K-WANG

Pepperl+Fuchs H-System and Schneider Electric Tricon CX

Pepperl+Fuchs H-System and Schneider Electric Tricon CX: Technological Integration and Industry Breakthrough of Intrinsic Safety Isolation Solution

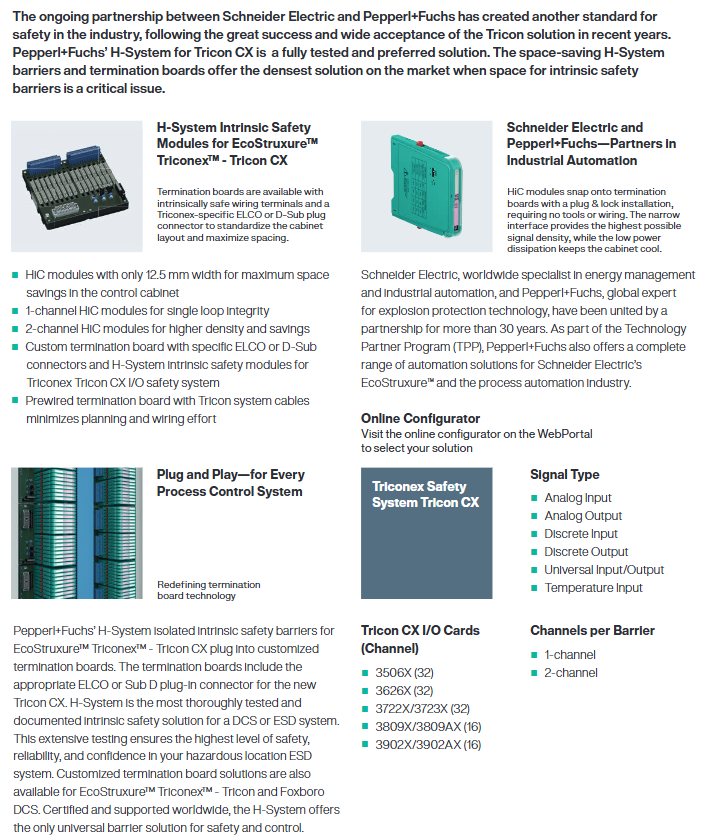

In the global field of industrial automation and process control, safety has always been the core of system design. Especially in high-risk industries such as chemical, oil and gas, and energy, how to build a control system that meets international safety standards and has high reliability and flexible scalability has always been a key issue in the technological evolution of the industry. In recent years, Schneider Electric's Triconex safety system has become an important choice for process safety systems such as ESD and emergency stop systems due to its outstanding performance and wide industry recognition. As a global leader in industrial sensors and explosion-proof technology, Pepperl+Fuchs' H-System intrinsic safety isolation solution provides highly adapted and fully validated terminal connection and signal isolation solutions for the Triconex platform, especially the new generation Tricon CX system. The deep cooperation between the two not only represents the technological integration of a "strong alliance", but also essentially redefines new standards for cabinet layout, signal density, and system security.

Collaboration cornerstone: Over 30 years of collaborative innovation

The partnership between Schneider Electric and Pepperl+Fuchs has lasted for over thirty years, built on a shared vision to enhance the safety and efficiency of industrial automation. As an important member of Schneider Electric's Technology Partnership Program (TPP), Pepperl+Fuchs plays a role far beyond that of ordinary suppliers. It is a major technology and product provider for Schneider Electric EcoStruxure architecture, particularly Triconex safety systems, in areas such as intrinsic safety barriers, signal conditioning, fieldbus infrastructure (such as FOUNDATION Fieldbus, PROFIBUS), HART multiplexing, and specialized HMI solutions. This deep integration ensures that every step from system planning, product selection to on-site implementation can obtain a seamless and optimized combination that has undergone interoperability testing.

Tricon CX System: The Next Generation Process Safety Core

The Tricon CX is the latest member of Schneider Electric's Triconex safety system family, designed specifically for demanding critical control and safety applications. It inherits the Triple Modular Redundancy (TMR) architecture of the Triconex system, which is highly available and reliable, and further enhances processing power, diagnostic capabilities, and system resilience through continuous optimization of hardware and software. The Tricon CX supports multiple types of I/O cards, including digital input/output, analog input/output, temperature input, and general-purpose I/O, to meet the needs of complex process control and safety interlocking. For example, the cards listed in the document, such as 3506X (32 channel digital input), 3626X (32 channel digital output), 3722X/3723X (32 channel analog/temperature input), 3809X/3809AX (16 channel analog output), and 3902X/3902AX (16 channel universal I/O), form its flexible and powerful I/O foundation.

However, when deploying these I/O signals in hazardous areas (such as environments where explosive gases may exist), intrinsic safety (IS) protection measures must be taken to limit the energy in the hazardous area to a level that cannot be ignited. This is precisely the stage where Pepperl+Fuchs H-System plays a crucial role.

H-System Solution: Intrinsic Safety Bridges Tailored for Tricon CX

Pepperl+Fuchs' H-System is not a universal product, but a specialized solution that is deeply customized and fully tested for the I/O characteristics of the Tricon CX system. Its core innovation is reflected in the following three aspects:

Highly integrated termination board design: Traditional intrinsically safe isolation barriers often occupy a large amount of cabinet space and have complex wiring. H-System provides prefabricated dedicated wiring boards. These patch panels integrate intrinsically safe terminals suitable for hazardous area wiring and come pre installed with ELCO or D-Sub plug-in connectors that directly match the Tricon CX I/O card. This design achieves "plug and play", greatly standardizes cabinet layout, reduces internal wiring workload, minimizes installation error risks, and significantly optimizes space utilization, providing the highest density intrinsic safety solution on the market.

Modular and narrow body designed HIC isolation barrier module: The core component of H-System is the HIC series intrinsic safety isolation barrier module. These modules have a width of only 12.5 millimeters and are installed in a unique "plug-in lock" style, securely clamping onto the wiring board without the need for tools. The module offers two specifications: single channel (1-channel) and dual channel (2-channel). The single channel design provides independent isolation and protection for each circuit, ensuring the integrity of the single circuit; The dual channel design further achieves a doubling of signal density while ensuring safety. All modules have undergone rigorous testing and comply with relevant Safety Integrity Level (SIL) certifications (such as SIL 2, SIL 3), ensuring high reliability of the entire safety circuit.

Comprehensive signal type coverage and customization capability: The H-System solution fully matches the various signal requirements of Tricon CX. The detailed configuration table in the document clearly shows this correspondence:

Digital input: Corresponding to the 3506X card, relay or transistor output isolation gates such as HIC2821/HIC2841 (single channel) or HIC2822/HIC2842 (dual channel) can be selected.

Digital output: Corresponding to 3626X card, it provides modules such as HIC2871/HIC2873 (supporting test pulse immunity), and even includes non intrinsic safety relay module options such as HIC5861/HICS863 to meet different load driving requirements.

Analog input: Corresponding to 3722X/3723X cards, the HIC2025 series module can handle standard 4-20mA signals, as well as special models designed specifically for fire detectors (with circuit currents up to 93mA) such as HIC2025A.

Temperature input: Using the 3722X/3723X card, the safe connection of thermocouple or RTD signals is achieved through modules such as HIC2081.

Analog output: Corresponding to 3809X/3809AX cards, HIC2031 series modules can safely transmit control system instructions to on-site actuators.

Universal I/O: Corresponding to 3902X/3902AX cards, HIC2441 and other modules, it provides extremely high flexibility and can be configured for input/output of analog or digital signals.

This refined matching ensures that the signal path from the on-site sensors/actuators to the Tricon CX controller is in an optimized state of safety and performance throughout the entire process.

Technological advantages and industry value

The integration solution of Pepperl+Fuchs H-System and Tricon CX brings significant multidimensional value:

Ultimate space saving: The 12.5mm narrow body module and high-density wiring board design achieve unprecedented space utilization in the control cabinet, especially suitable for renovation projects or new construction projects with limited space.

Excellent safety and reliability: As one of the most comprehensively tested and documented intrinsic safety solutions on the market, H-System ensures the highest level of safety for ESD systems in hazardous areas. The low-power design of its modules also helps to reduce cabinet temperature rise and improve long-term system stability.

Significant improvement in engineering and installation efficiency: The design concept of pre wiring and plug-in transforms complex cabinet wiring work into simple assembly tasks. The use of online configuration tools further simplifies the selection and ordering process, reducing engineering design time and on-site debugging costs.

Global Certification and Support: This solution has been certified in major global markets and supported by the global service networks of two industry giants, providing convenience and assurance for users' cross-border project deployment.

Future oriented flexibility: In addition to the Tricon CX, this customized patch panel and H-System module are also compatible with the previous generation Tricon system and Foxboro DCS, protecting users' existing investments and providing a smooth upgrade path.

Beyond Connection: Complete Product Ecology and Vision

Pepperl+Fuchs provides far more than intrinsic safety isolation for industrial automation. As an expert in the fields of "explosion-proof protection" and "industrial sensors", its product line covers from field level sensors (proximity switches, photoelectric sensors, ultrasonic sensors, etc.) to bus infrastructure (FieldConnex) ®)、 The complete chain of remote I/O, surge protection, wireless solutions, to human-machine interface (HMI), mobile communication devices, and identification systems. This means that under the cooperation framework with Schneider Electric, users can obtain a one-stop, collaborative optimization automation solution from on-site perception, signal security transmission, to upper level control and monitoring, truly achieving efficient integration from the device layer to the system layer.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

-

KEBA KeTop CB211 - Connection Box

-

KEBA HT4 / 20656 - Kammann Hand Held Keypad

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Y1-K1-Y2 PA9 - Engel Board Module

-

LTI MOTION CDA32.004C3.0 - Servo Drive 230V AC

-

KEBA E-CG-CONTROL - ECGCONTROL Module

-

KEBA Kemro K2-200 OP350/W 68334 - Engel EC200 Panel Membrane Touch Glass

-

KEBA i1075 - Membrane Keyboard

-

KEBA E-HSI-M - Interface Module

-

KEBA LQ10D321-ERSAT - ZTEILSET FNOB

-

KEBA E-16-DIGOUT/G - Circuit Board

-

KEBA HT4/Neutral/16846 - Mikron Handheld Terminal

-

KEBA KeTop CB310-000 - Connection Box

-

KEBA DC 161/IP20/17369 - Interface Card Module

-

KEBA E-16-DIGOUT-PLUS - Elektronik Bau Linz 262-1456-85-B

-

KEBA HT501 - Handheld Terminal

-

KEBA HT401-4X20 - Teach Pendant

-

KEBA E-3-ACU-10 D16738 - Controller Card Module

-

KEBA 240/A 068371 - Analog Output Module

-

KEBA E-7TEMP D1323E/F/G - Temperature Circuit Board

-

KEBA KeTop TT100-eaa - Communication Cable

-

KEBA E-16 DIGOUT-PLUS D1456D - Engel Output Board

-

KEBA Kemro K2-200 - Touch Panel Glass Digitizer

-

KEBA CC100A03/CAN/4 - PLC Chassis 16-Slot Rack Motherboard 1842E-0

-

KEBA CU 211 - PLC Power Supply

-

KEBA KeTOP CB310-S00 - Connection Box

-

KEBA I/O BUS KOPPLUNG D1547C - Engel Circuit Board

-

KEBA HCS01.1E-W0013-A-02 - Servo Drive

-

KEBA SMC1-Z30 - LTI Security Safety Control

-

KEBA E-PS88-M/C D1527C - Power Supply Board

-

KEBA D1678C / E-SEK - Control Board

-

KEBA 1.83E+02 - Circuit Board Module

-

LUST LTI/KEBA DSM4-05.4-20R.96-W1A - AC Servo Motor

-

Engel/KEBA OP 362-LD/W-5200 - Kemro Ke-200 Membrane Keypad Touch Screen

-

KEBA HT4 24V/0.2A - Kammann Hand Terminal C3052-R47

-

KEBA Kemro K2-200 BL210/B - Injection Molding Machine Controller Module

-

KEBA E-8-ANALOG D1432B - Analog Board

-

KEBA DM272 - Input Output Module

-

KEBA AR161 - PCB ML-EUMIG

-

KEBA E-PS-24V 1825E-1 - Power Supply Board

-

KEBA E-8-THERMO 1770B-1 - Engel Temperature Control Board

-

KEBA HT4-221-20556 - Kammann Hand Terminal

-

KEBA E-10-ANALOG-SUB D1458D - Circuit Board

-

KEBA AC 441 - Control Module 18-32 VDC

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA E-ANA-SUB2 D1690C - Analog Submodule Card

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad

-

KEBA OP 331/C-4400 - Keview V2 LCD Display Screen Panel

-

KEBA E-CRT D1630D - Circuit Board

-

KEBA DM570 - KeConnect C5 Digital Quantity Mixing Module 97825

-

KEBA KC-E10-3P-63A - AC Charger Accessories Electric Vehicle

-

KEBA G4E606-P - Industrial Computer Motherboard CPU PN:G4E606-501G

-

KEBA KEMROBUS 1842D-0 - Circuit Board

-

KEBA DM262/A - Interface Module K2-200

-

KEBA DI260/A - Controller Module 070257

-

KEBA PS240 - Power Supply Module

-

KEBA DM272/A - Kemro K2-200 Input Output Module 070258

-

KEBA AT 4041 / KeTop C70-10z-AaO-RB - LCD Screen Display

-

KEBA 3-XC 340/A - 2G Reservoir for CP520

-

KEBA JB 001/A - Set Controller Teaching Device

-

KEBA SC 102 / SC102A - Interface Module Cards PB201 PB101

-

KEBA Kemro K2-200 BL250/B - Injection Molding Machine Computer Input Module

-

KEBA Kemro K2-200 16in280/A - Controller Module Part Nr 2578 15

-

KEBA E-32-DIGIN / D1321F-1 - Digital Input Card

-

KEBA E-32-DIGIN / D1321E - Digital Input Board

-

KEBA FD353 / 17968 - Floppy Disk Drive

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923