K-WANG

SCHNEIDER Magelis range Graphic XBT-F / TXBT-F Instruction Manual

SCHNEIDER Magelis range Graphic XBT-F / TXBT-F Instruction Manual

The complete operation and development manual for Schneider Graphic Magelis series human-machine interface (HMI) terminals (including XBT-F, TXBT, and touch screen models) revolves around the XBT-L1000 software for application development, terminal operation, PLC communication, and fault handling. It supports core functions such as page design (application/alarm/help/recipe page), variable reading and writing, alarm management (priority/grouping/log), PLC data interaction (dialog box table), etc. The terminal protection level reaches IP65, supports 16 levels of alarm priority, 500 alarm log storage, adapts to multiple communication protocols such as UNI-TELWAY and Modbus, and is widely used in industrial automation control scenarios. It also provides detailed application development examples and fault troubleshooting solutions.

Document Overview

(1) Core positioning and scope of application

Category key information

Application development, installation and configuration, operation and troubleshooting of Graphic Magelis series terminals for document purposes

Applicable products XBT-F (5.7 "/10.4" buttons/touch screen), TXBT (with 1.6Gb hard drive, supports Windows 95)

Core tool XBT-L1000 development software (requires V3.3 or above version, compatible with firmware V2.1.15+)

Target users include industrial automation engineers, equipment maintenance personnel, and application developers

Application scenarios include production line monitoring, equipment control, parameter configuration, and fault alarm (compatible with PLCs such as Modicon and Siemens)

(2) Core Compliance and Security Requirements

Safety warning: Only authorized personnel are allowed to operate. Interruption of PLC communication may cause equipment to lose control, and redundant logic needs to be programmed

Protection level: Terminal protection level IP65 (compliant with IEC529), suitable for harsh industrial environments

Certification standards: UL 4/4x, NEMA 4, CE certification, meeting international industrial standards

Application development (based on XBT-L1000 software)

(1) Development process

Requirement specification: Clearly define user operation, control logic, and data interaction requirements

Page design: Create template pages (application/alarm/help/recipe), reuse common elements (logo, status line)

Content configuration: Add static text/graphics, dynamic variables (numerical/bar chart/curve), function keys

Dialogue box table configuration: Define the interaction data between PLC and terminal (up to 135 words)

Simulation testing: Terminal/PLC simulation to verify page navigation and data interaction

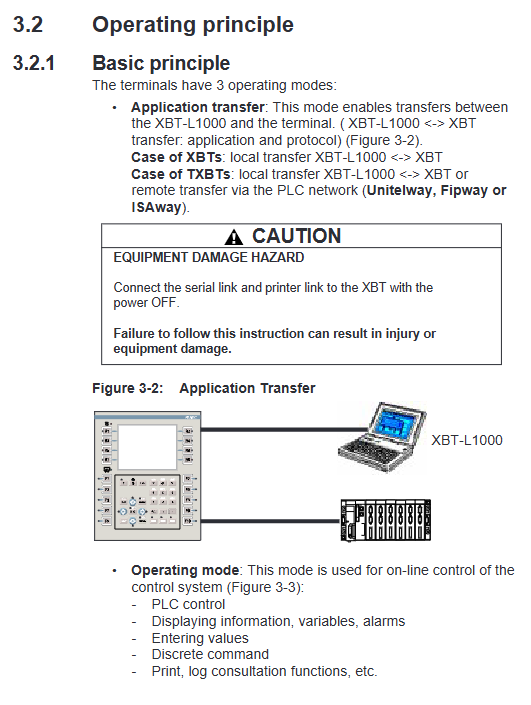

Application transmission: Local (serial port) or remote (PLC network) transmission to the terminal

Operation and maintenance: supports application updates, log queries, and troubleshooting

(2) Page type and function

Page Type Core Usage Key Features

Application page device monitoring and parameter input support static/dynamic elements, password protected

Alarm page fault prompt and handling with 16 priority levels and 16 alarm groups, supporting relay linkage

Help page operation guide can be associated with application/alarm pages, supporting multiple languages

Formula page parameter storage and reuse with 125 records and 5000 variables, supporting PCMCIA storage

Form page data printing is only for printing purposes and supports barcode and table formats

(3) Core configuration items

Multi language support: up to 3 languages, capable of translating system/custom text

Password protection: Level 3 password (A/B/C), controls page/field access permissions

Variable configuration: supports single character/double character/floating point/bit variables, can set threshold (Min/L/H/Max) and color linkage

Function key configuration: static keys (globally effective), dynamic keys (page specific), supporting jog/self-locking commands

Terminal operation

(1) Basic Operations

Page navigation: Switch between static/dynamic function keys, page numbers, and PLC commands (supports password protected pages)

Variable input: numerical input (keyboard), graphic input (slider/knob), supports instant writing/confirm writing

Print Control: Supports printing of alarm logs, form pages, and screenshots (TXBT supports SHIFT+RINT)

(2) Alarm management

Detailed Function Description

Alarm triggers PLC bit signal activation, supports multi PLC alarm distribution

Priority levels 1-16 (with 1 being the highest), high priority alarms are displayed first

Confirmation methods: manual confirmation (ENTER key), automatic confirmation (fault recovery)

500 events (triggered/confirmed/restored) are stored in the log, with timestamp records

Group management of 16 alarm groups, each with independent color identification

(3) Featured Features

Formula management: Store production parameters, support freezing/saving/restoring/transferring to PLC

TXBT exclusive: Running Windows 95 applications (such as calculators), external keyboard, ISA bus extension

Variable adjustment: Supports 16 adjustment pages, up to 448 variables (10 "terminal), supports symbol import (PL7/Concept)

PLC communication

(1) Communication Protocol and Link

Supported protocols: UNI-TELWAY, FIPWAY, Modbus, Modbus+, Jbus, etc. (downloadable)

Physical link: RS232/RS422/RS485 (serial port), PLC network (remote transmission)

Terminal role: Master/Slave mode, default client (actively reading and writing PLC data)

(2) Dialogue box table (core interactive medium)

Example of table type functional keywords

Status table (terminal → PLC) sends terminal status, button information, alarm confirmation result display page number (% MWn+8), button image (% MWn+0)

Command table (PLC → terminal) controls page switching, key locking, alarm triggering page switching (% MWn+16), key locking (% MWn+27)

Alarm table (PLC → terminal) triggers an alarm, with a maximum of 61 words (XBT)/125 words (TXBT) alarm bits (% MWn+30~% MWn+90)

Secure dialogue authorization to prevent illegal interaction of authorization words (% MWn+20), matching XBT-L1000 configuration values

(3) Interaction cycle optimization

Optimization mode: Variables are grouped by page and assigned to consecutive addresses to reduce communication volume

Refresh cycle: The dialog table cycle can be configured, and the variable supports cyclic/single/instant refresh

Communication monitoring: Monitor communication status through% MWn+3 words to prevent disconnection and loss of control

Technical specifications and troubleshooting

(1) Core technical specifications

Terminal type, screen specifications, function keys, storage capacity, working environment

XBT-F 5.7 "320x240 pixels, 16 grayscale static 10, dynamic 8 alarm logs 500 entries 0~45 ℃, 0~85% humidity

XBT-F 10.4 "640x480 pixels, 256 colors, 12 static and 10 dynamic formulas, 125 records, 0~45 ℃, 0~85% humidity

TXBT 10.4 "640x480 pixels, 256 colors, 12 static and 10 dynamic 1.6Gb hard drives, 0~45 ℃, 0~85% humidity

Touch screen 5.7 ", 320x240 pixels, 256 colors, 6x8 touch area alarm log 500 records, 0~45 ℃, 0~85% humidity

(2) Common faults and solutions

Possible causes and solutions for fault phenomena

Application transmission failed due to cable error and incorrect terminal mode. Check the XBT-Z915 cable and confirm that the terminal is in transmission mode

Alarm does not display PLC alarm bit not activated, priority configuration error check dialog box table alarm word, confirm alarm priority ≥ current display level

Variable read/write failed due to incorrect address and protocol mismatch. Please verify the variable address and PLC configuration, and confirm that the protocol has been downloaded

No response to PLC button lock, password not entered. Check for% MWn+27~% MWn+29 lock word, enter corresponding password

Application Development Example

Taking industrial bakery production control as an example, fully demonstrate:

Requirement analysis: dough preparation (parameter input), baking monitoring (temperature monitoring), maintenance mode (password protection)

Page design: Main menu → Production menu → Preparation/baking page → Maintenance page, associated with help page and alarm page

Function configuration: Static keys (start/stop), dynamic variables (raw material consumption, temperature curve), alarm (temperature exceeding limit)

Communication configuration: dialog table address% MW100, including page number, button status, and alarm bit

Test transmission: After simulation verification, transmit to the terminal through serial port and run debugging

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Automation Module

-

HIMA K9203 PLC Module | Safety Control System Module

-

HIMA F60AI801 PLC Module | Analog Input Module

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Module

-

HIMA K9203 PLC Module | Safety Automation Module

-

X-DO1201 HIMA Control Pulse Card | Digital Output Module

-

F6705 HIMA Analog Output Module | Safety Control Output Module

-

HIMA B9361 PLC Module | Safety Automation System Module

-

HIMA H41Q-HRS / H41QX PLC Module | Safety Automation Module

-

HIMA F3003 Controller Unit | HIMAtrix Compact Safety Controller

-

HIMA HIMatrix F1DI1601 PLC Module | Digital Input Module for Safety Systems

-

HIMA X-DI 64 51 PLC Module | Digital Input Module for Safety Automation

-

HIMA F30 Controller Unit HIMAtrix 01 OPEN | Safety PLC Controller

-

HIMA K9202B PLC Module | Safety-Oriented Control Module

-

HIMA F3DIO20802 Controller PLC Module | Digital I/O Control for Safety Automation

-

HIMA F8627-1 F8627X Communication Module | Safety System Communication Interface

-

HIMA B4237-2 PLC Module | Safety Control and Logic Processing Module

-

HIMA X-DO2401 PLC Module | Digital Output Module for Safety Automation

-

HIMA 22100 PLC Module | Industrial Safety Control and Logic Processing

-

HIMA 90100 PLC Module | Safety-Oriented Industrial Control Module

-

HIMA 895210001 PLC Module | Industrial Safety Control and Processing Module

-

HIMA 157528-0 PLC Module | Industrial Safety Control and Processing Module

-

HIMA B5322 PLC Module | Industrial Safety Control and Processing Module

-

HIMA BV7032 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F3300 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7105A PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7150 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7508 PLC Module | Industrial Safety Control Processing Module

-

HIMA F8627 984862765 PLC Module | Industrial Safety Control Module

-

HIMA M3410 PLC Module | Industrial Safety Control Processing Module

-

HIMA Z7308 PLC Module | Safety Control System Processing Module

-

F8640 HIMA Central Module | Safety System Core Controller

-

HIMA F8630 Module | Safety System Functional Module

-

F8651X HIMA Central Module | Safety System Core Controller

-

F3236 Digital Input Module | HIMA Safety System Input Interface

-

F7131 HIMA Power Monitoring Module | Safety System Power Supervision

-

F8627X HIMA Communication Module | Safety System Network Interface

-

HIMA F8560X PLC Module | Safety-Related Control System Component

-

HIMA P8403 PLC Module – Industrial Safety Control Processor

-

HIMA F8628X Communication Module – Industrial Safety System Interface

-

HIMA F8621A Communication Module – Safety System Communication Interface

-

HIMA 984865066 PLC Module – Safety Control Processing Unit

-

HIMA F60CPU01 PLC Module – Safety Control Processing Unit

-

HIMA F8650E PLC Module – Safety Control Processing Unit

-

HIMA F8652E Central Module – Safety Control Processing Unit

-

HIMA F8650X Card – Safety Central Processing Module

-

F8652X HIMA Central Module – Safety Control Central Processing Unit

-

HIMA 99-7105233 B5233-1 Safety Module – Industrial Safety Control Component

-

KEBA KeTop T70-rqa-AK0-LK Teaching Device – Industrial Robot Teach Pendant

-

KEBA KETOP T50-T41-CPU 2495D-0 – Industrial CPU Module

-

KEBA E-CON-CC100/A/ 22178 – Industrial Controller Module

-

KEBA Kemro K2-200 CP 250/X 71580 CPU-MODULE – Industrial Control CPU Module

-

KEBA D3‑DA 330/A‑1211‑00 Drive – KeDrive D3 Axis Controller Industrial Servo Drive

-

KEBA KETOP O70‑bra‑A0a‑F Demonstrator – Industrial Automation Control Module

-

KEBA KETOP O70-BRA-A0A-F Demonstrator | Industrial HMI Operating Terminal

-

KEBA SO84.012.0083.0101.2 Servo Drive | Industrial Motion Control Solution

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

XYCOM 1546 - Proface Industrial Workstation 1546-102031013

-

XYCOM 86864-002-E - Processor Board Module

-

XYCOM 3112T - Pro-face Operator Interface

-

XYCOM 3712 KPM - Pro-face Operator Panel

-

XYCOM 4615KPMT - Proface Industrial PC Display Panel PM-070007

-

XYCOM 5015T - Pro-Face Touch Monitor 100-240 VAC

-

XYCOM 5015T/R2 - Industrial Flat Panel Touch Monitor 5015R2-0100000

-

XYCOM 1341 - Proface Embedded Computer TF-AEC-6920-C2

-

XYCOM GLC150-BG41-DN - Graphic Logic Controller M-24V

-

XYCOM GP2301H-SC41-24V - Pro-face Operator Interface 5.7" w/ Cable

-

XYCOM 1547 - Pro-face Industrial PC Model 1547-00113101

-

XYCOM ST401-AG41-24V - Graphic Touchscreen Operator Interface

-

XYCOM 3310T - Pro-face Operator Panel 3310-001101001

-

XYCOM 5015 KPMT - Proface Operator Panel Display

-

XYCOM XVME-684 - PC Module VME Bus Processor 70684-201

-

XYCOM 3300 MT - Screen Monitor Display

-

XYCOM SXT1811T - Touch Panel Monitor 100/240VAC

-

XYCOM XT-1502 - Touch Screen Monitor Flat Panel Display Interface

-

XYCOM SXT1811 - Viewtronix SXGA Flat Panel Monitor 18.1" Display

-

XYCOM VT1040T - ViewTronix Touch Screen Monitor

-

XYCOM WS2786291 - Industrial Workstation PC

-

XYCOM XCME-540 - Analog I/O Module VMEbus 70540-001

-

XYCOM XVME-682 - CPU PCB Processor Module 70682-101

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923