K-WANG

REXRTOH ECODRIVE DKC01.1/DKC11.1 Drive Controllers

REXRTOH ECODRV DKC01.1/DKC11.1 series drive controllers

The official troubleshooting guide for Bosch Rexroth ECODRV DKC01.1/DCC11.1 series drive controllers revolves around four categories of diagnostic messages (error/warning/command/status), with detailed definitions of the causes, troubleshooting steps, and solutions for each diagnostic message. It covers 23 types of error messages (such as F218 radiator overheating shutdown), 22 types of warning messages (such as E250 radiator overheating warning), 33 types of command messages (such as C100 communication phase 3 transition check), and 16 types of status messages (such as A100 torque mode). It also provides replacement processes for drives, motors, and cables, as well as global customer service contact information, providing core guidance for maintenance personnel to quickly locate faults and efficiently repair.

Diagnostic message system

(1) Message classification and structure

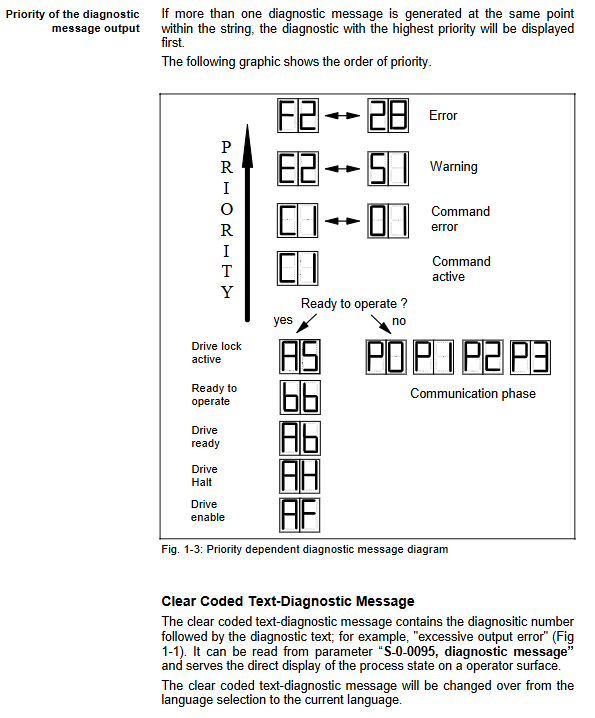

Classification rules: Divided into four categories based on their functions, distinguished by specific letters starting with them. The priority order is: error message>warning message>command message>status message.

Structure composition: Each diagnostic message contains a "diagnostic number+diagnostic text", for example, "F2/28 excessive output error". The number is displayed alternately on the H1 screen, and the complete text can be viewed for parameter S-0-0095.

(2) Detailed Explanation of Core Diagnostic Messages (Table Summary)

The message type represents the core cause of the message and key solutions

Error message (starting with F) F218 radiator overheating shutdown environment temperature>45 ℃, radiator dirty, fan failure cooling cleaning/driver replacement

F219 motor overheating shutdown motor overload, temperature monitoring line fault inspection load/repair circuit

F226 undervoltage error, power interruption, abnormal power supply check, power supply logic/restore power supply

F229 encoder quadrant error encoder cable damage, insulation interference replacement cable/separation of power line and encoder line

F860 power level short circuit overcurrent motor cable short circuit, drive power level fault check cable/replace driver

Warning message (starting with E) E250 radiator overheating warning Internal fan failure, insufficient heat dissipation in control cabinet Replace driver/install air conditioner

E251 motor overheating warning, continuous torque exceeding allowable value, inspection of motor installation/operating conditions

E254 did not return to zero absolute positioning command, did not execute return to zero, executed return to zero operation/selected relative positioning

E256 torque limit=0 parameter setting error, analog channel overload adjustment parameter S-0-0092/reducing analog voltage

Command message (starting with C/D) C101 communication parameter invalid parameter mode switch, invalid parameter connection DriveTop software correction parameter

C600 Drive Control Zero Return Command Activated but Drive Not Enabled Enable Drive Restart Command

D903 inertia detection failed due to low acceleration and excessive load inertia, increasing torque limit/improving positioning speed

Status message (starting with A/J) A100 torque mode drive operates in torque control mode and switches to speed/position mode as required

A203 position mode driver works in position control mode (stepper interface) to confirm that the command signal matches the parameters

The AF drive enable signal has been applied, and the drive is ready to operate normally without intervention

Key troubleshooting points

(1) High frequency fault classification and handling

Temperature related faults

Common reasons: excessive environmental temperature, blocked heat dissipation channels, fan failure, and excessive energy feedback.

Handling principle: Warning types (E250/E251/E252) need to be processed within 30 minutes; Shutdown type (F218/F219/F220) requires root cause investigation before restarting.

Encoder related faults

Core requirement: The amplitude of the encoder signal should be between 12.0-18.0V (F822 fault diagnosis standard).

Wiring specification: The encoder cable should be arranged separately from the power line, and the shielding layer should be reliably grounded.

Parameter related faults

Attention: Executing 'Load Default Parameters' (C800) will overwrite all existing parameters and positioning blocks, and backup is required in advance.

Common problem: Torque limit of 0 (E256) and feed rate of 0 (E255) will cause the drive to be inactive, and the parameters need to be reset to>0.

(2) Safety operation standards

Electrical safety: Before disassembly, disconnect the main power supply and take measures to prevent accidental closing. The discharge time of the capacitor should be ≥ 1 minute to avoid high-voltage electric shock.

Parameter operation: After modifying key parameters (such as travel limit and torque limit), it is necessary to verify the operating status of the equipment to prevent mechanical impact.

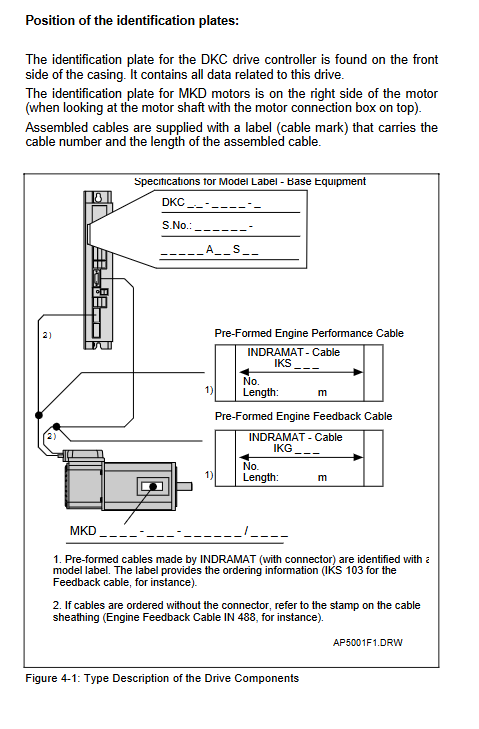

Replacement specification: When replacing the driver/motor/cable, the replacement part model must be exactly the same as the original equipment. After replacing the motor, the absolute position (absolute encoder type) must be reconstructed.

Component replacement process

(1) Replacement steps (universal framework)

Power off preparation: Turn off the main power supply, set up anti misoperation signs, and wait for the capacitor to discharge for ≥ 1 minute.

Disassembly operation: Separate the relevant cables (power line/encoder line/control line), remove the fixing screws, and remove the faulty components.

Install new components: Fix the new parts and reproduce the connection according to the wiring diagram (ensuring polarity/pin correspondence). The encoder cable should be firmly fixed.

Parameter loading: After replacing the driver, the backup parameter file needs to be loaded (or C700 basic loading needs to be performed), and after replacing the motor, absolute position calibration needs to be performed.

Test run: After powering on, check for no fault codes and conduct a trial run to verify that the function is normal.

(2) Key points for replacing different components

Key precautions and special requirements for replacing components

Drive (DKC) loads the original parameter file and confirms that the firmware version matches the discharge time of ≥ 1 minute

The motor (MKD/MDD) covers the temperature monitoring line of the motor, and the reconstruction of the absolute position joint requires protection (against coolant/oil contamination)

Replace the cable (power/feedback) according to its original length/specifications, and ensure that the shielding layer is reliably grounded to avoid parallel wiring with the power line

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB PFXA401SF Industrial Automation Controller

-

ABB HAC319AEV1 Industrial Process Automation Module

-

ABB SA9923A-E Advanced Industrial Automation Module

-

ABB CSA463AE Industrial Automation and Monitoring Module

-

ABB UAC326AE Industrial Process Control Module

-

ABB NU8976A Industrial Automation Control Module

-

ABB LT8978bV1 High-Performance Industrial Automation Module

-

ABB ARC093AV1 Industrial Control and Monitoring Module

-

ABB UAC318AE Advanced Automation Control Module

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923