K-WANG

SIEMENS SIMATIC S7-300 Beginner's Guide

SIEMENS SIMATIC S7-300 Beginner's Guide

The Siemens SIMATIC S7-300 Beginner's Guide (version 04/2007) takes conveyor belt motor control as an example and provides a detailed introduction to the entry-level operation of adapting CPU 312C (order number 6ES7312-5BE03-0AB0). The core process includes preparing a PC (installing STEP 7 Lite V3.0+SP2 and PC Adapter USB driver), installing wiring hardware components, configuring control in STEP 7 Lite, downloading programs, and executing test runs. The entire process must comply with electrical safety regulations and support motor start, direction switching, and stop functions. The overall operation time is about 1 hour, suitable for users with Windows operation and electrical basic knowledge.

Basic information of the document

Core positioning: A beginner's guide to S7-300 for beginners, explaining the complete process of PLC from hardware installation to program operation through an example of conveyor motor control

Key adaptation: Only applicable to CPU 312C (order number 6ES7312-5BE03-0AB0), requires SIMATIC Micro Memory Card (MMC), starting firmware version V2.6

Safety reminder: Clearly distinguish the four levels of "danger/warning/caution/attention" safety, emphasize that only qualified professionals are allowed to operate, and comply with safety standards such as IEC 204

Preparation in advance

Skill Requirements

Proficient in operating Microsoft Windows operating system

Master the basic knowledge of electronic and electrical engineering

List of Materials and Tools (Core Components)

|Category | Project | Order Number (Siemens) | Quantity | Remarks|

|Core module | CPU 312C | 6ES7312-5BE03-0AB0 | 1 | Integrated DI10/DO6, requires MMC card|

|Power Supply | Power Module | 6ES7307-1EA00-0AA0 | 1 | Provides DC 24V power supply|

|Installation accessories | Installation track | 6ES7390-1AB60-0AA0 | 1 | M6 screw is required to fix the grounding|

|Connection accessories | PC Adapter USB | 6ES7972-0CB20-0XA0 | 1 | MPI interface with driver program for connecting PC and CPU|

|Front connector | Screw type multi terminal front connector | 6ES7392-1AM00-0AA0 | 1 | Compatible with CPU wiring|

|Control element | Instantaneous contact switch | - | 4 | 24V/2A, used for motor start stop and commutation|

|Software | STEP 7 Lite | - | 1 | V3.0+SP2, available for free download|

|Tools | Screwdrivers, wire strippers, crimping tools, etc. | - | Several | Market procurement, including 3.5mm/4.5mm blade screwdrivers|

|Cable | Grounding cable (10mm ²), flexible cable (1mm ²), etc. | - | As needed | Grounding cable needs to be compatible with M6 screws|

Core operational process (step-by-step)

1. Prepare PC (software and interface settings)

Install STEP 7 Lite: from the official website( http://support.automation.siemens.com )Download and follow the wizard to complete the installation

Install PC Adapter USB driver: Insert the driver CD and follow the prompts to install

Set PG/PC interface: Select "PC Adapter (MPI)", configure USB connection, enable MPI communication between PC and CPU

2. Hardware installation and wiring

Installation track: fixed with 2 M6 screws, grounding cable cross-sectional area ≥ 10mm ², leaving a gap of ≥ 40mm above and below the track (for heat dissipation and operation)

Installation module: First install the power module (fixed by hand), then install the CPU 312C, and insert the front connector (not locked temporarily, convenient for wiring)

Wiring operation:

Prepare the cable: Cut it to the desired length, strip off the insulation layer, and put on a 6mm insulation ring

Wiring sequence: power supply → CPU 312C → momentary contact switch (connected to DI terminal) → motor (connected to DO terminal, optional)

Key requirement: Cut off the power before wiring, and set the line voltage selector correctly

Hardware debugging:

Connecting PC and CPU: Connect PC Adapter and PC with USB cable

Power on test: Insert the MMC card, set the CPU to STOP mode, and turn on the power (power DC24V LED lights up, CPU DC5V and STOP LED lights up)

Test wiring: Press the momentary contact switch and observe whether the corresponding CPU input LED lights up (such as the input 0.0 terminal LED corresponding to the start switch)

3. Software Configuration (STEP 7 Lite)

Open project: Start STEP 7 Lite and open the instance project "converyor.k7p"

Create module configuration:

New S7-300 station, automatically generate 4 installation tracks

Insert the power module (such as 6ES7307-1BA00-0AA0) and CPU 312C, and it will automatically display in the hardware view and configuration table

Set CPU parameters: Set the reserved bit storage quantity to "0" to avoid motor runaway startup after power failure

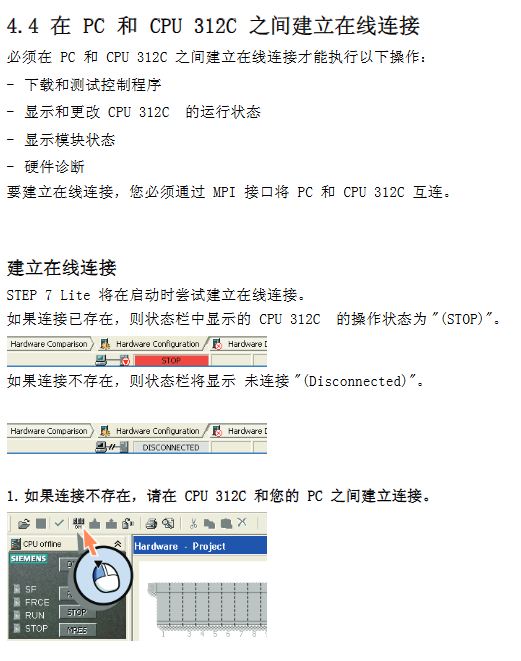

Establish online connection: When STEP 7 Lite starts, it automatically attempts to connect and the status bar displays "STOP" (connection successful) or "Disconnected" (manual connection required)

Download configuration: First, perform a CPU memory reset (delete old programs/configurations), then download a new configuration and check the consistency of offline/online configurations

4. Program operation and test run

Open program: The program in the project is stored in OB1 (Organizational Block 1), written using ladder logic (LAD), and includes 4 network segments (clockwise/counterclockwise/start/stop)

Download project: Download hardware configuration and OB1 program to CPU 312C, confirm to overwrite existing configuration/program

Test Run:

Switch CPU mode: Set the mode switch to "RUN", and the RUN LED will change from flashing to constantly on

Functional testing:

Start: Press the green momentary contact switch, input 0.0 LED briefly on, output 0.3 LED constantly on (motor ready)

Clockwise rotation: Press and hold the corresponding switch, input 0.2 LED lights up, output 0.0 LED lights up

Counter clockwise rotation: Press and hold the corresponding switch, input 0.3 LED lights up, output 0.5 LED lights up

Stop: Press the red momentary contact switch, input 0.1 LED briefly on, output 0.3 LED off

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

-

KEBA KeTop CB211 - Connection Box

-

KEBA HT4 / 20656 - Kammann Hand Held Keypad

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Y1-K1-Y2 PA9 - Engel Board Module

-

LTI MOTION CDA32.004C3.0 - Servo Drive 230V AC

-

KEBA E-CG-CONTROL - ECGCONTROL Module

-

KEBA Kemro K2-200 OP350/W 68334 - Engel EC200 Panel Membrane Touch Glass

-

KEBA i1075 - Membrane Keyboard

-

KEBA E-HSI-M - Interface Module

-

KEBA LQ10D321-ERSAT - ZTEILSET FNOB

-

KEBA E-16-DIGOUT/G - Circuit Board

-

KEBA HT4/Neutral/16846 - Mikron Handheld Terminal

-

KEBA KeTop CB310-000 - Connection Box

-

KEBA DC 161/IP20/17369 - Interface Card Module

-

KEBA E-16-DIGOUT-PLUS - Elektronik Bau Linz 262-1456-85-B

-

KEBA HT501 - Handheld Terminal

-

KEBA HT401-4X20 - Teach Pendant

-

KEBA E-3-ACU-10 D16738 - Controller Card Module

-

KEBA 240/A 068371 - Analog Output Module

-

KEBA E-7TEMP D1323E/F/G - Temperature Circuit Board

-

KEBA KeTop TT100-eaa - Communication Cable

-

KEBA E-16 DIGOUT-PLUS D1456D - Engel Output Board

-

KEBA Kemro K2-200 - Touch Panel Glass Digitizer

-

KEBA CC100A03/CAN/4 - PLC Chassis 16-Slot Rack Motherboard 1842E-0

-

KEBA CU 211 - PLC Power Supply

-

KEBA KeTOP CB310-S00 - Connection Box

-

KEBA I/O BUS KOPPLUNG D1547C - Engel Circuit Board

-

KEBA HCS01.1E-W0013-A-02 - Servo Drive

-

KEBA SMC1-Z30 - LTI Security Safety Control

-

KEBA E-PS88-M/C D1527C - Power Supply Board

-

KEBA D1678C / E-SEK - Control Board

-

KEBA 1.83E+02 - Circuit Board Module

-

LUST LTI/KEBA DSM4-05.4-20R.96-W1A - AC Servo Motor

-

Engel/KEBA OP 362-LD/W-5200 - Kemro Ke-200 Membrane Keypad Touch Screen

-

KEBA HT4 24V/0.2A - Kammann Hand Terminal C3052-R47

-

KEBA Kemro K2-200 BL210/B - Injection Molding Machine Controller Module

-

KEBA E-8-ANALOG D1432B - Analog Board

-

KEBA DM272 - Input Output Module

-

KEBA AR161 - PCB ML-EUMIG

-

KEBA E-PS-24V 1825E-1 - Power Supply Board

-

KEBA E-8-THERMO 1770B-1 - Engel Temperature Control Board

-

KEBA HT4-221-20556 - Kammann Hand Terminal

-

KEBA E-10-ANALOG-SUB D1458D - Circuit Board

-

KEBA AC 441 - Control Module 18-32 VDC

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA E-ANA-SUB2 D1690C - Analog Submodule Card

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad

-

KEBA OP 331/C-4400 - Keview V2 LCD Display Screen Panel

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923