K-WANG

SCHNEIDER PowerPact ™ H. Modbus Communication User Guide for J and L-type Circuit Breakers

SCHNEIDER PowerPact ™ H. Modbus Communication User Guide for J and L-type Circuit Breakers

Schneider PowerPact ™ H. The Modbus communication user guide for J and L-type circuit breakers covers four core contents: communication interfaces (IFM/IFE), Modbus protocol specifications, module registers and commands, and data acquisition and control. It clarifies the hardware configuration and communication parameters of IFM (RS-485 serial line) and IFE (Ethernet) interfaces, and lists in detail the register addresses, data types, and read-write rules of standard/old datasets, MicroLogic trip units, BSCM modules, and IO modules. It provides the execution process of remote commands such as circuit breaker opening and closing, parameter configuration, etc., while emphasizing safety operation standards (such as password management and permission control), suitable for remote monitoring and control in industrial distribution scenarios.

Document Overview

(1) Core positioning and scope of application

Category key information

Document Purpose: PowerPact ™ H. Installation, configuration, and operation guide for Modbus communication of J and L-type circuit breakers

Circuit breakers with firmware versions that meet the requirements (such as IMU module firmware ≥ V001.003.000)

The core value is to achieve remote reading of measurement data, diagnostic information, control of circuit breaker opening and closing, and configuration of protection parameters

Safe operation must be carried out by qualified electrical personnel, strictly following password management and permission control

(2) Compliance and reference standards

International standards: IEC/EN 60947-4-1, UL 508, CSA C22.2 No.14

Network Security: First use requires changing default password, disabling unused ports, deploying multi-layer network defense

Related documents: PowerPact Circuit Breaker User Guide, MicroLogic Release Unit User Guide, ULP System User Guide

Communication interface configuration

(1) IFM interface (Modbus SL)

Detailed parameters of configuration items

Part number LV434000 (replaces TRV00210/STRV00210)

Communication interface RJ45 port (Modbus SL), stacking interface (optional TRV00217)

Address setting rotary switch definition (1-99), default address 99, address 0 reserved for broadcasting

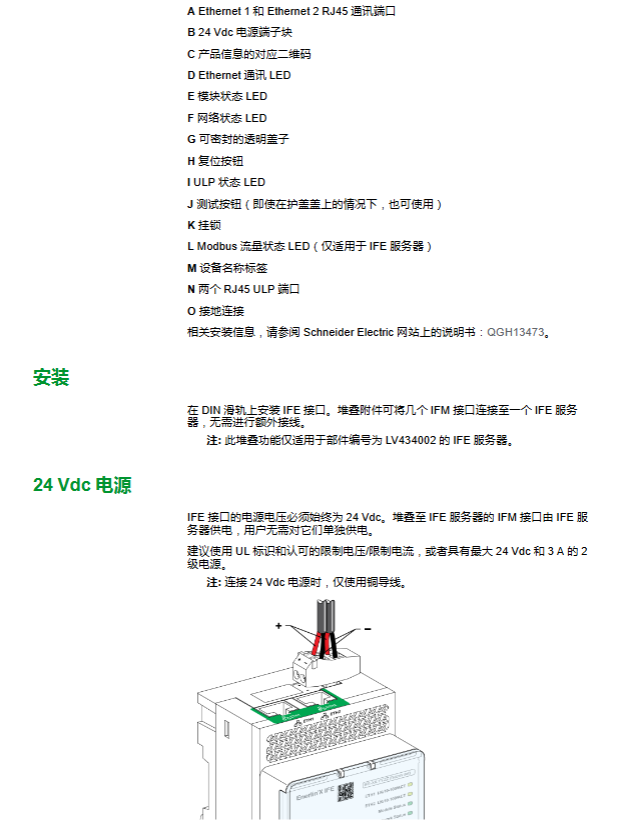

The power requirement is 24Vdc. It is recommended to use UL certified Level 2 power supply (maximum 3A) and only connect with copper wires

Padlock function enabled: Enable remote control command; Closed: Disabled (except for the 'Set Time' command only)

Automatic configuration method: detect baud rate (4800/9600/19200/38400) and parity; Manual configuration: through EcoStruxure Power Commission software

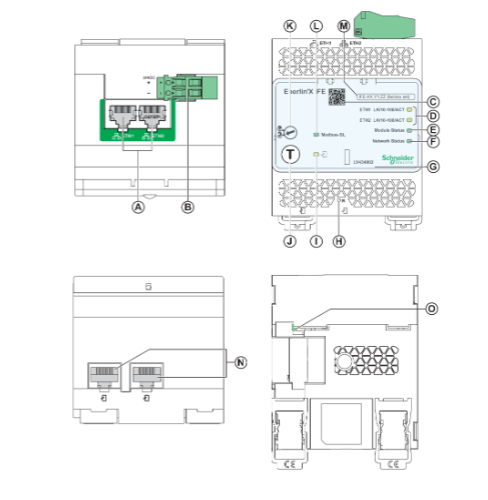

(2) IFE interface (Ethernet)

Detailed parameters of configuration items

Type and Part Number Single Circuit Breaker Interface (LV434001/LV434010), Ethernet Server (LV434002/LV434011)

Communication interface dual RJ45 ports (supporting daisy chain connection), no ring topology protection

IP configuration defaults to DHCP, which can be restored to default by pressing the reset button (1-5 seconds)

The power requirement is 24Vdc, and the stacked IFM interface is powered by the IFE server

The padlock function is the same as the IFM interface, only the "set time" command is not restricted

Featured features include embedded configuration/monitoring of web pages, device discovery services, email alert notifications

Modbus protocol specification

(1) Basic rules of communication

Master slave mode: 1 master device (monitor/PLC), up to 31 slave devices (circuit breakers)

Frame structure: Device address (1 byte) → Function code (1-2 bytes) → Data (n registers) → CRC16 checksum (2 bytes)

Response time: Typical<10ms, maximum value 700ms, recommended request interval ≥ 1 second

Data storage: INT32/64 type adopts Big Endian format (the most significant bit is transmitted first)

(2) Core functional code

Function code name usage restrictions

0x03 Read Hold Register Read Output/Internal Register (such as measurement value, status) Up to 52 registers

0x04 Read Input Register Read Input Register (such as sensor data) Up to 52 registers

0x06 Preset a register to write a single parameter (such as protection threshold)-

0x10 Preset multiple register batch write parameters (such as multiple protection settings) up to 52 registers

0x2B (sub function 0x0F/0x10) Get/set date and time synchronization from device time support broadcast synchronization

0x08 Diagnostic Function Management Counter (such as Bus Error Count)-

(3) Exception code description

Common reasons for the meaning of abnormal codes

0x01 The function code for the illegal function request is not supported

0x02 Illegal data address register address does not exist or is not compatible with firmware version

0x03 Illegal data value written to parameter exceeds allowed range

0x06 Busy device processing other commands

0x07 Negative confirmation programming request cannot be executed

Data collection and registers

(1) Dataset classification

Dataset type, register range, core content advantages

Standard dataset 32000-32341: Circuit breaker status, tripping reasons, current/voltage/power/energy, fast response to harmonic distortion, including high-precision data

The old dataset 12000-12165 is compatible with old devices and includes basic measurement values and status. A single request can read 114 registers

(2) Core module register

① MicroLogic trip unit (key register)

Register type, address range, core data update frequency

Real time measurement of 1000-1146 phase current (IA/IB/IC), line voltage (VAB/VBC/VCA), frequency of 1 second

Electricity measurement 2000-2031 Total active energy (kWh), total reactive energy (kVARh) 5 seconds

Protection parameter 8754-8930: Long delay Ir, short delay Isd, and instantaneous Ii settings are updated as needed

Log register 5732-29549 alarm logs (10 entries), trip logs (17 entries), maintenance logs (10 entries) event triggers

② BSCM module (circuit breaker status control)

Register type, address range, core data function

Status registers 563-564 Real time monitoring of circuit breaker opening and closing status and electric mechanism mode

Counter 571-582 opening and closing times, command execution times, threshold setting (default 5000), maintenance warning

Event log 602-652 10 event records (including timestamp and event type) fault tracing

③ IO module

Register Type Address Range (IO1) Core Data Function

Analog input 13824-13929 Pt100 temperature (-50~250 ℃), data validity, environmental monitoring

Digital input/output 13930-14000 6-channel input status, 3-channel output status switch control

Alarm status 203-205 User defined alarm (201-210) Activation status abnormal warning

Remote Command and Control

(1) Command execution process

Load command parameters into buffer (registers 8000-8015)

Send requests through Modbus function 16 (write multiple registers)

Read command status register 8021 and confirm if it is being executed (0x0003)

Verify if the command code of register 8020 matches the request

Read error code (register 8021 least significant bit), 0 indicates successful execution

(2) Example of Key Commands

Command Name Command Code Permission Requirements Core Parameters

Circuit breaker opening 904 administrator/operator has no additional parameters

Circuit breaker closing 905 administrator/operator has no additional parameters

Reset minimum/maximum value 46728 Administrators/operators need to specify the reset object (current/voltage/power, etc.)

Long delay protection setting 45192 administrator Ir setting value, tr delay (500~16000ms)

Password Modification - Administrator Old Password+New Password (4 ASCII characters)

(3) Permission and Security Control

User profiles: Administrator (highest authority), Service, Engineer, Operator (hierarchical authority)

Password rule: Default password (0000/111/2222/3333), must be changed for the first use

Write protection: dual protection of hardware padlock and software password to prevent illegal modification of protection parameters

Log audit: All operations (command execution, parameter modification) are recorded with timestamp logs

Safety and Maintenance Standards

Operation requirements: Installation and maintenance must be carried out by qualified electrical personnel, and wiring specifications must be strictly followed

Network Security: Disable unused ports/accounts, deploy firewalls, network segmentation

Firmware update: Ensure compatibility through EcoStruxure Power Commission software update

Maintenance indicator: By reading the usage time, contact wear rate, and tripping times of the circuit breaker through the register, a maintenance warning is triggered

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Automation Module

-

HIMA K9203 PLC Module | Safety Control System Module

-

HIMA F60AI801 PLC Module | Analog Input Module

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Module

-

HIMA K9203 PLC Module | Safety Automation Module

-

X-DO1201 HIMA Control Pulse Card | Digital Output Module

-

F6705 HIMA Analog Output Module | Safety Control Output Module

-

HIMA B9361 PLC Module | Safety Automation System Module

-

HIMA H41Q-HRS / H41QX PLC Module | Safety Automation Module

-

HIMA F3003 Controller Unit | HIMAtrix Compact Safety Controller

-

HIMA HIMatrix F1DI1601 PLC Module | Digital Input Module for Safety Systems

-

HIMA X-DI 64 51 PLC Module | Digital Input Module for Safety Automation

-

HIMA F30 Controller Unit HIMAtrix 01 OPEN | Safety PLC Controller

-

HIMA K9202B PLC Module | Safety-Oriented Control Module

-

HIMA F3DIO20802 Controller PLC Module | Digital I/O Control for Safety Automation

-

HIMA F8627-1 F8627X Communication Module | Safety System Communication Interface

-

HIMA B4237-2 PLC Module | Safety Control and Logic Processing Module

-

HIMA X-DO2401 PLC Module | Digital Output Module for Safety Automation

-

HIMA 22100 PLC Module | Industrial Safety Control and Logic Processing

-

HIMA 90100 PLC Module | Safety-Oriented Industrial Control Module

-

HIMA 895210001 PLC Module | Industrial Safety Control and Processing Module

-

HIMA 157528-0 PLC Module | Industrial Safety Control and Processing Module

-

HIMA B5322 PLC Module | Industrial Safety Control and Processing Module

-

HIMA BV7032 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F3300 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7105A PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7150 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7508 PLC Module | Industrial Safety Control Processing Module

-

HIMA F8627 984862765 PLC Module | Industrial Safety Control Module

-

HIMA M3410 PLC Module | Industrial Safety Control Processing Module

-

HIMA Z7308 PLC Module | Safety Control System Processing Module

-

F8640 HIMA Central Module | Safety System Core Controller

-

HIMA F8630 Module | Safety System Functional Module

-

F8651X HIMA Central Module | Safety System Core Controller

-

F3236 Digital Input Module | HIMA Safety System Input Interface

-

F7131 HIMA Power Monitoring Module | Safety System Power Supervision

-

F8627X HIMA Communication Module | Safety System Network Interface

-

HIMA F8560X PLC Module | Safety-Related Control System Component

-

HIMA P8403 PLC Module – Industrial Safety Control Processor

-

HIMA F8628X Communication Module – Industrial Safety System Interface

-

HIMA F8621A Communication Module – Safety System Communication Interface

-

HIMA 984865066 PLC Module – Safety Control Processing Unit

-

HIMA F60CPU01 PLC Module – Safety Control Processing Unit

-

HIMA F8650E PLC Module – Safety Control Processing Unit

-

HIMA F8652E Central Module – Safety Control Processing Unit

-

HIMA F8650X Card – Safety Central Processing Module

-

F8652X HIMA Central Module – Safety Control Central Processing Unit

-

HIMA 99-7105233 B5233-1 Safety Module – Industrial Safety Control Component

-

KEBA KeTop T70-rqa-AK0-LK Teaching Device – Industrial Robot Teach Pendant

-

KEBA KETOP T50-T41-CPU 2495D-0 – Industrial CPU Module

-

KEBA E-CON-CC100/A/ 22178 – Industrial Controller Module

-

KEBA Kemro K2-200 CP 250/X 71580 CPU-MODULE – Industrial Control CPU Module

-

KEBA D3‑DA 330/A‑1211‑00 Drive – KeDrive D3 Axis Controller Industrial Servo Drive

-

KEBA KETOP O70‑bra‑A0a‑F Demonstrator – Industrial Automation Control Module

-

KEBA KETOP O70-BRA-A0A-F Demonstrator | Industrial HMI Operating Terminal

-

KEBA SO84.012.0083.0101.2 Servo Drive | Industrial Motion Control Solution

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

XYCOM 1546 - Proface Industrial Workstation 1546-102031013

-

XYCOM 86864-002-E - Processor Board Module

-

XYCOM 3112T - Pro-face Operator Interface

-

XYCOM 3712 KPM - Pro-face Operator Panel

-

XYCOM 4615KPMT - Proface Industrial PC Display Panel PM-070007

-

XYCOM 5015T - Pro-Face Touch Monitor 100-240 VAC

-

XYCOM 5015T/R2 - Industrial Flat Panel Touch Monitor 5015R2-0100000

-

XYCOM 1341 - Proface Embedded Computer TF-AEC-6920-C2

-

XYCOM GLC150-BG41-DN - Graphic Logic Controller M-24V

-

XYCOM GP2301H-SC41-24V - Pro-face Operator Interface 5.7" w/ Cable

-

XYCOM 1547 - Pro-face Industrial PC Model 1547-00113101

-

XYCOM ST401-AG41-24V - Graphic Touchscreen Operator Interface

-

XYCOM 3310T - Pro-face Operator Panel 3310-001101001

-

XYCOM 5015 KPMT - Proface Operator Panel Display

-

XYCOM XVME-684 - PC Module VME Bus Processor 70684-201

-

XYCOM 3300 MT - Screen Monitor Display

-

XYCOM SXT1811T - Touch Panel Monitor 100/240VAC

-

XYCOM XT-1502 - Touch Screen Monitor Flat Panel Display Interface

-

XYCOM SXT1811 - Viewtronix SXGA Flat Panel Monitor 18.1" Display

-

XYCOM VT1040T - ViewTronix Touch Screen Monitor

-

XYCOM WS2786291 - Industrial Workstation PC

-

XYCOM XCME-540 - Analog I/O Module VMEbus 70540-001

-

XYCOM XVME-682 - CPU PCB Processor Module 70682-101

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923