+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

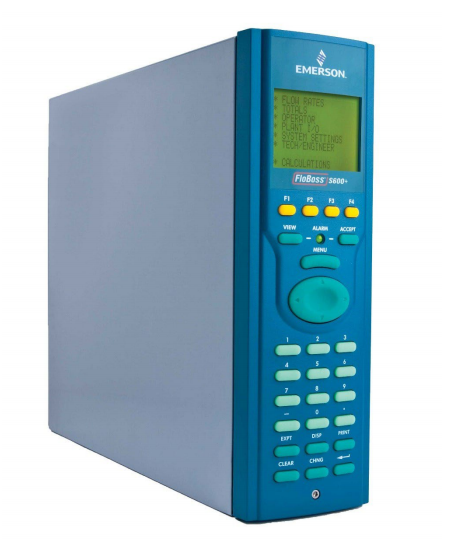

EMERSON FLOBOSS S600+ Flow Computer

This manual covers the installation and startup procedures (including

basic maintenance, operation, and troubleshooting) for the FloBoss™

S600+ flow computer (the “S600+”). For information about

Config600™, the PC-based configuration software for the S600+, refer

to the Config600 Software User Manual (Part D301220X412).

This manual focuses on the S600+, the enhanced version of the S600

with a new CPU module. Refer to technical specification FloBoss

S600+ Flow Computer (S600+) for technical information.

basic maintenance, operation, and troubleshooting) for the FloBoss™

S600+ flow computer (the “S600+”). For information about

Config600™, the PC-based configuration software for the S600+, refer

to the Config600 Software User Manual (Part D301220X412).

This manual focuses on the S600+, the enhanced version of the S600

with a new CPU module. Refer to technical specification FloBoss

S600+ Flow Computer (S600+) for technical information.

EMERSON FLOBOSS S600+ Flow Computer

This manual covers the installation and startup procedures (including

basic maintenance, operation, and troubleshooting) for the FloBoss™

S600+ flow computer (the “S600+”). For information about

Config600™, the PC-based configuration software for the S600+, refer

to the Config600 Software User Manual (Part D301220X412).

This manual focuses on the S600+, the enhanced version of the S600

with a new CPU module. Refer to technical specification FloBoss

S600+ Flow Computer (S600+) for technical information.

Note: Use of this equipment in a manner not specified by Remote

Automation Solutions may impair the protections the

equipment provides.

This chapter details the structure of this manual and provides an

overview of the S600+ and its components.

1.1 Scope of Manual

This manual contains the following chapters:

Chapter Contents

Chapter 1

General Information

Provides an overview of the S600+ and its

configuration software (Config 600).

Chapter 2

Installation

Provides instructions on installing the S600+

housing, as well as installation preparation and

panel mounting procedures. This chapter also

describes the installation and removal of the plug-in

modules.

Chapter 3

CPU

Describes the use of the communications and power

connector blocks, field wiring configurations, and

jumper settings for the CPU module.

Chapter 4

Input/Output (I/O)

Describes the use of the plug-in connector blocks,

field wiring configurations, and bit link settings for

the I/O modules.

Chapter 5

Front Panel

Describes the front panel keypad, communications

port, and display area. This chapter also shows how

you access the S600+ through the front panel

display, including keypad functions, screen displays,

display navigation basics, data entry, and report

printing.

Chapter Contents

Chapter 6

Webserver Access

Provides instructions on accessing the S600+

through a webserver interface, including

descriptions of screen displays and interface

navigation basics.

Chapter 7

Startup

Describes how to initiate a warm or cold system

start.

Chapter 8

Troubleshooting

Provides maintenance and troubleshooting

procedures, including basic board-level test

procedures.

Appendix A

Glossary

Provides definitions for pertinent terms and

acronyms.

Appendix B

Front Panel Display

Navigation

Lists the front panel display screens; provides a

navigation reference.

Appendix C

Chromatographs

Describes the operation of the gas chromatograph

software application module for the S600+.

Index Provides an alphabetic listing of items and topics

contained in this manual.

1.2 FloBoss S600+ Flow Computer

Figure 1-1. The FloBoss S600+ Flow Computer

The FloBoss S600+ Flow Computer is a panel-mounted (for indoor use) flow computer designed specifically to measure hydrocarbon

liquid and gas where versatility and accuracy matter. The standard

features of the S600+ make it ideal for fiscal measurement, custody

transfer, batch loading, and meter proving applications. The S600+

allows you to configure multi-stream, multi-station applications,

enabling you to simultaneously meter liquids and gasses.

The S600+ is designed for use either as a stand-alone flow computer or

as a system component. The intelligent I/O modules fit both gas and

liquid applications and typically support two dual-pulsed streams and a

header. Adding I/O modules (up to a maximum of three) allows you to

configure up to six dual-pulsed streams or up to 10 single-pulsed

streams and two headers. The S600+ supports orifice, ultrasonic

turbine, positive displacement, Coriolis, Annubar, and V-Cone® flow

meter types and master meter, small volume compact, and pipe (both

bi-directional and uni-directional) proving methods.

The S600+ offers a variety of communication interfaces:

Two LAN ports (on the enhanced CPU module) for Ethernet

10Base-T or 100Base-T full-duplex connectivity (using either

Modbus TCP or Modbus over Ethernet protocols).

Note: The Ethernet module (P190), which provided an additional

Ethernet port for previous versions of the S600, is not

compatible with the S600+.

HART® communication using up to two 12-channel HART

modules, each of which supports point-to-point and multi-drop

architectures for up to 50 transmitters.

Note: The FloBoss S600+ is fully compatible with HART 5

devices, and HART 7 devices are backwards compatible

with HART 5 devices.

An embedded webserver allows remote access to the flow

computer. Security is provided using user name and password

protection with a detailed event log for audit purposes (supports

Microsoft® Edge™ or Windows® Internet Explorer® version 5 or

greater [version 9 or greater must use compatibility mode]).

Two configurable RS-232 serial ports.

Three RS-422/RS-485 serial ports (supporting up to 57,600 bps

baud) and up to four RS-485 2-wire serial ports (supporting up to

57,600 baud rate) for connection to intelligent meters, Modbus

SCADA data networks, DCS supervisory systems, and so on.

One dedicated configuration port (located on the bottom of front

display panel) for connection to the Config 600 configuration

software.

Additional communications interfaces include:

• Serial Q.Sonic®

• Serial printer

• Serial or Modbus TCP Daniel chromatograph via Modbus

• Serial peer-to-peer

• Modbus EFM protocol, Modbus RTU, Modbus ASCII, Modbus

over Ethernet, and Modbus TCP

Miscellaneous interfaces which can operate via serial or Modbus

TCP:

Daniel liquid ultrasonic

Daniel gas ultrasonic

Sick ultrasonic

Daniel chromatograph

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

36

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector