K-WANG

SIEMENS SIMATIC S7-1500 S7-PLCSIM Advanced

SIEMENS S7-1500 S7-PLCSIM Advanced Function Manual

Overview of document basic information

Document Name Version/Year Core Adaptation Product Core Objectives Key Features

S7-PLCSIM Advanced Function Manual, 11th edition 2023, provides PLC virtual simulation for S7-1500, ET 200SP, SIMATIC Drive Controller, etc. It supports program testing, virtual debugging, supports 16 instances, API joint simulation, and virtual time adjustment

1FK6 Series Servo Motor Manual 2001 11th Edition 1FK6 03. -10. Series Three Phase Servo Motor Guide Product Transportation, Installation, Operation, Maintenance Full Process Multilingual Support, IP64 Protection, Self Cooling Design

S7-PLCSIM Advanced V6.0 Core Content

1. Basic characteristics of the product

Positioning: Virtual simulation software for SIMATIC S7-1500 series PLC, capable of testing STEP 7 programs without the need for a physical controller

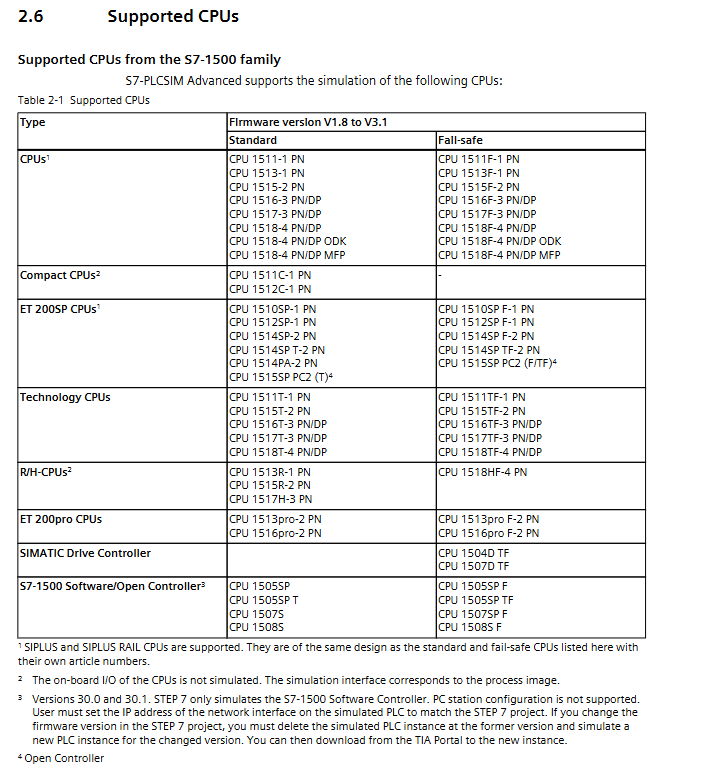

Support CPU:

Mainstream series: S7-1500 (standard/fail safe/technical type), S7-1500R/H redundant system ET 200SP/ET 200pro CPU

Special models: SIMATIC Drive Controller (1504D TF/1507D TF), S7-1500 software/open controller

Core functions:

Communication modes: local communication (Softbus), distributed communication (TCP/IP single adapter/multi adapter mode)

Scalability: API interface supports C++/C # joint simulation, supports OPC UA server and web server functions

Special simulation: ODK function simulation, motion control simulation, redundant system simulation (RUN Solo mode)

System requirements:

Minimum Hardware/Software Configuration Remarks

Processor Intel Core i7 6th generation or above, single instance 1 core+system 1 core+application 1 core virtual machine requires corresponding physical CPU allocation

1GB memory per instance, minimum 4GB system. When installing TIA Portal, the virtual machine needs to be ≥ 8GB

5GB of free space on the hard drive-

Operating system Windows (non Home version), supports VMware/Hyper-V/AWS Cloud and needs to be compatible with the corresponding TIA Portal version

2. Key operational procedures

Installation and License:

Installation process: Run the installation package → Select product components → Configure firewall exceptions (port 4410) → Restart the computer

License type: Floating license (single license supports 2 instances), 21 day trial license

Antivirus exception: The installation directory (such as C: Program Files Common Files Siemens PLCSIMADV) needs to be added to the antivirus software exception list

Communication configuration:

Local communication (Softbus): default mode, restricts communication within the local PC/virtual machine to avoid accidental downloading to the physical CPU

TCP/IP communication:

Single adapter mode (hybrid mode): supports distributed communication across PCs/virtual machines, requires activation of virtual switches

Multi adapter mode (non hybrid mode): Communication is achieved through MAC address mapping, suitable for cloud environments/enterprise networks

Enable distributed communication: Activate "S7-PLCSIM Advanced Virtual Switch" in the Windows network adapter properties

Simulation operation:

Instance creation: Enter the instance name (3-29 characters) through the control panel, select the CPU family, and configure the IP address

Project Download: Select PG/PC interface (PLCSIM/Virtual Ethernet Adapter) in TIA Portal, download hardware configuration and program

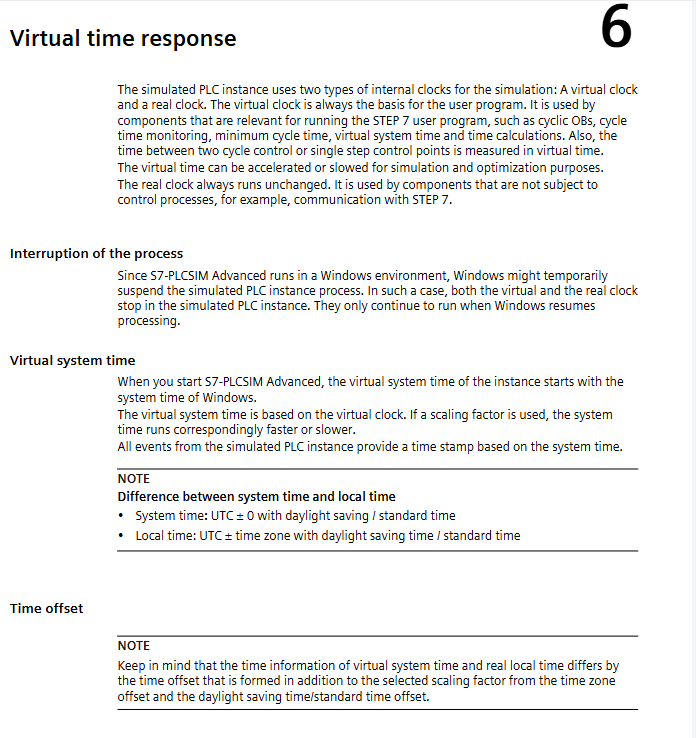

Operation monitoring: Switch the instance to RUN mode, support virtual time adjustment (scaling factor 0.01-100), and simulate acceleration/deceleration

Joint simulation: Connect third-party software (such as SIMIT) through API interfaces, supporting hardware interrupt simulation and synchronous control

Data management:

Virtual storage card: stores user programs, configuration data, supports backup/restore (only applicable to simulation environment)

Offline project provision: Create a "user-defined card reader" in STEP 7 and export project data to the virtual storage card directory

3. Common limitations and troubleshooting

Core limitations:

Does not support S7-1200 CPU, PROFINET/PROFIBUS fieldbus simulation

When communicating on a soft bus, multiple instances default to the same IP address and need to be started and downloaded one by one

Motion control simulation does not support isochronous mode or technical module logic

Typical faults and solutions:

Core causes of fault phenomena and solutions

Instance cannot start antivirus software interception, Npcap service is not running, add antivirus software exception, run 'net start npcap' in administrator mode

TCP/IP communication failure, virtual switch not activated, IP address conflict, activate virtual switch, ensure instance IP is unique and matches subnet

Project download failed due to incompatible CPU firmware version. Upgrade TIA Portal project firmware version and recreate simulation instance

Simulation lag/overflow scaling factor too high, insufficient system resources reduce virtual time scaling factor, close redundant background programs

Core content of 1FK6 series servo motor

1. Basic characteristics of the product

Type: Permanent magnet excitation three-phase synchronous servo motor, compatible with motor controlled AC converter, following the principle of sinusoidal current

Application scenarios: Drive and positioning of machine tools, production equipment, robots, and handling devices

Key parameters:

Category specific parameter notes

Protection level IP64 (basic model), optional IP65/IP67 driver end flange optional IP67

Working environment temperature -15 ℃~+40 ℃ Power coefficient 0.92 at 50 ℃, 0.82 at 60 ℃

Altitude adaptation ≤ 1000m (2000m coefficient 0.94, 2500m coefficient 0.9) requires load adjustment according to altitude

Structural parameters IM B5/V1/V3 installation form, self cooling bearings with permanent grease lubrication, maintenance free

Acoustic characteristics below 3000rpm: 55-70dB (A) 1FK6 03./04. Approximately 55dB (A), 1FK6 10. Approximately 70dB (A)

Electrical parameters: When the rotor rotates, the terminal voltage can reach 300V, and the brake is powered by 24V DC ± 10%. The brake is only used for emergency stop

2. Key operational procedures

Transportation and Storage:

Transportation requirements: The weight can reach 50kg, and lifting equipment that complies with Directive 98/37/EU must be used to avoid hitting the shaft end

Storage conditions: dry, low dust, low vibration (effective vibration<0.2mm/s), away from pacemaker wearers and electronic data media

Installation requirements:

Surface treatment: Use commercial solvents to remove the anti-corrosion agent from the shaft end, leaving a heat dissipation gap of ≥ 100mm

Fixed specification: Use hexagon socket screws with a strength grade of ≥ 8.8, and motors with integrated brakes are prohibited from bearing axial forces

Environmental taboos: Prohibited from use in explosive hazardous areas, vertical installation must prevent liquid from seeping into the upper bearing

Electrical connection:

Wiring specification: Use shielded power and signal wires, plug torque ≤ 12Nm (signal plug)/20Nm (1FK6 101/103 power plug)

Safe operation: Electrical work requires power-off inspection, following EN 50110-1 standard, and only professional personnel are allowed to operate

Start up and maintenance:

Pre start inspection: wiring fastening, activation of protective devices, brake testing (rotor rotates freely under 24V power supply)

Operating restrictions: maximum speed not exceeding the nameplate marking, surface temperature ≤ 140 ℃

Maintenance cycle: The bearing life is 20000 hours, and the radial shaft seal (oil lubrication) is about 5000 hours. After disassembly, the encoder needs to be recalibrated

3. Troubleshooting

Core causes of fault phenomena and solutions

Check for insufficient shielding of irregular motor/encoder cables and high controller gain, and adjust converter parameters for shielding and grounding

Abnormal vibration, unbalanced transmission components, poor alignment of the drive chain, loose screws. Rebalance the transmission components, correct alignment, and tighten screws

Motor overheating, overload, heat dissipation obstruction, load verification (refer to nameplate), clean surface to ensure ventilation

Contact the manufacturer for professional repair if there is abnormal noise during operation, foreign objects inside, or damaged bearings. Disassembly by oneself is prohibited

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

-

KEBA KeTop CB211 - Connection Box

-

KEBA HT4 / 20656 - Kammann Hand Held Keypad

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Y1-K1-Y2 PA9 - Engel Board Module

-

LTI MOTION CDA32.004C3.0 - Servo Drive 230V AC

-

KEBA E-CG-CONTROL - ECGCONTROL Module

-

KEBA Kemro K2-200 OP350/W 68334 - Engel EC200 Panel Membrane Touch Glass

-

KEBA i1075 - Membrane Keyboard

-

KEBA E-HSI-M - Interface Module

-

KEBA LQ10D321-ERSAT - ZTEILSET FNOB

-

KEBA E-16-DIGOUT/G - Circuit Board

-

KEBA HT4/Neutral/16846 - Mikron Handheld Terminal

-

KEBA KeTop CB310-000 - Connection Box

-

KEBA DC 161/IP20/17369 - Interface Card Module

-

KEBA E-16-DIGOUT-PLUS - Elektronik Bau Linz 262-1456-85-B

-

KEBA HT501 - Handheld Terminal

-

KEBA HT401-4X20 - Teach Pendant

-

KEBA E-3-ACU-10 D16738 - Controller Card Module

-

KEBA 240/A 068371 - Analog Output Module

-

KEBA E-7TEMP D1323E/F/G - Temperature Circuit Board

-

KEBA KeTop TT100-eaa - Communication Cable

-

KEBA E-16 DIGOUT-PLUS D1456D - Engel Output Board

-

KEBA Kemro K2-200 - Touch Panel Glass Digitizer

-

KEBA CC100A03/CAN/4 - PLC Chassis 16-Slot Rack Motherboard 1842E-0

-

KEBA CU 211 - PLC Power Supply

-

KEBA KeTOP CB310-S00 - Connection Box

-

KEBA I/O BUS KOPPLUNG D1547C - Engel Circuit Board

-

KEBA HCS01.1E-W0013-A-02 - Servo Drive

-

KEBA SMC1-Z30 - LTI Security Safety Control

-

KEBA E-PS88-M/C D1527C - Power Supply Board

-

KEBA D1678C / E-SEK - Control Board

-

KEBA 1.83E+02 - Circuit Board Module

-

LUST LTI/KEBA DSM4-05.4-20R.96-W1A - AC Servo Motor

-

Engel/KEBA OP 362-LD/W-5200 - Kemro Ke-200 Membrane Keypad Touch Screen

-

KEBA HT4 24V/0.2A - Kammann Hand Terminal C3052-R47

-

KEBA Kemro K2-200 BL210/B - Injection Molding Machine Controller Module

-

KEBA E-8-ANALOG D1432B - Analog Board

-

KEBA DM272 - Input Output Module

-

KEBA AR161 - PCB ML-EUMIG

-

KEBA E-PS-24V 1825E-1 - Power Supply Board

-

KEBA E-8-THERMO 1770B-1 - Engel Temperature Control Board

-

KEBA HT4-221-20556 - Kammann Hand Terminal

-

KEBA E-10-ANALOG-SUB D1458D - Circuit Board

-

KEBA AC 441 - Control Module 18-32 VDC

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA E-ANA-SUB2 D1690C - Analog Submodule Card

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad

-

KEBA OP 331/C-4400 - Keview V2 LCD Display Screen Panel

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923