K-WANG

SCHNEIDER Magelis XBT GT/GK/GH Series Human Machine Interface (HMI) Hardware Guide

SCHNEIDER Magelis XBT GT/GK/GH Series Human Machine Interface (HMI) Hardware Guide

The hardware guide for Schneider Magelis XBT GT/GK/GH series human-machine interface (HMI) covers five core modules: product model specifications, device connections, installation and wiring, settings, debugging, and maintenance. It supports 24Vdc power supply and has a protection level of IP65. It is compatible with Vijeo Designer V6.2 software and provides multiple screen sizes ranging from 3.8 inches to 15 inches (resolution 320x240~1024x768 pixels). It has serial/Ethernet/USB multi interface communication capabilities and supports CF card data storage and external device expansion. It also includes detailed installation steps, troubleshooting plans, and regular maintenance requirements, making it suitable for industrial automation control scenarios.

Document Overview

(1) Core positioning and scope of application

Category key information

Document purpose: Hardware installation, connection configuration, setting and debugging, maintenance and upkeep of XBT GT/GK/GH series HMI

Applicable software Vijeo Designer V6.2 (development software)

Target users: Industrial automation engineers and equipment maintenance personnel

Compliance standards UL 508, CSA C22.2, IEC 60529 (IP65), CE certification

Environmental compliance complies with RoHS and WEEE directives

(2) Product series classification

Series Core Features Screen Size Range Typical Models

XBT GT touch screen as the main feature, supporting Ethernet/USB expansion of 3.8 "~15" GT1135 (3.8 "color), GT5330 (10.4" color), GT7340 (15 "color)

XBT GK with industrial pointer+keyboard, supports multi key operation 5.7 "~10.4" GK2330 (5.7 "color), GK5330 (10.4" color)

XBT GH handheld model with emergency switch/enable switch 5.7 "GH2460 (5.7" color touch screen)

Core specifications of the product

(1) Electrical and Environmental Specifications

Specification item values

Rated power supply 24Vdc (voltage range 19.2~28.8Vdc)

Maximum power consumption of 50W (GT7000 series)

Working temperature: 0~50 ℃ (GT series), 0~40 ℃ (GK/GH series)

Storage temperature -20~60 ℃

Protection level: front panel IP65, rear panel IP20 (GT/GK); Full machine IP65 (GH)

Grounding requirements: Grounding resistance ≤ 100 Ω, grounding wire cross-section ≥ 2mm ²

(2) Display and hardware configuration

Key parameters of configuration items

Display technology STN (monochrome/4096 colors), TFT (256 colors~65536 colors)

Resolution 320x240 (QVGA)~1024x768 (XGA)

Backlight lifespan: CFL backlight 50000-75000 hours, LED backlight over 50000 hours

Touch screen analog 1024x1024 resolution, with a press life of over 1 million times

Memory configuration: Flash EPROM 16~32MB, DRAM 16~64MB, backup SRAM 128~512KB (powered by lithium battery)

Extended storage CF card (128MB~1GB), supporting recipe/historical data/alarm data storage

(3) Interface specifications

Interface type configuration details

Serial ports COM1 (RS-232C/RS-422/RS-485), COM2 (RS-485), baud rate 2400~115200 bps

Ethernet RJ45 interface, 10/100Base TX (not available on some models)

USB interface USB 1.1 host interface (TYPE-A), supports data transfer and peripheral connection

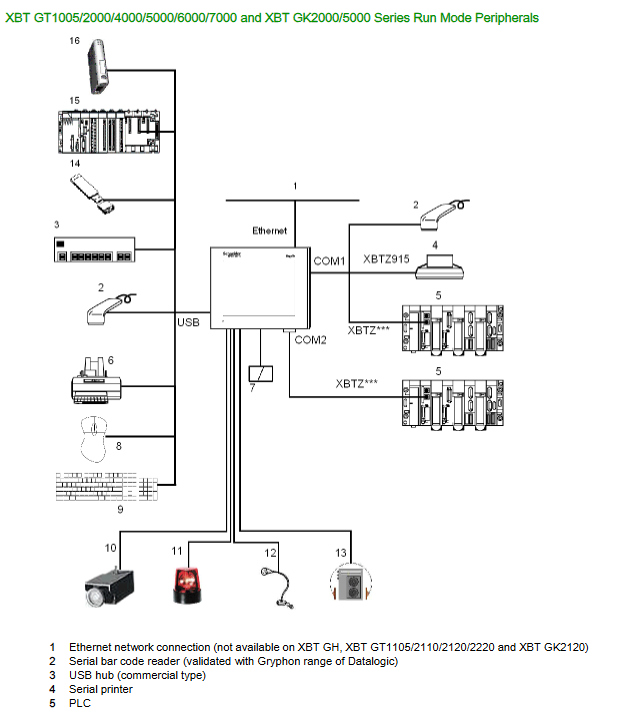

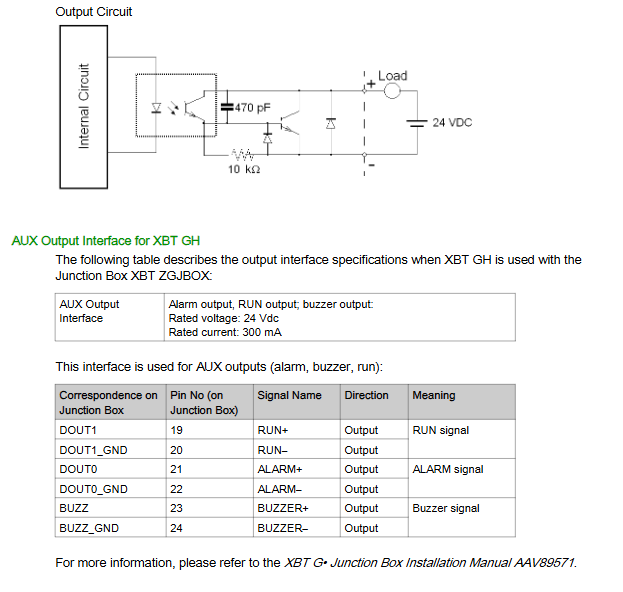

Expansion interface AUX interface (external reset/alarm output/audio output), video input (only GTxx40 model)

Equipment connection and accessories

(1) Core accessory list

Accessory type, model, example usage

Communication cable XBT Z915 COM port connected to printer

XBT Z9780 connected to Premium/Micro/Twido PLC

XBT ZG935 USB data transmission cable (connected to PC and HMI)

Storage accessories XBT ZGM128/XBT ZGM256 128MB/256MB CF card

Installation accessory XBT Z3002 spring clamping fastener (IP65 protection)

XBT ZG52/XBT ZG55 installation gasket (annual replacement)

Protective accessories XBT ZGEGD XBT GH emergency switch cover

XBT ZG60~XBT ZG69 screen protector

(2) Extended device support

Industrial control equipment: PLC from brands such as Modicon, Siemens, Omron, etc

Input/output devices: serial/parallel port printer, barcode reader (Datalogic Gryphon series)

Multimedia devices: Camera (NTSC/PAL standard, only supported by GT4340/5340/6340/7340), microphone/speaker

Storage devices: USB flash drive, CF card reader

Installation and wiring

(1) Installation process

Panel opening: Install holes according to device size (e.g. GT1005 series opening 118.5x92.5mm)

Equipment fixation: Choose spring clips (panel thickness 1.5~6mm) or screws (panel thickness 1.6~10mm) for fixation, with a torque of ≤ 0.5Nm

Gasket inspection: Confirm that the installed gasket is intact, protruding about 2mm from the groove, and avoiding corners at the joint

Distance requirement: The distance between the equipment and surrounding objects should be ≥ 100mm to avoid direct heat dissipation from high-temperature equipment

(2) Wiring specifications

Key requirements for wiring types

The cross-sectional area of the power wiring wire is 0.2~2.5mm ², with the positive and negative poles connected correctly, and the cross-sectional area of the grounding wire is ≥ 2mm ²

Communication wiring: Serial port cables should avoid high-voltage lines, and Ethernet cables should use RJ45 connectors to avoid mixing serial/network ports

Grounding specification: Independent grounding (resistance ≤ 100 Ω) to avoid electromagnetic interference caused by common grounding with other equipment

Wiring requirements: Input/output signal lines should be arranged separately from power lines, and shielded cables should be used for long distances

(3) Special installation requirements

XBT GH Handheld Type: Install emergency switch cover (torque 0.5Nm), equipped with hand strap to prevent falling

Tilt installation: Panel tilt angle ≤ 30 °, if exceeded, ambient temperature ≤ 40 ℃

Wet environment: Regularly check the sealing of the gasket and replace it once a year

Setting and Debugging

(1) Basic Settings

Set key parameters for type operation path

Network Settings Offline Settings → Network IP Address, Subnet Mask, Gateway (only supports Ethernet models)

System Settings ->Date/Time Date Format (DD/MM/YYYY, etc.), Time Synchronization

Display Settings System Settings → Brightness/Contrast 8-16 Level Adjustment, Reduce Brightness and Extend Backlight Life

Buzzer Settings Offline Settings → Buzzer Mode: Turn Off/Sound When Touched

(2) Troubleshooting

Troubleshooting steps and solutions

Display blank 1. Check the power supply voltage; 2. Confirm whether the backlight is burned out; 3. Verify if the application is downloaded. 1. Repair the power connection; 2. Replace the backlight; 3. Download the application again

Communication failure 1. Check cable connection; 2. Verify the driver configuration; 3. Test whether the interface is normal. 1. Reconnect the wiring; 2. Match device drivers in Vijeo Designer; 3. Run self-test test

Touch unresponsive 1. Calibrate the touch screen; 2. Check if there are any foreign objects obstructing; 3. Test touch panel 1. System settings → Calibration; 2. Clean the screen; 3. Offline settings → Self testing → Touch panel testing

Date cannot be saved. 1. Check the backup battery; 2. Confirm that the device is continuously powered on. 1. Contact the service provider to replace the battery; 2. Ensure continuous power supply and 24-hour charging of the equipment

(3) Self testing function

Support test items: character display, screen pattern, touch panel, serial port (COM1/COM2), video memory

Test path: Offline settings → Self testing, normal display shows "OK", abnormal display shows "NG"

Maintenance and upkeep

(1) Regular maintenance

Maintenance project cycle operation requirements

Screen cleaning should be done with neutral detergent and a soft cloth to avoid organic solvents

Replace aging/damaged gaskets once a year to ensure IP65 protection

Environmental inspection once a quarter to confirm that the working temperature/humidity is within the specified range and there are no corrosive gases

Cable inspection is conducted every six months to ensure that the cable connections are securely fastened and free from damage or aging

(2) Component replacement

Backlight replacement: Support models (GT5000 series, GT6330 RL08 and below), cool down for 10 minutes before replacement, wear gloves

Battery replacement: The backup battery has a lifespan of 10 years (≤ 25 ℃) and cannot be replaced by oneself. Please contact an authorized service provider

CF card maintenance: Regularly backup data, write frequency ≤ 100000 times, avoid frequent overwriting

(3) Lifespan and Protection

Key component lifespan: backlight 50000-75000 hours, touch screen pressing>1 million times, CF card writing 100000 times

Protective precautions: Avoid screen impact and liquid splashing, and avoid dropping handheld models (passing the 1-meter drop test)

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Automation Module

-

HIMA K9203 PLC Module | Safety Control System Module

-

HIMA F60AI801 PLC Module | Analog Input Module

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Module

-

HIMA K9203 PLC Module | Safety Automation Module

-

X-DO1201 HIMA Control Pulse Card | Digital Output Module

-

F6705 HIMA Analog Output Module | Safety Control Output Module

-

HIMA B9361 PLC Module | Safety Automation System Module

-

HIMA H41Q-HRS / H41QX PLC Module | Safety Automation Module

-

HIMA F3003 Controller Unit | HIMAtrix Compact Safety Controller

-

HIMA HIMatrix F1DI1601 PLC Module | Digital Input Module for Safety Systems

-

HIMA X-DI 64 51 PLC Module | Digital Input Module for Safety Automation

-

HIMA F30 Controller Unit HIMAtrix 01 OPEN | Safety PLC Controller

-

HIMA K9202B PLC Module | Safety-Oriented Control Module

-

HIMA F3DIO20802 Controller PLC Module | Digital I/O Control for Safety Automation

-

HIMA F8627-1 F8627X Communication Module | Safety System Communication Interface

-

HIMA B4237-2 PLC Module | Safety Control and Logic Processing Module

-

HIMA X-DO2401 PLC Module | Digital Output Module for Safety Automation

-

HIMA 22100 PLC Module | Industrial Safety Control and Logic Processing

-

HIMA 90100 PLC Module | Safety-Oriented Industrial Control Module

-

HIMA 895210001 PLC Module | Industrial Safety Control and Processing Module

-

HIMA 157528-0 PLC Module | Industrial Safety Control and Processing Module

-

HIMA B5322 PLC Module | Industrial Safety Control and Processing Module

-

HIMA BV7032 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F3300 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7105A PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7150 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7508 PLC Module | Industrial Safety Control Processing Module

-

HIMA F8627 984862765 PLC Module | Industrial Safety Control Module

-

HIMA M3410 PLC Module | Industrial Safety Control Processing Module

-

HIMA Z7308 PLC Module | Safety Control System Processing Module

-

F8640 HIMA Central Module | Safety System Core Controller

-

HIMA F8630 Module | Safety System Functional Module

-

F8651X HIMA Central Module | Safety System Core Controller

-

F3236 Digital Input Module | HIMA Safety System Input Interface

-

F7131 HIMA Power Monitoring Module | Safety System Power Supervision

-

F8627X HIMA Communication Module | Safety System Network Interface

-

HIMA F8560X PLC Module | Safety-Related Control System Component

-

HIMA P8403 PLC Module – Industrial Safety Control Processor

-

HIMA F8628X Communication Module – Industrial Safety System Interface

-

HIMA F8621A Communication Module – Safety System Communication Interface

-

HIMA 984865066 PLC Module – Safety Control Processing Unit

-

HIMA F60CPU01 PLC Module – Safety Control Processing Unit

-

HIMA F8650E PLC Module – Safety Control Processing Unit

-

HIMA F8652E Central Module – Safety Control Processing Unit

-

HIMA F8650X Card – Safety Central Processing Module

-

F8652X HIMA Central Module – Safety Control Central Processing Unit

-

HIMA 99-7105233 B5233-1 Safety Module – Industrial Safety Control Component

-

KEBA KeTop T70-rqa-AK0-LK Teaching Device – Industrial Robot Teach Pendant

-

KEBA KETOP T50-T41-CPU 2495D-0 – Industrial CPU Module

-

KEBA E-CON-CC100/A/ 22178 – Industrial Controller Module

-

KEBA Kemro K2-200 CP 250/X 71580 CPU-MODULE – Industrial Control CPU Module

-

KEBA D3‑DA 330/A‑1211‑00 Drive – KeDrive D3 Axis Controller Industrial Servo Drive

-

KEBA KETOP O70‑bra‑A0a‑F Demonstrator – Industrial Automation Control Module

-

KEBA KETOP O70-BRA-A0A-F Demonstrator | Industrial HMI Operating Terminal

-

KEBA SO84.012.0083.0101.2 Servo Drive | Industrial Motion Control Solution

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

XYCOM 1546 - Proface Industrial Workstation 1546-102031013

-

XYCOM 86864-002-E - Processor Board Module

-

XYCOM 3112T - Pro-face Operator Interface

-

XYCOM 3712 KPM - Pro-face Operator Panel

-

XYCOM 4615KPMT - Proface Industrial PC Display Panel PM-070007

-

XYCOM 5015T - Pro-Face Touch Monitor 100-240 VAC

-

XYCOM 5015T/R2 - Industrial Flat Panel Touch Monitor 5015R2-0100000

-

XYCOM 1341 - Proface Embedded Computer TF-AEC-6920-C2

-

XYCOM GLC150-BG41-DN - Graphic Logic Controller M-24V

-

XYCOM GP2301H-SC41-24V - Pro-face Operator Interface 5.7" w/ Cable

-

XYCOM 1547 - Pro-face Industrial PC Model 1547-00113101

-

XYCOM ST401-AG41-24V - Graphic Touchscreen Operator Interface

-

XYCOM 3310T - Pro-face Operator Panel 3310-001101001

-

XYCOM 5015 KPMT - Proface Operator Panel Display

-

XYCOM XVME-684 - PC Module VME Bus Processor 70684-201

-

XYCOM 3300 MT - Screen Monitor Display

-

XYCOM SXT1811T - Touch Panel Monitor 100/240VAC

-

XYCOM XT-1502 - Touch Screen Monitor Flat Panel Display Interface

-

XYCOM SXT1811 - Viewtronix SXGA Flat Panel Monitor 18.1" Display

-

XYCOM VT1040T - ViewTronix Touch Screen Monitor

-

XYCOM WS2786291 - Industrial Workstation PC

-

XYCOM XCME-540 - Analog I/O Module VMEbus 70540-001

-

XYCOM XVME-682 - CPU PCB Processor Module 70682-101

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923