K-WANG

Reliance Electric AutoMax Programming Executive V3.5

Reliance Electric AutoMax Programming Executive V3.5

Reliance Electric AutoMax Programming Executive V3.5 is a distributed control system programming software based on Windows 3.1+and MS-DOS 5.0+environments. It supports multi processor rack configuration, multi language task development (BASIC/Control Block/Adder Logic), network communication, and remote I/O management. It has complete offline configuration (system/rack/variable/task) and online operation (task start stop/monitoring/debugging) functions, and ensures system security through a triple security mechanism of key switch, password, and access level. It is compatible with AutoMax 6010/7010 series processors and UDC modules and is widely used in industrial automation control scenarios. It must strictly follow electrical safety standards and operating procedures.

Software Basic Information

Operating environment requirements

Specific specifications for hardware requirements

Processor compatible with IBM 80386 and above

At least 2MB of memory (recommended 4MB)

Storage capacity for hard drives of 40MB or more

At least one serial port interface (dual serial ports recommended, supporting mouse+processor connection)

Other supports mouse (optional, recommended)

The software requires Windows 3.1+(Enhanced Mode) MS-DOS 5.0+

Core adaptation hardware

Processor modules: AutoMax 6010 (M/N 57C430A/431), 7010 (M/N 57C435)

Control module: Universal Drive Controller (UDC, M/N 57552/57652)

Communication modules: Network Communication Module (M/N 57C404), PC Link Module (M/N 57C445)

Other modules: Common Memory Module, Remote I/O Module, Digital/Analog I/O Module

Offline configuration function

System and Rack Configuration

Hierarchical structure: Library (default AMXLIB) → System → Partition → Rack, supports multi-level document management

Rack configuration: Supports 10/16 slot racks, can add/remove/move modules, and configure remote I/O networks (AutoMax/Shark rack Remote Head)

Import and export: Supports importing systems/racks from ASD V8+or AutoMax V1/V2, supports disk transfer backup (supports formatted floppy disks)

variable configuration

Configuration objects: I/O points (local/remote), public memory variables (volatile/non-volatile), network variables

Variable types: Boolean value (@), single precision integer (%), double precision integer (!), real number, string ($), supports arrays and structures

Network variables: Support linking network wide names with local names to avoid address conflicts, and support cross rack data access

Task development and management

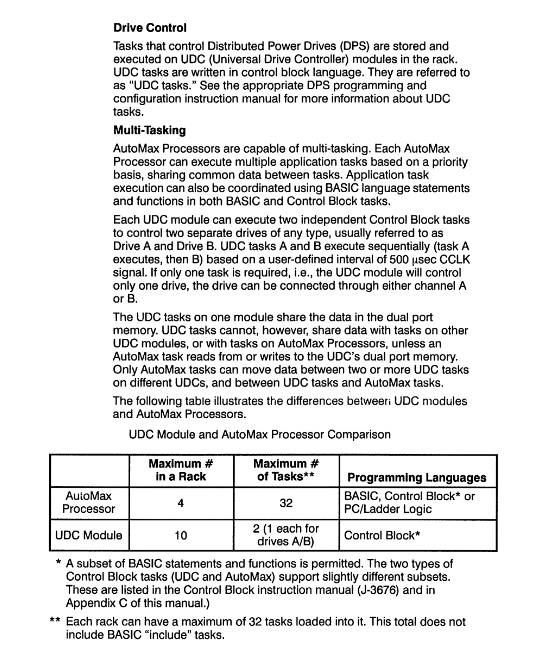

Task Type Programming Language Core Features Compilation Requirements

Basic (Enhanced) general programming and numerical processing for ordinary tasks require compilation and generation OBJ file

Control Block control loop programming (PID, etc.) needs to be compiled and generated OBJ file

Ladder Logic (PC) sequential logic and ladder diagram editing do not require compilation and can be loaded directly

UDC task Control Block driver control (A/B channels) needs to be compiled and generated OBJ file

Include (. INC) code reuse for auxiliary tasks, embed the main task and compile it along with the main task

Task attributes: Priority (4-11, with 4 being the highest), Critical flag (only STOP-ALL can be stopped), Reconstructable (supports exporting from processor)

Core operations: Create/Copy/Delete, Edit (Norton Editor/PC Editor), Compile Validation, Cross Reference Generation (. XRF file)

Online operation function

Connection and Communication

Communication method: ① Serial port connection (left most processor Programmer/Port B, default 9600/19200 baud); ② PC Link module (network communication, supports simultaneous connection of 4 PCs)

Connection management: Supports direct connection to local racks or connection to remote racks via network (up to 43), with adjustable baud rates (1200-19200bps)

AUTO-RUN setting: Automatically start previously run tasks when power is restored after enabling, disabled by default

Task Control and Monitoring

Task operations: Single task start stop (priority 4-11), full task start stop (STOP-ALL), task loading/saving (supports/All/. Unable/. Include options)

Monitoring function: Real time display of variables/I/O values (supports decimal/hexadecimal/binary), forced variables (up to 16), real-time status of Ladder Logic sequences

Debugging functions: variable tuning (incremental adjustment), I/O register modification, online editing of ladder diagram sequences

Fault handling and system recovery

Error log: Each task stores 3 error records (statement number, error type, timestamp), and supports clearing

System recovery: Export configuration and tasks from the processor through Save All, and then import and rebuild the rack

Fault clearing: supports clearing processor/UDC error logs, LED fault indication

Security mechanism

Triple security guarantee

Key switch (power module): PROTOCT (only monitoring/saving tasks), SETUP (monitoring+tuning variables), PROGRAMM (full permission, password required)

Password protection: The default password is "AUTOMAX", which can be modified through PWOS/PWRACK tools. It will expire after 2 minutes of timeout

Access level: None (monitoring only) → Data (modifying common variables) → Task (single task control) → Rack (full rack control), up to 4 users can access simultaneously

Operational safety regulations

Electrical safety: After power failure, wait for 5 minutes for capacitor discharge to prevent electric shock and arc flash

Mechanical safety: protection of rotating parts, configuration of emergency stop circuits (external hard wiring)

Programming security: parameter locking, task critical tagging, configuration backup requirements

Key Limitations and Compatibility

Core Limitations

Task quantity: Up to 32 tasks per rack (excluding Include tasks)

Variable monitoring: Each user can monitor up to 16 public/local variables, and the UDC module can monitor up to 32 local variables

Memory limit: 6010 processor available memory 122-137KB, 7010 processor 300KB

compatibility

Backward compatibility: Supports AutoMax V1/V2 rack import, V3. x file conversion for various versions

Hardware compatibility: M/N 57C430 and 57C430A are not supported in the same rack, and the network module needs to be of a unified version (M/N 57C404 and above)

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 3HAC9710-1 Industrial Control Module | Advanced Automation Component

-

ABB SPBLK01 Signal Processing Block | Industrial Automation Module

-

ABB IMDSM04 Distributed System Module | Industrial Automation Controller

-

ABB IMFECI2 Fieldbus Communication Interface | Industrial Automation

-

ABB IMDS014 Industrial Data Server | Advanced Automation Solution

-

ABB INIT03 Industrial Controller | Precision Automation Module

-

ABB INNIS21 Network Interface Module for Distributed Control Systems

-

ABB IMBLK01 Interface Module for Distributed Control Systems

-

ABB 3HAC031683-004 Control System Module for Industrial Automation

-

ABB SPBRC300 Controller Module for Industrial Automation Systems

-

ABB PFXA401SF Industrial Automation Controller

-

ABB HAC319AEV1 Industrial Process Automation Module

-

ABB SA9923A-E Advanced Industrial Automation Module

-

ABB CSA463AE Industrial Automation and Monitoring Module

-

ABB UAC326AE Industrial Process Control Module

-

ABB NU8976A Industrial Automation Control Module

-

ABB LT8978bV1 High-Performance Industrial Automation Module

-

ABB ARC093AV1 Industrial Control and Monitoring Module

-

ABB UAC318AE Advanced Automation Control Module

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923