K-WANG

SIEMENS QFM31xx series air duct sensor

SIEMENS QFM31xx series air duct sensor

Product basic information

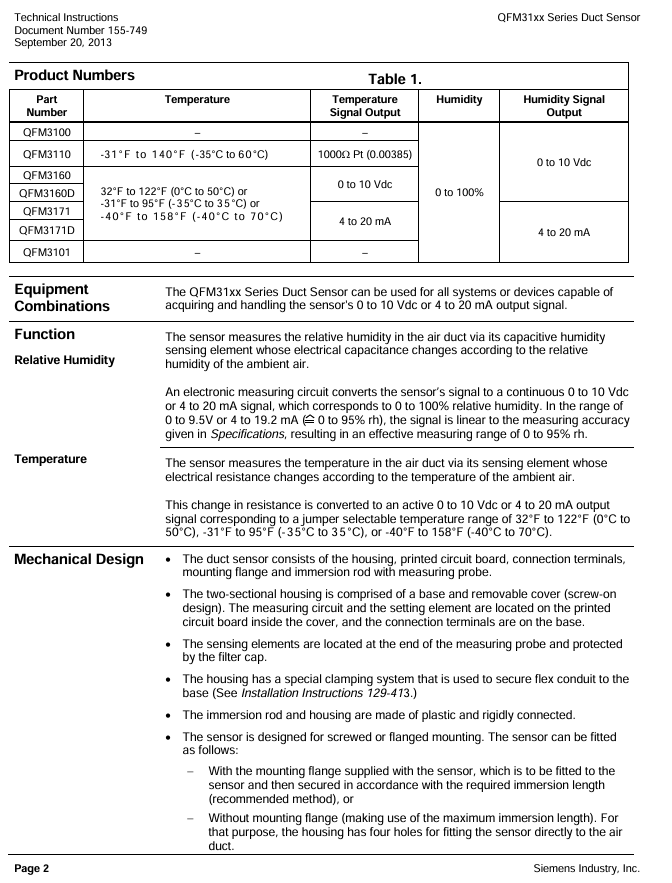

1. Product model

Covering sub models such as QFM3100 (basic version), QFM3160 (with display), QFM3171D (4-20mA output), etc., collectively referred to as the QFM31xx series, it provides high-precision measurement of air duct temperature and humidity.

2. Application scenarios

Sensors are suitable for ventilation and air conditioning systems with high requirements for temperature and humidity accuracy and response speed. Typical installation scenarios include:

Industrial scenarios: storage and production workshops in paper mills, textile factories, pharmaceutical factories, food factories, and electronic factories;

Special venues: laboratories, hospitals, computer data centers, indoor swimming pools, greenhouses;

Functional roles: Air supply/return control sensor, humidity limit sensor after steam humidifier, building automation system (BAS) access sensor.

Core technical characteristics of the product

1. Power supply and signal output

Category parameter content, key data

Supply voltage AC/DC dual compatible 24 Vac (± 20%, 50/60Hz); 13.5-35 Vdc

Low power consumption design<1 VA

Humidity output with two signal types: 0-10 Vdc (corresponding to 0-100% RH, maximum current 1mA); 4-20 mA (corresponding to 0-100% RH)

The temperature output range can be selected from 0-10 Vdc/4-20 mA, and the range can be selected through jumper wires (see Table 2)

Cable lengths are classified by wire diameter as 24 AWG (50m), 18 AWG (150m), and 16 AWG (300m)

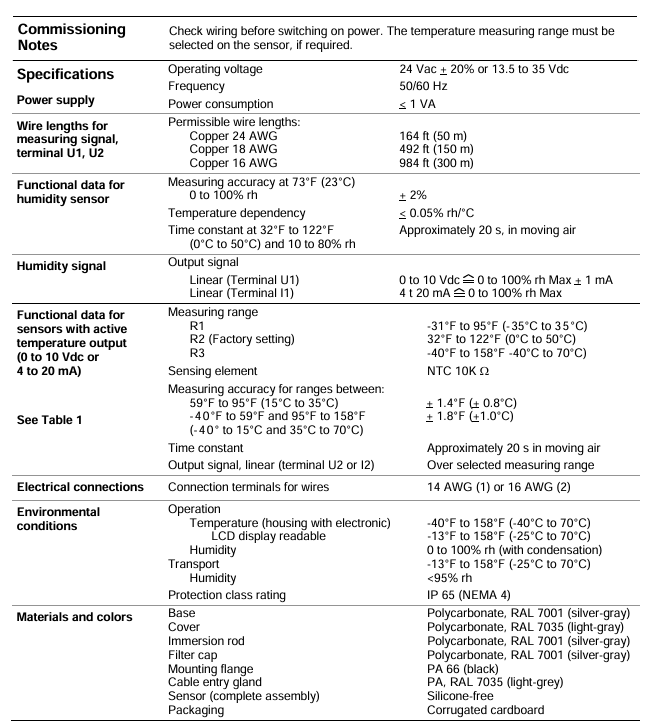

2. Measurement performance (accuracy and response)

Measurement Type Accuracy Index Response Characteristics Remarks

± 2% RH at relative humidity of 23 ℃; temperature coefficient<0.05% RH/℃ Time constant of about 20s (in flowing air) Effective measurement range 0-95% RH (0-9.5V/4-19.2mA linear)

± 0.8 ℃ at a temperature of 15-35 ℃; -The time constant of ± 1.0 ℃ at 40-15 ℃/35-70 ℃ is about 20 seconds (in flowing air). The sensing element is NTC 10K Ω

3. Protection and environmental adaptability

Protection level: IP65 (NEMA 4), dustproof and water-resistant, suitable for humid air duct environments;

Work environment: Adapt to the air temperature inside the duct (consistent with the selected temperature range), humidity 0-100% RH;

Material compatibility: The shell is made of polycarbonate (impact resistant), the filter cap is made of the same material, and the overall silicon free design avoids polluting sensitive environments (such as electronic factories).

Mechanical Design and Installation Specification

1. Mechanical structure

Overall composition: consisting of a housing (base+detachable cover plate), a printed circuit board (PCB), wiring terminals, mounting flanges, and an immersion probe (including sensing elements and filter caps);

Shell design:

Base: Integrated wiring terminal and conduit clamping system (fixing flexible conduit), color RAL 7001 (silver gray);

Cover plate: Built in measurement circuit and jumper (range configuration), color RAL 7035 (light gray), fixed with screws;

Probe: Made of polycarbonate material (RAL 7001), the end sensing element is protected by a filter cap to prevent dust contamination.

2. Installation method and requirements

Key requirements for installation method and operation steps

Install flange (recommended) 1. Assemble the flange with the sensor; 2. Fix the flange to the air duct according to the required immersion length; 3. Insert the sensor and tighten it to adjust the immersion length as needed. The flange material is PA66 (black)

No installation flange 1. Use 4 mounting holes on the shell; 2. Directly screw the sensor onto the air duct using the maximum immersion length to ensure measurement representativeness

Special scenario (dew point offset) 1. Only fix the flange to the air duct wall; 2. Insert the sensor from the flange and clamp it tightly. It must be installed in the return air duct to avoid measurement deviation

Installation taboos:

Avoid probe impact: Sensing components are easily damaged by impact and should be handled gently during installation;

Distance between steam humidifiers: The minimum distance from the humidifier should be ≥ 3m (recommended ≤ 10m) to prevent sudden humidity changes from affecting accuracy;

Sealing protection: It is forbidden to remove the seal between the shell and the cover plate to prevent water vapor from entering and damaging the circuit.

Parameter configuration and debugging

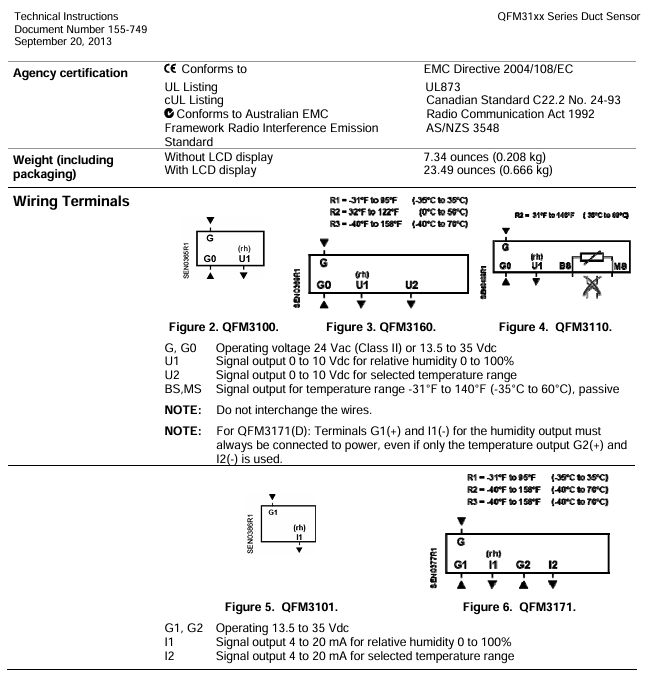

1. Jumper configuration (on PCB, under cover)

The jumper has 6 pins and 1 jumper cap, which is used to select temperature range, display unit, and activate testing functions. The specific configuration is as follows:

Configure the parameters corresponding to the jumper position of the configuration function

Temperature range selection left (1) -31 ° F~95 ° F (-35 ℃~35 ℃)

Right position (3) -40 ° F~158 ° F (-40 ℃~70 ℃)

Display unit selection (with LCD model) vertical right position Celsius (℃, factory default)

Vertical left Fahrenheit (℉)

Test function activation level signal output specific values (such as 0V/10V, 4mA/20mA) for troubleshooting

2. Debugging steps

Wiring inspection: Confirm that the power and signal lines are connected correctly (refer to the terminal definition in Figure 2-6, for example, QFM3171 needs to ensure that G1/I1 is powered on, even if only temperature output is used);

Range configuration: According to on-site requirements, set the temperature range and display unit through jumper wires;

Power on verification: Connect the power supply and check if the output signal (humidity 0-10V/4-20mA, temperature corresponding range signal) is normal. For models with LCD, it is necessary to confirm the alternating display of temperature and humidity (5-second interval).

Fault diagnosis and spare parts

1. Fault diagnosis (output characteristics when sensor failure occurs)

Fault type: Humidity signal output (U1/I1) Temperature signal output (U2/I2) Remarks

Temperature sensor fault rises to 10V (0-10V output) or corresponding 20mA (4-20mA output) drops to 0V (0-10V output) or corresponding 4mA (4-20mA output). The fault is immediately triggered

The humidity sensor malfunctions for 60 seconds and then rises to 10V/20mA to maintain normal output with a delay of 60 seconds, making it easier for the system to identify

2. Spare parts list (for replacement)

Spare part model, spare part name, and purpose

The AQF3101 filter cap protects the sensing elements inside the probe, preventing dust from entering

Replace damaged temperature and humidity sensing components with AQF3150 sensing head

74 662 01040 1/2 inch rigid conduit adapter for connecting conduit to sensor base

Compliance and physical specifications

1. Certification and Standards

Compliance Directive: Complies with EMC Directive 2004/108/EC (Electromagnetic Compatibility) and AS/NZS 3548 (Radio Interference Emission Framework Standard);

Electrical specifications: The power supply requires the use of a Class II transformer (independent winding, 100% duty cycle), and the selection should consider sensor power consumption and local electrical regulations.

2. Physical specifications

Project specification parameters

Material base/probe: polycarbonate (RAL 7001); Cover plate: polycarbonate (RAL 7035); Flange: PA66 (black)

Protection level IP65 (NEMA 4)

Weight (including packaging) without LCD display: 7.34 ounces (0.208kg); With LCD display: 23.49 ounces (0.666kg)

The wiring terminal is compatible with 14 AWG (1 way) or 16 AWG (2 ways) wires

Engineering precautions

Power selection: Class II transformers must be used with independent winding design to ensure safe isolation;

Cable selection: Shielded twisted pair cables are required for EMC interference environments, and secondary power lines and signal lines need to be twisted to reduce interference;

Wiring specifications: Avoid long-distance parallel laying of cables (too small spacing can easily cause interference), strictly follow the allowed cable length (distinguished by wire diameter);

Maintenance requirements: Regularly check the cleanliness of the filter cap (contamination can affect response speed), and replace it promptly if it is damaged.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

-

HIMA F60AI801 PLC Module | Analog Input Module

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Module

-

HIMA K9203 PLC Module | Safety Automation Module

-

X-DO1201 HIMA Control Pulse Card | Digital Output Module

-

F6705 HIMA Analog Output Module | Safety Control Output Module

-

HIMA B9361 PLC Module | Safety Automation System Module

-

HIMA H41Q-HRS / H41QX PLC Module | Safety Automation Module

-

HIMA F3003 Controller Unit | HIMAtrix Compact Safety Controller

-

HIMA HIMatrix F1DI1601 PLC Module | Digital Input Module for Safety Systems

-

HIMA X-DI 64 51 PLC Module | Digital Input Module for Safety Automation

-

HIMA F30 Controller Unit HIMAtrix 01 OPEN | Safety PLC Controller

-

HIMA K9202B PLC Module | Safety-Oriented Control Module

-

HIMA F3DIO20802 Controller PLC Module | Digital I/O Control for Safety Automation

-

HIMA F8627-1 F8627X Communication Module | Safety System Communication Interface

-

HIMA B4237-2 PLC Module | Safety Control and Logic Processing Module

-

HIMA X-DO2401 PLC Module | Digital Output Module for Safety Automation

-

HIMA 22100 PLC Module | Industrial Safety Control and Logic Processing

-

HIMA 90100 PLC Module | Safety-Oriented Industrial Control Module

-

HIMA 895210001 PLC Module | Industrial Safety Control and Processing Module

-

HIMA 157528-0 PLC Module | Industrial Safety Control and Processing Module

-

HIMA B5322 PLC Module | Industrial Safety Control and Processing Module

-

HIMA BV7032 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F3300 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7105A PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7150 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7508 PLC Module | Industrial Safety Control Processing Module

-

HIMA F8627 984862765 PLC Module | Industrial Safety Control Module

-

HIMA M3410 PLC Module | Industrial Safety Control Processing Module

-

HIMA Z7308 PLC Module | Safety Control System Processing Module

-

F8640 HIMA Central Module | Safety System Core Controller

-

HIMA F8630 Module | Safety System Functional Module

-

F8651X HIMA Central Module | Safety System Core Controller

-

F3236 Digital Input Module | HIMA Safety System Input Interface

-

F7131 HIMA Power Monitoring Module | Safety System Power Supervision

-

F8627X HIMA Communication Module | Safety System Network Interface

-

HIMA F8560X PLC Module | Safety-Related Control System Component

-

HIMA P8403 PLC Module – Industrial Safety Control Processor

-

HIMA F8628X Communication Module – Industrial Safety System Interface

-

HIMA F8621A Communication Module – Safety System Communication Interface

-

HIMA 984865066 PLC Module – Safety Control Processing Unit

-

HIMA F60CPU01 PLC Module – Safety Control Processing Unit

-

HIMA F8650E PLC Module – Safety Control Processing Unit

-

HIMA F8652E Central Module – Safety Control Processing Unit

-

HIMA F8650X Card – Safety Central Processing Module

-

F8652X HIMA Central Module – Safety Control Central Processing Unit

-

HIMA 99-7105233 B5233-1 Safety Module – Industrial Safety Control Component

-

KEBA KeTop T70-rqa-AK0-LK Teaching Device – Industrial Robot Teach Pendant

-

KEBA KETOP T50-T41-CPU 2495D-0 – Industrial CPU Module

-

KEBA E-CON-CC100/A/ 22178 – Industrial Controller Module

-

KEBA Kemro K2-200 CP 250/X 71580 CPU-MODULE – Industrial Control CPU Module

-

KEBA D3‑DA 330/A‑1211‑00 Drive – KeDrive D3 Axis Controller Industrial Servo Drive

-

KEBA KETOP O70‑bra‑A0a‑F Demonstrator – Industrial Automation Control Module

-

KEBA KETOP O70-BRA-A0A-F Demonstrator | Industrial HMI Operating Terminal

-

KEBA SO84.012.0083.0101.2 Servo Drive | Industrial Motion Control Solution

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

XYCOM 1546 - Proface Industrial Workstation 1546-102031013

-

XYCOM 86864-002-E - Processor Board Module

-

XYCOM 3112T - Pro-face Operator Interface

-

XYCOM 3712 KPM - Pro-face Operator Panel

-

XYCOM 4615KPMT - Proface Industrial PC Display Panel PM-070007

-

XYCOM 5015T - Pro-Face Touch Monitor 100-240 VAC

-

XYCOM 5015T/R2 - Industrial Flat Panel Touch Monitor 5015R2-0100000

-

XYCOM 1341 - Proface Embedded Computer TF-AEC-6920-C2

-

XYCOM GLC150-BG41-DN - Graphic Logic Controller M-24V

-

XYCOM GP2301H-SC41-24V - Pro-face Operator Interface 5.7" w/ Cable

-

XYCOM 1547 - Pro-face Industrial PC Model 1547-00113101

-

XYCOM ST401-AG41-24V - Graphic Touchscreen Operator Interface

-

XYCOM 3310T - Pro-face Operator Panel 3310-001101001

-

XYCOM 5015 KPMT - Proface Operator Panel Display

-

XYCOM XVME-684 - PC Module VME Bus Processor 70684-201

-

XYCOM 3300 MT - Screen Monitor Display

-

XYCOM SXT1811T - Touch Panel Monitor 100/240VAC

-

XYCOM XT-1502 - Touch Screen Monitor Flat Panel Display Interface

-

XYCOM SXT1811 - Viewtronix SXGA Flat Panel Monitor 18.1" Display

-

XYCOM VT1040T - ViewTronix Touch Screen Monitor

-

XYCOM WS2786291 - Industrial Workstation PC

-

XYCOM XCME-540 - Analog I/O Module VMEbus 70540-001

-

XYCOM XVME-682 - CPU PCB Processor Module 70682-101

-

XYCOM CU040103500 - VME Rack System Module 4200401

-

XYCOM XVME-085 - Proto VMEbus Non-Intelligent Prototyping Module

-

XYCOM XVME-100 - PCB Controller Card ROM Board 70100-001

-

XYCOM XVME-103 - VMEbus Board 10103-001

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923