K-WANG

Fault tolerant controller based on Triconex Triple Modular Redundancy (TMR) architecture

Fault tolerant controller based on Triconex Triple Modular Redundancy (TMR) architecture

The Triconex Tricon system is a fault-tolerant controller based on the Triple Modular Redundancy (TMR) architecture, consisting of a main processor module, I/O module, communication module, power module, and external terminal panel. It supports multiple types of I/O signals such as digital/analog/thermocouple, and has functions such as hot standby replacement, online maintenance, and sequence of events (SOE) recording. The working temperature range is -40 ° C to 75 ° C. It has passed international certifications such as T Ü V, CSA, FM, and is suitable for safety critical industrial scenarios such as emergency shutdown (ESD), boiler flame safety, and turbine control. The maximum system can be expanded to 15 chassis and 118 I/O modules, with a remote I/O distance of 7.5 miles (12 kilometers).

Product basic information

Key project information

Product Name: Triconex Tricon Fault Tolerant Controller System

Core architecture triple module redundancy (TMR), three channel parallel processing+2/3 voting mechanism

Core advantages include no single point of failure, online maintenance, hot standby replacement, and fault self diagnosis

Applicable scenarios include emergency shutdown (ESD), boiler flame safety, turbine control, and offshore fire and gas protection

International certified functional safety: IEC 61508 (SIL 1-3), DIN V 19250; Electrical safety: CSA, FM; Explosion proof: ATEX Zone 2; Nuclear power: NRC Class 1E

Environmental specifications: working temperature -40 ° C~75 ° C, storage temperature -40 ° C~75 ° C; relative humidity 5% -95% (no condensation); Anti vibration 2G (10-150Hz), anti impact 15G (6-11ms)

Core components of the system

(1) Core module type and specifications

Module category, key models, core parameters

Main processor (MP) 3008 16MB DRAM, 32-bit Motorola MPC860 processor, 50MHz

Power modules 8310 (120VAC/VDC), 8311 (24VDC), 8312 (230VAC) 175W (60 ° C), dual redundant design, output 6.5VDC ± 1%

Communication modules TCM (4351A/4352A), EICM (4119A), NCM (4329) TCM: 4 serial ports+2 Ethernet ports; EICM: 4 serial ports+1 parallel port; NCM: 2 Ethernet ports

Digital input (DI) 3501E (115VAC/VDC), 3504E (24/48VDC), 3564 (24VDC) with 32/64 points, response time<2ms~15ms

Digital output (DO) 3601E (115VAC), 3624 (24VDC), 3664 (dual redundancy) points 8/16/32, maximum current 2A/point

Analog input (AI) 3700A (0-5VDC), 3708E (thermocouple) with 16/32/64 points, accuracy<0.15%~0.25% FS

Analog output (AO) 3805E (4-20mA), 3806E (high current) with 8 points (3805E) and 6+2 points (3806E), resolution of 12 bits

Remote Expansion (RXM) 4200-3 (multimode), 4210-3 (single-mode) supports 3 remote sites, up to 12 kilometers away

(2) External terminals and extension components

Terminal panel: including standard type (9561-810, etc.), intrinsic safety type (9572-610, etc.), basic type (9551-110, etc.), supporting 16/32 point signals, including protective components such as fuses and current limiting resistors

Expansion cables: I/O bus cable (9000 series), I/O-COMM bus cable (9001 series), up to 300 meters in length

Auxiliary components: Blank slot panel (8105), heat dissipation baffle (2000361-001), NEMA standard chassis (Rittal/MarkHon series)

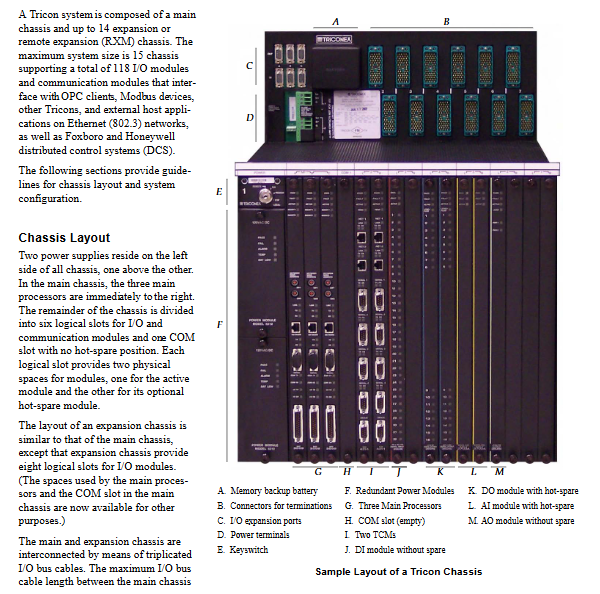

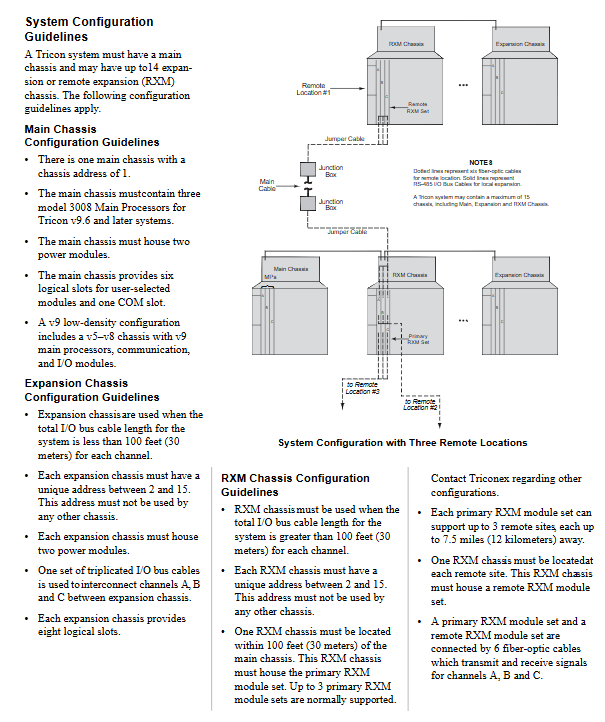

System configuration and expansion

Chassis types: main chassis (8110), expansion chassis (8111), remote expansion chassis (8112), dimensions 48.3cm × 57.8cm × 45.1cm, weight 24.5kg

Configuration rules:

The host box must contain 3 3008 main processors, 2 power modules, and provide 6 logical slots

Expansion chassis with up to 8 logical slots, I/O bus distance ≤ 300 meters

Remote chassis needs to be equipped with RXM module, supporting fiber optic transmission, with a maximum distance of 12 kilometers

Maximum size: 15 chassis (1 main+14 expansion/remote), 118 I/O/communication modules

Core functions and software tools

(1) Hardware core functions

Fault tolerance mechanism: Three channel parallel processing, 2/3 voting for digital signals, median for analog signals, single point failure does not affect system operation

Hot standby and maintenance: supports hot standby replacement of I/O modules, online replacement of faulty modules, and the system can run on 1/2/3 main processors

Sequence of Events (SOE): Record changes in discrete variable states with timestamp accuracy of ± 25ms, supporting synchronous acquisition by 31 controllers

Diagnostic function: module level, channel level self diagnosis, fault indicator light+alarm output, supports remote monitoring

(2) Software Tools

Software Name Core Function Compatibility System

TriStation 1131 Control Program Development (LD/FBD/ST Language), Simulation Testing, Download Monitoring Windows NT/2000/XP

CEMPLE Editor Causal Matrix (CEM) programming, automatically converted to FBD code integrated into TriStation 1131

SOE software event data collection, analysis, and export, supporting trip snapshot for Windows system

Enhanced Diagnostic Monitor Multi Controller Hardware/Program Status Monitoring Windows System

Communication capability

Supported protocols: Modbus (RTU/ASCII/TCP), Ethernet (802.3), Peer to Peer, TSAA, SNTP

Communication interfaces: serial port (RS-232/422/485), Ethernet (RJ-45/fiber optic) Honeywell UCN/LCN、Foxboro Nodebus

Redundant communication: dual communication modules+dual network cables, supporting link/module redundancy

Installation and maintenance

Installation requirements: The chassis should be installed vertically, with a reserved 5.25-inch (13.3cm) heat dissipation space above and below. It is recommended to install a baffle/fan (when the temperature is>50 ° C)

Wiring specifications: The terminal panel supports 24-12AWG cables, with both ends of the shielding layer grounded. The distance between the control cable and the power cable is ≥ 20cm

Maintenance points:

The faulty module can be plugged and unplugged online, and the hot standby module is automatically activated

Dual redundancy of power module, a single module can support the overall load of the machine

Suggest configuring one hot standby module for each type of I/O module and conducting regular module rotation tests

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

-

KEBA KeTop CB211 - Connection Box

-

KEBA HT4 / 20656 - Kammann Hand Held Keypad

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Y1-K1-Y2 PA9 - Engel Board Module

-

LTI MOTION CDA32.004C3.0 - Servo Drive 230V AC

-

KEBA E-CG-CONTROL - ECGCONTROL Module

-

KEBA Kemro K2-200 OP350/W 68334 - Engel EC200 Panel Membrane Touch Glass

-

KEBA i1075 - Membrane Keyboard

-

KEBA E-HSI-M - Interface Module

-

KEBA LQ10D321-ERSAT - ZTEILSET FNOB

-

KEBA E-16-DIGOUT/G - Circuit Board

-

KEBA HT4/Neutral/16846 - Mikron Handheld Terminal

-

KEBA KeTop CB310-000 - Connection Box

-

KEBA DC 161/IP20/17369 - Interface Card Module

-

KEBA E-16-DIGOUT-PLUS - Elektronik Bau Linz 262-1456-85-B

-

KEBA HT501 - Handheld Terminal

-

KEBA HT401-4X20 - Teach Pendant

-

KEBA E-3-ACU-10 D16738 - Controller Card Module

-

KEBA 240/A 068371 - Analog Output Module

-

KEBA E-7TEMP D1323E/F/G - Temperature Circuit Board

-

KEBA KeTop TT100-eaa - Communication Cable

-

KEBA E-16 DIGOUT-PLUS D1456D - Engel Output Board

-

KEBA Kemro K2-200 - Touch Panel Glass Digitizer

-

KEBA CC100A03/CAN/4 - PLC Chassis 16-Slot Rack Motherboard 1842E-0

-

KEBA CU 211 - PLC Power Supply

-

KEBA KeTOP CB310-S00 - Connection Box

-

KEBA I/O BUS KOPPLUNG D1547C - Engel Circuit Board

-

KEBA HCS01.1E-W0013-A-02 - Servo Drive

-

KEBA SMC1-Z30 - LTI Security Safety Control

-

KEBA E-PS88-M/C D1527C - Power Supply Board

-

KEBA D1678C / E-SEK - Control Board

-

KEBA 1.83E+02 - Circuit Board Module

-

LUST LTI/KEBA DSM4-05.4-20R.96-W1A - AC Servo Motor

-

Engel/KEBA OP 362-LD/W-5200 - Kemro Ke-200 Membrane Keypad Touch Screen

-

KEBA HT4 24V/0.2A - Kammann Hand Terminal C3052-R47

-

KEBA Kemro K2-200 BL210/B - Injection Molding Machine Controller Module

-

KEBA E-8-ANALOG D1432B - Analog Board

-

KEBA DM272 - Input Output Module

-

KEBA AR161 - PCB ML-EUMIG

-

KEBA E-PS-24V 1825E-1 - Power Supply Board

-

KEBA E-8-THERMO 1770B-1 - Engel Temperature Control Board

-

KEBA HT4-221-20556 - Kammann Hand Terminal

-

KEBA E-10-ANALOG-SUB D1458D - Circuit Board

-

KEBA AC 441 - Control Module 18-32 VDC

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA E-ANA-SUB2 D1690C - Analog Submodule Card

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad

-

KEBA OP 331/C-4400 - Keview V2 LCD Display Screen Panel

-

KEBA E-CRT D1630D - Circuit Board

-

KEBA DM570 - KeConnect C5 Digital Quantity Mixing Module 97825

-

KEBA KC-E10-3P-63A - AC Charger Accessories Electric Vehicle

-

KEBA G4E606-P - Industrial Computer Motherboard CPU PN:G4E606-501G

-

KEBA KEMROBUS 1842D-0 - Circuit Board

-

KEBA DM262/A - Interface Module K2-200

-

KEBA DI260/A - Controller Module 070257

-

KEBA PS240 - Power Supply Module

-

KEBA DM272/A - Kemro K2-200 Input Output Module 070258

-

KEBA AT 4041 / KeTop C70-10z-AaO-RB - LCD Screen Display

-

KEBA 3-XC 340/A - 2G Reservoir for CP520

-

KEBA JB 001/A - Set Controller Teaching Device

-

KEBA SC 102 / SC102A - Interface Module Cards PB201 PB101

-

KEBA Kemro K2-200 BL250/B - Injection Molding Machine Computer Input Module

-

KEBA Kemro K2-200 16in280/A - Controller Module Part Nr 2578 15

-

KEBA E-32-DIGIN / D1321F-1 - Digital Input Card

-

KEBA E-32-DIGIN / D1321E - Digital Input Board

-

KEBA FD353 / 17968 - Floppy Disk Drive

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923