K-WANG

REXRTOH Axial piston variable pump A4VG Series 40

REXRTOH Axial piston variable pump A4VG Series 40

Product Overview and Core Positioning

The A4VG Series 40 is a high-pressure inclined disc axial piston variable displacement pump launched by Bosch Rexroth, designed specifically for closed-loop hydraulic systems. Its core advantages are high power density and stable high-pressure performance. Its rated pressure reaches 450 bar, and the maximum pressure can reach 500 bar (single working time ≤ 10s, total working time ≤ 300h), suitable for scenarios such as machine tools, construction machinery, industrial transmission, etc. that require high-pressure power output. The product integrates a built-in auxiliary pump, which can provide pressure compensation and pilot oil supply, while supporting multiple control modes and expansion functions, with strong flexibility.

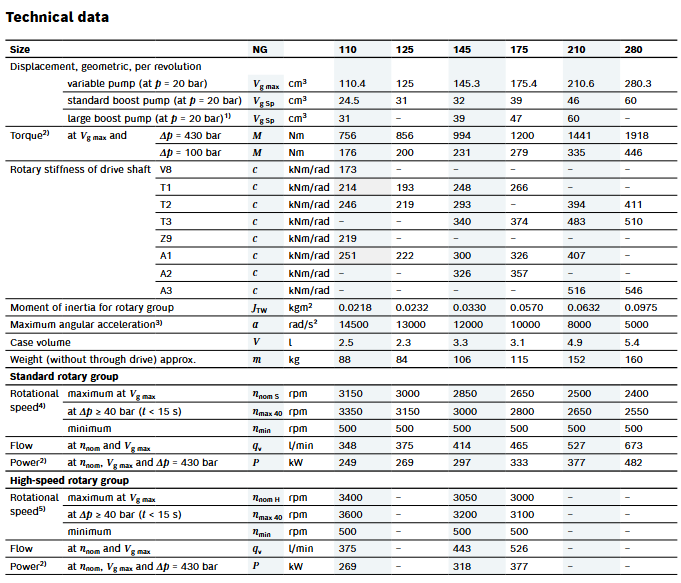

Core specifications and technical parameters

Key dimensions and displacement | Specification (NG) | Main pump displacement (cm ³/rev) | Auxiliary pump displacement (standard/large, cm ³/rev) | Weight (without through drive, kg) | Maximum speed (rpm)|

| 110 | 110.4 | 24.5/31 | 88 | 3150 |

| 125 | 125 | 31/- | 84 | 3000 |

| 145 | 145.3 | 32/39 | 106 | 2850 |

| 175 | 175.4 | 39/47 | 115 | 2650 |

| 210 | 210.6 | 46/60 | 152 | 2500 |

| 280 | 280.3 | 60/- | 160 | 2400 |

Hydraulic oil and environmental parameters

Recommended hydraulic oil: HLP mineral oil (DIN 51524), also compatible with environmentally friendly and fire-resistant hydraulic oil (please refer to the corresponding data manual).

Viscosity requirement: Continuous operation at 10-400 mm ²/s (optimal at 36-16 mm ²/s), cold start at ≤ 1600 mm ²/s (duration ≤ 3 minutes).

Temperature range: working temperature of hydraulic oil NBR seal ≤ 85 ℃, FKM seal ≤ 110 ℃; Storage and transportation temperature -30~+85 ℃.

Cleanliness requirements: ISO 4406 20/18/15, viscosity<10 mm ²/s needs to be increased to 19/17/14.

Control mode and functional configuration

Detailed Explanation of Mainstream Control Methods | Control Types | Model Codes | Core Features | Power Supply/Signal Requirements|

|Hydraulic proportional control (related to pilot pressure) | HP1/HW2/HW8 | Flow rate is continuously adjustable from 0-100%, proportional to pilot pressure (6-18 bar) | Hydraulic pilot signal|

|Mechanical servo control | HW series | Adjust flow rate through control rod swing angle, with spring centering | Mechanical force (maximum 170Ncm)|

|Speed related automatic control | DA1 (12V)/DA2 (24V) | Suitable for walking drive, flow rate automatically adjusts with engine speed | 12V/24V, rated power ≈ 26W|

|Electric proportional control | EP1/EP3 (12V)/EP2/EP4 (24V) | Flow proportional to control current (200-1200mA), some with manual emergency adjustment | 12V/24V, 100Hz jitter frequency|

|Electric two-point control | EZ1 (12V)/EZ2 (24V) | Only switch between "zero displacement/maximum displacement" | 12V/24V, minimum operating current 0.67-1.32A|

Core auxiliary functions

Pressure cut-off: After the pressure reaches the set value, reduce the displacement to the minimum, which should be 30 bar lower than the high-pressure relief valve to avoid frequent operation of the relief valve.

Bypass function: It can connect ports A and B (such as in towing scenarios), with a maximum towing flow rate of ≤ 30L/min.

Neutral valve: When the power is cut off, the pump torque is zero to ensure safety and adapt to safety critical scenarios.

Mechanical travel limiter: It can infinitely limit the maximum displacement and adapt to different load requirements.

Installation and maintenance requirements

Installation specifications

Installation position: Supports 12 installation methods, recommended bottom mounted (pump body below the lowest liquid level in the tank), maximum allowable suction height is 800mm.

Port connection: The working ports A/B are SAE J518 standard, and the oil suction port S and oil discharge port T1/T2 need to be connected according to the installation position (to avoid liquid accumulation).

Through drive: Supports the installation of additional pumps of the same specifications, and attention should be paid to the through drive torque (934Nm for 110NG and 2641Nm for 280NG).

Filtering and pressure compensation requirements

Oil suction filter: It is recommended to install an oil suction filter with a cold start valve. When working continuously, the oil suction pressure should be ≥ 0.8 bar absolute pressure, and when starting cold, it should be ≥ 0.5 bar absolute pressure.

Pressure compensation circuit: The rated pressure of the auxiliary pump is 25 bar, with a maximum of 40 bar. It can be equipped with built-in or external filtration (to meet cleanliness requirements).

Safety and Maintenance

Safety protection: When working, the temperature of the pump body and electromagnetic coil is high, and protective equipment should be worn; To avoid valve group jamming caused by hydraulic oil contamination, filters need to be replaced regularly.

Filling and deflation: After the first start-up or long-term shutdown, it is necessary to fill hydraulic oil and deflate it. The oil outlet should be connected to the highest position of the oil tank to avoid negative pressure.

Shelf life: The standard rust prevention period is 12 months, and can be extended up to 24 months (please specify in the order and meet the optimal storage conditions).

Expansion configuration and accessories

Sensor options

Pressure sensor: PR4 series (0-600bar), installed on MA/MB port, suitable for high pressure monitoring.

Speed sensor: DSA/DSM series, capable of monitoring pump speed and steering, non retrofit.

Swing angle sensor: Hall effect type, outputting 1-4V analog signal, suitable for displacement closed-loop control, non retrofit.

Connectors and accessories

Electromagnetic coil connector: DEUTSCH DT04-2P-EP04 (IP67/IP69K protection), without suppression diode.

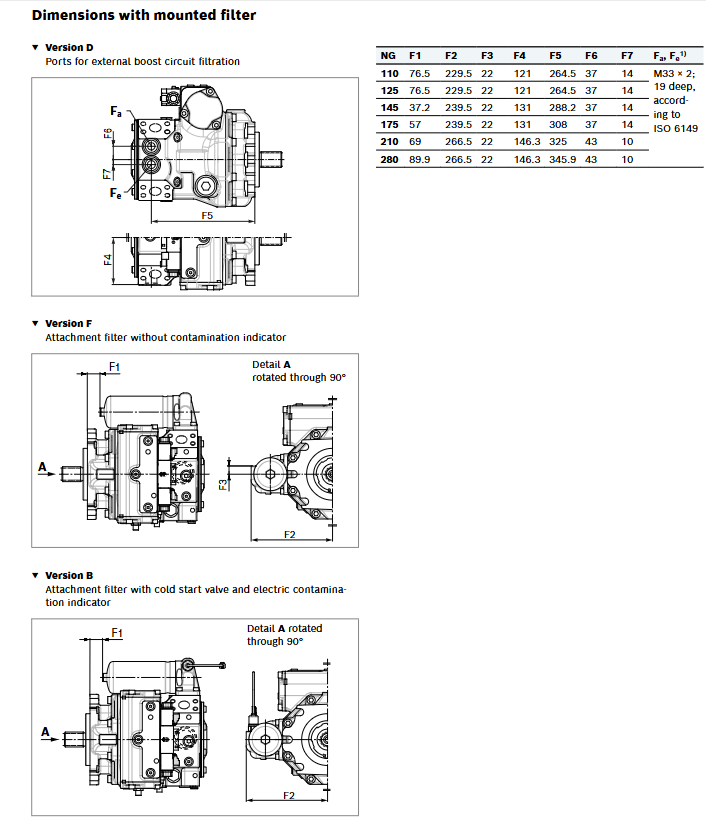

Filter accessories: oil suction filter (version S), pressure filter (version D), and installed filter with pollution indicator (versions B/F).

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923