K-WANG

REXRTOH SE 200 Electric Tool Controller and Supporting LTH Power Unit

REXRTOH SE 200 Electric Tool Controller and Supporting LTH Power Unit

Basic Information

Core product portfolio

SE 200 Controller: The core control unit of the electric tool system, responsible for program selection, job control, and status feedback.

LTH power unit: a frequency converter that provides a variable power/frequency rotating magnetic field for EC motors, available in two specifications: 230V (order number 0 608 750 056) and 110V (order number 0 608 750 064).

Document type and purpose: Official technical manual, covering safe operation, installation and wiring, functional settings, fault handling, etc., suitable for electric tightening/loosening operation systems in industrial assembly scenarios.

Adapt devices and accessories

Suitable motors: EC 37, EC 48 type EC motors (such as ECH12-MG, ECH37-MG, etc., please refer to the appendix for order numbers).

Core accessories: current control board ST1, programming module PM-1, dedicated connection cable (straight 1.6-10m/spiral 6.3-10m).

Core Technical Parameters

Parameter Category Specific Parameters LTH 230V LTH 110V Remarks

Power supply parameters rated voltage 220-240V AC 100-110V AC 50/60Hz ± 10%

Maximum input current 10A 20A-

Power consumption 400VA 400VA-

Output parameters Output voltage range 0-230V 0-230V-

Rated output current 2A 2A-

Maximum output current 12A 12A-

Output frequency range 0-500Hz 0-500Hz, suitable for motor speed regulation

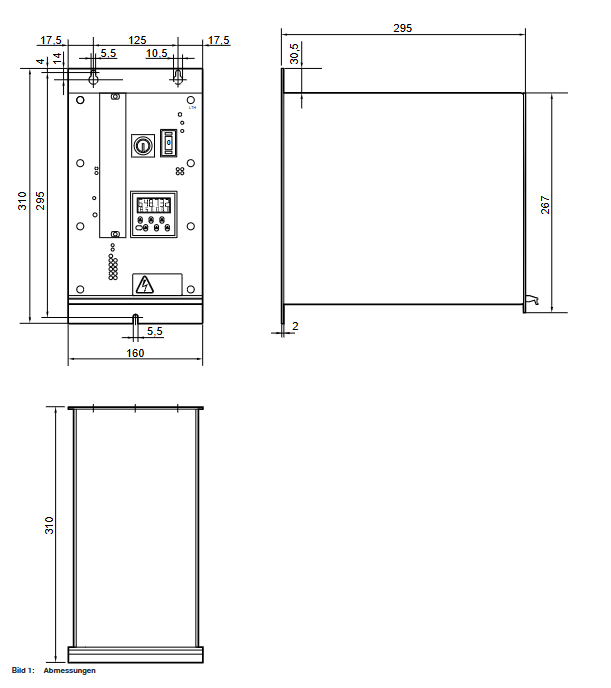

Physical dimensions (length x width x height) 310 × 160 × 310mm 310 × 160 × 310mm-

Weight 13.4kg 13.4kg including installation accessories

Environmental parameters Operating temperature 0-50 ℃ 0-50 ℃-

Storage temperature -20-70 ℃ -20-70 ℃-

Relative humidity 20-90% (no condensation) 20-90% (no condensation)-

Protection and Electromagnetic Compatibility Protection Level IP 42 IP 42 Solid Foreign Object Protection+Splash Protection

EMC level IEC 801 level 4 IEC 801 level 4 Anti electromagnetic interference

Data storage battery specifications: 2 1/2 AA 3.6V lithium batteries, 2 1/2 AA 3.6V lithium batteries, data storage for 8 years

Key points of safety regulations

Electrical safety

After power failure, it is necessary to confirm that there is no voltage before operation to avoid the risk of high voltage electric shock.

It is strictly prohibited to connect the motor to the PE line. Electrical isolation should be achieved by relying on the isolation transformer of the LTH power unit (in accordance with VDE 0551 standard).

The fuse (6.3A slow melting type) is only allowed to be replaced by professionals and unauthorized modification of the circuit is prohibited.

Operational Security

Only trained and qualified personnel are allowed to operate, and they must be familiar with safety regulations and equipment functions.

In environments with severe dust or high humidity, the LTH unit needs to be installed in a control cabinet with an IP 54 protection level.

It is prohibited to connect non specialized equipment (such as coffee makers, toasters, etc.) to IEC sockets.

Equipment Protection

During installation, a ventilation gap of ≥ 40mm should be reserved to avoid overheating caused by poor heat dissipation.

Transportation and storage should avoid severe vibration, condensation, and dust pollution.

Installation and wiring specifications

(1) Installation requirements

Installation method: Hanging installation is carried out through the back hanging ears, without the need to be in close proximity to power tools.

Cable limitation: The maximum length of the cable between the LTH power unit and the motor should not exceed 50m, and original factory specific cables must be used.

Environmental adaptation: Install directly in regular environments, but in harsh environments, an IP 54 control cabinet is required.

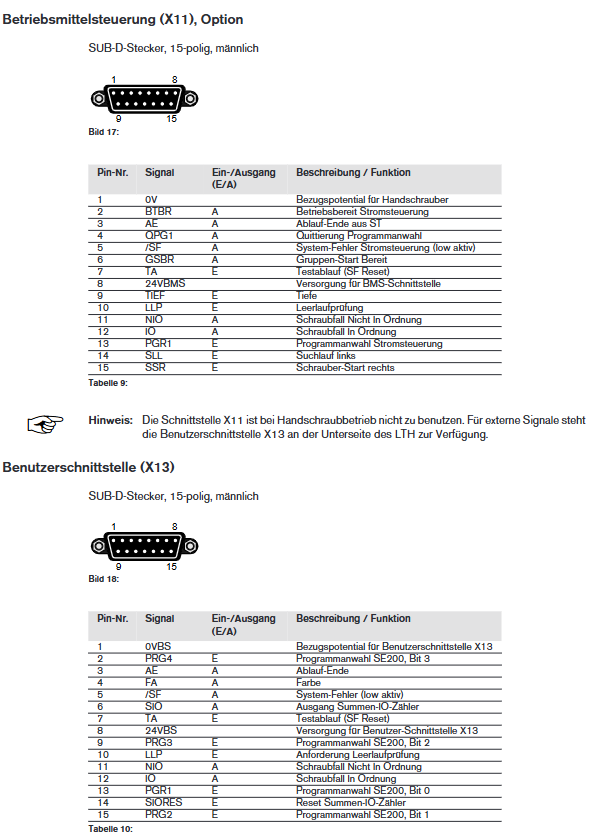

(2) Core Interface Definition (Summary of Key Interfaces)

Interface Identification Type Pin Count Core Function Key Pin Description

X1 (Netz) IEC socket 3 (L/N/PE) power input L=phase wire, N=neutral wire, PE=ground wire

X3 (Handschauber) circular plug 19+PE motor connection U/V/W=motor phase line, TMA=motor temperature sensor

X2 (Sensorik SE200) SUB-D socket 15 sensor signal CLK/DATA=RS422 serial signal, 24VSE=control power supply

X7 (Betriebsmittelsteuerung) SUB-D socket 37 material control SSR=tighten start, SLL=loosen start, IO/NIO=job success/failure signal

X8 (Kommandoleitung) SUB-D plug 25 command line ST1-ST3=speed gear, FG=release signal, IM1/IM2=torque measurement

X13 (Benutzerschnittstelle) SUB-D plug 15 user interface SIO=IO count output, SF=system fault, TA=test reset

(3) Wiring process

Connect the interface cable and secure it with screws to ensure reliable contact.

Insert the Amphenol plug into the motor and tighten the locking ring.

Connect the power cable (IEC plug) and secure it with a wire clamp.

By turning on the bottom power switch, the device automatically performs hardware self-test.

Operation and Function Description

(1) Core components of panel operation

Motor selection switch: Switch the EC 37/EC 48 motor type, and the corresponding LED indicator light will light up to confirm.

Program selection mode:

Internal mode: Select the 0-15 program through the panel buttons (even=tighten P0, odd=tighten P1, 15=loosen SLL).

External mode: Select the program using hexadecimal code through the X13 interface, and the "ExternalN" LED will light up.

IO Count Statistician:

Function: Record the number of qualified assignments (0-999999), supporting cumulative/decreasing modes.

Operation: Reset with the red SET button, set preset values with 6 buttons, and display "Lo bat" for low battery.

Fault handling: Reset the fault by pressing the "RESET" button. If the power module fails, the device needs to be restarted.

(2) Core functional parameters

Parameter Name Optional Setting Default Value Function Description

Count mode: Add/SubAdd: Count from 0 to the preset value; Decrease: Count from preset value to 0

Loop mode: On/Off Off On=Delay reset loop after reaching the preset value; Off=continuous counting without looping

Relay output type when NO (normally open)/NC (normally closed) NO count meets the standard

Delay 100/200/300/400/500ms - SIO signal duration when Loop=On

DP (decimal point) with no/1/2 decimal places and no count display

(3) Homework process

Select motor type (EC 37/EC 48) and program mode (internal/external).

Set the preset value and working parameters of the IO counter (accumulate/decrease, loop, etc.).

Trigger the operation (tightening/loosening) through the X7 interface or motor start button.

After the homework is completed, the IO/NIO signal feedback indicates success or failure, and the counter is automatically updated.

When there is a malfunction, the corresponding LED lights up, and after resetting, the operation can be restarted.

Fault diagnosis

(1) Common faults and LED indications

LED identification color fault type handling method

USP red middle circuit overvoltage check power supply voltage, reset device

If the NTF red power module fails, restart the device. If it is ineffective, return it to the factory for repair

TF/TFVM red temperature fault (unit/motor), restart after cooling, check heat dissipation and temperature sensor

FI red current fault (short circuit): Check the motor cable and eliminate the short circuit point

BL red motor stalling check load, eliminate mechanical jamming

Accessory ordering information (core accessories)

Accessory category Product name Order number Remarks

Power Unit LTH 230V 0 608 750 056-

LTH 110V 0 608 750 064 -

Controller SE 200 Electric Tool Control 0 608 830 123-

Motor ECH37-MG 0 608 841 009 EC 37 type

ECH48-MG 0 608 841 010 EC 48 type

Cable straight cable (4.0m) 0 608 750 067 motor connection

Spiral cable (6.3m) 0 608 750 070 motor connection

Control module current control board ST1 0 608 750 054 optional accessories

Programming module PM-1 0 608 750 055 optional accessories

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB PFXA401SF Industrial Automation Controller

-

ABB HAC319AEV1 Industrial Process Automation Module

-

ABB SA9923A-E Advanced Industrial Automation Module

-

ABB CSA463AE Industrial Automation and Monitoring Module

-

ABB UAC326AE Industrial Process Control Module

-

ABB NU8976A Industrial Automation Control Module

-

ABB LT8978bV1 High-Performance Industrial Automation Module

-

ABB ARC093AV1 Industrial Control and Monitoring Module

-

ABB UAC318AE Advanced Automation Control Module

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923