K-WANG

REXROTH MKD series explosion-proof synchronous motor

REXROTH MKD series explosion-proof synchronous motor

The REXROTH MKD series explosion-proof synchronous motor is a Class II, Zone 3 (gas/dust environment) explosion-proof motor that complies with ATEX standards. The models include MKD025, MKD041, MKD071, MKD090, with a continuous torque of 0.4-12 Nm, a maximum speed of 5000-9000 min ⁻¹, a protection level of IP65, an insulation level of F, and comes standard with a rotary transformer encoder. Multiple absolute value encoders and brake configurations can be selected, and specialized controllers such as DIAX04 and ECODRIVE are suitable for industrial scenarios such as machine tools, printing, and packaging. Installation, operation, and maintenance must strictly follow explosion-proof and safety regulations.

Product Overview

Product positioning: The Bosch Rexroth MKD series is a synchronous servo motor designed specifically for potentially explosive environments, complying with the ATEX directive 94/9/EG, classified as Class II, Zone 3 (GD), with a protection type of EEx nA (non spark type), a maximum surface temperature of 155 ° C, and suitable for industrial scenarios where gas or dust occasionally occurs.

Core strengths

Explosion proof safety: meets the EN 50021 standard, avoiding sparks or high temperatures that may cause explosions during operation.

Flexible configuration: supports multiple optional configurations such as encoder type, brake, output shaft form, etc.

Wide adaptability: compatible with Rexroth dedicated controllers, covering low, medium, and high power requirements.

Stable and reliable: The rated life of the bearing is 30000 hours, and its anti vibration and anti impact performance meets the DIN EN 60068 standard.

Applicable scenarios: Machine tools, printing and paper processing equipment, packaging and food processing equipment, automation and handling systems, etc. It is prohibited to use them in coal mines, personnel transportation equipment, medical equipment and other scenarios.

Core technical parameters

(1) Summary of Key Performance Parameters

Model: Machine Base Length, Continuous Torque (60K), Maximum Speed, Motor Weight, Brake Torque

MKD025A A 0.4 Nm 9000 min⁻¹ 1.5 kg -

MKD025B B 0.9 Nm 9000 min⁻¹ 2.0 kg 1.0 Nm

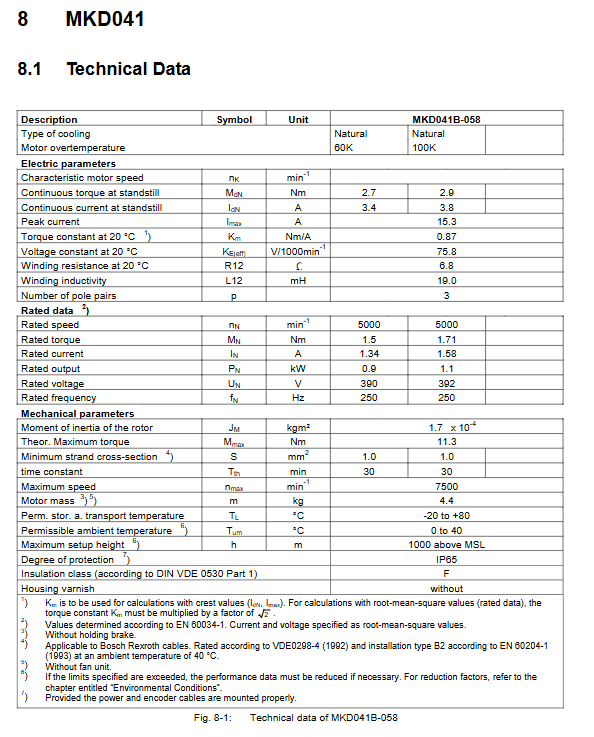

MKD041B B 2.7 Nm 7500 min⁻¹ 4.4 kg 2.2 Nm

MKD071B B 8.0 Nm 6000 min⁻¹ 8.8 kg 5.0/10 Nm

MKD090B B 12.0 Nm 5000 min⁻¹ 14.0 kg 11.0 Nm

(2) Classification parameter details

Electrical parameters: rated power supply 24VDC (± 10%), continuous current 2.2~17.2A, peak current 10.0~79.0A; torque constant 0.2~2.01 Nm/A, voltage constant 18.2~174.9 V/1000min ⁻¹.

Mechanical parameters: moment of inertia 0.2 × 10 ⁻⁴~43.0 × 10 ⁻⁴ kgm ²; Allow the radial load to vary with the model (e.g. MKD025 maximum 500N), and the axial load to be 0.34-0.59 times the radial load.

Environmental and explosion-proof parameters: storage temperature -20~+80 ° C, working environment temperature 0~40 ° C; altitude up to 1000m; suitable for gas (G) and dust (D) explosion-proof environments, temperature group T155 ° C.

Structure and optional configurations

Core structure

Motor body: The base adopts RAL 9005 black coating, B5 installation form (flange installation), and the output shaft complies with DIN 748 standard.

Encoder: standard rotary transformer (relative type, accuracy ± 8 arcminutes), optional multi turn absolute encoder (4096 turns, battery backup, lifespan of about 10 years).

Brake (optional): 24VDC electric release type, power-off clamping, connection time 3-26ms, disconnection time 4-43ms, suitable for vertical axis anti fall requirements.

Optional configuration

Output shaft: Optical axis (with central threaded hole), keyway shaft (compliant with DIN 6885).

Accessories: GTS/GTP/GTM series planetary gearbox (IP65 protection, lifetime lubrication), dedicated power/encoder cable, connectors (6-pin+PE, 4-pin).

Selection rules (ordering code)

The ordering code consists of 10 core codes, and the key fields are described as follows:

Example of optional values for the meaning of encoding fields

1-3 Product Series MKD

4-6 aircraft seat number 025/041/071/090

7 machine base length A/B (length B has higher torque)

8-10 winding codes 024/035/058/061, etc

13 Encoder Type G (Rotary Transformer)/K (Absolute Value)

14 output shaft form G (optical axis)/P (with keyway)

15 brake 0 (none)/1/2/3 (different torque)

18 Explosion proof Type S (Class II, Zone 3 Explosion proof)

Installation and operation specifications

Installation requirements

Installation form: Only supports B5 flange installation (IM B5/V1/V3 posture), vertical installation (IM V3) needs to prevent liquid intrusion.

Transportation and storage: must be placed horizontally to avoid impact; The storage environment should be dry and dust-free, and the shaft end protective cover should be retained.

Fixed torque: Different models correspond to different installation screw torques (such as MKD025 using M4 screws with a torque of 3.1 Nm).

Wiring and Grounding

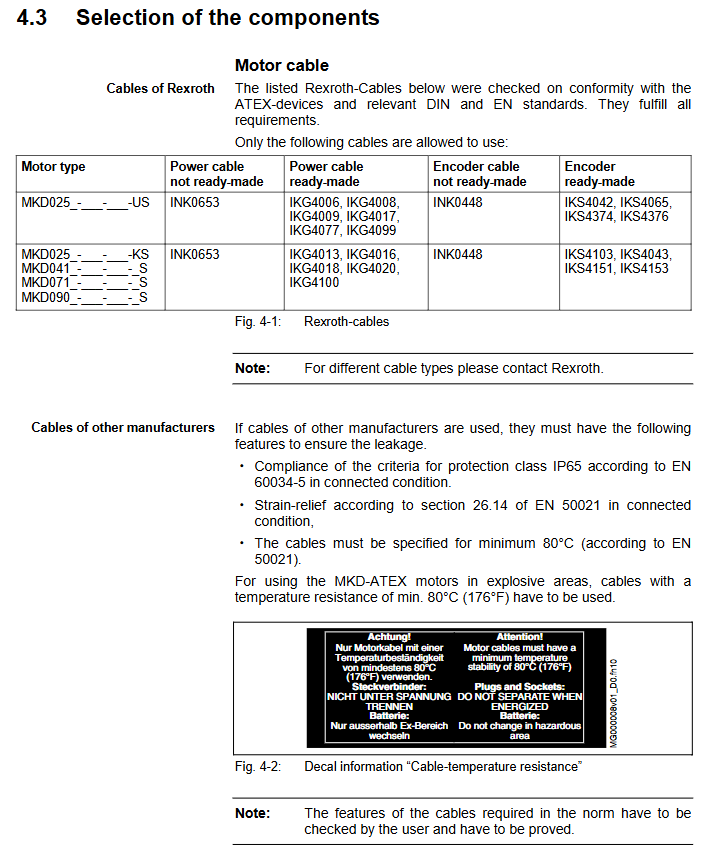

Cable requirements: Special cables with a temperature resistance of ≥ 80 ° C and a cross-section of ≥ 1.0mm ² must be used; Separate the wiring of power cables and encoder cables.

Grounding specification: The motor requires dual grounding - cable internal grounding wire+flange separate grounding wire (section ≥ 4mm ²), in accordance with EN 50021 standard.

Taboo: Do not plug or unplug connectors with electricity in explosive environments; Prohibit the use of non explosion proof accessories (such as ordinary blowers).

safe operation

Pre start inspection: manually rotate the rotor without any jamming, the brake function is normal, and the wiring is tight.

Emergency stop: An independent emergency stop circuit is required to cut off the motor power supply for rapid braking.

Maintenance taboos: It is prohibited to disassemble explosion-proof related components, modify windings or sealing structures.

Maintenance and troubleshooting

routine maintenance

Cleaning: Regularly clean the dust on the heat sink to avoid affecting heat dissipation.

Brake maintenance: Activate the brake every 48 hours (100 minutes ⁻¹ speed, 1 turn) to prevent rust film from forming; Before first use, it needs to be run in (5 laps).

Cable inspection: Regularly check the integrity of the cable sheath, and replace it immediately if it is damaged.

Battery replacement: The absolute value encoder battery needs to be replaced when the device is loaded and the control voltage is turned on to avoid absolute position loss; The replacement component model needs to be matched (such as MKD025 corresponding to part number 296044).

Common taboos

Overloading operation is prohibited: otherwise, it will cause the motor temperature to exceed the standard and damage the explosion-proof performance.

Prohibited from arbitrary adjustment: Zero calibration, torque parameters, etc. must be operated by professional personnel, and factory presets cannot be modified without authorization.

Prohibition of mixing controllers: Only compatible with dedicated controllers such as Rexroth DIAX04 and ECODRIVE are allowed.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB IMFECI2 Fieldbus Communication Interface | Industrial Automation

-

ABB IMDS014 Industrial Data Server | Advanced Automation Solution

-

ABB INIT03 Industrial Controller | Precision Automation Module

-

ABB INNIS21 Network Interface Module for Distributed Control Systems

-

ABB IMBLK01 Interface Module for Distributed Control Systems

-

ABB 3HAC031683-004 Control System Module for Industrial Automation

-

ABB SPBRC300 Controller Module for Industrial Automation Systems

-

ABB PFXA401SF Industrial Automation Controller

-

ABB HAC319AEV1 Industrial Process Automation Module

-

ABB SA9923A-E Advanced Industrial Automation Module

-

ABB CSA463AE Industrial Automation and Monitoring Module

-

ABB UAC326AE Industrial Process Control Module

-

ABB NU8976A Industrial Automation Control Module

-

ABB LT8978bV1 High-Performance Industrial Automation Module

-

ABB ARC093AV1 Industrial Control and Monitoring Module

-

ABB UAC318AE Advanced Automation Control Module

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923