K-WANG

YASKAWA S-7 series linear servo

YASKAWA S-7 series linear servo

Product basic information

1. Product classification and model

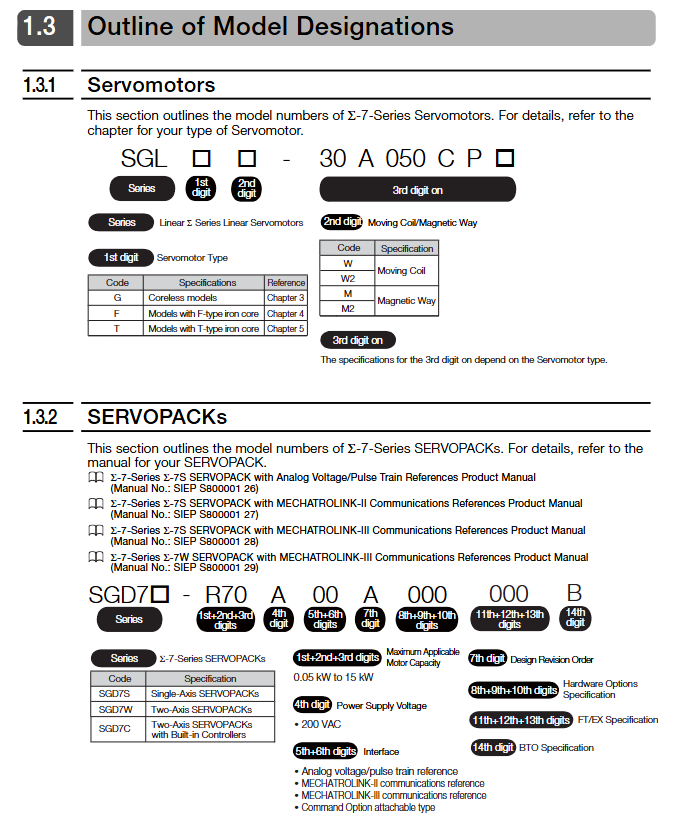

Model system: The core is divided into three categories, corresponding to different iron core structures and application scenarios:

Model Series Structure Type Core Features Applicable Scenarios

SGLG ironless, low inertia, silent operation, precise positioning, high-speed reciprocating motion

SGLF F-type iron core with high thrust density, supporting self cooling/water-cooled medium and heavy-duty automation equipment

SGLT T-shaped iron core vigorously promotes heavy-duty machine tools and large-scale production lines

Model interpretation: Taking SGLFW2-30A070AS1 as an example, "SGL" is the ∑ -7 series identifier, "F" is the F-type iron core, "W2" is the rotor, "30" is the magnet height of 30mm, "A" is powered by 200V, "070" is the rotor length of 70mm, "AS" is with polarity sensor and thermal protector, and "1" is the self cooling method.

2. Core performance parameters

Power supply voltage: uniformly 200VAC (single-phase/three-phase), insulation level B, withstand voltage 1500VAC/1 minute

Thrust range: rated thrust 0.1-2520N, instantaneous maximum thrust 30-7560N

Speed range: rated speed 0.5-5m/s, maximum speed 1.5-7.5m/s

Environmental requirements: working temperature 0-40 ℃, humidity 20% -80% RH (non condensing), altitude ≤ 1000m

Selection calculation

1. Core formula for selection

Steady state thrust:F L=9.8×M×(m W+m T+m M)+F(m Acceleration thrust:F P=(m W+m T+m M)× t onev+F L (v is speed, t ₐ is acceleration time)

Effective thrust:F RMS= tF Ptwo⋅t one+F L two⋅t C+F S two⋅t d(t is the cycle time)

2. Selection verification criteria

Acceleration thrust ≤ maximum thrust × 0.9

Effective thrust ≤ rated thrust × 0.9

Load quality ≤ maximum allowable load (to be combined with brake resistor configuration)

Installation specifications

1. Installation environment requirements

Environmental restrictions: Indoor use, no corrosive/explosive gases, no strong magnetic field interference

Mechanical conditions: vibration acceleration ≤ 49m/s ², impact acceleration ≤ 196m/s ² (twice)

Special protection: The magnetic track contains strong permanent magnets and should be kept away from electronic medical equipment such as pacemakers to avoid magnetic substances from approaching

2. Installation operation process

(1) Magnetic track installation

Positioning accuracy: magnetic track spacing tolerance ± 0.1mm, alignment with reference marks when connecting multiple magnetic tracks

Fixed requirement: Use grade 10.9 hex screws with a tightening torque of 3.6-41.5N · m (depending on the model)

Gap control: The gap between the magnetic track and the rotor is 0.8-1.4mm (0.5-1.2mm with magnetic cover)

(2) Assembly of moving parts

Installation steps: First fix the rotor to the workbench → slowly approach the magnetic track → confirm that there is no contact noise → calibrate the gap with a non-magnetic feeler gauge

Screw specification: M4-M8 grade screw, tightening torque 2.4-20N · m, fitting length ≥ 4mm

Cable handling: The moving sub cable needs to be fixed with a bending radius of ≥ 15mm (when the cable diameter is less than 8mm)

3. Special requirements for water-cooled models (SGLFW2-90A series)

Cooling medium: Deionized water, pH6.8-8.0, Conductivity ≤ 30mS/m

Flow pressure: rated flow 4L/min, maximum pressure 0.5MPa, water temperature 5-25 ℃

Protective measures: The pipeline needs to be made of stainless steel material and equipped with a filter (to filter impurities ≥ 0.5mm)

Connection configuration

1. Linear encoder connection

Compatible brands: Supports mainstream brands such as Heidenhain, Renishaw, Mitutoyo, etc

Installation conditions: The distance between the magnetic track and the magnetic track should be ≥ 10-40mm (depending on the motor model) to avoid magnetic leakage interference

Adjustment requirements: The exposed encoder needs to calibrate the position of the scanning head, and the sealed encoder needs to meet the installation tolerance

2. Wiring of servo amplifier

Wiring process: Main circuit cable → Encoder cable → Sensor cable (polarity sensor/thermal protector)

Cable selection:

Recommended models for cable type length restrictions

Servo main circuit cable ≤ 20 meters JZSP-CLN11/21/39 series

Encoder cable ≤ 50 meters JZSP-CLL00/30 series

Sensor cable ≤ 15 meters JZSP-CLL10/CL2L100 series

Grounding requirements: The grounding resistance of the servo amplifier should be ≤ 10 Ω (400V level)/≤ 100 Ω (200V level), and the shielding layer should be grounded at one end

3. Serial Conversion Unit (JZDP Series)

Function: Convert encoder signal to servo amplifier, support polarity sensor and thermal protector signal transmission

Key parameters: Power supply+5V ± 5%, current consumption ≤ 160mA, operating temperature 0-55 ℃

Maintenance and disposal

1. Regular inspection

Daily inspection: Check for vibration, abnormal noise, and cable wear daily to confirm that screws are not loose

Regular inspection: calibrate the gap between the magnetic track and the rotor annually, measure the insulation resistance (≥ 10M Ω/500VDC)

Overhaul cycle: Contact the manufacturer for comprehensive maintenance every 5 years, and do not disassemble on your own

2. Key points for troubleshooting

Common problems: Abnormal encoder signal (check installation spacing), overload alarm (verify effective thrust), cable breakage (check bending radius)

Insulation testing: Measure after disconnecting the servo amplifier, and do not perform voltage withstand testing on the sensor

3. Scrap disposal

Demagnetization requirement: The magnetic track needs to be heated to above 300 ℃ and maintained for 1 hour to eliminate magnetism

Environmental requirements: Follow the WEEE directive and classify the disposal of electronic components and metal casings

Safety and Compliance

1. Core security standards

Strong magnetic protection: The magnetic track has an adsorption force of up to 21500N, and non-magnetic tools should be used during operation to avoid finger squeezing

Power off operation: Disconnect the power before maintenance and wait for the servo amplifier CHARGE indicator light to turn off (≥ 5 minutes)

Static protection: Release static electricity before touching the connector, and do not directly touch the encoder pins with your hands

2. Compliance standards

North America: UL 1004-1, UL 1004-6, CSA C22.2 No.100

EU: CE certification (EMC 2014/30/EU, LVD 2014/35/EU), EN 61800-3

China: RoHS compliance, restricting harmful substances such as lead and mercury

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923