K-WANG

SIEMENS SIMATIC S5 S5-115U Programmable Controller

SIEMENS SIMATIC S5 S5-115U Programmable Controller

Product Overview

1. Core positioning

6ES5 998-0UF23 is a programmer/operation panel interface module (PG/OP Interface Module) designed by Siemens specifically for SIMATIC S5 series programmable logic controllers (PLCs). As a dedicated communication relay unit between S5 series PLCs and external programming devices (PG) and human-machine interaction devices (OP), its core function is to solve communication protocol adaptation, signal conversion, and link management problems when multiple devices are connected. It is a key hardware component for program debugging, parameter configuration, and on-site operation monitoring in S5 series PLC control systems.

2. Product ownership and historical background

This module belongs to the Siemens SIMATIC S5 series industrial automation product family, which is a mainstream equipment in the industrial control field from the late 20th century to the early 21st century. It is widely used in traditional manufacturing, chemical, metallurgical, power, transportation and other industries. 6ES5 998-0UF23, as a supporting interface module for the S5 series, was designed specifically for the dual device access requirements of "programming equipment+operation panel" in industrial scenarios at that time. It made up for the shortcomings of the early S5 PLC host's insufficient number of native interfaces and single communication protocol, and is still the core maintenance and operation support component for a large number of in-service S5 series PLC systems today.

3. Core values

Realize stable bidirectional communication between S5 PLC, programmer, and operation panel, ensuring core functions such as program upload and download, online monitoring, and parameter modification.

Support simultaneous access of multiple devices without the need for additional communication expansion modules, simplifying system architecture and reducing hardware configuration costs.

Industrial grade design is suitable for harsh on-site environments, ensuring anti-interference and low latency of communication links, and guaranteeing the stability of continuous production scenarios.

Key technical parameters

1. Hardware specifications

(1) Communication interface

Interface type: 2 RS422 balanced differential interfaces, supporting full duplex communication, strong anti-interference ability, suitable for industrial long-distance transmission.

Interface features: Each interface supports the S5 series dedicated PG/OP communication protocol and is compatible with the hardware interface standards of Siemens S5-PG programmer and S5-OP operation panel.

Transmission rate: Supports multi speed adaptation such as 19.2kbps, 9.6kbps, 4.8kbps, etc. The default speed is 9.6kbps, which can be adjusted through programming configuration.

Transmission distance: Maximum communication distance of 1200 meters (shielded cable), meeting the layout requirements of large-scale industrial field equipment.

(2) Power supply parameters

Power supply method: There is no independent power supply interface, and the working power is obtained from the PLC system through the backplane bus of the S5 PLC rack.

Working voltage: DC 5V ± 5% (provided by PLC backplane bus), power consumption ≤ 1.5W, low-power design does not increase the power supply burden of PLC system.

(3) Physical and installation characteristics

Dimensions: Width 40mm x Height 125mm x Depth 180mm (standard S5 series module size), compatible with standard rack installation of S5 series PLC.

Installation method: rail installation (in accordance with DIN EN 50022 standard rail) or screw fixed installation. The bottom of the module is equipped with a snap on design, which can be quickly mounted on the PLC rack.

Weight: Approximately 280g, lightweight design does not affect the load-bearing balance of the rack.

(4) Environmental adaptability

Working temperature: 0-60 ℃, meeting the high temperature operation requirements of industrial sites.

Storage temperature: -20~85 ℃, suitable for temperature fluctuations in warehouse storage and transportation.

Humidity range: Relative humidity 5%~95% (no condensation), strong moisture resistance.

Electromagnetic compatibility (EMC): Complies with EN 61000-6-2 industrial environment anti-interference standard, anti-static discharge (air discharge ± 8kV, contact discharge ± 4kV), and anti radio frequency interference (80-1000MHz, 10V/m).

2. Communication Protocol and Compatibility

(1) Support agreement

Core protocol: Siemens S5 series dedicated PG/OP communication protocol, supporting program data (PB/FB/SB/DB block) transmission, I/O signal status reading, parameter configuration, fault diagnosis information exchange and other functions.

Protocol features: Based on a connection oriented communication mode, the data transmission belt verification mechanism (parity check/no check optional) ensures the accuracy of data transmission.

(2) Adapting devices

Compatible with PLC models: Fully compatible with S5 series full spectrum PLCs, including mainstream models such as S5-90U, S5-100U, S5-115U (CPU 941/942/943/944), S5-135U, S5-155U, etc.

Compatible Programmer (PG): Siemens S5-PG series programmers (such as PG 605U, PG 635, PG 685), third-party industrial programming devices compatible with S5 protocol.

Adaptation operation panel (OP): Siemens S5-OP series operation panel (such as OP 393, OP 395, OP 396), industrial touch screen with RS422 interface (supporting S5 PG/OP protocol).

Core functions and working principles

1. Detailed explanation of core functions

(1) Programming communication function

Program transmission: Supports uploading control programs (written in STEP 5 language, including logic blocks, data blocks, function blocks, etc.) from the programmer to the S5 PLC host, or downloading programs from the PLC host to the programmer for offline modification.

Online monitoring: Real time transmission of PLC I/O signal status, internal flag bit (F), timer (T), counter (C) data to the programmer, supporting visualization of program running status (such as ladder diagram/statement table online monitoring).

Parameter configuration: PLC system parameters (such as scan cycle, interrupt priority, I/O address allocation) are configured through a programmer, and the configuration data is transmitted to the PLC host through the module and stored.

(2) Communication function of operation panel

Status display: Transmit the running status (RUN/STOP) and fault alarm information (such as I/O faults and program errors) of the PLC to the operation panel for on-site visual prompts.

Command input: Receive manual input commands from the operation panel (such as start/stop commands, parameter settings, manual operation signals), convert them into digital signals recognizable by the PLC, and transmit them to the host.

Data interaction: Real time synchronization of key data between the operation panel and PLC (such as production counting, process parameters, equipment operating time), ensuring real-time human-machine interaction.

(3) Multi device access management

Support simultaneous access of 1 programmer and 1 operation panel, with communication link time-division multiplexing implemented within the module to avoid data conflicts.

Equipped with a communication priority management mechanism, the online debugging instructions of the programmer have a higher priority than the normal operation instructions on the control panel, ensuring that the debugging process is not disturbed.

(4) Fault diagnosis and protection

Communication fault detection: When the communication between the programmer/operation panel and the module is interrupted, the module sends a fault signal to the PLC host through the PLC backplane bus, which can trigger the PLC's alarm mechanism (such as outputting alarm indicators and storing fault codes).

Overcurrent protection: The interface circuit is equipped with overcurrent protection components to prevent module damage caused by external device short circuits and improve hardware reliability.

2. Working principle

6ES5 998-0UF23 is essentially a protocol conversion and signal relay unit, and its workflow is as follows:

Physical layer: Convert the RS422 differential signal of the programmer/operation panel into a parallel signal recognizable by the S5 PLC backplane bus, and vice versa.

Protocol layer: parses S5 PG/OP protocol instructions (such as program transfer instructions and data read instructions) sent by external devices, converts them into the internal bus instruction format of the PLC host, and implements protocol adaptation.

Data link layer: manages the communication timing of dual interfaces, processes the data transmission requirements of multiple devices accessing simultaneously through time division multiplexing mechanism, and ensures orderly and conflict free data transmission.

Feedback layer: Feedback the response data of the PLC host (such as program transmission confirmation and I/O status data) to the corresponding external device in the original protocol format, completing a two-way communication loop.

Installation and configuration process

1. Installation steps

(1) Hardware installation

Power off preparation: Disconnect the power supply of the S5 PLC system to ensure that there is no risk of electric shock during installation.

Module positioning: Insert the module into the vacant slot of the S5 PLC rack, ensuring that the bus interface at the bottom of the module is fully aligned with the rack backplane, and secure the module with buckles or screws.

Interface connection:

Programmer connection: Use RS422 shielded cable to connect the PG interface of the programmer to the "PG" interface of the module. The shielding layer should be tightened at both ends of the cable to ensure good grounding.

Operation panel connection: Use RS422 shielded cable to connect the communication interface of the operation panel to the "OP" interface of the module, with a cable length not exceeding 1200 meters.

Power on inspection: Connect the power supply of the PLC system. If there is no obvious heating or abnormal noise in the module, and there is no "interface module fault" alarm in the PLC host, it is considered that the installation is normal.

(2) Software configuration

Programmer connection: Start the programmer (such as PG 605U), establish a communication connection with the PLC through STEP 5 software, and select "6ES5 998-0UF23" as the interface module in the communication settings.

Communication parameter configuration: Set the communication rate (default 9.6kbps) and verification method (default no verification) to ensure that the parameters of the programmer, operation panel, and module are consistent.

Device recognition: Through the "device scan" function of the programmer, confirm that the module has been recognized by the PLC host and that the operation panel has successfully connected to the communication link.

2. Wiring specifications

Cable selection: Shielded RS422 cables (such as Siemens 6XV1830-0EH10) must be used, with a core wire cross-sectional area of ≥ 0.5mm ² and a shielding layer coverage rate of ≥ 85% to reduce electromagnetic interference.

Wiring definition: correspondence between module interface pins and external devices (following S5 PG/OP interface standard):

Pin 1: Send positive (TX+)

Pin 2: Send negative (TX -)

Pin 3: Receive positive (RX+)

Pin 4: Receive negative (RX -)

Pin 5: Signal Ground (GND)

Pin 6: Shielding layer ground (SH)

Grounding requirements: The two ends of the cable shielding layer should be grounded with a grounding resistance of ≤ 4 Ω to avoid interference caused by grounding loops.

Typical application scenarios

1. Traditional production line control

Scenario: Automated production lines based on S5-115U PLC (such as automotive parts assembly lines, food packaging lines).

Application: Connect the PG 635 programmer and OP 396 operation panel through 6ES5 998-0UF23 to achieve:

The programmer writes logic programs offline and uploads them to the PLC, monitors the operation status of the production line online, and debugs faults.

The operation panel is used by on-site workers to start/stop the production line, set production parameters (such as packaging speed, counting targets), and view fault alarm information.

2. Industrial machine tool control

Scenario: CNC machine tools and machining centers based on S5-135U PLC.

Application: Connect the module programmer with the machine operation panel to achieve:

Upload the processing logic program to the programmer, modify the tool parameters and motion trajectory parameters.

The operation panel receives manual operation instructions from workers (such as spindle start stop and feed adjustment), and displays real-time machine operation status (such as machining progress and fault codes).

3. Process control scenarios

Scenario: Temperature/pressure control system for chemical reaction kettle and metallurgical furnace based on S5-155U PLC.

Application: Connect the module programmer with the on-site operation panel to achieve:

Configure PID control parameters and set temperature/pressure thresholds for the programmer.

The operation panel displays real-time temperature/pressure data and alarm information, and workers manually intervene in the control process through the panel (such as emergency shutdown and parameter fine-tuning).

Maintenance and troubleshooting

1. Key points of daily maintenance

Regular inspection: Check the module fixation and cable connections for looseness every month, clean the surface dust of the module (wipe with a dry cloth to avoid liquid contact).

Cable maintenance: Check the shielding layer of RS422 cables for damage and oxidation of wiring terminals every quarter, and replace damaged cables in a timely manner.

Environmental monitoring: Ensure that the working environment temperature of the module does not exceed 60 ℃, and avoid contact with the module with moisture, dust, and corrosive gases.

2. Common troubleshooting

(1) Communication interruption

Phenomenon: The programmer/operation panel cannot establish a connection with the PLC or frequently disconnects after connection.

Troubleshooting steps:

Check power supply: Confirm that the PLC system power supply is normal and the module has obtained 5V power supply through the backplane bus.

Check the cable: Replace the RS422 cable, confirm that the wiring definition is correct, and that the shielding layer is well grounded.

Check parameters: Confirm that the communication rate and verification method of the programmer/operation panel are consistent with the module configuration.

Check module status: If the PLC reports "interface module failure", unplug and reinstall the module. If the fault persists, the module may be damaged and needs to be replaced.

(2) Data transmission error

Phenomenon: Program upload/download failed, or the data displayed on the operation panel is inconsistent with the actual data of the PLC.

Troubleshooting steps:

Check the interference source: Confirm that the distance between the module and strong interference equipment such as frequency converters and motors is ≥ 1 meter, and that the cables are kept away from the power cables (with a distance of ≥ 30cm).

Reduce transmission speed: Reduce communication speed from 19.2kbps to 9.6kbps to improve long-distance transmission stability.

Check PLC status: Confirm that the PLC is in RUN mode and there are no alarms affecting communication such as memory or I/O faults.

(3) Module unresponsive

Phenomenon: After the module is connected, the PLC cannot recognize it, and the programmer/operation panel cannot establish a connection.

Troubleshooting steps:

Check the slot: Replace the vacant slot of the PLC rack and reinstall the module to eliminate the slot fault.

Check module hardware: Observe whether there are burn marks or bent pins on the module. If there are, the module is damaged and needs to be replaced.

Confirm compatibility: Verify whether the module model is compatible with the PLC model (e.g. S5-90U needs to be paired with the corresponding version of 6ES5 998-0UF23).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

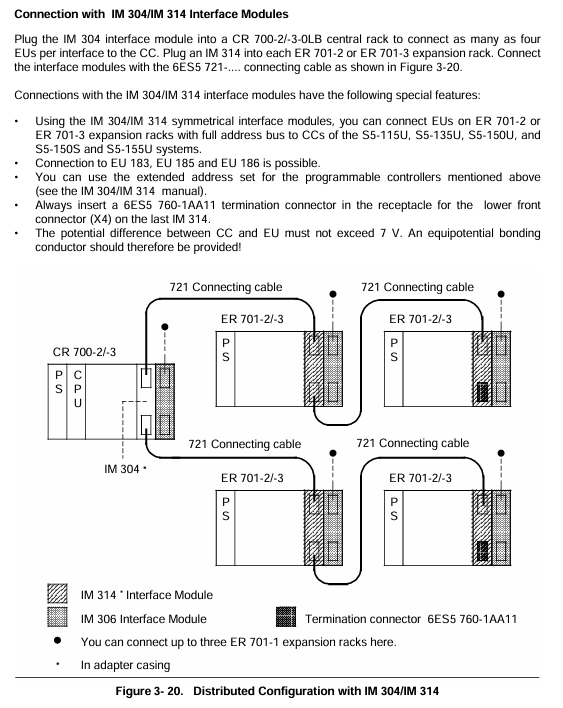

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

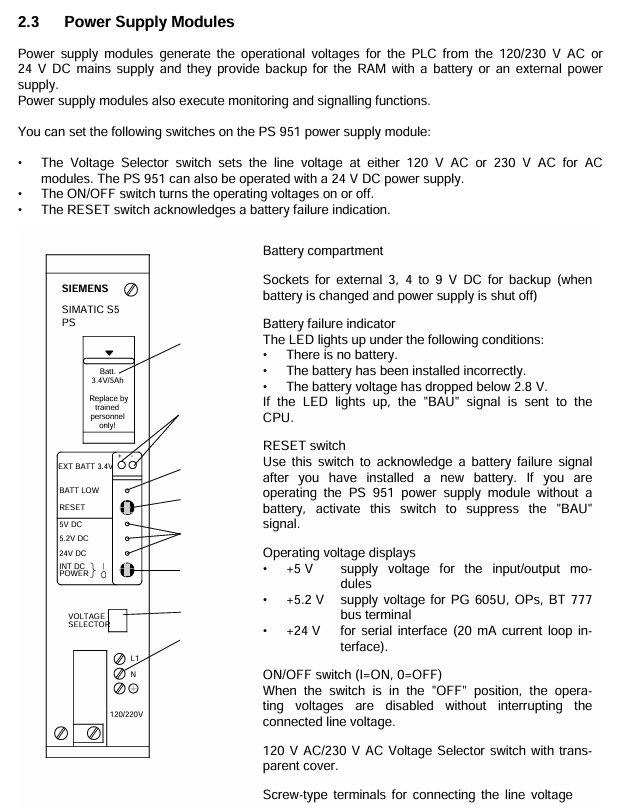

Tell:+86-15305925923