K-WANG

SERVOSTAR ™ 601... 620 digital servo amplifier (S600 series)

Version and Compatibility: The document version is the 12th edition of December 2015, applicable to hardware version 05.40, and requires a specific firmware version (such as firmware ≥ 8.50_ND0/ND1 for hardware version 05.40). Different hardware versions correspond to different firmware requirements and functional support (such as BiSS/EtherCAT support requiring specific firmware).

Core Identification and Compliance: The product complies with CE, UL, cUL, GOST-R and other standards, with UL file number E217428, following the EMC Directive (2014/30/EC), Low Voltage Directive (2014/35/EC), protection level IP20, and pollution level 2.

SERVOSTAR ™ 601... 620 digital servo amplifier (S600 series)

Basic information of the document

Product range: Covering SERVOSTAR 601-620 series digital servo amplifiers, rated current 1.5-20A, suitable for specific brushless synchronous servo motors, supporting torque, speed, and position closed-loop control.

Version and Compatibility: The document version is the 12th edition of December 2015, applicable to hardware version 05.40, and requires a specific firmware version (such as firmware ≥ 8.50_ND0/ND1 for hardware version 05.40). Different hardware versions correspond to different firmware requirements and functional support (such as BiSS/EtherCAT support requiring specific firmware).

Core Identification and Compliance: The product complies with CE, UL, cUL, GOST-R and other standards, with UL file number E217428, following the EMC Directive (2014/30/EC), Low Voltage Directive (2014/35/EC), protection level IP20, and pollution level 2.

Safety and operational standards

(1) Personnel qualification requirements

Transportation: Personnel who need to master the operation of electrostatic sensitive components;

Unpacking and installation: Electrical professionals;

Debugging: Professional personnel with knowledge of electrical and drive technology must comply with IEC 60364/60664 and national safety regulations.

(2) Key safety warning

Risk of electric shock: During equipment operation, there is a high voltage of up to 900V. After power failure, dangerous voltage may remain in the capacitor. It is necessary to wait for at least 5 minutes to confirm that the DC bus voltage is below 50V before operation; It must be reliably grounded (PE bus), otherwise it may cause fatal electric shock.

Hot air hazard: The surface temperature of the equipment may exceed 80 ℃, and it needs to be cooled to below 40 ℃ before touching to avoid burns.

Automatic restart risk: When the parameter AENA is set to 1, the device may automatically restart after power on, voltage drop, or power failure recovery. Warning signs should be posted and the dangerous area should be powered on when no one is present.

Prohibited scenarios: Not suitable for explosive environments, corrosive/conductive environments, non grounded/asymmetrically grounded power grids (voltage>240V), and ship/offshore applications; Using a servo amplifier alone to control the brake cannot guarantee functional safety and requires additional mechanical braking.

(3) Operation restrictions

It can only operate in a closed distribution cabinet, with an ambient temperature of 0-45 ℃ (rated 2.5%/K for 45-55 ℃) and an altitude of ≤ 1000m (rated 1.5%/100m for 1000-2500m);

Only use copper wire for wiring, and the wire diameter must comply with EN 60204 or NEC 310-16 standards (60 ℃/75 ℃ column).

Product Technical Parameters

(1) Core electrical parameters

Parameter Range

Rated supply voltage 3 × 208V (-10%) -480V (+10%) (50/60Hz)

DC bus voltage 260-675V (rated), protection threshold 450-900V

Rated output current (rms) 1.5A (601) -20A (620), peak current is 2-2.8 times rated (up to 5s)

Output stage clock frequency 8kHz (16kHz can be set below 400V)

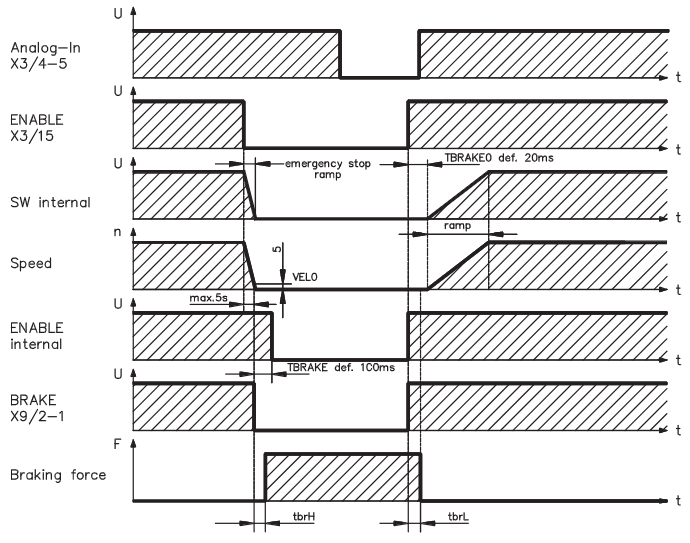

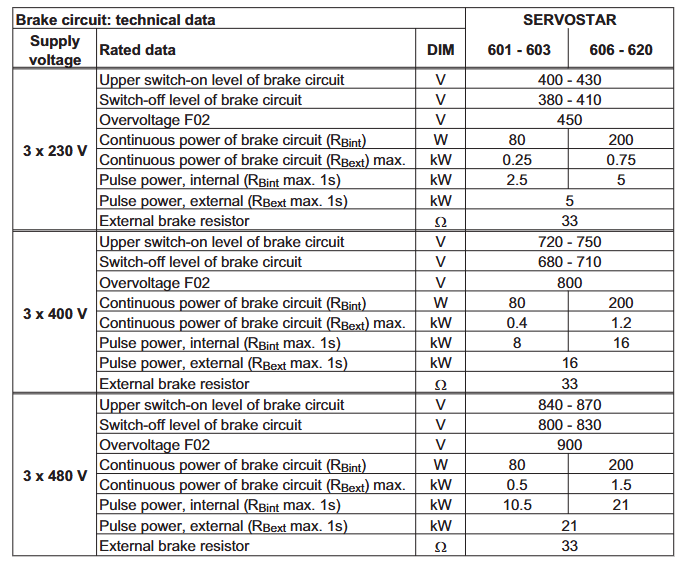

The braking circuit is equipped with a built-in braking resistor (80W for 601/603 and 200W for 606-620), and supports external braking resistors (maximum power 0.25-1.5kW)

(2) Interface and Control

Analog input: 2-channel differential input (± 10V, resolution 14bit/12bit), supporting speed/torque settings;

Analog output: 2 channels (± 10V, 10 bit resolution), default output actual speed and actual current;

Digital I/O: 4-channel input (24V, compliant with IEC 61131-2), 2-channel open collector output+1-channel relay output (BTB/RTO, used for emergency stop circuit);

Communication interface: Integrated CANopen (default 500kBaud, supporting DS301/DS402 protocol), RS232 (for PC debugging), expandable interfaces such as PROFIBUS, SERCOS, DeviceNet, EtherCAT, SynqNet, etc.

Feedback support: solver (X2), sine encoder (BiSS/EnDet/HIPERFACE, X1), incremental encoder (X5), supports encoder simulation (A quad B/SSI output).

Installation process

(1) Mechanical installation

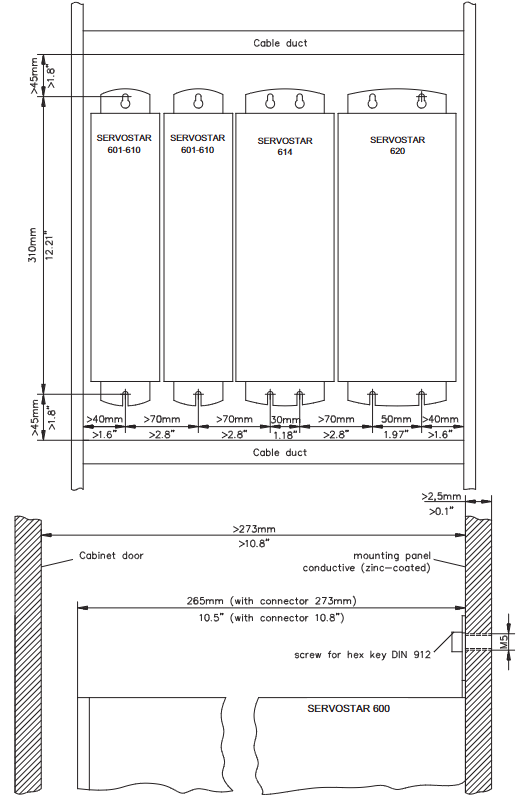

Installation position: Vertically installed on the conductive grounding mounting plate, with reserved heat dissipation space around (such as 601-610 width of 70mm, above ≥ 40mm, below ≥ 70mm);

Fixing method: Use M5 hexagon socket screws (EN 4762) with a torque of 3.5Nm;

Protection requirements: Avoid approaching equipment with strong magnetic fields. The distribution cabinet should be forcibly ventilated to ensure that the ambient temperature is ≤ 45 ℃.

(2) Electrical installation

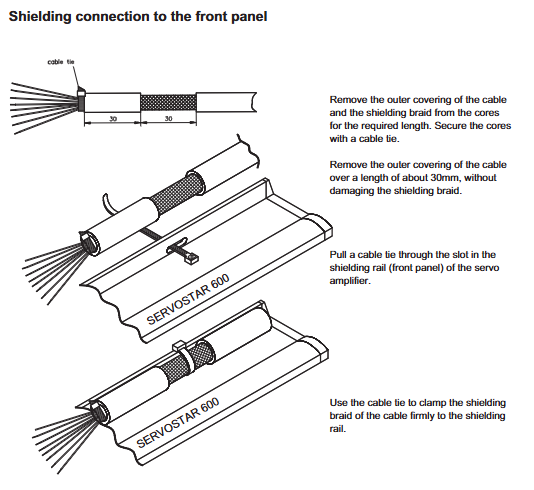

Wiring specifications: Power lines and control lines should be wired separately (spacing ≥ 200mm), motor cable length ≤ 25m (motor choke coil 3YL should be added if exceeding 25m), and both ends of the shielding layer should be grounded;

Key Connection:

Main power supply (X0A/X0B): 3-phase+PE, requiring external fuses (e.g. 6AT for 601/603, 10AT for 606/610, 20AT for 614/620);

DC bus (X7): Multi axis system can be connected in parallel, with a total rated current of ≤ 40A and a line length of ≤ 200mm (shielding is required for lines exceeding 200mm);

Motor (X9): including brake control (24V, max 2A), voltage drop needs to be confirmed;

Feedback devices: resolver (X2, SubD9), encoder (X1, SubD15), shielding layer grounded through front-end shielding rail.

Grounding system: Distinguish between AGND (analog ground), DGND (digital ground), XGND (24V ground), and PGND (communication ground), and ensure reliable connection to the cabinet grounding.

Debugging and parameter settings

(1) Debugging Tools and Preparation

Software requirements: Use DRIVE. EXE software (installed on Windows system, minimum Pentium I/8MB memory), connect PC and amplifier (X6) through RS232 null mode cable;

Preliminary inspection: Confirm that the hardware version matches the manual. If the storage exceeds 1 year, the capacitor needs to be recharged (single-phase 230VAC applied to L1/L2 for 30 minutes), and the wiring should comply with the drawings.

(2) Quick debugging steps

Power on initialization: First, turn on the 24V auxiliary power supply. After 30 seconds, the display screen will show the current level (such as "3" representing 3A). If there are no fault codes (such as F02=overvoltage, F04=feedback fault), it is normal;

Software connection: Start DRIVE. EXE, select the COM port, establish communication, and upload parameters;

Basic configuration:

Basic settings: Select power supply voltage, phase loss response (warning n05/fault F19), unit (speed/position unit);

Motor configuration: Select the motor model from the database and enable the brake function (if necessary);

Feedback configuration: Select the feedback type (such as resolver/FBTYPE=0), save the parameters, and cold start;

Motor jogging: Enable hardware (X3/15+24V) and software (Shift+F12), enter "Speed" mode, set safe speed (such as 100rpm), and start jogging test.

Fault handling and maintenance

(1) Fault codes and troubleshooting

Troubleshooting measures for fault code causes

F01 heat sink overheating check ventilation, clean fan filter, reduce load

F02 DC bus overvoltage check brake resistor connection, reduce braking energy (such as extending deceleration time)

F04 feedback fault check feedback cable connection and shielding, confirm feedback type parameters

F05 DC bus undervoltage check main power supply voltage, fuse, confirm phase loss protection settings

F19 main power supply phase loss check the main power supply wiring and confirm that the input voltage meets the requirements

(2) Daily maintenance

Cleaning: Wipe the outer shell with isopropanol, clean the internal dust with the manufacturer, and clean the fan filter with a dry brush;

Storage: Original packaging storage (-25~55 ℃, humidity 5-95%, no condensation), capacitor restoration is required for over 1 year;

Repair and disposal: Only the manufacturer can repair, and scrapping must comply with the WEEE Directive (2002/96/EC). Contact the manufacturer for recycling.

Expansion options and accessories

Restart Lock Option (- AS -): Compliant with EN 954-1, it controls the safety relay through external signals to cut off the output stage drive power and prevent accidental restarts. It is suitable for debugging/maintenance scenarios;

Expansion card:

I/O expansion card (- I/O-14/08-): Added 14 inputs/8 outputs for triggering motion tasks;

Communication expansion cards: PROFIBUS (supporting DP protocol), SERCOS (fiber optic connection), EtherCAT (RJ45 interface), etc;

Special accessories: Encoder power supply (SINCOS, max 400mA), terminal adapter (for encoders without built-in terminal resistors), Hall Dongle (for encoders without commutation information).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923