K-WANG

REXRTOH Drive Controllers Control Sections CSB01, CSH01, CDB01

REXRTOH Drive Controllers Control Sections CSB01, CSH01, CDB01

Product Overview and Core Positioning

IndraDrive CSB01/CSH01/CDB01 is a modular servo drive control unit launched by Bosch Rexroth. As the control core of the IndraDrive drive system, it is divided into two series: BASIC (basic type) and ADVANCED (advanced type), suitable for single axis or dual axis drive scenarios. The product focuses on modular expansion, multi protocol compatibility, and high-precision control, which can be seamlessly matched with Rexroth IndraDyn series motors and various encoders. It is widely used in industrial automation equipment such as machine tools, packaging, printing, and material handling, meeting the driving and control needs of single machine or multi axis collaboration.

Product series and core configuration

Series model classification, number of axes, configuration characteristics, core differences

BASIC CSB01.1N (FC/SE/PB/AN) single axis fixed configuration, no additional expansion slots, only supports preset communication protocols, non expandable optional modules

BASIC CSB01.1C single axis configurable, including expansion slots to support communication, encoder, and security module expansion

BASIC CDB01.1C dual axis configurable, dual axis independent control supports dual axis synchronization, multiple expansion slots

ADVANCED CSH01.1C/CSH01.2C/CSH01.3C Single axis Advanced Configurable, Multiple Expansion Slot Supports Cross Communication (CCD), Higher Control Frequency (62.5 μ s)

Core functions and technical parameters

control performance

Control cycle: current control 62.5-125 μ s, speed control 250-500 μ s, position control 500-1000 μ s.

Switching frequency: Supports 2kHz-16kHz, adjustable through parameter P-0-0001.

Compatible with encoders: Supports 12V (ENS module), 8V (EN1 module), 5V (EN2 module) power supply, compatible with various encoder types such as Sin cos, Hiperface, EnDat 2.1, etc.

communication interface

Built in protocols: BASIC series supports fixed protocols such as Sercos, PROFIBUS, analog, etc; The ADVANCED series supports Multi Ethernet (EtherCAT/ProfiNet) and CANopen/DeviceNet.

Extension protocol: Supports Sercos III, Parallel interface, Cross Communication (CCD), etc. through optional modules.

Debugging interfaces: RS232 serial port (X2), Engineering Ethernet interface (X26), supporting control panel and MMC card parameter reading and writing.

I/O and scalability

Digital I/O: The basic unit includes 5-22 digital inputs and 0-4 digital outputs, supporting Type A/B/C/D inputs (24V, 3mA).

Analog I/O: The basic unit includes 2 analog inputs (± 10V/0-20mA) and 2 analog outputs (0-10V), which can be extended to 4-6 inputs and 4 outputs through AN/MA1 modules.

Expansion module: Supports encoder simulation (MEM), digital I/O expansion (MD1/MD2), SSI encoder evaluation (MD2 module integration).

safety technology

Basic security: L1 (start lock, compliant with EN60204-1 stop category 0) L2(Safe Torque Off,SIL3/PL e)。

Advanced security: S1 (Safe I/O), S2 (Safe Motion), supporting functions such as safe stop and safe speed limit, SIL2/PL d)。

Safe power supply: Independent 24V power supply (19.2-30V), maximum current 1.6A.

Environmental and power supply parameters

Power supply requirements: Control voltage DC 24V (fluctuation range 19-30V), basic unit power consumption 8-16W, optional module 1-6W.

Environmental conditions: working temperature 0-45 ℃, storage temperature -30-85 ℃, protection level IP20, anti electromagnetic interference (compliant with EN 61000 series standards).

Optional module details

Module type represents the model, core functions, and key parameters

Communication module SE (Sercos) fiber optic communication, supporting 16MBaud with fiber optic cable, maximum transmission distance of 100m

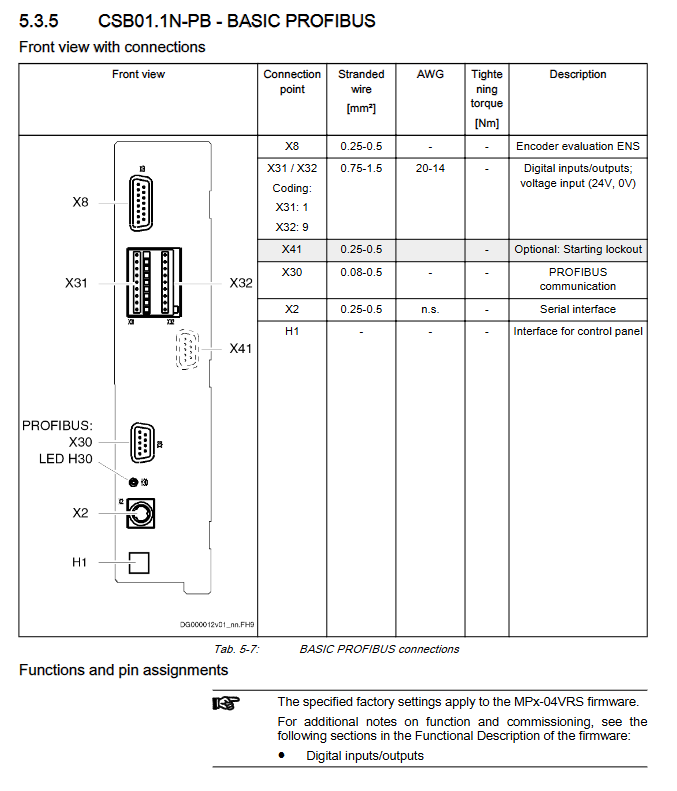

Communication module PB (PROFIBUS) bus communication, supports 12MBaud 9-pin D-Sub interface, shielded twisted pair cable

Encoder module ENS 12V encoder evaluation, compatible with Hiperface/EnDet 2.1 input frequency 400kHz, 12 bit A/D conversion

Encoder module EN1 8V rotary transformer/HSF encoder evaluation input frequency 18kHz, 12 bit A/D conversion

I/O expansion module MA1 2 analog inputs+2 analog outputs 12 bit resolution, ± 10V output

I/O expansion module MD2 16 channel digital I/O+SSI encoder evaluation digital I/O support 24V/0.5A, SSI clock frequency 100-1000kHz

The safety module S2 (Safe Motion) requires encoders for safety stop, speed limit, and position limit, and supports multiple safety function combinations

Installation and maintenance requirements

Installation specifications

Installation method: 35mm standard guide rail (EN 60715), vertically installed, with at least 2cm of reserved heat dissipation space above and below.

Wiring requirements: Digital I/O requires external 24V power supply. It is recommended to connect protective diodes in series to prevent polarity reversal; The signal cable and power cable are wired separately, and the shielding layer is grounded at both ends.

Insertion and removal restrictions: The control unit and power unit should not be inserted or removed more than 20 times to avoid poor contact.

Maintenance points

Firmware update: Update firmware through MMC card (PFM02.1) or Engineering interface, supporting parameter backup and recovery.

Fault diagnosis: Read fault codes through LED indicator lights, control panel or upper computer, and support 16 channel real-time data recording.

Spare parts requirements: Only Bosch Rexroth certified spare parts are allowed, and parameters need to be reconfigured after module replacement.

Typical Applications

Single machine drive: machine tool spindle/feed axis, packaging machinery actuator, printing machine tension control.

Multi axis collaboration: Material handling robots, assembly line multi axis synchronization, automated production line drive system.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923