K-WANG

Yokogawa ROTAMASS TI Coriolis Mass Flow Meter

Yokogawa ROTAMASS TI Coriolis Mass Flow Meter

Basic Information

Focusing on the application scenarios of SIS equipment, clarifying the responsibilities of users in installation, operation, maintenance and other aspects, covering key contents such as verification testing, maintenance and replacement, reliability data, etc., to ensure that the equipment maintains the design safety level.

SIS application core requirements

(1) Safety functions and signal transmission

Function positioning: Supports HART communication and can be used as a mass flow rate, fluid density, and fluid temperature measurement component in SIS, equipped with 1-2 4-20mA analog outputs and other I/O interfaces.

Signal connection: The signal needs to be transmitted to the logic solver of SIS (such as safety PLC/DCS) through 4-20mA output; The fault alarm mechanism is "simulated current out of range", which needs to be connected to enable the automatic diagnostic function of the device.

(2) Key technical parameters

Specific requirements for parameter categories

The safety accuracy is set at 2%, which means that internal component failures that result in measurement errors ≥ 2% will be included in the equipment failure rate

Diagnostic response time amplitude error: Report within 3 minutes after the fault occurs; Other errors (such as frequency errors, signal failures): reported within 7 seconds

Generate a valid signal within 20 seconds after powering on the startup time

The expected service life is 10 years, and only reliability data within this period is valid; After more than 10 years, the equipment failure rate may increase, and the safety integrity level (SIL) calculation results based on the original data may become invalid

(3) Set up and validate testing

Device Settings

During installation, it is necessary to configure the engineering unit parameters through a field communicator or display, and verify the correctness of the parameters (which can be read from the local display or checked for actual calibration of the equipment).

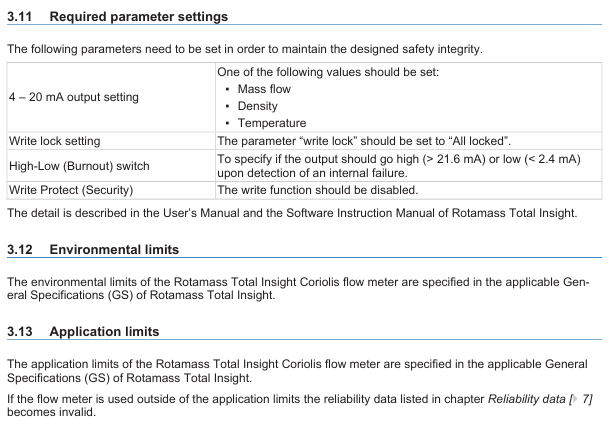

Key parameters need to be set according to the following requirements to maintain safety integrity:

|Parameter Category | Setting Requirements|

|4-20mA output | Select one of "Mass Flow", "Density", or "Temperature"|

|Write lock | Set to "All locked"|

|High Low (Burnout) switch | Specify the output current state in case of internal fault (High:>21.6mA; Low:<2.4mA)|

|Write Protect | Disable write function|

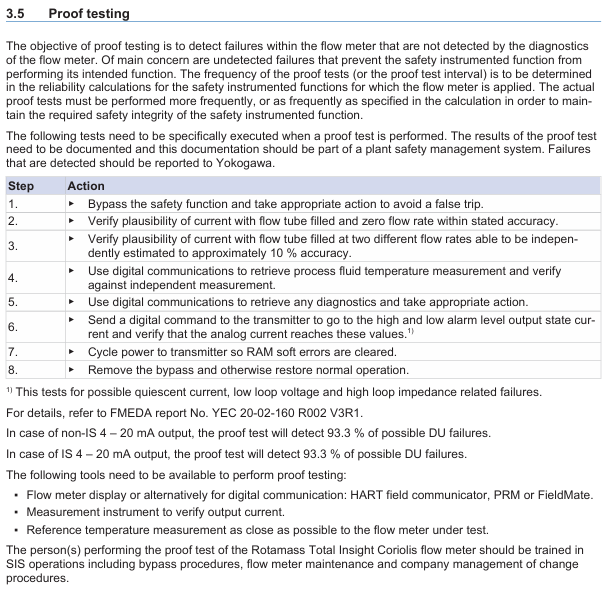

Proof Testing

Purpose: To detect faults that have not been detected by the equipment's self diagnosis (especially undetected faults that may cause safety instrument function (SIF) failure), the testing frequency should be determined based on the reliability calculation results of SIF, and the actual execution frequency should not be lower than the calculation requirements.

Test steps:

|Step | Operation Content|

|1 | Bypass safety function, take measures to avoid accidental tripping|

|2 | Verify the rationality of the output current (in compliance with the specified accuracy) when the flow tube is full and in a zero flow state|

|3 | Verify the rationality of the output current when the flow tube is filled with two different flow rates (which can be independently estimated with an accuracy of about 10%)|

|4 | Read the temperature measurement value of the process fluid through digital communication and compare it with the independent measurement value for verification|

|5 | Read diagnostic information through digital communication and take corresponding measures|

|6 | Send digital commands to the transmitter to enter the high and low alarm level output state, verify whether the analog current reaches the corresponding value (test static current, low loop voltage, high loop impedance related faults)|

|7 | Restart the transmitter power supply and clear the RAM soft error|

|8 | Release bypass and restore normal operation|

Detection effect: Both non intrinsic safety (non IS) and intrinsic safety (IS) 4-20mA outputs can detect 93.3% of potential hazard undetected (DU) faults.

Required tools: device display (or digital communication tools such as HART field communicator, PRM, FieldMate, etc.), output current verification instrument, reference temperature measurement tool close to the tested device.

Personnel requirements: Testers must receive SIS operation training, master bypass processes, equipment maintenance, and company change management processes.

(4) Repair, replacement, and firmware update

Repair and replacement: If online repair is required, bypass the equipment first and establish a compliant bypass process; Maintenance/replacement personnel need to have sufficient skills. If maintenance is required, please contact the Yokogawa sales office.

Firmware update: Only executed by the factory, users do not need to operate on their own, and after the update, they need to fulfill relevant responsibilities according to the replacement process.

(5) Reliability, Environment, and Application Limitations

Reliability data

Detailed Failure Mode, Effects, and Diagnostic Analysis (FMEDA) report (No. YEC 20-02-160 R002 V3R1) can be obtained from Yokogawa, including all failure rates and failure modes.

The device is suitable for "Low Demand Mode" (long average interval between hazardous conditions).

SIL certification: The highest certification under a single (1oo1) configuration is SIL2 (calculated based on the average failure probability (PFDavg) of the entire SIF); The highest certification for device development process is SIL3. When configuring redundancy (hardware fault tolerance level 1), the PFDavg calculation results of the entire SIF can be used for SIL3 scenarios. It is recommended to use a 2% common factor coefficient (β - factor) for redundant configuration.

Environmental and application limitations: The environmental and application limitations of the device must comply with the General Specification (GS) of ROTAMASS Total Insight; If the application limit is exceeded, the reliability data will be invalidated.

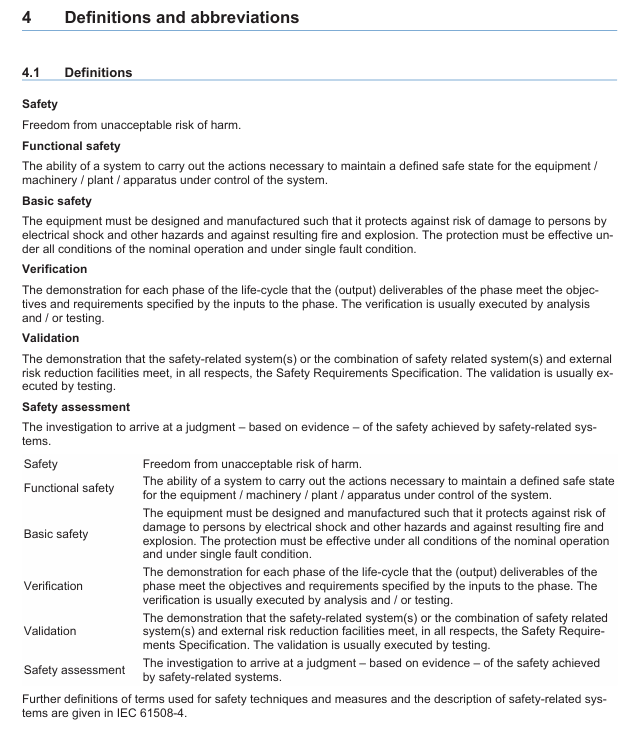

Definition and Abbreviations

Core definition: Clearly define terms such as "Safety", "Functional safety", "Basic safety", "Verification", "Validation", "Safety assessment", etc., in accordance with the relevant interpretations of IEC 61508-4 standard.

Key abbreviations:

|Abbreviation | Full name and description|

|DU | Dangerous Undetected|

|FMEDA | Failure Mode, Effects and Diagnostic Analysis|

|IS | Intrinsically safe explosion proof|

|PFDavg | Average Probability of Failure on Demand|

|PLC/DCS | Programmable Logic Controller/Distributed Control System|

|PRM | Plant Resource Manager|

|SIF | Safety Instrumented Function|

|SIL | Safety Integrity Level|

|SIS | Safety Instrumented System|

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923