K-WANG

Yokogawa ROTOMETER RAMC Metal Variable Area Flow Meter

Yokogawa ROTOMETER RAMC Metal Variable Area Flow Meter

Positioning and core use

The dedicated user manual for Yokogawa ROTOMETER RAMC series metal variable area flow meters is suitable for volumetric/mass flow measurement of liquids and gases, especially for turbulent, opaque or corrosive fluid scenarios. The core uses float magnetic transmission to achieve flow indication and supports extended functions such as electronic transmitters and limit switches.

Core principles and structure of the product

1. Measurement principle

RAMC is a variable area flowmeter that operates based on the principle of "float force balance"

The fluid flows through the conical measuring tube from bottom to top, generating upward lift on the float;

The float rises to the equilibrium position of "lift=gravity+buoyancy", and its height is proportional to the flow rate;

The float is equipped with a built-in magnet, which drives the indicator pointer through magnetic transmission or triggers the electronic transmitter to output a 4-20mA signal/limit switch action.

Key feature: Within the "viscosity independent range" (fluid viscosity below a specific value), flow rate is only related to float height; When exceeding this range, the influence of viscosity on measurement needs to be considered, and the calibration scale and EEPROM need to be recalculated by the manufacturer.

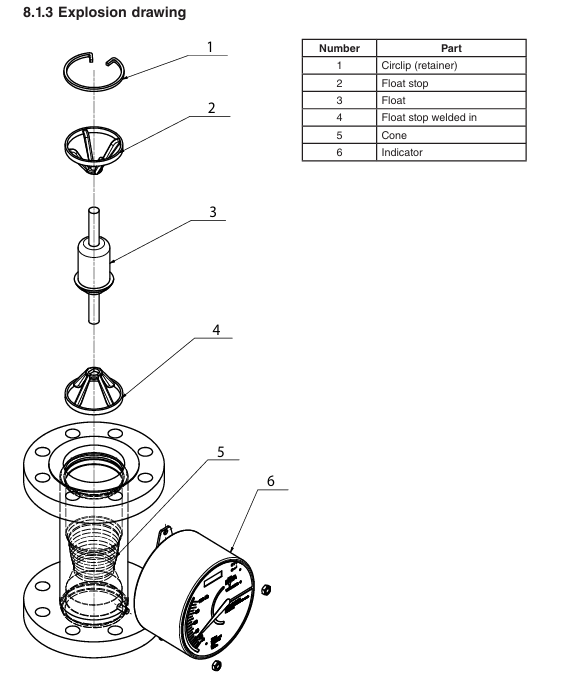

2. Product structure and core components

Component Name Function Description

The conical measuring tube provides a float rising channel, and the material is selected according to the corrosiveness of the fluid (such as stainless steel 1.4404/316L, PTFE)

Float core sensing element, built-in magnet, material adapted to fluid characteristics (such as corrosion-resistant alloy)

Indicator mechanical pointer indicates flow rate, optional LCD digital display (displaying flow rate, cumulative value, percentage, etc.)

The electronic transmitter (- E/- J type) converts the float position into a 4-20mA analog signal, while the - J type supports HART 7 communication

Limit switch (/K1-/K10 options) realizes flow upper and lower limit alarm, supporting standard type (/K1-/K3) and fail safe type (/K6-/K10)

Calibration EEPROM stores customized calibration data (such as fluid density, temperature, viscosity parameters), corresponding one-to-one with the measuring tube

Installation and wiring specifications

1. Preparation before installation and environmental requirements

Environmental restrictions:

Temperature: -40 ° C~+70 ° C (standard), -20 ° C~+60 ° C (explosion-proof type);

Avoid strong vibrations, corrosive environments (if necessary, choose high anti-corrosion coating shells), and strong magnetic field interference (keep a distance from solenoid valves, etc. Ferromagnetic objects should be kept away from ≥ 250mm);

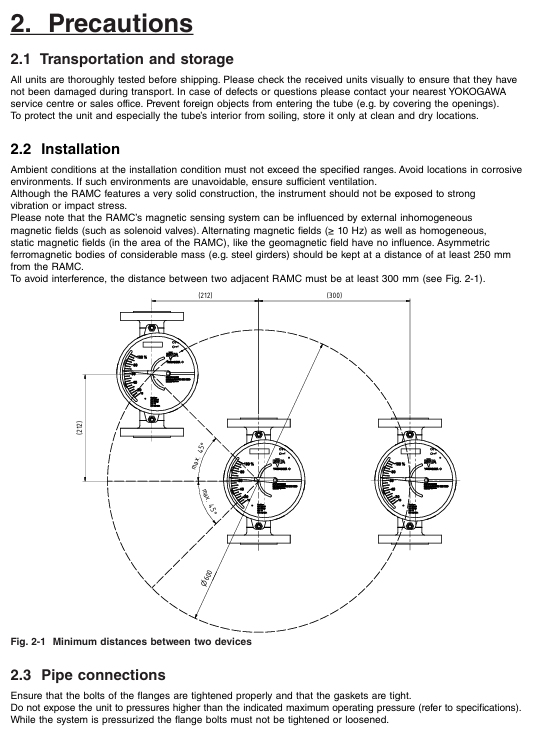

The distance between adjacent RAMCs should be ≥ 300mm to prevent mutual interference of magnetic fields.

Pipeline requirements:

It must be installed vertically, with the fluid flow direction being "downward and upward", and the flanges should be aligned parallel to avoid pipeline stress;

For models with a nominal diameter greater than RAMC08, it is necessary to reserve a straight pipe section for the first 5 times the nominal diameter and a straight pipe section for the last 3 times the nominal diameter;

If the fluid may contaminate the measuring tube, it is recommended to install a bypass pipeline for easy disassembly and cleaning of the equipment.

2. Pipeline connection and wiring operation

Flange connection: Supports EN, ASME and other standard flanges, and bolt torque must strictly follow the specifications, such as DN15 PN40 flange (EN 1092-1) torque of 9.8 Nm, DN50 PN40 flange torque of 57 Nm; PTFE lined flanges require additional attention to sealing performance to avoid fluid leakage.

Wiring specifications:

Cable sealing sleeve: Suitable for cables with a diameter of 6-9mm. If not in use, M16 × 1.5 (shell 90 type) or M20 × 1.5 (shell 91 type) blind plug sealing is required for the entrance;

Signal and power separation: Analog signals (4-20mA), digital communication (HART), and power cables need to be wired separately to avoid interference;

Grounding requirements: The protective grounding (PE terminal) must be firmly connected, with a grounding resistance of ≤ 100 Ω, and an additional external grounding clamp is required for the 91 type shell.

Core functions and parameter configuration

1. Operation of electronic transmitter (- E/- J type)

(1) Basic functions and parameter settings

The electronic transmitter supports functions such as flow display, cumulative value statistics, 4-20mA output calibration, etc. It can be configured through two operation keys (up key "exit", down key "switch menu", combination key "confirm"). The core parameters are as follows:

Function Description of Key Setting Items for Parameter Categories

Display function (F11) default display of flow/cumulative value/percentage/temperature cumulative value, switchable units (such as m ³/h, L/min, kg/s)

Unit setting (F12/F13): Volume/mass unit+time unit. The European version supports m ³, Nm ³, kg, etc., while the American version (/A12 option) supports gal, scf, etc

Damping setting (F21): Smooth output signal for 0/1/5/10 seconds to reduce the impact of flow fluctuations, with a default of 1 second

Current output (F3-) 4-20mA/0-20mA switch 2-wire system default 4-20mA, adjustable zero point (F32) and range (F33), 20 μ A per step

Fault detection (F4-) error code displayed as "08" indicates that the float is stuck and needs to be cleaned or automatically zeroed (F74)

Float stuck detection (F7-) on/off, monitoring lower limit (5%/15%/30% Qmax), monitoring time 5/15 minutes optional. If there is no signal fluctuation beyond the deadline, a fault alarm will be triggered

(2) HART 7 communication (- J type exclusive)

Communication features: Supports 2-wire 4-20mA overlay with HART signal, enables remote parameter configuration and data reading (such as real-time flow, cumulative value, diagnostic information), supports multi slave mode (up to 63 devices), and can set polling address 1-63.

Core functions:

Process variable monitoring: real-time reading of flow rate, temperature, current output, etc;

Fault diagnosis: detect RAM errors, ADC faults, EEPROM anomalies, etc;

Burst mode: Continuously sending specified data (such as traffic+cumulative value) to reduce communication latency;

Trend configuration: Record 12 sets of historical data, with adjustable sampling intervals of 1-2 hours.

2. Limit switch (/K1-/K10 options)

Type and Function:

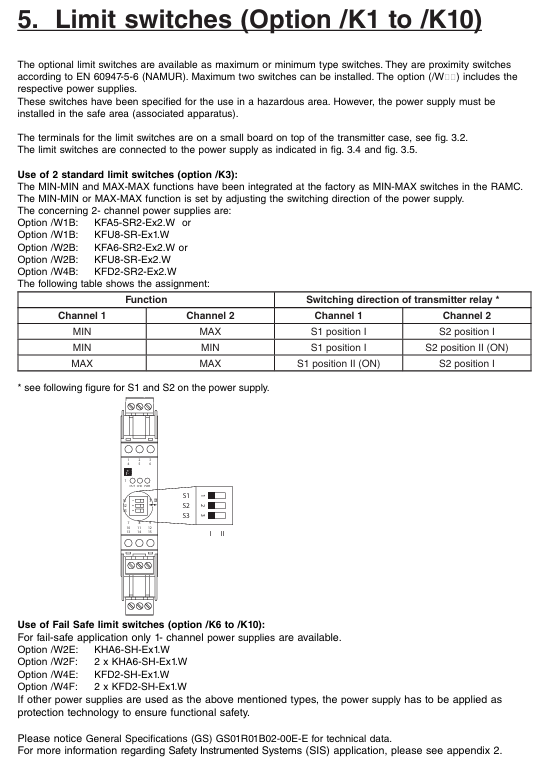

Standard type (/K1-/K3): Supports MAX/MIN dual contacts and complies with EN 60947-5-6 (NAMUR) standard;

Fault safe type (/K6-/K10): When power is cut off, the contacts automatically switch to a safe state and require a dedicated power supply (such as/K2E,/W4F).

Parameter configuration: Set the MIN-MAX/MIN-MIN/MAX-MAX function by switching the direction of the power supply. For example, when the K3 option is paired with the W2B power supply, the S1/S2 relay position determines the contact logic.

Explosion proof certification and safety regulations

1. Explosion proof type and applicable scenarios

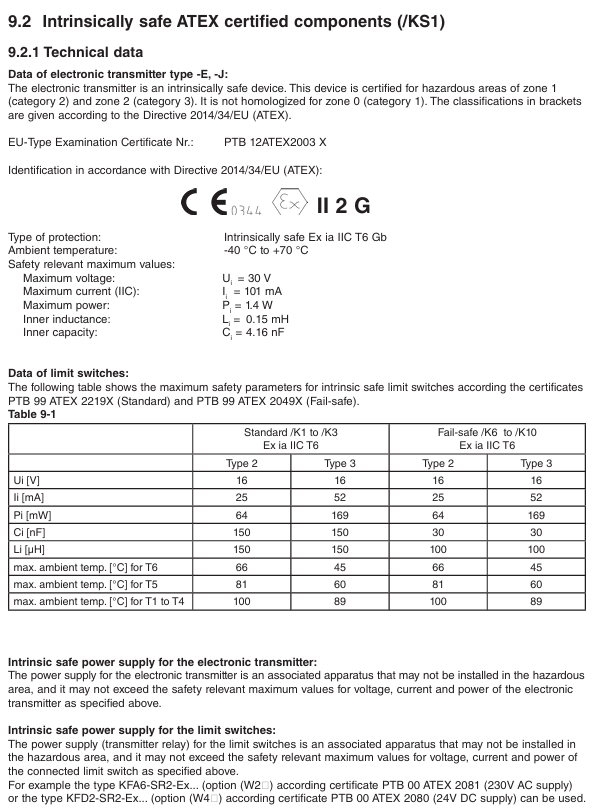

RAMC provides two types of explosion-proof designs: intrinsic safety (Ex ia) and explosion-proof (Ex db), covering major certification systems worldwide. The core parameters are as follows:

Certification Type Model Options Explosion proof Mark Applicable Area Key Parameters (Electronic Transmitter)

ATEX/KS1 (intrinsic safety) Ex ia IIC T6 Gb Zone 1/2 (gas), Zone 21/22 (dust) Ui=30V, Ii=101mA, Pi=1.4W

IECEx/ES1 (Intrinsic Safety) Ex ia IIC T6 Gb Global Explosion proof Zone Li=0.15mH, Ci=4.16nF

NEPSI (China)/NS1 (Intrinsic Safety) Ex ia IIC T6 Gb Explosion proof Area Environmental Temperature in China -40 ° C~+70 ° C

FM/UL (US Canada)/FS1 (Intrinsic Safety) Class I Div1 GP A-D T6 US Canada Zone 1/Zone 2 Vi=30V, Ii=100mA, Pi=1.4W

EAC (Eurasian Economic Union)/GS1 (Explosion proof+Dust) Ex db IIC T6 Gb/Ex tb IIIC T80 ° C Db Eurasian Union Explosion proof Area Surface Temperature ≤ 80 ° C (T6)

2. Explosion proof installation and operation taboos

Intrinsic safety requirements:

The power supply must be a certified associated device (such as KFA6-SR2-Ex2. W) installed in a safe area;

The cable capacitance/inductance should be ≤ Ci/Li (e.g. Ci=4.16nF, Li=0.15mH) to avoid safety risks caused by exceeding the limit.

Explosion proof type requirements:

Power off and wait for 15 minutes before opening the lid to ensure the safety of the internal gas;

The cable sealing sleeve must comply with the IEC 60079-1 standard and be sealed with certified blind plugs for entry purposes;

When the shell is damaged (such as the observation window breaking), it should be immediately stopped to avoid the failure of explosion-proof performance.

Maintenance and troubleshooting

1. Daily maintenance and regular inspections

Routine inspection (weekly):

Pointer/display screen: Confirm that the flow indication matches the actual working conditions without any jamming or jumping;

Sealing state: The flange and cable sealing sleeve have no leakage, and the shell has no corrosion;

Explosion proof mark: The label is clear, without wear or detachment.

Regular maintenance (every 6 months):

Cleaning: The measuring tube and float need to be disassembled and cleaned (avoiding the use of corrosive solvents), and the magnetic properties of the float should be checked for normal operation;

Calibration: The electronic transmitter needs to be verified for 4-20mA output accuracy through a HART communicator, and the limit switch needs to be tested for contact action reliability;

Grounding inspection: The grounding resistance is ≤ 100 Ω, and the grounding terminal is not loose.

2. Common faults and troubleshooting

Possible causes and solutions for the fault phenomenon

The pointer is unresponsive/stuck, the float is stuck by impurities, and the inner wall of the measuring tube is scaled. Disassemble and clean the float and measuring tube, and replace the float if necessary

Electronic transmitter has no output power supply fault, calibration EEPROM is missing, wiring is loose. Check power supply (24VDC ± 10%), reinsert EEPROM, and tighten wiring terminals

HART communication failure, load resistance not between 250-600 Ω, pole address conflict, adjust load resistance, reset unique pole address (1-63)

The flow indication deviation is large, and the viscosity/density of the fluid does not match the calibration value. The wear of the float provides new fluid parameters, and the manufacturer recalculates the scale; Replace the worn float

Improper threshold setting for triggering limit switch misoperation, recalibration of switch threshold due to magnetic field interference (such as 5% Qmax), and staying away from strong magnetic field sources

Application of Safety Instrumented System (SIS)

1. Applicable models and safety functions

RAMC only comes with fail safe limit switches (V1) and standard limit switches (V2), which can be used for SIS as flow monitoring components connected to safety instrument functions (SIF). The core realizes "flow over limit alarm" or "emergency cut-off trigger", and supports SIL1-SIL2 levels (depending on configuration and verification cycle).

2. Key SIS requirements

Verification cycle: It should be set according to safety integrity requirements, with a recommended duration of 1-5 years. The verification coverage rate should be ≥ 99%, and the verification results should be recorded (such as forcing the float to trigger the MAX/MIN threshold and verifying the switch action);

Reliability data: V1 type (fail safe switch) SFF=61%, MTBF=530 years, V2 type (standard switch) SFF=42%, MTBF=401 years. Detailed FMEDA reports can be obtained from the manufacturer;

Lifecycle: Designed for a lifespan of 10 years, if exceeded, reliability needs to be reassessed or core components such as measuring tubes and floats need to be replaced.

Compliance and Disposal Standards

1. Compliance with PED Pressure Equipment Directive

RAMC complies with 2014/68/EU (PED), the measuring tube is classified as "pipeline", the heating element (/T1-/T6 options) is classified as "container", fluid group 1-2, module H, and some models (such as RAMC03-15) belong to Class III pressure equipment and need to comply with pressure temperature ratings (such as stainless steel material -196 ° C~370 ° C, PTFE material -80 ° C~130 ° C).

2. Requirements for abandonment and return to factory

Decontamination treatment: After coming into contact with harmful fluids, the equipment should be thoroughly cleaned to avoid residual corrosion or toxicity. A "Decontamination Declaration" should be submitted when returning to the factory;

Environmental disposal: It belongs to WEEE equipment (2012/19/EC) and is prohibited from being mixed with municipal waste. It must be collected by professional institutions or returned to designated outlets in Yokogawa for disposal.

Summary and selection suggestions

1. Core advantages

Wide applicability scenarios: Supports corrosive, opaque, turbulent fluids, temperature range -196 ° C~370 ° C, pressure range PN16~PN100;

Flexible function expansion: optional electronic transmitter (HART communication), limit switch (fail safe), explosion-proof certification (global major system);

Low maintenance cost: The measuring tube and float are made of durable materials (such as 316L stainless steel), with no vulnerable parts. Calibration only requires replacing the EEPROM and scale.

2. Key parameters for selection

Fluid characteristics: Select the material of the measuring tube/float based on density, viscosity, and corrosiveness (such as PTFE for strong corrosion and stainless steel for conventional fluids);

Explosion proof requirements: Hazardous areas require matching certification types (such as China Select/NS1, US Canada Select/FS1);

Signal output: Remote monitoring should select the - J type (HART), only local indication should select the - T type, and alarm control should be equipped with/K series limit switches.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923