K-WANG

Rockwell Automation AutoMax™ Distributed Power System

Rockwell Automation AutoMax ™ Distributed Power System

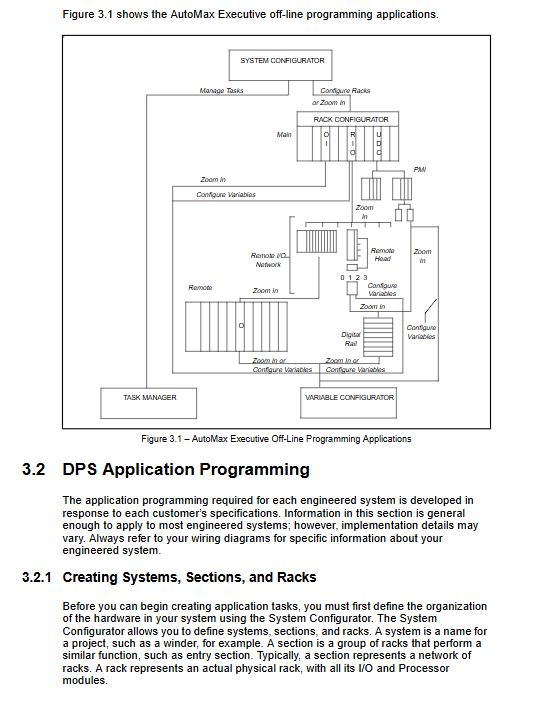

AutoMax Distributed Control System and Programming Software V3.5 is an industrial automation solution launched by Rockwell Automation. Its core includes Distributed Power System (DPS) and AutoMax Programming Executive V3.5 programming software, supporting multiple types of AC/DC drivers (such as SA500/SA3000/SD3000, etc.). Distributed control is achieved through hardware architecture of UDC module+PMI interface and fiber optic communication (10Mbit/s). The programming software supports three languages: BASIC/Control Block/Adder Logic, with offline configuration, online monitoring, multiple security mechanisms (key switch+password+access level), and is suitable for industrial motor speed regulation, process control and other scenarios. Electrical safety standards and operating procedures must be strictly followed.

Overall system architecture

Core positioning and components

System positioning: Industrial grade distributed control system, integrating hardware drivers and software programming to achieve multi device collaborative control

Core components: divided into two parts: hardware (DPS distributed power system) and software (AutoMax Programming Executive V3.5). Hardware is responsible for power conversion and signal transmission, while software is responsible for configuration, programming, and monitoring

Compatibility feature: Supports mixing with AutoMate, Shark and other series modules, and can upgrade existing third-party drives

Hardware core parameters | Hardware modules | Key specifications | Core functions|

|UDC module | 10 units/rack, dual port memory, 2 fiber optic interfaces | Drive control, PMI communication, dual task independent operation (Drive A/B)|

|PMI interface | 4 slots (medium power)/8 slots (high power) rack | Signal processing, I/O expansion, and UDC fiber optic communication|

|Drive | DC: SD3000 (3-1000HP), SF3000 (1000-5000HP); AC:SA500(14-48A)、SA3000(70-1457A); Medium voltage: 1500-5500HP | Motor speed regulation, power output, fault self diagnosis|

|Communication link | Fiber optic: 10Mbit/s, maximum 750m; RS-232; PC Link module | Anti EMI interference, long-distance transmission, multi device synchronization|

Distributed Power System (DPS)

Hardware architecture hierarchy

Control layer: AutoMax processor+UDC module, responsible for instruction issuance and status feedback

Interface layer: PMI module, implementing signal conversion between UDC and driver (Resolver feedback, I/O extension)

Power layer: Various AC/DC drivers provide motor operation power and support N+1 redundant parallel connection

Communication layer: Fiber optic link (Manchester encoding) to avoid electromagnetic interference and ensure stable data transmission

Driver classification and characteristics | Driver type | Power range | Core configuration | Applicable scenarios|

|DC (SD3000/SF3000) | 3-5000HP | 4-channel PMI rack, SCR rectifier, regenerative/non regenerative mode | DC motor speed regulation, heavy-duty starting|

|AC (SA500) | 14-48A (corresponding to power 1-15HP) | Built in PMI, IGBT inverter, DC bus power supply | Small fan and pump equipment|

|AC (SA3000) | 70-1457A (corresponding power 30-600HP) | 4/8 slot PMI rack, vector control, parallel expansion | industrial production line, large fan|

|Medium voltage (1567 PowerMax) | 1500-5500HP | Liquid cooled rectifier/inverter, 8-slot PMI rack, 3-level topology | Medium voltage motor drive, heavy industry|

Key hardware functions

Fiber optic communication: 10Mbit/s transmission between UDC and PMI, supporting 750m long distance deployment, and resistant to EMI interference

Redundant design: Drivers support N+1 parallel connection, UDC module dual task independent operation, improving system reliability

Self diagnosis: PMI monitors voltage, temperature, and I/O status in real-time, triggering LED alarms and relay actions in case of faults

Core functions of programming software V3.5

Offline configuration function

System configuration: Create system/partition/rack hierarchy, support importing ASD/V2 version configuration files

Hardware configuration: Add UDC/PMI/driver module, configure driver parameters (motor nameplate, torque boost, etc.)

Variable configuration: Map I/O variables, public memory variables, network variables, support local/network name linking

Task development: Create BASIC/Control Block/Adder Logic tasks that support compilation and cross referencing generation

Online operation function

Connection management: supports serial port (9600-19200bps), PC Link module, network connection, and can set AUTO-RUN

Task control: single task/full task start stop, load/delete, supports remote reset and fault clearing

Monitoring and debugging: Real time viewing of variable/I/O status, forcing variables (up to 16), online editing of ladder diagram sequences

Fault handling: Store 10 error logs, support fault code query, manual/automatic reset

Programming and Task Characteristics

Language support:

BASIC: General programming, numerical processing, supports array and string operations

Control Block: Control loop programming (PID, integrator, etc.), UDC task specific

Ladder Logic: Sequential logic programming, graphical editing, supports counters/timers

Task limit: Up to 32 tasks per rack, UDC module up to 2 tasks (Drive A/B)

Compile validation: syntax check, object file generation, error log output, supports debugging and optimization

Security mechanisms and regulations

Triple security guarantee

Key switches: PROTOCT (monitoring only), SETUP (monitoring+tuning), GRAM (full permission)

Password protection: default password "AUTOMAX", supports modification, expires after 2 minutes of timeout

Access level: None (monitoring only) → Data (modifying variables) → Task (task control) → Rack (full control), up to 4 users can access simultaneously

Electrical and operational safety

Electrical safety: protection against electric shock and arc flash, wait for 5 minutes for capacitor discharge after power failure

Mechanical safety: protection of rotating parts, zero speed warning, motor steering verification

Operation specifications: parameter locking, emergency stop configuration, task critical marking (only STOP-ALL can be stopped)

Application scenarios and compatibility

Typical Applications

Industrial production: production line motor speed regulation, fan/pump control, machine tool auxiliary drive

Mobile scenarios: ships, RVs, off grid solar systems

Special scenarios: medium voltage motor drive (1567 PowerMax), heavy industrial process control

Compatibility Description

Hardware compatibility: Supports AutoMax 6010/7010 processors, UDC modules (57552/57652), and various third-party I/O modules

Software compatibility: backward compatible with V2 version configuration files, supports ASD V8 system import, compatible with Windows 3.1+, MS-DOS 5.0+

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 3HAC9710-1 Industrial Control Module | Advanced Automation Component

-

ABB SPBLK01 Signal Processing Block | Industrial Automation Module

-

ABB IMDSM04 Distributed System Module | Industrial Automation Controller

-

ABB IMFECI2 Fieldbus Communication Interface | Industrial Automation

-

ABB IMDS014 Industrial Data Server | Advanced Automation Solution

-

ABB INIT03 Industrial Controller | Precision Automation Module

-

ABB INNIS21 Network Interface Module for Distributed Control Systems

-

ABB IMBLK01 Interface Module for Distributed Control Systems

-

ABB 3HAC031683-004 Control System Module for Industrial Automation

-

ABB SPBRC300 Controller Module for Industrial Automation Systems

-

ABB PFXA401SF Industrial Automation Controller

-

ABB HAC319AEV1 Industrial Process Automation Module

-

ABB SA9923A-E Advanced Industrial Automation Module

-

ABB CSA463AE Industrial Automation and Monitoring Module

-

ABB UAC326AE Industrial Process Control Module

-

ABB NU8976A Industrial Automation Control Module

-

ABB LT8978bV1 High-Performance Industrial Automation Module

-

ABB ARC093AV1 Industrial Control and Monitoring Module

-

ABB UAC318AE Advanced Automation Control Module

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923