K-WANG

SERVOSTAR ® CD series servo amplifier

SERVOSTAR ® CD series servo amplifier

Basic Information

Product positioning: SERVOSTAR ® The CD series is an industrial grade servo amplifier launched by Danaher Motion, covering three models: Cx03 (3A continuous), Cx06 (6A continuous), and Cx10 (10A continuous), suitable for high-precision motor control scenarios. It has passed UL/cUL 508C certification (US and Canadian markets) and CE certification (EU market), and needs to be integrated into industrial equipment for use.

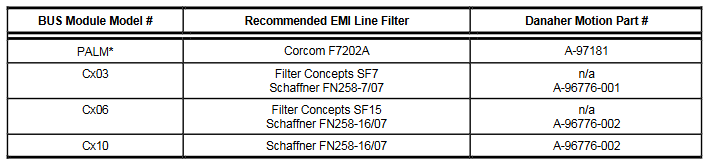

Core support: The document comes with a CD-ROM, which includes a technical manual (in PDF format), MOTIONLINK debugging software, and Adobe Acrobat Reader installation program; Hardware needs to be equipped with motors, feedback devices (encoders/rotary transformers), optional regenerative resistors (ERH-26), and EMI filters (such as Corcom F7202A, Schaffner FN258 series).

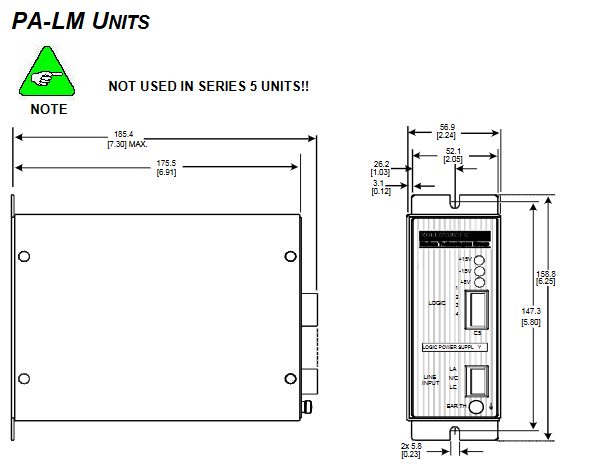

Version Description: The document version is M-SS-017-07 Rev C. The Series 5 (Version 2) model is not compatible with the PA-LM bus module, and some features (such as extended I/O interface C9) are only supported by Series 5; The firmware needs to be version 4.0.0 or higher (UCB1V2 label model), and it must be paired with a compatible version of IGNITE upgrade tool.

Safety and compliance requirements

(1) Personnel qualifications and operating standards

Qualification requirements: Only professionals with experience in motor installation and commissioning are allowed to operate, and they must be familiar with standards such as IEC 364/CENELEC HD 384, DIN VDE 0100, and national safety regulations.

Core Warning:

Risk of electric shock: During equipment operation, there is a 230VAC input and a 430VDC bus voltage. After power failure, there is residual dangerous voltage in the capacitor. It is necessary to wait for at least 10 minutes and measure the voltage (<50V) before operation; Reliable grounding is necessary (low impedance grounding, otherwise personal safety cannot be guaranteed).

Electrostatic protection: Contains electrostatic sensitive components. Before operation, it is necessary to release human static electricity and avoid contact with high insulation materials (such as chemical fibers and plastic films). The equipment should be placed on a conductive surface.

High temperature and mechanical risks: During operation, the temperature of the heat sink can reach 80 ℃ (176 ° F) to avoid burns; The start-up process may cause the motor to rotate, and it is necessary to ensure that there are no personnel/obstacles in the hazardous area.

(2) Compliance standards

Key standards applicable to certification/instruction scope

UL/cUL 508C specifies design requirements for power filtering, grounding, insulation, etc. to prevent fires, electric shock, and personal injury in the US and Canadian markets

CE certification EU market EMC directive (89/336/EEC): compliant with EN 55011 (radiated/conducted emissions), EN 61000-4 series (immunity); Low Voltage Directive (73/23/EEC): Complies with EN 50178, EN 60204

Global mechanical safety requires equipment to comply with EN 60204 (Mechanical Electrical Equipment) and EN 292 (Mechanical Safety), and equipment manufacturers need to complete risk assessments

Installation and wiring

(1) Mechanical installation

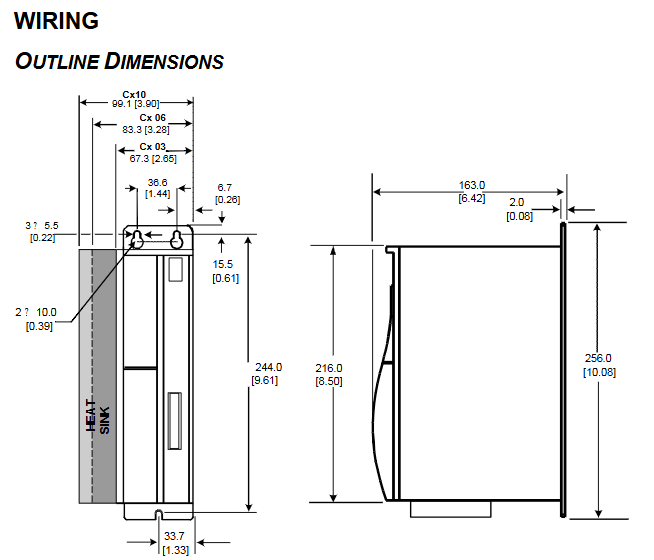

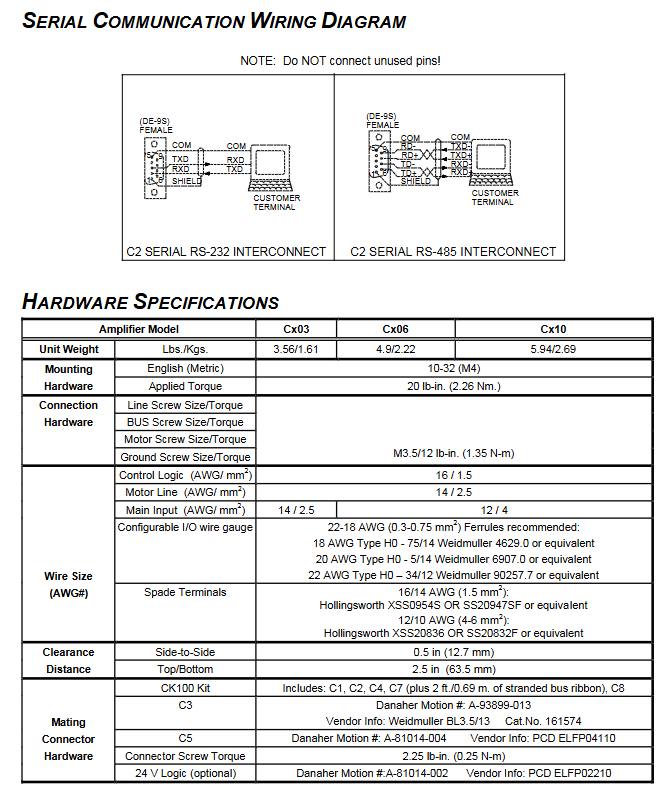

Installation requirements: Vertically fixed to the conductive grounding backplate (metal contact ensures EMC performance), with reserved heat dissipation space around (left-right spacing ≥ 12.7mm, up-down spacing ≥ 63.5mm); Secure with M4 (or 10-32) screws, torque 20 lb in (2.26 Nm).

Dimensions and Weight: Cx03 measures 67.3 × 163 × 244mm (width × height × depth) and weighs 1.61kg; Cx06 measures 83.3 × 163 × 244mm and weighs 2.22kg; Cx10 measures 99.1 × 163 × 256mm and weighs 2.69kg.

(2) Electrical wiring

Grounding and bonding:

Safe grounding: All components (amplifiers, filters, motors) need to be connected to a "star shaped grounding point". It is recommended to use copper bars or flat braided wires (to reduce high-frequency impedance) to avoid relying on a single wire (inductance 8nH/inch, which affects the filtering effect).

Shielding bonding: The shielding layer of the motor line and feedback line should be exposed near the amplifier and connected to the backplane through metal clamps (such as Phoenix Contact products); If metal conduits are not used for power supply incoming lines, shielded cables must be used and reliably bonded.

Key interface wiring:

Power input: 115/230VAC (± 10%), single/three-phase optional (Cx0x200 only single-phase), wire diameter 14-12AWG (2.5-4mm ²), external fuse required (10AT for Cx03, 15AT for Cx06, 22-27AT for Cx10).

Motor and Feedback: The length of the motor wire (14AWG/2.5mm ²) is recommended to be ≤ 25m. The feedback wire (encoder/rotary transformer) needs to be shielded with twisted pair. The C2 interface (feedback) pin corresponds to different functions of the resolver/encoder/sine encoder (such as the resolver sine signal connected to Pin1-2, and the encoder A/B phase connected to Pin1-2/4-5).

The control I/O: C3 interface includes ± 10V differential analog input (Pin2-3), 24V remote enable (Pin7-8), fault relay output (Pin5-6, 1A/24VDC) and analog output (Pin13, monitoring speed/current, ± 10V/12 bit resolution), wire diameter 18-22AWG (0.3-0.75mm ²), and it is recommended to use cold pressed terminals.

EMI filtering:

Input filtering: EMI filters (such as Cx03 with Corcom F7202A and Cx10 with Schaffner FN258-16/07) need to be installed at the power input end. The filters should be installed tightly against the input end (distance ≤ 30cm, and over distance should be connected with flat braided wire), and the shell should be in contact with the backplate metal (remove oil paint).

Motor filtering: Not mandatory, but it is recommended to add filtering for long motor wires (>25m) or non-metallic cabinets to reduce differential mode noise coupling.

Hardware specifications and electrical parameters

(1) Core electrical parameters

Parameter Cx03 Cx06 Cx10

Continuous output current (RMS) 3A 6A 10A

Peak output current (500ms/RMS) 9A 18A 20A

Input voltage 110-230VAC (± 10%), single-phase/three-phase (Cx0x200 only single-phase) 230VAC (± 10%), three-phase 230VAC (± 10%), three-phase

Bus voltage 325VDC (nominal), overvoltage protection 430VDC, undervoltage protection 90VAC

PWM frequency 16kHz (current loop update rate 62.5 μ s) 8kHz (current loop update rate 62.5 μ s) 8kHz (current loop update rate 62.5 μ s)

Environmental temperature operation: 5-45 ℃ (41-113 ° F), storage: 0-70 ℃ (32-158 ° F)

Cooling power consumption 60W, 80W, 132W

(2) Interface definition

Communication interface C1: Supports RS232 (Pin2=RXD, Pin3=TXD) and RS485 (Pin6=TXD+, Pin7=TXD -, Pin8=RXD+, Pin9=RXD -), used for PC debugging or multi machine networking (MultiDrop address is set by DIP switches 1-5, optional 0-31).

Feedback interface C2 (25 pins):

Resolve: Pin1-2 (sine signal), Pin4-5 (cosine signal), Pin15-16 (reference signal);

Encoder:Pin1-2(A/A)、Pin4-5(B/B)、Pin15-16(Index/Index)、Pin22-24( Hall signals H1A/H2A/H3A); Sine Encoder:Pin1-2(A/A)、Pin4-5(B/B)、Pin9-10(Data/Clock), Requires 5V power supply (Pin18-20).

Expansion interfaces: C4 (equivalent output of encoder, RS485 differential), C8 (remote encoder input), C9 (only Series 5, 3-channel input/2-channel output), C7 (RS232 multi machine communication, CK100 kit required).

DIP switch (10 bits): Switch 1-5 sets MultiDrop address, switch 6 sets baud rate (0=9600/2M, 1=19200/4M), switch 7 sets position hold (1=active), switch 8 sets driver enable (1=disabled), switch 9 sets SERCOS transmit power (1=high power).

Control performance and functionality

(1) Control loop characteristics

Key parameters of control loop update rate and bandwidth

Current loop 62.5 μ s (16kHz)<2000Hz fully digital pole configuration, supports adaptive gain, monitors A/C phase current (IA/IC), with I ² t turn back protection (to prevent driver overheating)

Reversing ring 62.5 μ s (16kHz) - sine wave commutation, supports "torque angle lead" technology, maximum commutation frequency 400Hz, needs to be aligned with the back electromotive force of the motor

Speed loop 250 μ s (4kHz)<400Hz PDFF (pseudo differential feedforward) algorithm, speed resolution 1RPM or VLIM/16384, long-term speed stability 0.01%

Position ring 500 μ s (2kHz) - supports hardware limit (C3 interface IN1/IN2), software limit (PMAX/PMIN), position deviation monitoring (PE>PEMAX triggering fault)

(2) Core functions

Feedback support: Compatible with incremental encoders (A/B/Z+Hall), rotary transformers (single/multi speed), sine encoders (EnDat/HIPERFACE), supports encoder equivalent output (C4 interface, up to 3MHz frequency, scalable resolution).

Protection mechanism: Over temperature (trip at 80 ℃), overvoltage (430VDC), undervoltage (90VDC), overcurrent (power level surge), feedback disconnection (A/B phase/rotary transformer disconnection), motor overheating (thermal monitoring, PTC>12.4k Ω or NTC<0.5k Ω triggering fault).

Regeneration control: Built in braking circuit, activated when the bus voltage reaches 390VDC, external regeneration resistor (ERH-26) can handle excess energy, Cx03 has a minimum resistance of 20 Ω and a maximum power of 200W.

Debugging and troubleshooting

(1) Debugging process

Software installation: Install MOTIONLINK from the CD-ROM or official website (www.danahermotion. com), which supports Windows 95/98/NT 4.0/2000 systems and requires configuration of a serial port (COM1-COM4, baud rate matching DIP switch).

Quick Startup Wizard:

Motor configuration: Select the motor model (such as GOLDLINE series) from the database, click "To Drive" to download parameters. For unknown motors, manually enter parameters such as MBEMF (back electromotive force) and MENCRES (feedback resolution).

Feedback configuration: Select the feedback type (encoder/rotary transformer), confirm the C2 interface wiring, and the rotary transformer needs to perform a zeroing program.

Enable and Test: Connect the 24V enable power supply (C3 Pin7-8), and the software executes the "EN" command to enable the driver. Test the motor rotation through the "Jog" mode and monitor the speed/current (MOTIONLINK monitoring interface).

Firmware upgrade: Series 5 models do not support it. For older models, DIP switch 8/10 needs to be set to 1, enter Ember mode, load the firmware (Lccd_ xxx. emb) using IGNITE tool, and restore the switch to 0 after upgrading.

(2) Troubleshooting

Fatal malfunction (requiring power outage/enable reset):

Overheating (t): Check if the cooling fan and load are overloaded, reset after cooling;

Overvoltage (o): Reduce deceleration rate and check the connection of the regeneration resistor;

Overcurrent (P): Check for motor short circuit and power level fault, and power off reset is required;

Feedback fault (r0-r13): Check for broken feedback cables (such as r1=rotary transformer broken, r4=encoder A/B broken), reconnect and reset.

Non fatal malfunction (enable reset):

Undervoltage (u): Check the input voltage and eliminate power supply faults;

Motor overheating (H): Cool the motor and check the thermostat wiring (C2 Pin13/25);

Overspeed (J/J1): Adjust VOSPD (overspeed threshold) or VLIM (speed limit) to optimize the tuning parameters of the speed loop.

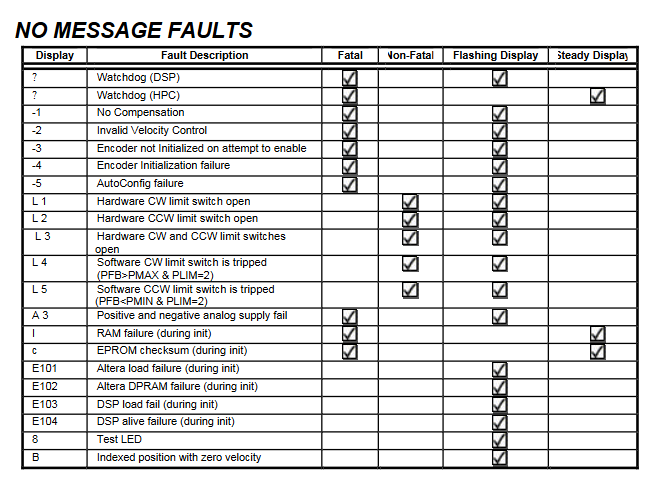

No message fault (only displayed in the status bar):

Limit trigger (L1/L2/L3): Hardware limit switch open circuit (C3 IN1/IN2), check mechanical limit or wiring;

Memory failure (I/c): RAM/EPROM test failed, hardware replacement is required;

Watchdog (≡): Software malfunction, contact manufacturer technical support.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923