K-WANG

User Guide for SCHNEIDER Service Interface (Part Number LV485500)

User Guide for SCHNEIDER Service Interface (Part Number LV485500)

The user guide for Schneider Service Interface (part number LV485500) is primarily used for on-site testing and configuration of MasterPact NT/NW, ComPacT, PowerPacT, and EasyPact series circuit breakers. It supports automatic trip curve testing, zone selection interlock (ZSI) testing, forced trip testing, primary injection testing preparation, and Enerlin'X equipment configuration for communication/non communication MicroLogic trip units through EcoStruxure Power Commission (EPC) software. It requires the use of dedicated cables (such as LV485512SP/LV485513SP) for power supply (24Vdc). The operation must be performed by qualified personnel and comply with safety regulations such as password management and power-off protection. After testing, a project report can be generated to verify the effectiveness of equipment protection functions. Sex.

Document Overview

(1) Core positioning and scope of application

Category key information

Document Usage: Installation, Connection, Testing, Configuration, and Troubleshooting Guide for Service Interface

Applicable tool Service Interface (part number LV485500, firmware ≥ 001.001.040)+EPC software

Applicable equipment circuit breakers: MasterPact NT/NW, EasyPact MVS, ComPacT NS/NSX, PowerPacT P/R/H/J/L series

Release unit: MicroLogic 2.0~7.0 series (communication/non communication), ET release system

Enerlin'X devices: IO modules, FDM121 displays, IFE/IFM interfaces, etc

Core Value: On site verification of circuit breaker protection function, configuration of equipment parameters, firmware updates, and generation of test reports for acceptance

(2) Safety and compliance requirements

Personnel qualifications: Only qualified electrical personnel are required to perform installation, testing, and maintenance, and must have the ability to operate equipment and identify risks

Network Security: First use must change default password, disable unused ports/services/default accounts, deploy firewalls and network segmentation

Electrical safety: During testing, the circuit breaker may trip, causing downstream power outages, and preventive measures need to be planned in advance; To avoid the risk of arc flash and electric shock, execute the operation after confirming that there is no danger involved

Compliance standards: Complies with IEC 61010-1, IEC 60947-6-2, UL 61010-1 and other standards, with certification covering cULus, CE, etc

Service Interface Hardware and Technical Parameters

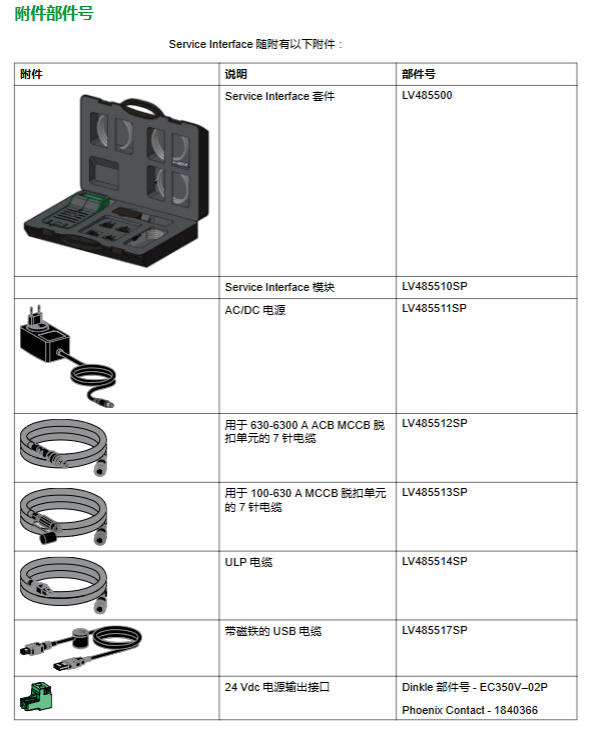

(1) Hardware composition and accessories

Specific specifications of component types

Core interface 24Vdc power input port, 24Vdc power output port (120mA), Mini-B USB port, test port, magnetic mount (magnetic installation)

Indicator light power LED (green: powered on), USB LED (green: connected), status LED (orange: boot mode), test port LED (green/blue/orange: corresponding to different device connections)

Special accessory 7-pin cable (LV485512SP: 630-6300A trip unit; LV485513SP: 100-630A trip unit, ULP cable (LV485514SP: Enerlin'X equipment), AC/DC power adapter (110-230Vac to 24Vdc), USB cable with magnet (LV485517SP)

(2) Key technical parameters

Specific numerical values for parameter categories

Electrical parameter input voltage: 24Vdc (-20%~+10%), maximum 525mA

Output voltage: 24Vdc (-20%~+10%), maximum 120mA

Rated power: Service Interface 10W, Adapter 12W

Environmental parameters Operating temperature: -10 ℃~+55 ℃ (14 ° F~+131 ° F)

Storage temperature: -40 ℃~+85 ℃ (-40 ° F~+185 ° F)

Protection level: ULV0 (compliant with IEC/EN 60068-2-30)

Pollution level: Level 3

Mechanical parameters Mechanical impact: Complies with IEC 62262 IK07

Installation methods: wall mounted, countertop, magnetic suction

Core testing functions (classified by circuit breaker type)

(1) MasterPact NT/NW, EasyPact MVS, ComPacT NS, PowerPacT P/R circuit breakers

Compatibility of release unit

The type of trip unit supports testing function

Communication type (such as MicroLogic 2.0A/E, 5.0P/H, 6.0 series) automatic trip curve testing, ZSI testing, forced trip testing, primary injection testing preparation, configuration

Non communication type (such as MicroLogic 2.0/3.0, ET 2. I) automatic trip curve test, forced trip test (without configuration/firmware update function)

Core testing process (taking communication unit as an example)

Connection: Connect the Service Interface to the test port of the trip unit using LV485512SP cable, and connect the 24Vdc power supply

Device discovery: EPC software → Start device discovery → USB/SRIAL → Select device → Enter project information → Connect device

Test execution:

Automatic trip curve test: Select pre configured/custom test points → Enter administrator password → Reset closing circuit breaker → Execute test (can be aborted) → Repeat test → View results

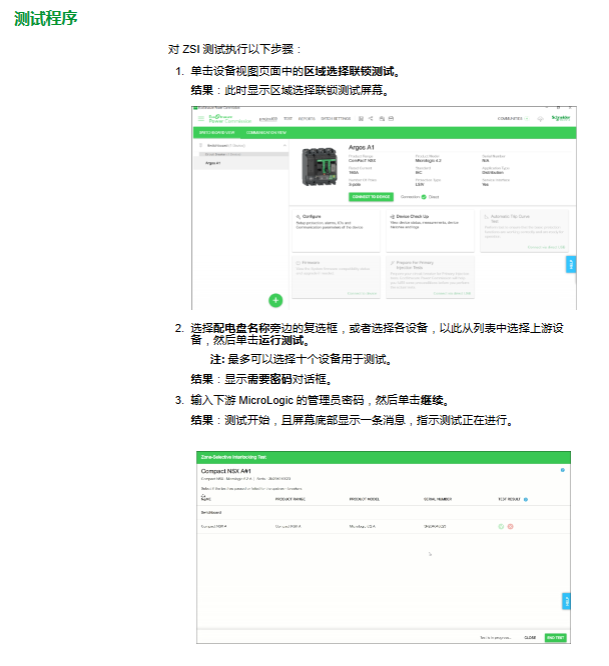

ZSI test: Select upstream devices (≤ 10 units) → Enter password → Run test → Confirm LED flashing status → End test

Forced tripping test: Equipment inspection → Confirm closing → Enter password → Confirm tripping → Generate results

Primary injection preparation: Select test type → Enter password → Suppress thermal memory/ground fault → Manually inject current → Test completed → Restore normal mode

Report generation: EPC software → Report → Project Report → Save/Print

(2) ComPacT NSX, PowerPacT H/J/L circuit breakers

Compatibility of release unit

MicroLogic release unit supports functions

1.2/1.3/2.2/3.2/4.3 series automatic trip curve test, forced trip test, primary injection preparation

5.2/5.3 B/A/E, 6.2/6.3 A/E, 7.2/7.3 E series automatic trip curve testing, ZSI testing, forced trip testing, primary injection preparation, alarm simulation, configuration, firmware update

Featured feature: Alarm simulation

Simulated objects: warning (PAL Ir/IG/I Δ n), 10 user-defined alarms

Verification scenario: FDM121 display (LED flashing/constant, pop-up, alarm history), communication network (Modbus register), SDx module (output status change)

Process: EPC Configuration → Alarm Tab → Select Activate Alarm → Enter Password → Simulate → Verify Results

Enerlin'X device configuration

(1) Compatible devices and functions

Equipment Name Part Number Example Support Function

IO input/output module LV434063 configuration, firmware update

FDM121 Front Display Module TRV00121/STRV00121 Firmware Update

IFE Ethernet interface LV434001 firmware update

IFM Modbus SL interface LV434000 configuration, firmware update

BSCM Circuit Breaker Status Control Module LV434205- (only compatible with connections)

(2) Connection and operation

Connection method: Use ULP cable (LV485514SP) to connect the Service Interface to the RJ45 ULP port of the device

Core operation: EPC software → Configure device parameters (some models), update firmware → Synchronize to other Enerlin'X devices in IMU

Firmware updates and troubleshooting

(1) Firmware update process

EPC software → Connect devices directly → Analyze firmware status → Check Service Interface → Next step

Enter password → click 'Upgrade' → wait for completion (cannot be disconnected)

View current/latest firmware version → Close window

Attention: The firmware adopts Schneider digital signature, and the validity of the certificate needs to be checked regularly

(2) Common troubleshooting

Possible causes and solutions for the fault phenomenon

Unrecognized release unit test interval<5 seconds, disconnect → wait for 5 seconds → reconnect

The primary injection test tripped too early, and the suppression function was not disabled before stopping and restarting the suppression function after tripping

Ground fault test without tripping injection current insufficient/MDGF/SGR configuration increases current → Check compatibility → Switch to primary injection test

Automatic tripping test failed (tripping<10ms), closing lock/instantaneous override protection ensures circuit breaker closing → verify protection level

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Automation Module

-

HIMA K9203 PLC Module | Safety Control System Module

-

HIMA F60AI801 PLC Module | Analog Input Module

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Module

-

HIMA K9203 PLC Module | Safety Automation Module

-

X-DO1201 HIMA Control Pulse Card | Digital Output Module

-

F6705 HIMA Analog Output Module | Safety Control Output Module

-

HIMA B9361 PLC Module | Safety Automation System Module

-

HIMA H41Q-HRS / H41QX PLC Module | Safety Automation Module

-

HIMA F3003 Controller Unit | HIMAtrix Compact Safety Controller

-

HIMA HIMatrix F1DI1601 PLC Module | Digital Input Module for Safety Systems

-

HIMA X-DI 64 51 PLC Module | Digital Input Module for Safety Automation

-

HIMA F30 Controller Unit HIMAtrix 01 OPEN | Safety PLC Controller

-

HIMA K9202B PLC Module | Safety-Oriented Control Module

-

HIMA F3DIO20802 Controller PLC Module | Digital I/O Control for Safety Automation

-

HIMA F8627-1 F8627X Communication Module | Safety System Communication Interface

-

HIMA B4237-2 PLC Module | Safety Control and Logic Processing Module

-

HIMA X-DO2401 PLC Module | Digital Output Module for Safety Automation

-

HIMA 22100 PLC Module | Industrial Safety Control and Logic Processing

-

HIMA 90100 PLC Module | Safety-Oriented Industrial Control Module

-

HIMA 895210001 PLC Module | Industrial Safety Control and Processing Module

-

HIMA 157528-0 PLC Module | Industrial Safety Control and Processing Module

-

HIMA B5322 PLC Module | Industrial Safety Control and Processing Module

-

HIMA BV7032 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F3300 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7105A PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7150 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7508 PLC Module | Industrial Safety Control Processing Module

-

HIMA F8627 984862765 PLC Module | Industrial Safety Control Module

-

HIMA M3410 PLC Module | Industrial Safety Control Processing Module

-

HIMA Z7308 PLC Module | Safety Control System Processing Module

-

F8640 HIMA Central Module | Safety System Core Controller

-

HIMA F8630 Module | Safety System Functional Module

-

F8651X HIMA Central Module | Safety System Core Controller

-

F3236 Digital Input Module | HIMA Safety System Input Interface

-

F7131 HIMA Power Monitoring Module | Safety System Power Supervision

-

F8627X HIMA Communication Module | Safety System Network Interface

-

HIMA F8560X PLC Module | Safety-Related Control System Component

-

HIMA P8403 PLC Module – Industrial Safety Control Processor

-

HIMA F8628X Communication Module – Industrial Safety System Interface

-

HIMA F8621A Communication Module – Safety System Communication Interface

-

HIMA 984865066 PLC Module – Safety Control Processing Unit

-

HIMA F60CPU01 PLC Module – Safety Control Processing Unit

-

HIMA F8650E PLC Module – Safety Control Processing Unit

-

HIMA F8652E Central Module – Safety Control Processing Unit

-

HIMA F8650X Card – Safety Central Processing Module

-

F8652X HIMA Central Module – Safety Control Central Processing Unit

-

HIMA 99-7105233 B5233-1 Safety Module – Industrial Safety Control Component

-

KEBA KeTop T70-rqa-AK0-LK Teaching Device – Industrial Robot Teach Pendant

-

KEBA KETOP T50-T41-CPU 2495D-0 – Industrial CPU Module

-

KEBA E-CON-CC100/A/ 22178 – Industrial Controller Module

-

KEBA Kemro K2-200 CP 250/X 71580 CPU-MODULE – Industrial Control CPU Module

-

KEBA D3‑DA 330/A‑1211‑00 Drive – KeDrive D3 Axis Controller Industrial Servo Drive

-

KEBA KETOP O70‑bra‑A0a‑F Demonstrator – Industrial Automation Control Module

-

KEBA KETOP O70-BRA-A0A-F Demonstrator | Industrial HMI Operating Terminal

-

KEBA SO84.012.0083.0101.2 Servo Drive | Industrial Motion Control Solution

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

XYCOM 1546 - Proface Industrial Workstation 1546-102031013

-

XYCOM 86864-002-E - Processor Board Module

-

XYCOM 3112T - Pro-face Operator Interface

-

XYCOM 3712 KPM - Pro-face Operator Panel

-

XYCOM 4615KPMT - Proface Industrial PC Display Panel PM-070007

-

XYCOM 5015T - Pro-Face Touch Monitor 100-240 VAC

-

XYCOM 5015T/R2 - Industrial Flat Panel Touch Monitor 5015R2-0100000

-

XYCOM 1341 - Proface Embedded Computer TF-AEC-6920-C2

-

XYCOM GLC150-BG41-DN - Graphic Logic Controller M-24V

-

XYCOM GP2301H-SC41-24V - Pro-face Operator Interface 5.7" w/ Cable

-

XYCOM 1547 - Pro-face Industrial PC Model 1547-00113101

-

XYCOM ST401-AG41-24V - Graphic Touchscreen Operator Interface

-

XYCOM 3310T - Pro-face Operator Panel 3310-001101001

-

XYCOM 5015 KPMT - Proface Operator Panel Display

-

XYCOM XVME-684 - PC Module VME Bus Processor 70684-201

-

XYCOM 3300 MT - Screen Monitor Display

-

XYCOM SXT1811T - Touch Panel Monitor 100/240VAC

-

XYCOM XT-1502 - Touch Screen Monitor Flat Panel Display Interface

-

XYCOM SXT1811 - Viewtronix SXGA Flat Panel Monitor 18.1" Display

-

XYCOM VT1040T - ViewTronix Touch Screen Monitor

-

XYCOM WS2786291 - Industrial Workstation PC

-

XYCOM XCME-540 - Analog I/O Module VMEbus 70540-001

-

XYCOM XVME-682 - CPU PCB Processor Module 70682-101

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923