K-WANG

REXRTOH RAC 2 Series Spindle Drive Controller and CDH1/CGH1/CSH1 Series Milling Machine Hydraulic Cylinder

REXRTOH RAC 2 Series Spindle Drive Controller and CDH1/CGH1/CSH1 Series Milling Machine Hydraulic Cylinder

Basic Information

Covering products

RAC 2 Series: Spindle Drive Controller, compatible with INDRAMAT 2AD asynchronous spindle motors (30-52kW) and 1MB frameless spindle motors, supporting spindle positioning and C-axis operation functions.

CDH1/CGH1/CSH1 series: milling machine type hydraulic cylinder, CDH1 is a differential cylinder, CGH1 is a double piston rod cylinder, CSH1 is a differential cylinder with magnetostrictive position measurement, suitable for various media such as mineral oil and water ethylene glycol.

Core applicable scenarios

Commonly applicable to CNC machine tools, industrial automation equipment, and heavy-duty transmission systems.

RAC 2 focuses on high-precision spindle control; The hydraulic cylinder is compatible with milling machines and hydraulic heavy-duty equipment, supporting multiple installation scenarios.

Comparison of core technical parameters

(1) Key parameters of RAC 2 series

Remarks on the numerical range of parameter items

Rated output power (motor shaft) 30-52kW continuous output

Input voltage 3 × 400V (50Hz ± 15%)/3 × 460V (60Hz ± 10%) directly connected to the three-phase power grid

Position resolution 1/4000000 RPM supports high-precision control of C-axis

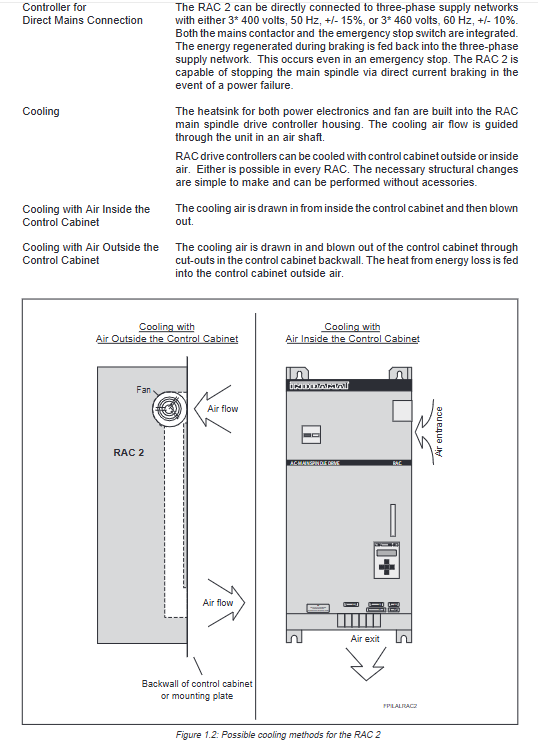

Cooling method: Air cooling inside and outside the control cabinet, hose cooling, built-in fan+heat sink

Equipment weight 121kg including installation frame

Environmental temperature 5-45 ℃ (rated), maximum 55 ℃ (reduced capacity), humidity level F (DIN 40040)

(2) Key parameters of hydraulic cylinder series

Remarks on the numerical range of parameter items

Rated pressure 250bar Static test pressure 375bar

Piston diameter (Ø AL) 40-320mm in accordance with ISO 3320 standard

Piston rod diameter (Ø MM) 22-220mm matches with piston diameter

The maximum travel of 6m needs to be combined with anti buckling calculation

Medium temperature -20 ℃~+120 ℃ adjusted according to sealing type

Cleanliness requirements ISO 4406 20/18/15 require a matching filtering device

Protection level IP65 (main body), IP50 (partial output shaft) to prevent solid foreign objects and water splashes

Key points of safety regulations

(1) RAC 2 Security Requirements

Electrical safety

After power failure, wait for 5 minutes for the capacitor to discharge and confirm that the voltage is below 50V before operation.

Grounding conductor cross-sectional area ≥ 10mm ², leakage current>3.5mA, permanent and reliable connection.

Mechanical safety

Safety fences and emergency stop switches need to be installed, and the vertical axis requires additional mechanical locking. The standard motor brake does not meet personnel safety requirements.

The cooling air duct should be kept unobstructed to avoid overheating, and the temperature of the heat sink may exceed 60 ℃.

environmental safety

Pacemaker wearers are prohibited from entering the operating area, with a device protection level of IP10 (EN 60529).

The cooling of the control cabinet should avoid condensation water dripping onto electronic components, and the cooling temperature should not be lower than 40 ℃.

(2) Safety requirements for hydraulic cylinders

Pressure and Buckling Resistance

The maximum working pressure does not exceed 250 bar, and the pressure amplification caused by the area ratio needs to be considered.

When installed vertically, the allowable travel is calculated according to Euler's formula, with a safety factor of 3.5.

Environment and Protection

The corrosion protection level is divided into CP3-CP7, suitable for conventional to high salt spray environments near the sea.

To avoid lateral forces acting on the piston rod, it is necessary to ensure the mechanical alignment of the motion axis.

Installation and configuration specifications

(1) RAC 2 Installation and Wiring

Installation requirements

The installation of the control cabinet requires the use of M1-RAC 2 installation frame, with a minimum spacing of 150mm at the top and 80mm at the bottom.

The cooling method can be switched to air cooling inside the control cabinet, external air cooling, or hose cooling (M2-RAC accessories required).

core interface

X2 (standard interface): Control signal and analog output, 37 pins.

X3: Motor feedback connection, 15 pins; X4: Speed setpoint (simulated ± 10V/SERCOS).

X5: Additional encoder input, supporting spindle synchronization feedback; X13: Optional RS232/incremental encoder output.

(2) Hydraulic cylinder installation and adaptation

Classification of installation methods

|Installation method | Applicable series | Applicable scenarios|

|MP3 | CDH1/CSH1 | Base rotating earrings require swinging load|

|MP5 | CDH1/CSH1 | Base self-adjusting fork head, compensating for installation deviation|

|MF3 | Full Series | Head Circular Flange, Fixed Installation Axial Load|

|MF4 | CDH1/CSH1 | Circular flange base, integrated installation of the body|

|MT4 | Full Series | Ear Shaft Installation, Heavy Duty Swing Scenario|

|MS2 | Full range | Foot mount installation, horizontal/vertical fixation|

Key configurations

Sealing system: 9 designs (M/G/V/L, etc.), suitable for different media (mineral oil/water ethylene glycol/synthetic oil).

Position measurement: CSH1 supports IO Link/Profinet/SSI interfaces with a maximum resolution of 1 μ m.

Tightening torque: MF3 flange with a piston diameter of 100mm, bolt specification M12, tightening torque 100Nm.

Programming modules and accessories

(1) RAC 2 AS programming module

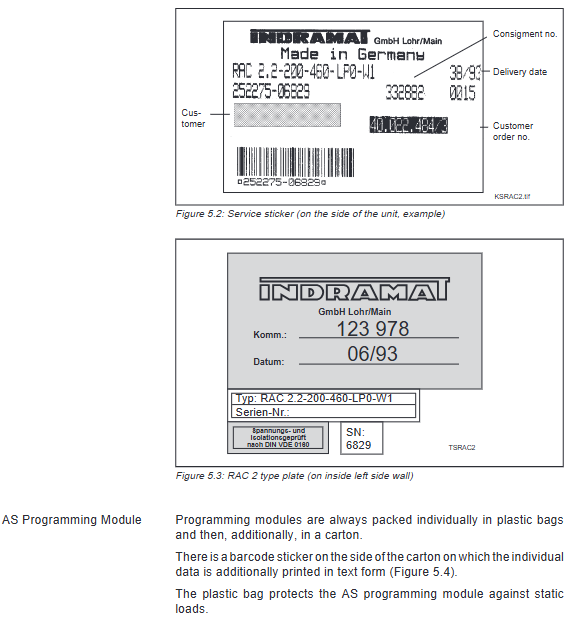

Core function: Store motor optimization parameters and application parameters, which can be directly reused when replacing the controller without the need for re debugging.

Compatibility: The updated module is compatible with the old module and supports parameter copying (PC or dedicated adapter).

Type code: Example AS 53/004-003, including controller model, software version, and motor adaptation information.

(2) Core components of hydraulic cylinder

Seals: M-type compatible with mineral oil, G-type compatible with mineral oil+water ethylene glycol, V-type compatible with synthetic oil.

Position measurement: IO Link interface powered 24VDC, transmission rate 230.4kBaud; Profinet supports RT/IRT protocols, with a maximum speed of 100MBit/s.

Auxiliary accessories: proximity switch (PNP normally open, IP68 protection), throttle valve, air release measurement connector.

Operations and Services

fault diagnosis

RAC 2 displays faults through the control panel, automatically brakes and loses power when faults occur. Refer to the supplementary documentation for troubleshooting.

Common problems with hydraulic cylinders: seal leakage (replace corresponding medium seals), position measurement deviation (calibrate sensors).

repair and replacement

RAC 2 replacement requires the use of lifting equipment, programming modules can be directly plugged and reused, and faulty equipment needs to be returned with a repair card.

The replacement of hydraulic cylinder seals needs to be selected according to the medium, and corrosion protection requires regular inspection of the coating (CP3-CP7).

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB PFXA401SF Industrial Automation Controller

-

ABB HAC319AEV1 Industrial Process Automation Module

-

ABB SA9923A-E Advanced Industrial Automation Module

-

ABB CSA463AE Industrial Automation and Monitoring Module

-

ABB UAC326AE Industrial Process Control Module

-

ABB NU8976A Industrial Automation Control Module

-

ABB LT8978bV1 High-Performance Industrial Automation Module

-

ABB ARC093AV1 Industrial Control and Monitoring Module

-

ABB UAC318AE Advanced Automation Control Module

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923