K-WANG

Toshiba TOSBERT S7 series frequency converter

Toshiba TOSBERT S7 series frequency converter

Document Overview and Basic Equipment Information

Document positioning: Toshiba TOSBERT S7 series frequency converter official user manual, covering the entire process of equipment installation, wiring, operation, parameter setting, fault handling, and maintenance, suitable for professional users such as electrical engineers and operation and maintenance personnel.

Equipment specifications and models:

Voltage level, power range, applicable scenarios, typical model examples

200V level 0.4-75kW small and medium-sized motor (conveyor, small pump) S7-2037H (200V/37kW)

400V class 0.75-630kW medium and large motors (fans, compressors, large pumps) S7-4220H (400V/220kW)

High voltage 6.6kV/11kV high-power equipment (high-voltage fan, large compressor) S7-HV630 (6.6kV/630kW)

Model coding rules: Taking "S7-4055H" as an example, the meanings of each part are as follows:

S7: Series Code (TOSBERT S7 Series)

4: Voltage level (2=200V level, 4=400V level, HV=high voltage level)

055: Capacity (55kW, direct rated power of high voltage level such as 630)

H: Configuration (H=standard configuration, F=with brake unit, C=with communication module)

Core technical features:

High control accuracy: In sensorless vector control (SVC) mode, 150% of the rated torque can be output at 0.5Hz, and in sensorless vector control (FVC) mode, the speed accuracy is ± 0.01%.

Multi mode compatibility: supports three control modes: V/f control, SVC, FVC, and adapts to different load types such as fans, pumps, and machine tools.

Flexible protection level: The basic model has an IP20 rating (finger touch only), and an optional IP40 rating (solid foreign object intrusion prevention) to meet different environmental requirements.

Strong anti-interference ability: The control circuit is equipped with a built-in filter and supports the selection of common mode inductors to reduce electromagnetic interference (EMI).

Installation and wiring specifications

1. Installation requirements

Installation method:

200V level (≤ 75kW), 400V level (≤ 75kW): Only supports vertical wall mounted installation and needs to be fixed on a metal bracket with a load-bearing capacity of ≥ twice the weight of the frequency converter.

400V level (≥ 90kW), high voltage level: floor mounted, requiring a dedicated base with a height of ≥ 10cm (to prevent water damage on the ground).

Environmental restrictions:

Temperature: -10 ℃~40 ℃ (up to 50 ℃ for models without casing), exceeding this range requires the installation of a cooling fan or air conditioner.

Humidity: ≤ 90% RH, no condensation (dehumidification device needs to be installed in condensation environment).

Altitude: ≤ 1000m (for every 100m increase, the rated output power decreases by 1%, up to a maximum of 3000m).

Vibration: Acceleration ≤ 0.6G (10-50Hz), amplitude ≤ 0.08mm (50-150Hz), exceeding it requires the installation of damping pads.

Ventilation gap (Figure 2-1):

Model power, top/bottom gap, left/right side gap, back gap

≤75kW ≥10cm ≥5cm ≥10cm

90-220kW ≥15cm ≥10cm ≥15cm

≥250kW ≥20cm ≥15cm ≥20cm

2. Wiring specifications

(1) Main circuit wiring (power segment differences)

200V level (0.4-75kW) and 400V level (0.75-37kW) (Figure 3-1):

Terminal name, function, wiring requirements

The R/L1, S/L2, and T/L3 three-phase power inputs require a circuit breaker (MCCB) with a capacity of 1.2-1.5 times the rated current of the frequency converter

U. The output of the V and W 3-phase motors corresponds to the U, V, and W terminals of the motor, and can be reversed to exchange any two phases

PE protection grounding Class 3 grounding, grounding resistance ≤ 10 Ω, wire diameter ≥ 1/2 of the main circuit power wire diameter

When the B1 and B2 braking units/resistors need to be connected for braking, an external braking unit can be connected. If the power is ≤ 15kW, an internal braking resistor can be connected

400V level (≥ 45kW) and high voltage level (Figure 3-2):

Add "input reactor terminals (L1R, L2S, L3T)" and force external input reactors (to suppress harmonics and protect power modules).

The brake terminals are divided into "B1, B2 (main brake)" and "B3, B4 (auxiliary brake)", suitable for high-power braking requirements.

(2) Control circuit wiring

Analog inputs (AI1, AI2):

AI1: Default 0-10VDC (frequency command), can be switched to 4-20mA (load resistance ≤ 500 Ω) through parameter P07.01.

AI2: Default 4-20mA (torque command), switchable to 0-10VDC (parameter P07.02).

Switching input (DI1-DI8):

Default functions: DI1=forward rotation, DI2=reverse rotation, DI3=multi speed 1, DI4=multi speed 2, DI5=jog, DI6=reset, DI7=emergency stop, DI8=allowed operation.

Input method: leakage/source type optional (parameter P06.01), voltage 24Vdc ± 10%, current ≤ 10mA.

Communication interface:

Standard RS485 interface (terminals TX+, TX -, RX+, RX -), supports MODBUS-RTU protocol, baud rate 9600-115200bps (parameter P20.01).

Optional PROFINET (P21 parameter group) and EtherNet/IP (P22 parameter group) communication modules require separate wiring.

(3) Wiring taboos

Do not connect power factor compensation capacitors at the motor or power supply end (as it may cause overvoltage tripping of the frequency converter).

The control circuit cable needs to be shielded twisted pair (wire diameter 0.5-1.0mm ²), with a distance of ≥ 20cm from the main circuit cable, to avoid parallel wiring (reduce interference).

High voltage level frequency converters need to be separately connected to the high-voltage grounding grid and are prohibited from being grounded together with low-voltage equipment.

Operation process and core function settings

1. Operation panel and basic operations

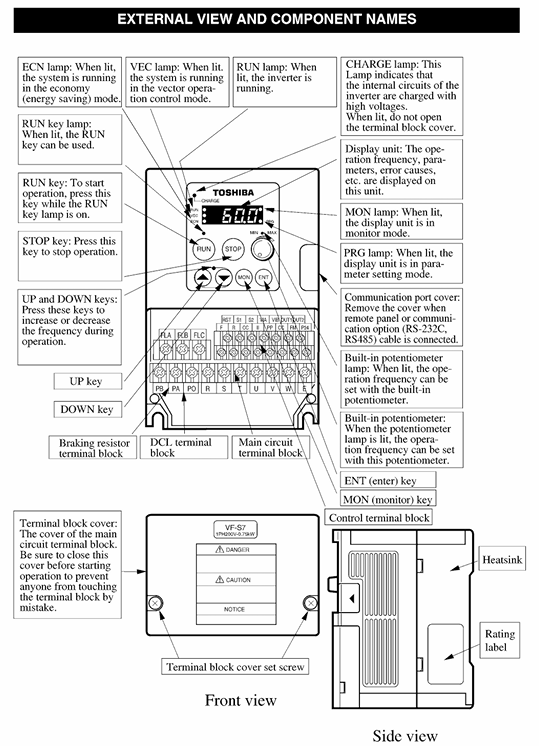

Panel layout (Figure 4-1): including a 5.7-inch LCD display screen (supporting Chinese/English switching), parameter knob (setting values), function keys (RUN/STOP/RESET/ESC/ENTER), and status indicator lights (power/run/fault).

Basic operation process (trial operation):

Power on: MCCB is closed, and the panel displays the "TOSHIBA" logo before entering the standby interface (displaying "0.0Hz").

Switch control mode: Press the "MODE" key, select "Panel Control" (parameter P05.01=0), and the "PANEL" indicator light will turn on.

Set frequency:

Knob adjustment: Rotate the parameter knob to the target frequency (such as 50Hz) and press "ENTER" to save.

Number input: Press the "NUM" key, enter "50", press "ENTER", and the display screen will show "50.0Hz".

Start/Stop: Press the "RUN" button to accelerate the frequency converter to the set frequency; Press the "STOP" button to slow down and stop (default soft stop time is 5 seconds, parameter P03.02 is adjustable).

2. Core functions and parameter settings

(1) Control mode setting (parameter P01 group)

Parameter code, parameter name, function description, optional values, default values, applicable scenarios

P01.01 Control mode selection switch V/f/SVC/FVC mode 0=V/f, 1=SVC, 2=FVC 1 (SVC) 0=fan/pump, 1=conveyor/machine tool, 2=high-precision speed regulation

P01.02 V/f Curve Type Voltage Frequency Relationship in V/f Mode 0=Linear, 1=Square (Fan/Pump), 2=Custom 1 1=Energy saving, 2=Special Load

P01.03 Torque Boost: In SVC/FVC mode, the starting torque compensation ranges from 0.0% to 30.0%, and increases when the low-speed starting torque is insufficient (such as for cranes)

(2) Torque control function (parameter P04 group)

Torque limit: P04.01 (forward torque limit), P04.02 (reverse torque limit), range 0-200% rated torque, default 150% (to prevent overload).

Torque following: enabled when P04.05=1, torque is controlled through AI2 input 4-20mA signal, suitable for coiling machines and tension control equipment.

Zero speed torque maintenance: When P04.08=1, 0Hz can maintain 150% of the rated torque (requiring FVC mode+encoder feedback), suitable for elevators and hoists.

(3) Multi speed and brake control

Multi speed operation (parameter P08 group):

Supports 16 speeds (S1-S16), selected through DI3-DI6 terminal combination (such as DI3=ON → S1, DI3+DI4=ON → S2).

Each speed value is set through P08.01 (S1) - P08.16 (S16), with a range of 0.0-400.0 Hz.

Brake control (parameter P09 group):

DC injection braking: P09.01=1 enabled, starting frequency 0-10Hz (P09.02), braking voltage 0-30% (P09.03), braking time 0.1-10.0 seconds (P09.04), suitable for precise positioning.

Regenerative braking: P09.10=1 enabled, requires external braking unit (400V level ≥ 45kW forced external connection), braking torque 0-100% (P09.11), suitable for inertial loads (such as centrifuges).

(4) Energy saving function (parameter P15 group)

Fan/pump energy-saving mode (P15.01=1): Automatically adjusts the output voltage according to the load current, saving 5-15% energy compared to the normal V/f mode.

Automatic sleep/wake-up (P15.05=1): When the frequency is below the sleep threshold (P15.06, default 5.0Hz) and the duration exceeds the set value (P15.07, default 10 seconds), the inverter will shut down; Automatically wake up when the load increases.

Troubleshooting and Maintenance

1. Common fault codes and solutions

Fault code, fault type, possible causes, and solutions

OC1 acceleration overcurrent 1. The acceleration time is too short; 2. Motor short circuit; 3. Excessive load: 1. Increase P03.01 (acceleration time); 2. Check the insulation of the motor winding; 3. Reduce load or replace high-power frequency converter

OH1 power module overheating 1. Cooling fan failure; 2. Insufficient ventilation gap; 3. If the ambient temperature is too high, replace the fan (model FS-1238); 2. Adjust the installation spacing to the standard value; 3. Install a heat dissipation device

OV1 DC bus overvoltage: 1. The power supply voltage is too high; 2. Excessive regenerative energy; 3. The deceleration time is too short. 1. Check the grid voltage (within ± 10% of the rated voltage); 2. External braking unit; 3. Increase P03.02 (deceleration time)

GF grounding fault 1. Motor grounding short circuit; 2. Internal grounding of the frequency converter; 3. Cable damage: 1. Use a megohmmeter to measure the insulation of the motor (≥ 500M Ω); 2. Contact after-sales maintenance; 3. Replace damaged cables

Err12 communication fault: 1. Communication cable disconnected; 2. Baud rate mismatch; 3. Incorrect slave station address. 1. Check the RS485 wiring; 2. Unified master-slave station baud rate (P20.01); 3. Confirm the slave station address (P20.02)

2. Maintenance plan

Regular inspection (every 6 months):

Appearance inspection: Check whether the cabinet is deformed, whether the cables are damaged, and whether the terminals are oxidized.

Tightening inspection: Main circuit terminal screws (torque values see Table 5-1) and control circuit terminal screws to prevent loosening and heating.

Heat dissipation cleaning: Use compressed air (below 0.3MPa) to clean the dust on the heat dissipation fan and fins. If the fan makes abnormal noise, it needs to be replaced.

Insulation test: Disconnect the power supply and use a 500V megohmmeter to measure the insulation of the main circuit (≥ 10M Ω) and control circuit (≥ 100M Ω).

Regular testing (every 2 years):

Capacitor detection: Measure the capacitance of the DC bus (attenuation ≤ 20% is normal). If it exceeds the tolerance, it needs to be replaced (model CBB65).

Module detection: Use a multimeter to test the conductivity of the power module (IGBT), and replace the module if there is an abnormality.

Parameter backup: Back up the current parameters through the panel or software to prevent parameter loss.

Long term storage (≥ 6 months):

Environment: Temperature -20~40 ℃, humidity ≤ 60%, no corrosive gases.

Activation: Power on every 6 months (no load, voltage gradually increases from 0 to rated value for 30 minutes) to prevent capacitor aging.

Optional accessories and warranty terms

Optional accessories:

Accessory Type Model Example Function Applicable Scenarios

Input reactor ACL-4055 suppresses grid harmonics and protects power modules with 400V level ≥ 45kW mandatory selection

Braking unit BU-4220 enhances regenerative braking capability and absorbs braking energy inertia load (centrifuge, elevator)

The communication module MOD-PN supports PROFINET communication to achieve industrial Ethernet control of automated production lines

External control panel OP-S7 remote operation, cable length 1-10m. The frequency converter is installed inside the control cabinet and is inconvenient to operate directly

Filter EMI-4037 suppresses electromagnetic interference and meets EN 55011 standard near medical equipment and precision instruments

Warranty terms:

Warranty period: 12 months from the date of delivery, and 3 months for parts warranty.

Warranty scope: Malfunctions caused by equipment quality issues, including repair and replacement of parts.

Warranty expiration situation:

Unauthorized disassembly or modification of the frequency converter (such as replacing non original parts).

Installation/wiring does not comply with the instructions (such as poor grounding, overvoltage operation).

Damage caused by natural disasters (earthquakes, floods), power grid failures (lightning strikes, voltage surges).

Used for non industrial purposes (such as household appliances) or operating beyond rated parameters (such as overload, overclocking).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923