K-WANG

COTEK SD Series Pure Sine Wave Inverter

COTEK SD Series Pure Sine Wave Inverter

The COTEK SD series (SD1500/2500/3500) pure sine wave inverter is a multifunctional power conversion device that supports N+1 parallel redundancy and three-phase output. The input voltage covers 12/24/48VDC, and the output is 100-240VAC pure sine wave (THD<3%), with a rated power of 1500-3500VA. It has ATS automatic switching (optional STS module, switching time<4ms), multiple protections (overvoltage/undervoltage/short circuit/overload, etc.), remote control (RS-232/CAN bus), and energy-saving mode. It is suitable for scenarios such as RVs, ships, emergency equipment, industrial machinery, etc. The installation must follow strict safety regulations and support multiple parallel expansion power or forming a three-phase system.

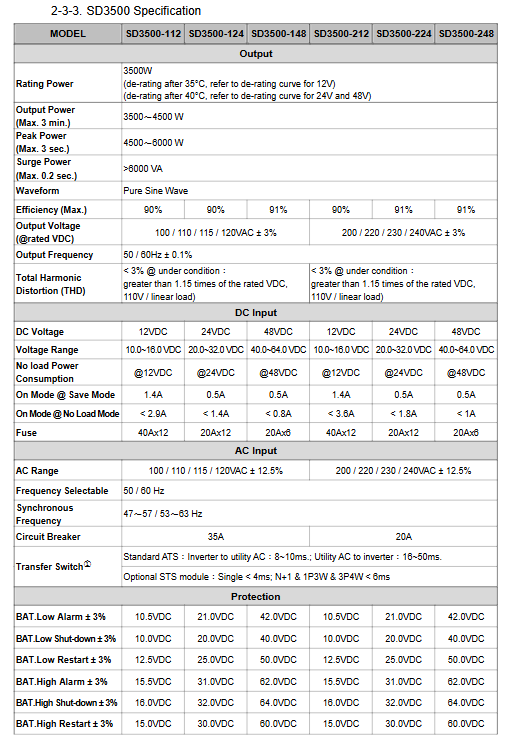

Product basic parameters

Specification item SD1500 SD2500 SD3500 Remarks

Rated power: 1500VA, 2500VA, 3500VA, capacity reduction after 40 ℃ (refer to the capacity reduction curve)

Peak power (0.2 seconds)>2400VA>4000VA>6000VA-

Input voltage 12/24/48VDC 12/24/48VDC 12/24/48VDC Voltage range 10.0-16.0/20.0-32.0/40.0-64.0VDC

Output voltage 100-120/200-240VAC ± 3% 100-120/200-240VAC ± 3% 100-120/200-240VAC ± 3% DIP switch optional

Output frequency 50/60Hz ± 0.1% 50/60Hz ± 0.1% 50/60Hz ± 0.1% DIP switch switching

Total Harmonic Distortion (THD)<3% (linear load)<3% (linear load)<3% (linear load) When the input voltage is greater than 1.15 times the rated value

Maximum efficiency 88% -90% 88% -90% 90% -91% varies with model and input voltage

Working temperature -20~60 ℃ -20~60 ℃ -20~60 ℃ Storage temperature -40~70 ℃

Dimensions (W × H × D) 283 × 128 × 351mm 283 × 128 × 436mm 283 × 128 × 496mm Weight 5.5/8/10kg

Detailed explanation of core functions

Parallel expansion function

Supports up to 5 inverters in parallel, achieving N+1 redundancy or power expansion

Supported topologies: 1 Φ 2W (maximum 16 units), 1 Φ 3W (maximum 2 units), 3 Φ 4W (maximum 3 units)

Automatic master-slave mechanism: Only one master device needs to be configured, and the slave devices automatically synchronize parameters

Parallel communication: via CAN1/CAN2 ports (RJ-45 cable connection), a green terminal parallel jumper needs to be set up

Switching and control functions

Automatic Switching (ATS): Switching time between inverter and mains power is 8-10ms (inverter → mains power), 16-50ms (mains power → inverter)

Quick switching (STS, optional): Single unit<4ms, N+1/three-phase system<6ms

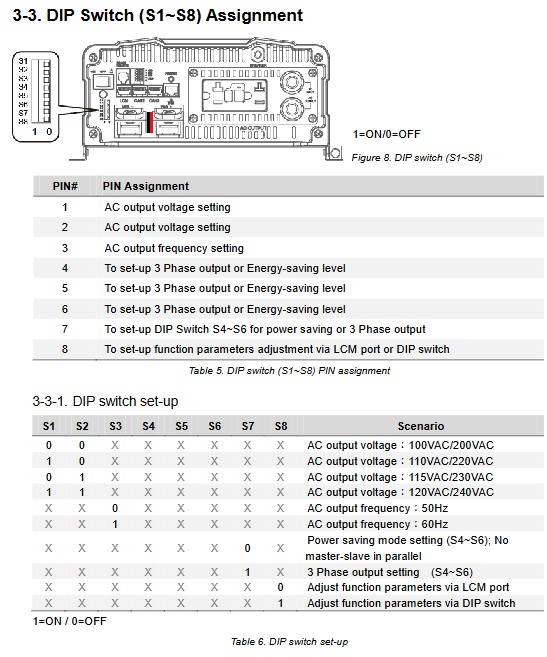

Control mode: local switch (ON/OFF/EMOTE), DIP switch (voltage/frequency/energy-saving mode), remote control (CR-6/8/10 panel)

Energy saving mode: triggered when the load is below 4% -8% of the rated power for 10 seconds, and restored when the load exceeds the threshold by 2-3 times

Communication and Monitoring

RS-232 interface: supports power on/off, parameter query (voltage/current/frequency), function configuration (OVP/UVP/language, etc.)

CAN bus: only used for communication between master and slave devices in parallel mode

LED indication: green (power supply normal/energy-saving/bypass), orange (overvoltage/undervoltage alarm), red (over temperature/overload/fault)

Fault record: supports short circuit, overload, overheating and other fault prompts and self recovery

Installation and wiring specifications

Installation requirements

Environmental conditions: dry, ventilated (with a reserved space of ≥ 1 foot around), dust-free, away from batteries (avoiding corrosive gases)

Safe distance: The distance between the exhaust outlet of the cooling fan and obstacles should be ≥ 1 foot to avoid covering the ventilation opening

Grounding requirement: Use 8AWG cable to connect the equipment casing to the vehicle/hull chassis

Wiring parameters | Model | Input voltage | Recommended wire diameter (AWG) | Series fuse specification | Maximum cable length|

|SD1500-112/212 | 12VDC | 0 | 250A | 1.8 meters|

|SD1500-124/224 | 24VDC | 1 | 125A | 1.8 meters|

|SD1500-148/248 | 48VDC | 4 | 90A | 1.8 meters|

|SD2500-112/212 | 12VDC | 3/0 | 350A | 1.8 meters|

|SD2500-124/224 | 24VDC | 1 | 175A | 1.8 meters|

|SD3500-112/212 | 12VDC | 4/0 | 500A | 1.8 meters|

|SD3500-124/224 | 24VDC | 0 | 250A | 1.8 meters|

Parallel wiring steps

Step 1: Set the main switches of all devices to OFF, and set the green terminal parallel jumper (the first and last devices are ON, and the middle is OFF)

Step 2: Unify the output voltage and frequency parameters of all devices through DIP switches

Step 3: Connect the CAN1/CAN2 ports with an RJ-45 cable, connect the positive and negative terminals of the DC end correspondingly, and connect the phase/neutral wires of the AC end correspondingly

Step 4: Set the DIP switches (S4-S7) for the master and slave devices, and automatically synchronize their operation after startup

Protection mechanism and security standards

Core protection function | Protection type | Trigger condition (12VDC as an example) | Action mode|

|Under Voltage Protection (UVP) | Input ≤ 10.0VDC | Shutdown, voltage restored to 12.5VDC, automatic restart|

|Overvoltage protection (OVP) | Input ≥ 16.0VDC | Shutdown, voltage drops to 15.0VDC and automatically restarts|

|Overload protection (OLP) | Output power>110% rated value | Shutdown, manual reset required|

|Over temperature protection (OTP) | Device temperature ≥ 60 ℃ | Shutdown, automatic restart after temperature drops|

|Short circuit protection | Output terminal short circuit | Stop immediately, reset after troubleshooting|

|Reverse polarity protection | Positive and negative polarity reversed | Internal fuse blown, fuse needs to be replaced|

Safety operation standards

Battery operation: Avoid contact with acid, prohibit smoking/open flames, remove metal jewelry

Electrical safety: Wait for 5 minutes after power failure to discharge, ensure reliable grounding, and use qualified copper cables

Mechanical safety: protection of rotating parts, zero load verification of motor direction, avoidance of covering ventilation openings

Certification standards: Complies with UL 458, EN 62368-1 safety standards, FCC Class B, EN 55032 EMC standards

Application scenarios

Mobile power bank: RV, yacht, camping equipment (compatible with 12/24VDC battery)

Emergency power supply: Home and office emergency equipment (computers, printers, lighting)

Industrial scenarios: metal halide lamps, high-pressure sodium lamps, small industrial machinery

Special scenarios: Off grid solar energy systems, ship equipment, remote area power supply

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 3HAC9710-1 Industrial Control Module | Advanced Automation Component

-

ABB SPBLK01 Signal Processing Block | Industrial Automation Module

-

ABB IMDSM04 Distributed System Module | Industrial Automation Controller

-

ABB IMFECI2 Fieldbus Communication Interface | Industrial Automation

-

ABB IMDS014 Industrial Data Server | Advanced Automation Solution

-

ABB INIT03 Industrial Controller | Precision Automation Module

-

ABB INNIS21 Network Interface Module for Distributed Control Systems

-

ABB IMBLK01 Interface Module for Distributed Control Systems

-

ABB 3HAC031683-004 Control System Module for Industrial Automation

-

ABB SPBRC300 Controller Module for Industrial Automation Systems

-

ABB PFXA401SF Industrial Automation Controller

-

ABB HAC319AEV1 Industrial Process Automation Module

-

ABB SA9923A-E Advanced Industrial Automation Module

-

ABB CSA463AE Industrial Automation and Monitoring Module

-

ABB UAC326AE Industrial Process Control Module

-

ABB NU8976A Industrial Automation Control Module

-

ABB LT8978bV1 High-Performance Industrial Automation Module

-

ABB ARC093AV1 Industrial Control and Monitoring Module

-

ABB UAC318AE Advanced Automation Control Module

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923