K-WANG

SIEMENS SMART S7-200 Intelligent Programmable Controller

High speed processing performance: Equipped with Siemens dedicated chips, the basic instruction execution time is as low as 0.15 μ s, which is superior to micro PLCs of the same level and can cope with complex and fast control processes.

SIEMENS SMART S7-200 Intelligent Programmable Controller

Product positioning and core advantages

Siemens SIMATIC S7-200 SMART is a miniature PLC (Programmable Logic Controller) designed specifically for developing markets, with the core goal of balancing performance and cost, providing a cost-effective solution for small automation equipment. Key advantages include:

High speed processing performance: Equipped with Siemens dedicated chips, the basic instruction execution time is as low as 0.15 μ s, which is superior to micro PLCs of the same level and can cope with complex and fast control processes.

Flexible expansion capability: Provides two types of CPUs: standard (expandable I/O modules and signal boards) and compact (integrated I/O, non expandable), adapted to different point requirements.

Convenient communication and operation: Equipped with Ethernet and RS485 dual interfaces as standard, it supports fast program/firmware updates for general Micro SD cards, reducing on-site maintenance difficulty.

Seamless integration solution: Perfectly compatible with Siemens BASIC LINE HMI and SINAMICS V20/V90 drivers, forming a complete micro automation system.

CPU module classification and key parameters

2.1 Classification of CPU Types

Type Series Core Features Representative Models

Standard SR series AC/DC/relay output, supports I/O expansion+signal board SR20, SR30, SR40, SR60

Standard ST series DC/DC/transistor output, supporting high-speed pulse (PWM/PTO) ST20, ST30, ST40, ST60

Compact CR series AC/DC/relay output, non expandable, lower cost CR40, CR60

2.2 Comparison of Core Parameters (Key Models)

Parameter SR20 (Standard) ST30 (Standard) CR40 (Compact)

The number of I/O points in the main body is 12DI/8DO, 18DI/12DO, 24DI/16DO

Maximum I/O capacity (including expansion) 212 points, 222 points, and 40 points (non expandable)

High speed pulse output -3 channels at 100kHz-

High speed counter (single-phase) 4-channel 200kHz 4-channel 200kHz 4-channel 100kHz

Real time clock support (7 days of power failure) support (7 days of power failure) not support

Number of expansion modules: 6, 6, 0

Power type AC 85-264V DC 20.4-28.8V AC 85-264V

Expansion components (signal board and expansion module)

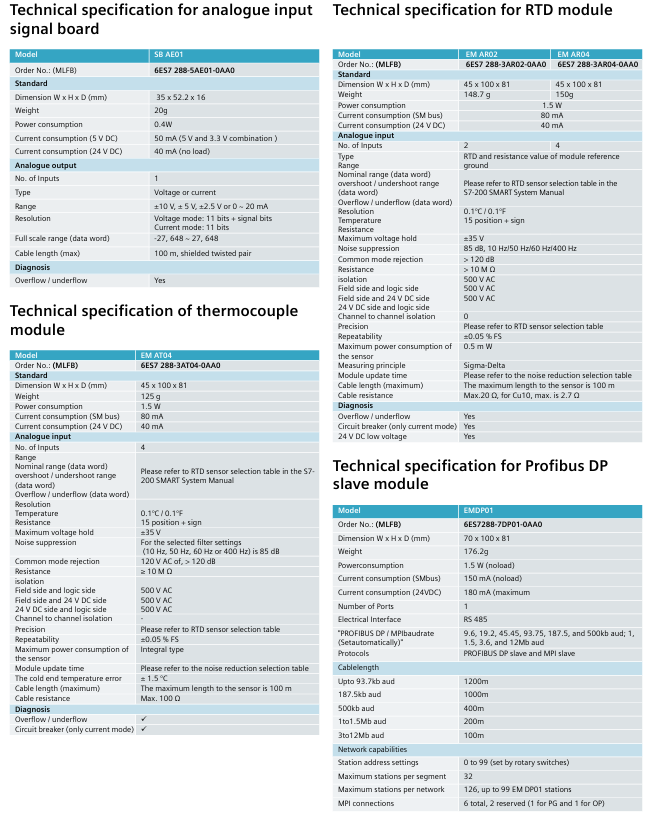

3.1 Signal board (SB): directly installed on the front of the CPU without occupying cabinet space

Model Function Description Key Parameters Order Number (MLFB)

SB DT04 Digital I/O Expansion 2DI/2DO (Transistor Output) 6ES7288-5DT04-0AA0

SB AE01 Analog Input Extension 1AI (12 bit accuracy, supporting ± 10V/0-20mA) 6ES7288-5AE01-0AA0

SB AQ01 Analog Output Extension 1AO (12 bit accuracy, supporting ± 10V/0-20mA) 6ES7288-5AQ01-0AA0

SB CM01 communication extension supports RS232/RS485 conversion, with 4 devices connected to 6ES7288-5CM01-0AA0

SB BA01 battery module compatible with CR1025 battery, clock endurance of about 1 year 6ES7288-5BA01-0AA0

3.2 Expansion Module (EM): Used for extensive I/O expansion or special functions

Module type, model, function, key parameters

Digital input EM DI08 8-channel digital input 24V DC, filtering time adjustable from 0.2-12.8ms

Digital output EM DR08 8-channel relay output supports 5-30V DC/5-250V AC, 2A per point

Digital output EM DT08 8-channel transistor output 24V DC, 0.75A per point, surge current 8A

Analog input EM AI04 4-channel analog input with 12 bit accuracy, supporting ± 10V/0-20mA

Analog output EM AQ02 2-channel analog output with 12 bit accuracy, load resistance ≥ 1k Ω (voltage)

Temperature acquisition EM AR04 4-channel RTD input (platinum resistance) accuracy ± 0.1 ℃, cable length ≤ 100m

Temperature acquisition EM AT04 4-channel thermocouple input supports K/J type, cold junction error ± 1.5 ℃

Bus Expansion EM DP01 PROFIBUS DP Slave Module Supports 9.6kbps-12Mbps, Maximum 244 Byte I/O

Core functional characteristics

4.1 Communication Capability

Standard interface:

Ethernet interface: Supports Siemens S7 protocol, can download programs, connect HMI (up to 8 units), communicate with other CPUs, supports 8 active GET/PUT connections+8 passive GET/PUT connections, transmission rate 10/100Mbps (CAT5e shielded wire).

RS485 interface: Supports Modbus RTU, PPI, USS protocols, can connect to third-party devices such as frequency converters and touch screens, with a maximum of 4 HMIs per port.

Expansion interface: Add RS232/RS485 through SB CM01, compatible with barcode scanners, weighing instruments and other devices.

4.2 Motion Control

Hardware foundation: The ST series (transistor output) supports high-speed pulses, with ST20 having 2 channels of 100kHz and ST30/ST40/ST60 having 3 channels of 100kHz.

Core functions:

PWM mode: Fixed pulse period, adjustable duty cycle through program to achieve motor speed regulation and valve opening control.

PTO mode: supports multi-mode positioning (absolute/relative/manual), 4 reference point searches, 32 sets of motion envelopes (16 speed levels per set), and is compatible with stepper/servo motors.

Configuration tool: STEP 7-Micro/WIN SMART motion control wizard, which can quickly generate control instructions and support real-time status monitoring (speed, position, I/O status).

4.3 Convenient operation and maintenance

Micro SD card function (supporting 4-16GB universal cards):

Program transfer: Batch download programs without software, saving time and cost.

Firmware upgrade: Update CPU and expansion module firmware on-site without returning to the factory.

Factory reset: Clear all retained data and quickly reset the device.

Status monitoring: The software supports I/O numerical/waveform monitoring, PID parameter adjustment, and motion control testing, which can verify the correctness of wiring and the rationality of configuration.

Programming software and integration solutions

5.1 STEP 7-Micro/WIN SMART (Programming Software)

Operating environment: Windows XP SP3/Windows 7, installation file<100MB.

Core functions:

Programming language: Supports LAD (ladder diagram), STL (statement table), FBD (function block diagram), and can be freely converted.

Wizard configuration: Provide HSC (high-speed counter) PID、PWM、 Motion control guide, simplifying complex function settings.

Variables and Annotations: Support custom variable names, add annotations to program blocks, networks, and variables to improve readability.

Instruction library: Built in Modbus RTU, USS protocol library, supports password protection to prevent program tampering.

5.2 Micro automation integration solution

Component configuration: SIMATIC S7-200 SMART PLC+BASIC LINE HMI (human-machine interaction)+SINAMICS V20 (frequency converter)+SINAMICS V90 (servo system).

Customer value: Improve equipment performance, reduce development costs, shorten product launch cycles, and enhance OEM customer market competitiveness.

Typical applications and environmental requirements

6.1 Typical Application Scenarios

Small mechanical equipment: labeling machine, pillow packaging machine, woodworking machinery, automatic feeding equipment.

Control requirements: precise positioning, speed adjustment, logical control (such as material counting, process switching).

6.2 Environmental Parameters

Operating temperature: 0-55 ℃ (horizontal installation), 0-45 ℃ (vertical installation), humidity ≤ 95% (no condensation).

Electromagnetic compatibility: Complies with EN 61000 standard, anti-static (air discharge 8kV), anti radio frequency interference (80-1000MHz, 10V/m).

Installation method: Supports rail installation/screw installation, detachable module terminals for easy wiring and maintenance.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923