suppress high-frequency noise

Control and output related

Control loop: 16 loops (dual output) or 32 loops (single output), supporting On/Off, P, PI, PID control

Digital output: 34 channels (32 PID/alarm outputs+1 global alarm+1 system safety output), continuous sink current of 10mA

Output types: Time Proportional (TP), Distributed Zero Crossing Trigger (DZC), On/Off, SDAC (optional)

Cycle time: 1-255 seconds (TP output)

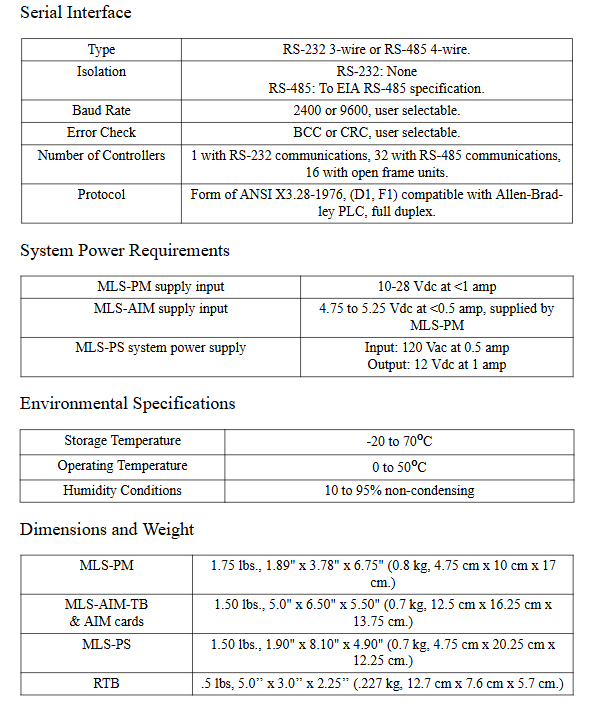

Communication and power related

|Module | Power Parameters | Communication Parameters|

|MLS-PM | Input 10-28Vdc, current<1A | RS-232/RS-485, baud rate 2400/9600|

|MLS-AIM | Input 4.75-5.25VDC, current<0.5A | Communicate with MLS-PM through RJ12 cable|

|MLS-PS | Input 120/240Vac, Output 15Vdc (1.2A)+5Vdc (4A) | -|

|Communication protocol | Supports ANSI X3.28-1976, Allen Bradley PLC compatible protocol | Error checking: BCC/CRC optional|

Installation Guide

Module installation requirements

MLS-PM: 1/8 DIN panel installation, hole size 3.63 × 1.80 inches, weight 1.75 lbs

MLS-AIM: Size 6.5 x 5 x 7 inches, Weight 1.5 lbs, Requires 6 inches of headroom reserved

RTB terminal block: size 5.0 × 3.0 × 2.25 inches, weight 0.5 lbs, DIN rail installation

Power Supply Unit (MLS-PS): Size 1.4 x 8 x 3.9 inches, Weight 1.2 lbs

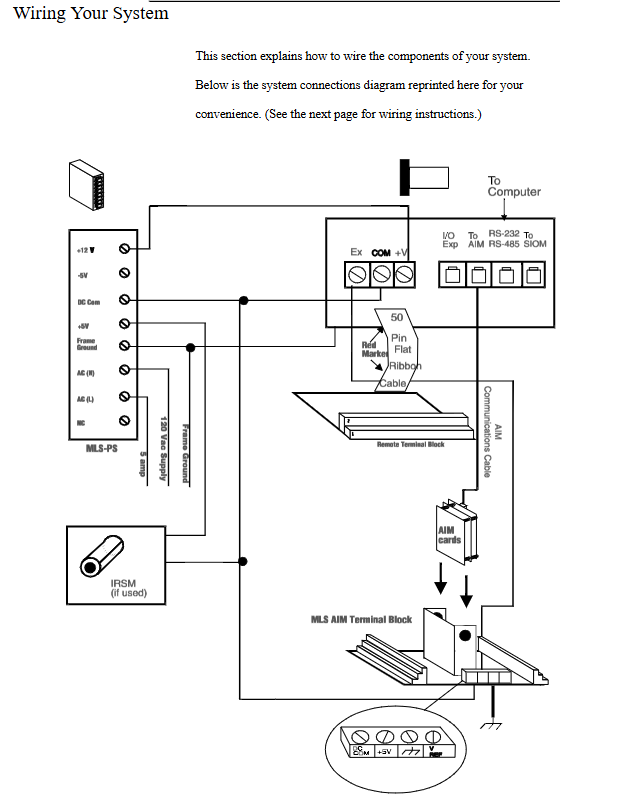

Wiring specifications

Wire gauge requirement: Priority should be given to using 18/20 AWG twisted wire to avoid excessive/insufficient wire diameter

Shielded wire usage: Input/output wires need to be shielded and grounded at one end (MLS panel grounding)

Cable recommendations: Special extension cords for thermocouples, Belden # 9154/8451 for analog inputs, Belden # 9729/9842 for communication lines

Noise suppression: When driving electromagnetic relays, a 0.01 μ F capacitor and a 47 Ω resistor need to be connected in series, or MOV/Transorb devices can be used

Key points for sensor connection

Thermocouple: Use 18/20 AWG extension wire with positive and negative electrodes connected to A+/A - to avoid grounding type thermocouples

RTD: Recommended 3-wire 100 Ω platinum resistor, wired to A+/A -/A COM

Current input: Converted into a voltage signal through a series resistor, 4-20mA corresponds to 12-60mV

Voltage input: directly connected to A+/A -, over 60mV needs to be adjusted through a scaling resistor

Operation and Settings

Front panel operation

Key functions: YES/NO (menu selection/numerical adjustment), ENTER (confirm storage), BACK (return), ALARM ACK (alarm confirmation), CHNG SP (modify set value), Man/Auto (mode switching)

Display mode:

Bar chart display: Simultaneously display the status and deviation of 8 circuits

Single loop display: displays the PV, SP, output percentage, and control status of a single loop

Alarm display: flashing to indicate high/low process/deviation alarm, sensor malfunction

Homework management: Supports storing 8 homework programs (including PID parameters, alarm settings, and set values), which can be remotely selected through digital input

Core Settings Menu

Global parameter settings

Controller address: 1-32 (unique when multiple controllers are cascaded)

Communication parameters: baud rate (2400/9600), protocol (ANASOFT/Allen Bradley), error checking (BCC/CRC)

Keyboard lock: Disable CHNG SP, Man/Auto and other keys

Power on output status: Off (default) or Memory (restore pre power off state)

Input settings

Input type: Select sensor type (thermocouple/RTD/linear/pulse/skip)

Linear scaling: Input 2 measurement points (e.g. 0PSI=4mA, 50PSI=20mA) for automatic calibration

Input offset: -300~+300, correct sensor error

Input filtering: 0-255 scan period, input signal with rapidly changing damping

Control and output settings

PID parameters: PB (proportional band), TI (integration time 0-6000 seconds), TD (differentiation time 0-255 seconds)

Output type: TP/DZC/On/Off/SDAC, SDAC supports 0-5VDC/4-20ADC switching

Output limit: 0-100%, supports continuous or timed limit (1-999 seconds)

Hot/Cold Output Configuration: Independently set PID parameters, action mode (reverse/forward), output interval

Alarm Settings

Alarm types: high/low process alarm, high/low deviation alarm, supporting three modes: Alarm/Control/Off

Alarm parameters: high/low set value (adapted to sensor range), deviation bandwidth (0-255), dead zone (0-255), delay (0-255 seconds)

Alarm output: can be allocated to 34 digital outputs, supporting multiple alarms sharing one output

Advanced features and troubleshooting

Advanced features

SDAC module: optional serial digital to analog conversion module, requiring configuration of SDAC high/low values (such as 4-20mA corresponding to 0-50PSI), occupying digital output 34 as the clock line

Remote job selection: Binary selection of 8 jobs through 1-3 digital inputs

Output forced override: triggers all circuits to switch to manual mode through digital input, and the output percentage can be customized

Linear scaling example: supports custom measurement range conversion for sensors such as pressure and flow (the manual includes 2 detailed examples)

Common troubleshooting

|Fault phenomenon | Key troubleshooting points|

|AIM communication failure | Check AIM power supply (4.75-5.25VDC), communication cable connection, manual reset controller|

|No display/button response | Check if MLS-PM power and keyboard lock function are enabled|

|Abnormal sensor reading | Confirm sensor type settings, wiring polarity, scaling resistor installation, input filtering parameters|

|Communication failure | Verify baud rate/protocol/address consistency, serial port wiring, and RS-232/RS-485 jumper settings|

|Alarm false triggering | Adjust the alarm dead zone and delay time, and check if there is noise interference in the sensor|

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

-

HIMA F60AI801 PLC Module | Analog Input Module

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Module

-

HIMA K9203 PLC Module | Safety Automation Module

-

X-DO1201 HIMA Control Pulse Card | Digital Output Module

-

F6705 HIMA Analog Output Module | Safety Control Output Module

-

HIMA B9361 PLC Module | Safety Automation System Module

-

HIMA H41Q-HRS / H41QX PLC Module | Safety Automation Module

-

HIMA F3003 Controller Unit | HIMAtrix Compact Safety Controller

-

HIMA HIMatrix F1DI1601 PLC Module | Digital Input Module for Safety Systems

-

HIMA X-DI 64 51 PLC Module | Digital Input Module for Safety Automation

-

HIMA F30 Controller Unit HIMAtrix 01 OPEN | Safety PLC Controller

-

HIMA K9202B PLC Module | Safety-Oriented Control Module

-

HIMA F3DIO20802 Controller PLC Module | Digital I/O Control for Safety Automation

-

HIMA F8627-1 F8627X Communication Module | Safety System Communication Interface

-

HIMA B4237-2 PLC Module | Safety Control and Logic Processing Module

-

HIMA X-DO2401 PLC Module | Digital Output Module for Safety Automation

-

HIMA 22100 PLC Module | Industrial Safety Control and Logic Processing

-

HIMA 90100 PLC Module | Safety-Oriented Industrial Control Module

-

HIMA 895210001 PLC Module | Industrial Safety Control and Processing Module

-

HIMA 157528-0 PLC Module | Industrial Safety Control and Processing Module

-

HIMA B5322 PLC Module | Industrial Safety Control and Processing Module

-

HIMA BV7032 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F3300 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7105A PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7150 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7508 PLC Module | Industrial Safety Control Processing Module

-

HIMA F8627 984862765 PLC Module | Industrial Safety Control Module

-

HIMA M3410 PLC Module | Industrial Safety Control Processing Module

-

HIMA Z7308 PLC Module | Safety Control System Processing Module

-

F8640 HIMA Central Module | Safety System Core Controller

-

HIMA F8630 Module | Safety System Functional Module

-

F8651X HIMA Central Module | Safety System Core Controller

-

F3236 Digital Input Module | HIMA Safety System Input Interface

-

F7131 HIMA Power Monitoring Module | Safety System Power Supervision

-

F8627X HIMA Communication Module | Safety System Network Interface

-

HIMA F8560X PLC Module | Safety-Related Control System Component

-

HIMA P8403 PLC Module – Industrial Safety Control Processor

-

HIMA F8628X Communication Module – Industrial Safety System Interface

-

HIMA F8621A Communication Module – Safety System Communication Interface

-

HIMA 984865066 PLC Module – Safety Control Processing Unit

-

HIMA F60CPU01 PLC Module – Safety Control Processing Unit

-

HIMA F8650E PLC Module – Safety Control Processing Unit

-

HIMA F8652E Central Module – Safety Control Processing Unit

-

HIMA F8650X Card – Safety Central Processing Module

-

F8652X HIMA Central Module – Safety Control Central Processing Unit

-

HIMA 99-7105233 B5233-1 Safety Module – Industrial Safety Control Component

-

KEBA KeTop T70-rqa-AK0-LK Teaching Device – Industrial Robot Teach Pendant

-

KEBA KETOP T50-T41-CPU 2495D-0 – Industrial CPU Module

-

KEBA E-CON-CC100/A/ 22178 – Industrial Controller Module

-

KEBA Kemro K2-200 CP 250/X 71580 CPU-MODULE – Industrial Control CPU Module

-

KEBA D3‑DA 330/A‑1211‑00 Drive – KeDrive D3 Axis Controller Industrial Servo Drive

-

KEBA KETOP O70‑bra‑A0a‑F Demonstrator – Industrial Automation Control Module

-

KEBA KETOP O70-BRA-A0A-F Demonstrator | Industrial HMI Operating Terminal

-

KEBA SO84.012.0083.0101.2 Servo Drive | Industrial Motion Control Solution

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

XYCOM 1546 - Proface Industrial Workstation 1546-102031013

-

XYCOM 86864-002-E - Processor Board Module

-

XYCOM 3112T - Pro-face Operator Interface

-

XYCOM 3712 KPM - Pro-face Operator Panel

-

XYCOM 4615KPMT - Proface Industrial PC Display Panel PM-070007

-

XYCOM 5015T - Pro-Face Touch Monitor 100-240 VAC

-

XYCOM 5015T/R2 - Industrial Flat Panel Touch Monitor 5015R2-0100000

-

XYCOM 1341 - Proface Embedded Computer TF-AEC-6920-C2

-

XYCOM GLC150-BG41-DN - Graphic Logic Controller M-24V

-

XYCOM GP2301H-SC41-24V - Pro-face Operator Interface 5.7" w/ Cable

-

XYCOM 1547 - Pro-face Industrial PC Model 1547-00113101

-

XYCOM ST401-AG41-24V - Graphic Touchscreen Operator Interface

-

XYCOM 3310T - Pro-face Operator Panel 3310-001101001

-

XYCOM 5015 KPMT - Proface Operator Panel Display

-

XYCOM XVME-684 - PC Module VME Bus Processor 70684-201

-

XYCOM 3300 MT - Screen Monitor Display

-

XYCOM SXT1811T - Touch Panel Monitor 100/240VAC

-

XYCOM XT-1502 - Touch Screen Monitor Flat Panel Display Interface

-

XYCOM SXT1811 - Viewtronix SXGA Flat Panel Monitor 18.1" Display

-

XYCOM VT1040T - ViewTronix Touch Screen Monitor

-

XYCOM WS2786291 - Industrial Workstation PC

-

XYCOM XCME-540 - Analog I/O Module VMEbus 70540-001

-

XYCOM XVME-682 - CPU PCB Processor Module 70682-101

-

XYCOM CU040103500 - VME Rack System Module 4200401

-

XYCOM XVME-085 - Proto VMEbus Non-Intelligent Prototyping Module

-

XYCOM XVME-100 - PCB Controller Card ROM Board 70100-001

-

XYCOM XVME-103 - VMEbus Board 10103-001

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923