K-WANG

RELIANCE ELECTRIC GV3000/SE AC Drive (Version 6.06)

RELIANCE ELECTRIC GV3000/SE AC Drive (Version 6.06)

The GV3000/SE AC drive (Version 6.06) is a universal AC drive that supports V/Hz regulation and vector regulation (FVC/SVC). It has core functions such as keyboard/display operation, multi parameter programming, and fault diagnosis. It can be adapted to different application scenarios by setting universal parameters (P series), V/Hz parameters (H series), or vector parameters (U series). It supports local/remote control, built-in alarm and fault handling mechanisms, and is widely used in industrial motor speed control. It must strictly follow safety regulations and startup processes to ensure stable operation.

Product Overview

Basic Information

Model: GV3000/SE AC Drive, software version 6.06

Core positioning: Universal motor speed control driver, supporting two adjustment modes, suitable for industrial general scenarios

Control Scalability: Supports local keyboard, terminal block, network (DeviceNet/ControlNet, etc.), serial port (CS3000 software/OIM module) control

Core Features

Adjustment modes: V/Hz adjustment (open-loop, default), vector adjustment (closed-loop, including FVC requiring encoder, SVC without encoder)

Monitoring function: It can display six types of operating data, including speed, voltage, current, frequency, power, and torque (vector only)

Protection functions: 30+fault protections including motor overload protection, overcurrent protection, overvoltage protection, encoder loss protection, etc

Programming flexibility: Parameters are divided into two levels of menus, support password protection, and parameter values are retained in case of power failure

Detailed explanation of the startup process

Key steps of core preparation work for adjustment mode (simplified) Core parameter configuration

V/Hz adjustment 1. Complete hardware installation (power supply, motor wiring)

2. Record the motor nameplate parameters (rated voltage/current/fundamental frequency)

3. Confirm that programming has not been disabled (P.051) 1. Power on self-test (displaying SELF)

2. Enter program mode configuration P.000-P.005 (control source, acceleration/deceleration time, etc.)

3. Enter password 107 (P.006) to unlock the second menu

4. Configure H-series parameters (motor nameplate, torque boost, etc.)

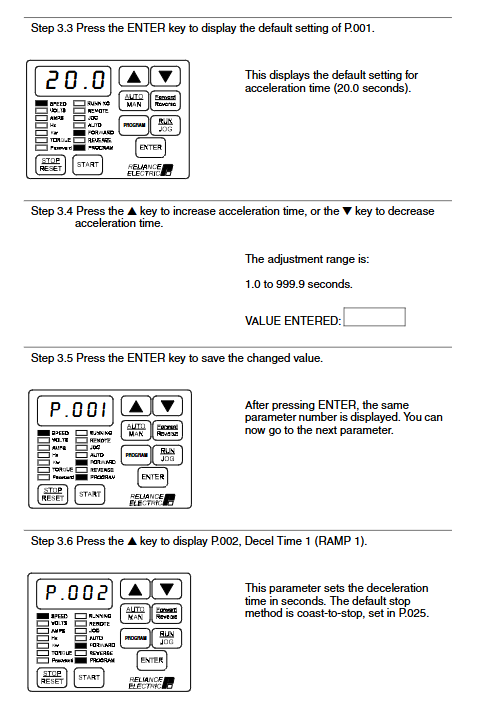

5. Verify motor steering → Test run P.000 (LOCL local control), P.001-P.002 (default for 20.0 seconds), H.000 (motor voltage), H.003 (default for torque increase of 0.5%)

Vector adjustment 1. Complete hardware installation (including encoder wiring, FVC mode)

2. Record motor/encoder parameters (pole count, PPR, etc.)

3. Disconnect the motor load. 1. Power on self-test → Enter program mode

2. Enter password 107 → switch adjustment mode (P.048=UEC)

3. Configure P/U series parameters (speed limit, motor nameplate, etc.)

4. Perform self-tuning (U.008=ON) → Verify steering

5. Connect the load → Test run P.003 (default 150 RPM), U.001 (default 1024 PPR), U.002 (default 4-pole), U.017 (maximum motor speed)

Keyboard and Display Operations

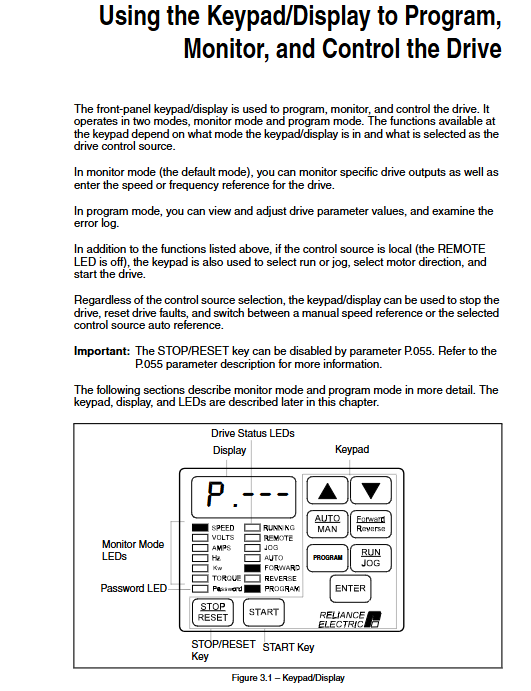

Operation Mode

Monitoring mode (default): Press ENTER to switch display data, supports manual input of speed reference

Program mode: Press the Program key to enter, used for parameter configuration and error log query

Keyboard key function

Core buttons: AUTO/MAN (switch between automatic/manual reference source), GRAM (mode switch), START/STOP/RESET (start stop/reset)

Adjustment buttons: ↑ (increase value), ↓ (decrease value), ENTER (confirm/save)

LED indicator

Status LEDs (8): Running, Remote Control, Program Mode, etc

Monitoring LEDs (6): SPEED (speed), VOLTS (voltage), AMPS (current), etc., corresponding to display data types

Detailed Explanation of Parameter System

Parameter classification and access

First menu (P.000-P.006): Basic general parameters, no password required, including control source, acceleration/deceleration time, current limit, etc

Second menu: Password 107 (P.006) is required to access, including extended general parameters, V/Hz specific parameters, vector specific parameters, and RMI board parameters

Parameter types: configurable (only for shutdown modification), adjustable (can run/shut down), read-only (such as software version P.098)

Key parameter description

General core parameters

Parameter number, parameter name, function, adjustment range (V/Hz), adjustment range (vector), default value

P. 000 Control Source Select Control Source - LOCL (Local)

P. 001 Accel Time 1 Acceleration Time 1.0-999.9 seconds 0.1-999.9 seconds 20.0 seconds

P. 003 Minimum Speed Minimum Speed 0.5-Hz (P.004) 0-RPM (P.004) 5.0Hz 150RPM

P. 005 Current Limit 50-110% U.006-150% 100% 150%

P. 051 Programming Disable programming lock 0-9999 (password 26) -0 (unlocked)

V/Hz exclusive parameters

Parameter number, parameter name, function, adjustment range, default value

H. 000 Motor Nameplate Volts Motor rated voltage 100-690VAC 460VAC

H. 003 Torque Boost Voltage Low Speed Torque Boost 0.0-20.0% 0.5%

H. 009 Avoidance Frequency Enable ON/OFF

H. 022 Overfrequency Limit Overfrequency protection threshold 30.0-210Hz 90.0Hz

Vector specific parameters

Parameter number, parameter name, function, adjustment range, default value

U. 001 Encoder PPR Encoder Pulse Count 512/1024/2048/4096/SE 1024

U. 002 Motor Poles Motor Pole 2/4/6/8 4

U. 008 Torque Self Tune Enable self-tuning enable ON/OFF OFF

U. 012 Speed Regulator Proportional Gain Speed Proportional Gain 0.01-99.99 Module Dependence

Fault and alarm handling

alarm mechanism

Definition: Non fatal exception, drive continues to run, flashing alarm code displayed

Common alarms: 7 categories including AIn (loss of analog input signal), LIL (low input voltage), S-En (self-tuning enabled), etc

Solution: Investigate the cause of the abnormality (such as signal lines, input voltage), no need to reset, automatically clear after the abnormality is resolved

Fault mechanism

Definition: Fatal exception, immediate shutdown of the drive (free parking or slope parking), flashing display of fault code

Common faults: OC (overcurrent), OL (motor overload), OH (driver overheating), OSP (overspeed), EL (encoder loss), etc

Error log: Automatically stores 10 latest faults, including date (0-248 days) and timestamp (24-hour format), supports manual clearing

Fault reset method

Local reset: Press the STOP/RESET key on the keyboard

Remote reset: sending a fault reset signal through the control source

Attention: It is necessary to first investigate the cause of the fault (such as short circuit, overload), otherwise resetting may trigger the fault again

Safety regulations

Electrical safety

Anti electric shock: There is dangerous voltage inside the equipment, and non professionals are prohibited from opening the cover

Arc flash protection: Suitable personal protective equipment (PPE) must be worn

Capacitor discharge: After power failure, wait for 5 minutes to confirm that the DC bus capacitor discharge is complete before contacting internal components

Mechanical safety

Rotating components: When the motor is running, the rotating shaft should be protected to avoid contact

Zero speed warning: The drive supports zero speed operation and requires warning devices (such as indicator lights and alarms) to be installed

Direction verification: The motor direction must be verified during the first start-up, and if there is an error, the two-phase wiring of the motor needs to be swapped

Operational Security

Password management: The second menu password (107) and programming lock password (26) should be properly kept to prevent unauthorized modification

Emergency shutdown: An external hard wired emergency shutdown circuit must be configured to ensure rapid shutdown in case of abnormalities

Parameter verification: After modifying key parameters such as speed limit and current limit, a trial run is required to verify stability

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 3HAC9710-1 Industrial Control Module | Advanced Automation Component

-

ABB SPBLK01 Signal Processing Block | Industrial Automation Module

-

ABB IMDSM04 Distributed System Module | Industrial Automation Controller

-

ABB IMFECI2 Fieldbus Communication Interface | Industrial Automation

-

ABB IMDS014 Industrial Data Server | Advanced Automation Solution

-

ABB INIT03 Industrial Controller | Precision Automation Module

-

ABB INNIS21 Network Interface Module for Distributed Control Systems

-

ABB IMBLK01 Interface Module for Distributed Control Systems

-

ABB 3HAC031683-004 Control System Module for Industrial Automation

-

ABB SPBRC300 Controller Module for Industrial Automation Systems

-

ABB PFXA401SF Industrial Automation Controller

-

ABB HAC319AEV1 Industrial Process Automation Module

-

ABB SA9923A-E Advanced Industrial Automation Module

-

ABB CSA463AE Industrial Automation and Monitoring Module

-

ABB UAC326AE Industrial Process Control Module

-

ABB NU8976A Industrial Automation Control Module

-

ABB LT8978bV1 High-Performance Industrial Automation Module

-

ABB ARC093AV1 Industrial Control and Monitoring Module

-

ABB UAC318AE Advanced Automation Control Module

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923