K-WANG

REXRTOH MSK series synchronous servo motor

REXRTOH MSK series synchronous servo motor

The official use manual of Bosch Rexroth MSK series synchronous servo motors (including 15 frame sizes and models such as MSK030/040/050) (March 2021), which focuses on safety specifications, product parameters, transportation and storage, assembly wiring, commissioning and operation, maintenance and repair, and environmental protection disposal, defines key specifications such as motor protection level IP65 (optional IP67), ambient temperature 0-40 ℃, insulation level 155, and bearing service life 30000 hours, specifies two installation methods of flange/anchor, power supply/encoder/coolant connection requirements, commissioning measures after long-term storage, and troubleshooting procedures, provides full life cycle operation guidance for professionals, and products comply with low-voltage directive 2014/35/EU and other standards.

Core technical parameters

Parameter category, specific specifications, remarks

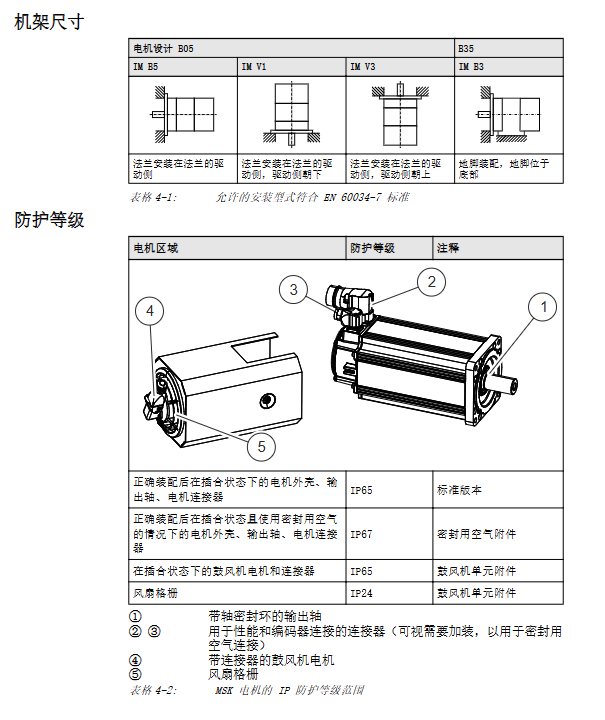

Protection level IP65 (standard), IP67 (sealed air accessory) motor housing/output shaft in plugged in state

Environmental conditions: working temperature 0-40 ℃, storage temperature -20~+60 ℃, installation height 0-1000m

Insulation class 155 (EN 60034-1)-

Bearing life nominal L ₁₀ h=30000 hours Permanent lubrication deep groove ball bearings

Sound pressure level < 75dB (A)-

Installation types IM B5 (flange drive side) and IM B35 (foot assembly) comply with EN 60034-7

Encoder type: Single cycle (S1/S2/S3), multi cycle (M1/M2/M3) signal period 16-2048, supporting Hiperface/EnDet 2.1

Keep the brake optional, 24V DC ± 10%, torque 10.0Nm, electric release type

Cooling method: natural convection, surface ventilation (fan unit), liquid cooling (FN model), liquid cooling inlet pressure ≤ 6bar

Key points of safety regulations

(1) Electrical safety

Only skilled electricians are allowed to operate. Before starting work, power off, prevent accidental closing, ground short circuit, and shield adjacent live parts.

When the rotor of a permanent magnet motor rotates, a voltage greater than 60V will be generated at the terminal, and the motor must be stopped before operation. It is forbidden to plug or unplug connectors while they are live.

Encoder, KTY84 and other components contain electrostatic sensitive devices (ESD) and must comply with anti-static measures.

(2) Mechanical safety

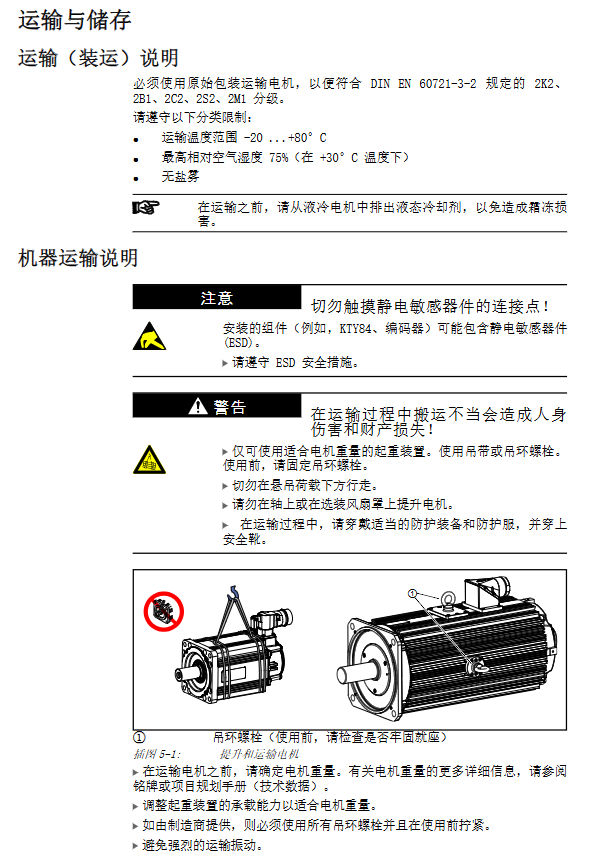

Suitable equipment (lifting eye bolts) must be used for lifting. It is strictly prohibited to walk under suspended loads or to grip shafts or fan covers during lifting.

Rotating components need to be equipped with cover plates, and the longitudinal axis needs to be mechanically locked or externally braked to prevent sinking after stopping the machine.

When installing transmission components (couplings/pulleys), it is forbidden to strike the shaft end to avoid exceeding the allowable radial/axial force.

(3) Special protection

Electromagnetic fields pose health risks to wearers of pacemakers and metal implants. Such individuals are prohibited from approaching and should consult a doctor.

The surface operating temperature of the motor may exceed 70 ℃, and it needs to be cooled for at least 15 minutes before touching. If necessary, anti contact protective devices should be installed.

Recharging/disassembling/using open flames is prohibited for batteries, and discarded batteries must be separately recycled.

Transportation and Storage Standards

(1) Transportation requirements

Original packaging is required, in accordance with DIN EN 60721-3-2 classification (2K2, 2B1, etc.), transportation temperature -20~+80 ℃, relative humidity ≤ 75% (+30 ℃).

Before transporting liquid cooled motors, it is necessary to drain the coolant to prevent damage from frost; Fix the lifting ring bolts during lifting to avoid strong vibrations.

(2) Storage requirements

The storage environment should be dry, dust-free, vibration free, and dark, with a temperature of -20~+60 ℃, a relative humidity of 5-95% (no condensation), and no salt spray.

Long term storage measures (table):

Storage duration, motor debugging measures, cable/joint debugging measures

Visual inspection in January showed no damage

Replace the brake surface in December, inspect the electrical contacts, run for 1 hour without load (800-1000rpm) to check the electrical contacts, and visually inspect the cable sockets

Additional replacement of bearings, encoders, and measurement of insulation resistance in June-

Assembly and connection specifications

(1) Installation method

Flange assembly (table):

Installation hole diameter (mm), screw specification, tightening torque (Nm), washer requirements

4.5 M4 × 20 3 None

6.6 M6 × 20 10.1 None

9 M8 × 20 24.6 requires a washer

11 M10 × 30 48 requires washer

14 M12 × 40 84 requires a washer

18 M16 × 35 206 requires a washer

Foot assembly: Align the motor shaft with the centerline of the connecting shaft. Radial force is only effective within ± 15 ° of the vertical installation surface. It is prohibited to transmit force to the foot through gears.

(2) Wiring specifications

Power connection: Supports M23/M40/M58 connectors or junction boxes (RZK3100/RKL1200, etc.), wire cross-sectional area of 1.5-35mm ², tightening torque of 2.5-3.8Nm.

Encoder connection: 8-16 pole connector, the shielding layer needs to be reliably grounded, the equipment connector can rotate 210 °~220 °, and the maximum tightening torque is 12-18Nm.

Coolant connection (liquid cooling model): The inlet/outlet can be freely distributed. The frame size is 071/075, and the tightening torque is 14-15Nm. 101/133 is 18-20Nm. It is prohibited to use Teflon tape for sealing.

(3) Accessory assembly

Fan unit: Supports 115V/230V (single-phase) and 400V (three-phase), connected according to the nameplate voltage, integrated with thermal protection device, and the fan cover needs to reserve an encoder connection cover plate.

Air pressure connector: Working pressure of 0.1 ± 0.05 bar, SUP-M01-MSK (encoder side)/SUP-M02-MSK (power side) kit is required, with a tightening torque of 1.3-3.1 Nm.

Debugging and Running

(1) Debugging prerequisites

Confirm the storage duration of the motor and implement corresponding debugging measures; Check that all connectors are securely connected and that the brake voltage is 24V ± 10%.

Verify that the brake function is normal, the protection key is fixed, and there are no residual transport locking devices.

(2) Operation monitoring

During operation, it is necessary to comply with the environmental and technical parameters in the project planning manual, and monitor abnormal noise and vibration increments.

Regularly check the cleanliness of the motor/fan, the sealing of the coolant interface, pay attention to the diagnostic error messages of the controller, and stop the drive in case of abnormalities.

(3) Troubleshooting (Table)

Possible causes and solutions for the fault phenomenon

Motor not running, controller enable signal missing, power supply voltage missing, brake not released activation enable signal, check power supply, verify brake activation status

Abnormal vibration, poor balance of coupling components, insufficient alignment of shaft end attachments, loosening of installation screws, rebalancing of components, calibration of attachments, and locking of screws according to specifications

High operating noise, foreign objects inside the motor, damaged bearings, and shutdown. Contact the manufacturer for repair after shutdown

Motor temperature exceeds rated load, heat dissipation is damaged, temperature sensor is not connected to reduce load, clean motor/check fan/cooling circuit, connect sensor

Maintenance and environmental disposal

(1) Maintenance points

Cleaning and maintenance: Regularly (no later than 1 year) clean the surface of the motor to avoid dust covering and affecting heat dissipation; The connecting cable needs to be checked for damage, and the drag chain needs to be checked for defects.

Spare parts replacement: It is recommended to replace the bearings after 30000 hours; Visually inspect the shaft sealing ring after 5000 hours and replace it if necessary; Only use Rexroth original spare parts.

(2) Environmental disposal

Product Ingredients: Steel, Aluminum, Copper, Permanent Magnet, Electronic Components, Can be Classified and Recycled; The packaging materials (cardboard/wood/polystyrene) can be routinely recycled.

Permanent magnets need to be demagnetized before disposal, and it is prohibited to transport magnetized rotors; Waste batteries need to be recycled according to the national dedicated system to avoid pollution.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB PFXA401SF Industrial Automation Controller

-

ABB HAC319AEV1 Industrial Process Automation Module

-

ABB SA9923A-E Advanced Industrial Automation Module

-

ABB CSA463AE Industrial Automation and Monitoring Module

-

ABB UAC326AE Industrial Process Control Module

-

ABB NU8976A Industrial Automation Control Module

-

ABB LT8978bV1 High-Performance Industrial Automation Module

-

ABB ARC093AV1 Industrial Control and Monitoring Module

-

ABB UAC318AE Advanced Automation Control Module

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923