K-WANG

REXROTH BTV04.2 Micro Control Panel

REXROTH BTV04.2 Micro Control Panel

REXROTH BTV04.2 Micro Control Panel is a human-machine interaction product suitable for industrial equipment operation and control. It has a 128 × 64 pixel graphic LCD display screen and a 38 key operation panel (including 7 customizable keys), supports RS232/RS485 dual communication interfaces, is equipped with 10 24V inputs/11 24V outputs, has a protection level of IP65 (front), and a working voltage of 24VDC (18-30VDC). It is suitable for automation, packaging, machine tools and other scenarios, and can be adapted to multiple controllers such as MTC200 and Ecodrive3. The first firmware loading needs to be completed through Dolfi software.

Product Overview

Core positioning: BTV04.2 is an industrial grade micro control panel launched by Bosch Rexroth, used for operation control, parameter setting, and operation status display of industrial equipment. It communicates with the controller through dual serial interfaces and is compatible with multi brand industrial control systems.

Core strengths

Easy to operate: 38 key streamlined layout, 7 customizable keys supporting scene based annotation, in line with industrial operation habits.

Wide adaptability: compatible with multiple controllers such as MTC200, ISP200, Ecodrive3, etc., supporting RS232/RS485 dual communication mode.

Reliable protection: IP65 protection on the front, suitable for industrial dust and slight splashing environments. The housing adopts an aluminum alloy front panel, which is sturdy and durable.

Flexible expansion: Comes with 10 24V inputs and 11 24V outputs, which can be directly connected to external sensors or actuators.

Applicable scenarios: automation and handling equipment, packaging and food processing machinery, machine tool equipment, etc. It is prohibited to use them in personnel transportation equipment, medical equipment, nuclear industry and other scenarios.

Key technical parameters

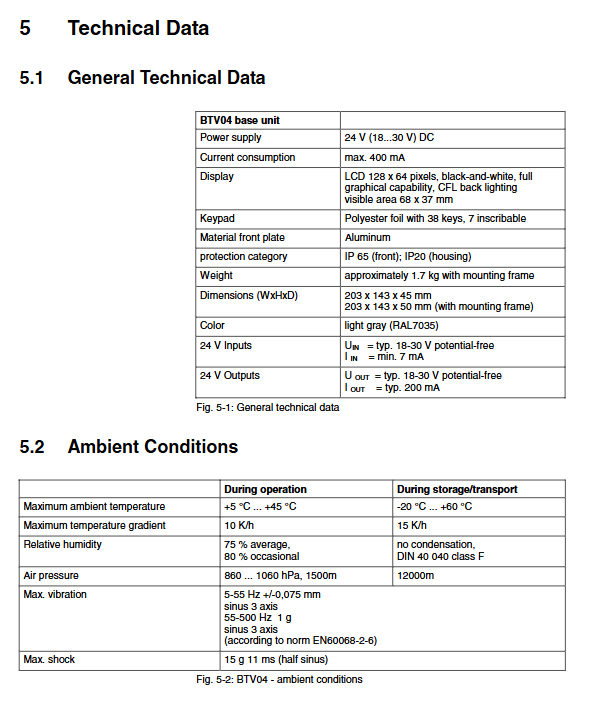

(1) Summary of Basic Parameters

Category specific indicators

Power supply specification 24VDC (18~30VDC), maximum current consumption 400mA

Display system 128 × 64 pixel LCD, black and white graphic display, LED backlight, visible area 68 × 37mm

38 key polyester film keyboard with 7 customizable keys (marked with insert bars)

Communication interfaces RS232 (COM2), RS485 (COM1, no isolation, supports bus connection)

IO interface input: 10 channels of 24V (minimum input current 7mA); Output: 11 channels of 24V (typical output current 200mA)

Environmental parameters: working temperature of 5-45 ℃, storage temperature of -20~60 ℃, temperature gradient ≤ 10K/h (working)/15k/h (storage)

Physical dimensions without frame: 203 × 143 × 45mm; including frame: 203 × 143 × 50mm

(2) Hardware configuration

Core processor: 68000 series microcontroller

Storage capacity: 1MB flash memory (for storing firmware and applications), 512KB RAM (for running cache)

Structural material: The front panel is made of aluminum alloy, the shell is made of engineering plastic, and the color is RAL7035 (light gray)

Connection and adaptation

Communication interface details

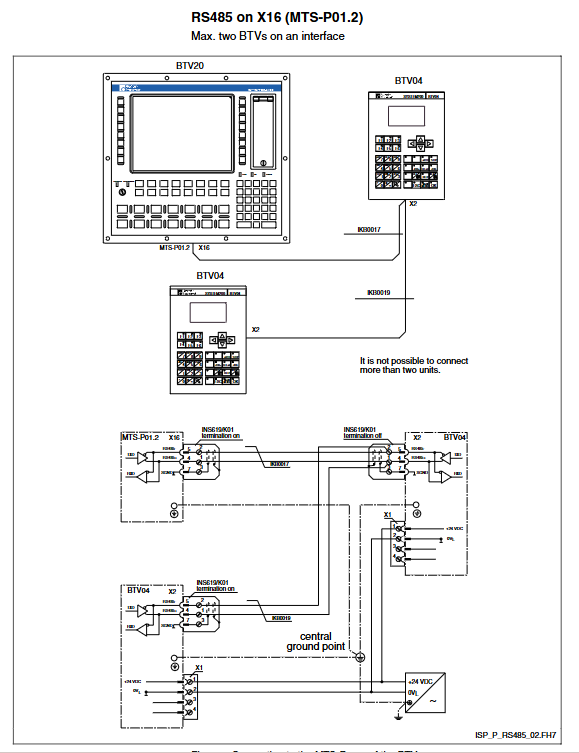

RS485 interface (COM1): Complies with Indramat standards, supports bus topology, and can connect up to 2 BTV04 on a single bus. It requires the use of INS0619/K01 connectors with terminal resistors.

RS232 interface (COM2): Used for connecting with PC, only supports point-to-point communication, mainly used for firmware download and debugging.

Typical adaptive controller

|Controller type | Connection method | Dedicated cable|

|MTC200-P/MTA200-P | RS485 connection X40/X41 interface | IKB0018/19|

|MTC200-R/ISP200-R | RS485 connection X16 or X40/X41 interface | IKB0017/18/19|

|CLC-D | RS485 connection X27/X28 interface | IKB0017/24|

|Ecodrive3/ELC | RS485 connection X2 interface | IKB0017/19|

|PPC-R | RS485 connection X10/X16 interface | IKB0017|

Special cable specifications

|Cable model | Communication type | Maximum length | Two end connectors | Purpose|

|IKB0012 | RS232 | 10m | One end INS0439/L01, one end INS0588/L01 | PC and BTV04 debugging connection|

|IKB0017 | RS485 | 400m | INS0619/K01 at both ends | Controller connected to BTV04|

|IKB0018 | RS485 | 400m | One end INS0619/K01, one end INS0526/L01 | Specific controller adaptation|

|IKB0019 | RS485 | 400m | One end INS0619/K01, one end connection sleeve | Bus expansion or terminal connection|

Debugging and operation process

First debugging preparation

Hardware: BTV04 host, 24V power supply, IKB0012 connection cable, PC (installed with Windows 3.11/95/98/NT).

Software: Dolfi download tool (SWD-DOL * PC-INB-01VRS-MS-C1,44), BTV04 application firmware.

Debugging steps

Connect the RS232 interface (X3) of BTV04 to the COM port of the PC using IKB0012 cable.

Supply power to BTV04 (24VDC) and display IndramatLogo upon power on.

Start the PC Dolfi software, select COM port, baud rate 9600bps, and receive address 03.

Click on "Serial Connect" to establish a connection, and select "Backup" to back up the original firmware (if needed).

Select 'Serial Send' to load the new firmware, the progress bar displays the transfer status, and after completion, it prompts' Programming successful '.

Click on 'Serial Disconnect' to disconnect, and BTV04 will automatically restart and run the new firmware.

Startup and maintenance mode

Normal startup: After powering on, check the firmware integrity → turn off the LED → start the application.

Maintenance mode: Before starting the application after power on, press the F1 key → display the boot program and firmware version → to perform firmware updates or troubleshooting.

Ordering and accessory instructions

Model coding rules (example: BTV04.2GN-FW)

|Encoding field | Meaning | Optional values/Description|

|1-3 | Product Series | BTV (Micro Control Panel)|

|4-5 | Product Version | 04 (Main Version)|

|6 | Design Version | 2 (Second Edition)|

|7 | Display type | G (graphic display, 128 × 64 pixels)|

|8 | Keyboard Type | N (Standard Keyboard)|

|9-10 | Firmware Identification | FW (firmware needs to be ordered separately)|

Core accessory list

|Accessory Name | Model/Order Number | Purpose|

|RS232 debugging cable | IKB0012 (MN: 281715) | Communication between PC and BTV04, firmware download|

|RS485 connection cable | IKB0017 (MN: 282872) | BTV04 connected to controller RS485|

|RS485 terminal connector | INS0619/K01 (MN: 279583) | Bus terminal matching, including switch|

|Download Tool Software | SWD-DOL * PC-INB-01 | Firmware Loading, Backup, and Update|

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB IMFECI2 Fieldbus Communication Interface | Industrial Automation

-

ABB IMDS014 Industrial Data Server | Advanced Automation Solution

-

ABB INIT03 Industrial Controller | Precision Automation Module

-

ABB INNIS21 Network Interface Module for Distributed Control Systems

-

ABB IMBLK01 Interface Module for Distributed Control Systems

-

ABB 3HAC031683-004 Control System Module for Industrial Automation

-

ABB SPBRC300 Controller Module for Industrial Automation Systems

-

ABB PFXA401SF Industrial Automation Controller

-

ABB HAC319AEV1 Industrial Process Automation Module

-

ABB SA9923A-E Advanced Industrial Automation Module

-

ABB CSA463AE Industrial Automation and Monitoring Module

-

ABB UAC326AE Industrial Process Control Module

-

ABB NU8976A Industrial Automation Control Module

-

ABB LT8978bV1 High-Performance Industrial Automation Module

-

ABB ARC093AV1 Industrial Control and Monitoring Module

-

ABB UAC318AE Advanced Automation Control Module

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923