K-WANG

Meggitt Vibro Meter RPS 6U rack power module

Multi output voltage supply: Provides three DC power supplies of+5V DC,+12V DC, and -12V DC for all cards in the rack (such as MPC 4 monitoring card) to meet the power supply needs of different cards, with output currents of 35A, 6A, and 2A respectively, and a total rated power of 300W;

Redundant deployment capability: Supports parallel installation of 1-2 modules. In the event of a single module failure, redundant modules automatically take over power supply to avoid system power outages, especially suitable for critical equipment monitoring scenarios that require high power continuity;

Wide input and protection design: Supports AC or DC wide range input (such as AC 90~264V adaptive, DC 18~145V model adaptation), integrated overvoltage protection (+5V output protection threshold 5.9~6.7V), short circuit protection (electronic current limiting, continuous short circuit without damage), to cope with power fluctuations in industrial sites;

VME compatibility: fully compliant with the VME bus specification, directly connected to the VM 600 rack backplane through two connectors, without the need for additional wiring, simplifying installation;

Low loss and temperature adaptability: Only 1%/℃ power reduction within the range of 60-70 ℃, reducing performance degradation in high-temperature environments and adapting to industrial high-temperature scenarios.

Meggitt Vibro Meter RPS 6U rack power module

Core functions and positioning

RPS 6U is a dedicated power supply unit for VM 600 series racks, with core functions designed around "stable power supply, high reliability, and flexible adaptation", as follows:

Multi output voltage supply: Provides three DC power supplies of+5V DC,+12V DC, and -12V DC for all cards in the rack (such as MPC 4 monitoring card) to meet the power supply needs of different cards, with output currents of 35A, 6A, and 2A respectively, and a total rated power of 300W;

Redundant deployment capability: Supports parallel installation of 1-2 modules. In the event of a single module failure, redundant modules automatically take over power supply to avoid system power outages, especially suitable for critical equipment monitoring scenarios that require high power continuity;

Wide input and protection design: Supports AC or DC wide range input (such as AC 90~264V adaptive, DC 18~145V model adaptation), integrated overvoltage protection (+5V output protection threshold 5.9~6.7V), short circuit protection (electronic current limiting, continuous short circuit without damage), to cope with power fluctuations in industrial sites;

VME compatibility: fully compliant with the VME bus specification, directly connected to the VM 600 rack backplane through two connectors, without the need for additional wiring, simplifying installation;

Low loss and temperature adaptability: Only 1%/℃ power reduction within the range of 60-70 ℃, reducing performance degradation in high-temperature environments and adapting to industrial high-temperature scenarios.

Electrical parameters and performance indicators

(1) Core electrical parameters

Parameter category specification requirements

Output characteristics -+5V DC: rated output of 35A, voltage stability under load ≤ ± 0.2%, ripple (20MHz bandwidth) ≤ 50mVpp;

-+12V DC: rated output of 6A, voltage stability under load ≤ ± 0.2%;

--12V DC: rated output 2A, voltage stability under load ≤ ± 0.2%;

-Overvoltage protection: The+5V output factory is set to 5.9-6.7V, and other outputs default to overvoltage protection.

The input characteristics are divided into two types: AC/DC, and the specific range depends on the model (such as AC type 90~264V adaptive, DC type 18~32V/38.4~57.6V, etc.); AC type supports frequency fluctuations of 48-65Hz, with an efficiency of ≥ 75% (AC type) and ≥ 70% (DC type).

The power outage tolerance supports short-term power outages without resetting MPC 4 cards, and the tolerance time is related to the number of cards and power modules:

-2 MPC 4 boards: 1 module can withstand 190ms, 2 modules can withstand 250ms;

-12 MPC 4 cards: 1 module can withstand 10ms, and 2 modules can withstand 20ms.

(2) Physical and installation parameters

Specification category specific parameters

Size 6U height (compliant with rack standards), 12TE width, depth 187mm, compatible with VM 600 series ABE 04X rack

Weight approximately 2.1kg, lightweight design to avoid excessive rack load

Installation position: front of the rack, directly connected to the backplane through two connectors, without the need for additional fixing screws (relying on rack buckles)

The front panel of the panel design is equipped with+5V/+12V/-12V status indicator lights. The AC/DC versions have different panel markings for easy differentiation of models

Environmental adaptability and compliance certification

(1) Environmental parameters

RPS 6U is designed for harsh industrial environments and has the following environmental tolerance capabilities:

Environmental category specification requirements

Temperature operation: -25~65 ℃ (-13~149 ° F); Storage: -40~85 ℃ (-40~185 ° F), compliant with IEC 68-2-1/2 standard

Humidity ≤ 95% non condensing (compliant with IEC 68-2-3 standard), suitable for high humidity industrial scenarios

Vibration and shock vibration: 10-2000Hz, 5g acceleration, 2 hours in each direction (in accordance with IEC 68-2-6);

Shock: 100g acceleration, 6ms half sine pulse (compliant with IEC 68-2-27), withstand vibration shock during equipment transportation or operation.

(2) Compliance certification

Safety standards: comply with UL 1950, CSA 22.2 # 234, IEC 950, EN 60950 standards to ensure electrical safety;

EMC Compliance: Compliant with the EU EMC Directive, reducing the impact of electromagnetic interference on surrounding equipment;

Low Voltage Directive: CE Low Voltage Directive certification, labeled LR111641 Level 3, meets EU market access requirements.

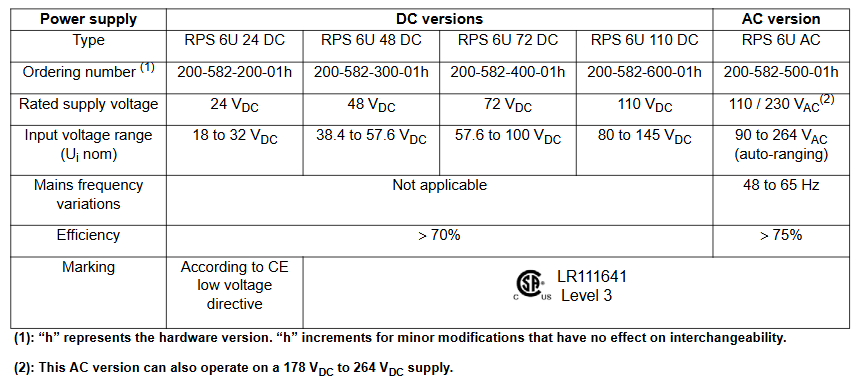

Model classification and adaptation scenarios

RPS 6U is classified into different models based on input power type (AC/DC) and input voltage range. Different models are suitable for different industrial power supply scenarios. The specific classification is as follows:

Model Type Specific Model Rated Input Voltage Input Voltage Range Adaptation Scenarios

DC input type RPS 6U 24 DC 24V DC 18~32V DC Low voltage DC power supply scenario (such as vehicle mounted, small equipment)

RPS 6U 48 DC 48V DC 38.4~57.6V DC Industrial Standard 48V DC System

RPS 6U 72 DC 72V DC 57.6-100V DC medium voltage DC power supply scenario (such as large industrial equipment)

RPS 6U 110 DC 110V DC 80~145V DC High Voltage DC Power Supply Scenario

AC input type RPS 6U AC 110/230V AC 90~264V AC (adaptive) universal AC power supply scenario, compatible with global voltage standards

RPS 6U AC (Special) 115V AC 90~132V AC Specific Area 115V AC System

Special adaptation: The AC type also supports 178-264V DC input, achieving "AC/DC dual compatibility" and further enhancing scene adaptability.

Rear panel and installation configuration

RPS 6U requires a dedicated rear panel for power input and protection. Different panels are compatible with different input types and functional requirements. The core panel types and characteristics are as follows:

Panel type, model number, core function, adaptation scenario

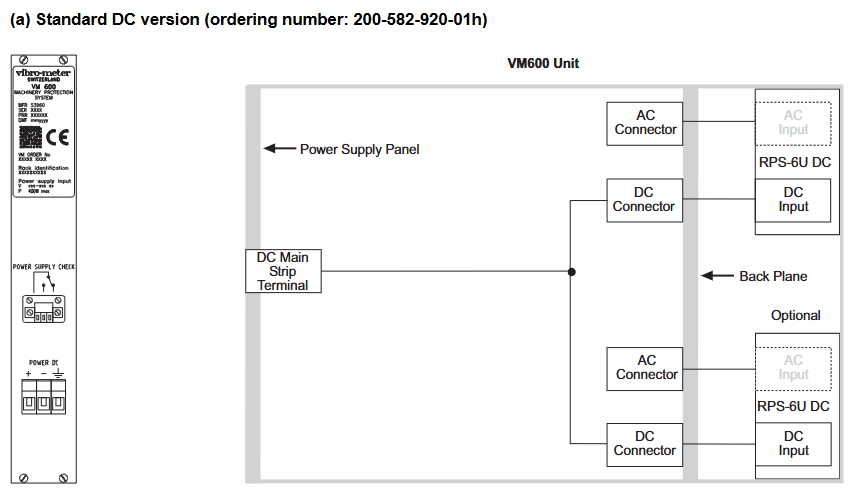

Standard DC panel 200-582-920-01h single channel DC screw terminal input, with backplane connection for ordinary DC power supply scenarios

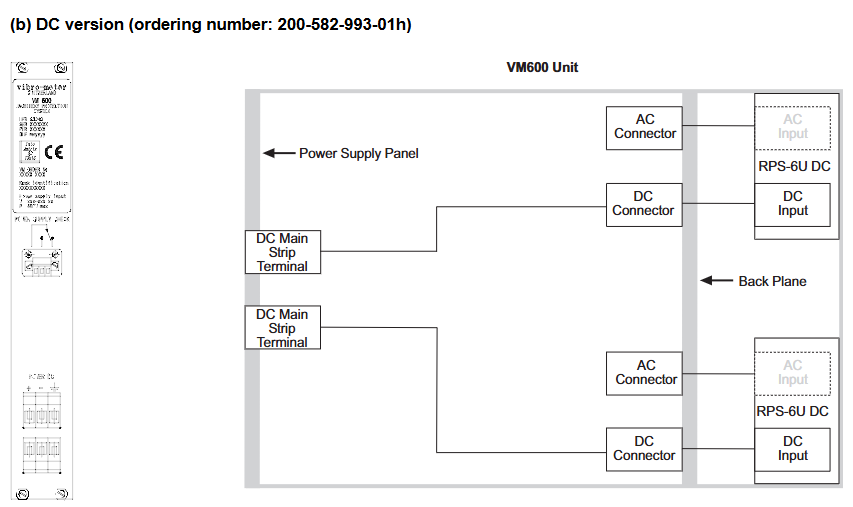

Dual DC input panel 200-582-990-01h, two independent DC terminal inputs, critical scenario where dual DC power redundancy is required for parallel backplane connection

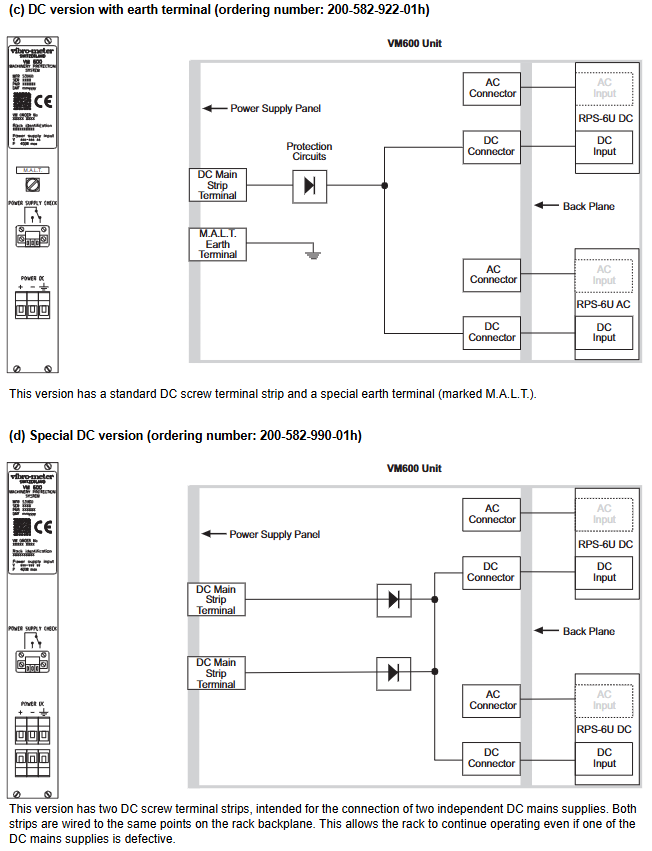

Industrial environment with grounded DC panel 200-582-922-01h standard DC terminal+M.A.L.T. grounding terminal requiring strengthened grounding protection

Standard AC panel 200-582-910-02h AC socket+fuse+filter universal AC power supply scenario

Scenario where AC panel with switch 200-582-911-02h AC terminal+power switch+fuse requires manual control of power on/off

Dual AC redundant panel 200-582-960-03h with two AC sockets and automatic switching circuit for AC power redundancy, automatic switching in case of faults

AC+DC hybrid panel 200-582-970-01h AC socket+DC terminal, independently connected to the backplane and compatible with AC/DC input in flexible scenarios

Installation note: All rear panels are pre installed with cables, which can be directly connected to the rack backplane without the need for on-site wiring; DC input needs to distinguish between positive and negative poles, while AC input needs to confirm voltage level and frequency compatibility.

Ordering Information and Additional Instructions

(1) Core ordering parameters

Power module selection: It is necessary to specify the "model+input type+order number", for example:

24V DC input: model RPS 6U 24 DC, order number 200-582-200-01h;

110/230V AC input: model RPS 6U AC, order number 200-582-500-01h;

Note: "h" in the number represents the hardware version, minor changes do not affect interchangeability.

Rear panel selection: Choose according to input type and protection requirements, for example, choose 200-582-960-03h for dual AC redundant scenarios, and 200-582-922-01h for strengthened grounding DC scenarios.

(2) Key precautions

Power matching: Calculate the total power consumption based on the number of cards in the rack, ensuring that it does not exceed the rated power of RPS 6U (300W). For example, for 12 MPC 4 cards, priority should be given to redundant deployment;

Temperature management: During installation, it is necessary to reserve heat dissipation space to avoid modules being placed in close proximity to high heating equipment. For environments above 60 ℃, attention should be paid to power derating (1%/℃);

Redundant configuration: When deploying redundancy, it is necessary to use RPS 6U modules of the same model to ensure consistent output characteristics and avoid uneven load;

Compliant use: Only applicable to VM 600 series racks, prohibited for use in other non compatible systems to avoid damage caused by electrical mismatch.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923