K-WANG

SIEMENS SGT-2000E series gas turbine

Core values: Low unit kilowatt investment cost, wide fuel adaptability, flexible operation, low maintenance cost, long service life, fast investment return, and fleet reliability exceeding 99%.

Market performance: As of July 2011, over 400 units have been delivered globally with a total operating time of approximately 9 million hours. Among them, the SGT5-2000E standalone model has accumulated over 6.4 million hours of operation, verifying its stability.

SIEMENS SGT-2000E series gas turbine

Overview of Core Products

1. Product positioning and core values

Positioning: Mature heavy-duty gas turbine, designed for efficient and flexible power production, suitable for multi scenario energy needs, and can be used as the core equipment of single cycle or combined cycle power plants.

Core values: Low unit kilowatt investment cost, wide fuel adaptability, flexible operation, low maintenance cost, long service life, fast investment return, and fleet reliability exceeding 99%.

Market performance: As of July 2011, over 400 units have been delivered globally with a total operating time of approximately 9 million hours. Among them, the SGT5-2000E standalone model has accumulated over 6.4 million hours of operation, verifying its stability.

2. Key performance parameters (ISO standard conditions, natural gas fuel, gross value)

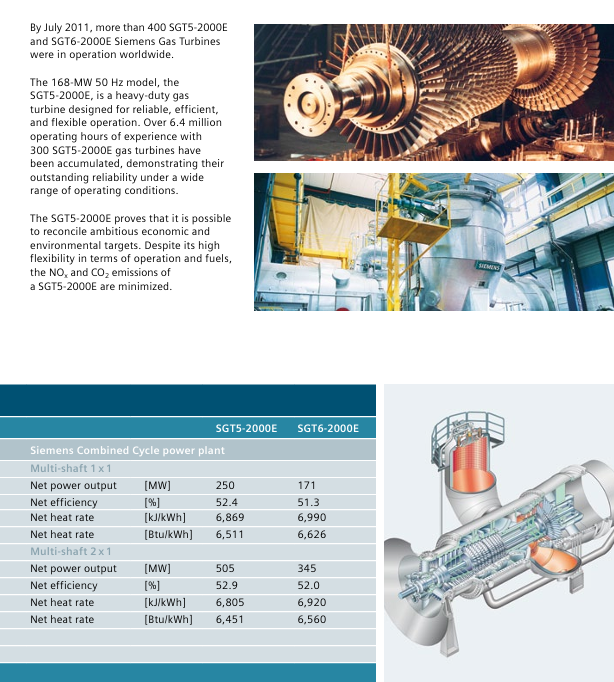

Parameter SGT5-2000E (50Hz) SGT6-2000E (60Hz)

Output power 166MW 112MW

Efficiency 34.7% 33.9%

Heat consumption 10375kJ/kWh (9834Btu/kWh) 10619kJ/kWh (10066Btu/kWh)

Exhaust temperature 541 ℃ (1005.8 ℉) 540 ℃ (1004 ℉)

Exhaust mass flow rate 525kg/s (1157lb/s) 365kg/s (804lb/s)

Pressure ratio 12 12.1

Dimensions (length x width x height) 10 x 12 x 7.5m (including combustion chamber) 8.3 x 10 x 6.25m (including combustion chamber)

Weight 234t (including combustion chamber) 163t (including combustion chamber)

3. Combined cycle performance (multi axis configuration)

1 × 1 configuration: SGT5-2000E with a net output of 250MW and an efficiency of 52.4%; SGT6-2000E has a net output of 171MW and an efficiency of 51.3%.

2 × 1 configuration: SGT5-2000E with a net output of 505MW and an efficiency of 52.9%; SGT6-2000E has a net output of 345MW and an efficiency of 52.0%.

Core design features

1. Infrastructure design

Core configuration: Single shaft and single cylinder design, dual rotor bearings, cold end driven generator, disc rotor (with Hess serrated connection and center pull rod bolt).

Core components:

Compressor: SGT5-2000E has 16 stages, SGT6-2000E has 17 stages; Variable pitch inlet guide vanes, supporting operation at loads as low as 50% and stable exhaust temperature.

Turbine: A 4-stage structure, with the first 3 stages of stationary blades and the first 2 stages of moving blades cooled by convective air. The first 3 stages of the turbine are coated with special materials and do not have film cooling (suitable for dusty fuels).

Combustion chamber: Double silo structure with ceramic insulation cover, 8 burners per chamber for SGT5-2000E and 6 burners per chamber for SGT6-2000E, supporting dry low NOx technology.

2. Core advantageous features

Fuel flexibility: Suitable for both gaseous (natural gas, low calorific value gas, synthetic gas) and liquid fuels (fuel oil, heavy oil, crude oil, naphtha, kerosene), including specialized burners for unconventional fuels.

Operational flexibility: Fast start-up (accelerating to full load within 4 minutes), low emissions under partial load, support for flexible grid regulation, adaptable to special power plant scenarios such as IGCC.

Convenience of maintenance: Manholes are installed inside the combustion chamber for easy inspection of hot aisle components; The dynamic/static blades can be replaced separately (without disassembling the rotor); Ash fuel is easy to clean and inspect during operation.

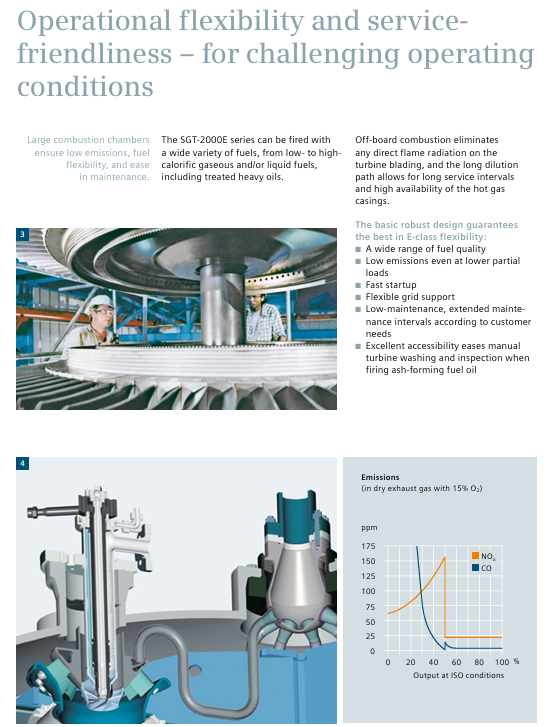

Environmental performance: Adopting a premixed burner, NOx and CO ₂ emissions are minimized, and low emission levels can still be maintained under partial load.

Core design details and technological advantages

1. Overall structural design

Core configuration: Single shaft and single cylinder design, supported by dual rotor bearings, with the cold end (compressor end) driving the generator to avoid high temperature losses and maintenance risks caused by the hot end driving.

Rotor design: The disc rotor structure is fixed to the central pull rod bolt through Hirsh serrations, ensuring that the rotor components self align during steady-state and transient operation, thereby improving operational stability; Internally designed air circulation channels to minimize thermal stress and support quick start stop.

Modular design: The device structure has a high degree of modularity, making it easy to transport, install, and maintain. It can be flexibly combined and configured according to project requirements.

2. Technical analysis of key components

(1) Compressor

Level configuration: SGT5-2000E has 16 levels, SGT6-2000E has 17 levels; Provide a modified version of a 17 stage compressor for non air integrated synthesis gas/IGCC applications.

Core features: Variable pitch inlet guide vanes (VIGV), capable of maintaining a constant exhaust temperature at loads as low as 50%, and adapting to flexible load regulation requirements; The dynamic/static blades adopt a free standing design, optimized by frequency modulation, and can operate continuously at full load within a wide frequency offset range.

(2) Turbine

Structural parameters: 4-stage turbine design, with convective air cooling technology used for the first 3 stages of stationary blades and the first 2 stages of moving blades, suitable for high-temperature working environments; The first three stages of turbine blades are covered with special coatings to enhance their high temperature resistance and corrosion resistance.

Adaptation design: No gas film cooling structure, avoiding cooling channel blockage caused by ash accumulating fuels (such as heavy oil and crude oil), and expanding the fuel adaptation range.

(3) Combustion chamber

Structural form: Double silo type large volume combustion chamber with ceramic insulation cover, reducing the impact of direct flame radiation on turbine blades and extending component life.

Burner configuration: 8 burners per combustion chamber for SGT5-2000E, 6 burners per combustion chamber for SGT6-2000E; Adopting a hybrid burner and dry low NOx technology, the premixed combustion design reduces emissions.

Maintenance advantage: There is a manhole on the side of the combustion chamber, which can directly inspect the hot channel components from the burner to the turbine blades without disassembling the overall structure, improving maintenance convenience.

3. Three core advantageous characteristics

(1) Fuel flexibility: adaptable to multiple types of fuels, reducing fuel dependence

Gaseous fuels: standard natural gas, low calorific value natural gas, synthesis gas (IGCC output), naphtha derived gas, etc.

Liquid fuels: standard fuel, heavy oil, crude oil, kerosene, naphtha, and ash based fuels.

Adaptation technology: Provide specialized modified burners for unconventional fuels such as synthesis gas and heavy oil to ensure combustion stability and efficiency; Siemens has accumulated rich experience in unconventional fuel applications and can provide customized solutions for projects.

(2) Operational flexibility: adaptable to complex working conditions, fast response

Quick start stop: With standard static excitation and variable frequency starting system, it can accelerate from start-up to full load within 4 minutes, meeting the needs of power grid peak shaving, emergency power supply, etc.

Load regulation: Supports flexible adjustment of 50% -100% load, and can maintain low emission levels even under partial load, adapting to power grid load fluctuations.

Grid adaptation: With flexible grid support capabilities, it can adapt to different regional grid frequency requirements (50Hz/60Hz) and has strong stability.

(3) Maintenance convenience: reduce operation and maintenance costs, extend service life

Component replacement: All stationary and moving blades of the compressor and turbine can be replaced separately without disassembling the rotor and lower cylinder body, reducing maintenance downtime.

Inspection channel: A manhole is installed inside the combustion chamber, and the hot channel components (burner, turbine blades) can be directly inspected without disassembling the equipment.

Special adaptation: Design a structure that is easy to manually clean and inspect for the operation scenario of greyed fuel, reducing the impact of greying on equipment performance.

Lifespan design: The core components are made of high wear-resistant and high-temperature resistant materials, combined with optimized cooling and coating technology, to extend the service life of the components and reduce replacement frequency.

(4) Environmental performance: Low emission design, in compliance with environmental standards

Emission control: Using dry low NOx combustion technology and premixed burners, NOx emissions can be maintained at a low ppm level under ISO conditions, and even partial load operation can meet strict environmental requirements.

Energy saving design: High cycle efficiency reduces CO ₂ emissions per unit of power generation, while optimized combustion chamber and turbine design reduces fuel waste and improves energy utilization efficiency.

Application scenarios and delivery solutions

1. Main application areas

(1) Power industry

Single cycle power station: suitable for emergency power supply, peak shaving power stations, or projects with abundant natural gas resources and sensitive investment costs.

Combined Cycle Power Plant: Composed of 1 × 1 or 2 × 1 multi axis configurations, it forms a large-scale and efficient power plant suitable for main power supply, with an efficiency of up to 52.9% (SGT5-2000E 2 × 1 configuration).

IGCC power station: suitable for use as gas fuel and can be integrated with coal based IGCC systems, such as the Buggenum project in the Netherlands, to achieve efficient and clean power generation.

(2) Oil and gas industry

Compressor Drive: Used for direct mechanical drive of compressors in liquefied natural gas (LNG) production, or as a fully electric generator version adapted for power supply in oil and gas extraction sites.

Special chemical scenarios: suitable for gas to liquid (GTL) factories, synthesis gas production factories, etc., supporting unconventional fuels such as low calorific value gas and synthesis gas.

2. Delivery and Configuration Plan

(1) Standard Delivery Package (SGT-PAC Module)

Core equipment: gas turbine, electrical generator.

Auxiliary systems: fuel gas system, hydraulic oil system, instrument air system, lubricating oil system, compressor cleaning system, intake system, exhaust diffuser.

Control and Electrical: Instrumentation and Control Systems, Electrical Equipment, Power Control Centers, Start Up VFDs.

Safety and protection: soundproof enclosure, fire protection system.

Delivery features: Most equipment is pre assembled and delivered, including a large number of prefabricated pipelines and wiring, auxiliary system grouping and integration, significantly shortening the on-site installation and commissioning cycle, and reducing project implementation costs.

(2) Optional configurations (partial list)

Fuel related: liquid fuel system, dual fuel operation system, heavy oil operation adaptation, synthesis gas operation adaptation.

Emission optimization: liquid fuel NOx spray system.

Air intake treatment: intake evaporative cooling system, intake anti icing system, intake self-cleaning pulse filter.

Exhaust and smoke exhaust: Single cycle gas turbine chimney, combined cycle bypass baffle and bypass chimney.

Cooling and noise reduction: Generator and lubricating oil finned fan cooling system, enhanced noise reduction configuration.

3. Analysis of typical project cases

Project Location Operating Party Project Scale and Configuration Fuel Type Operating Performance Core Highlights

The Buggenum Nuon Power Buggenum 290MW IGCC power station in the Netherlands features a 1 × 1 single axis combined cycle system, with one SGT5-2000E synthesis gas (main) and natural gas (backup) operating for over 80000 hours to adapt to IGCC scenarios. The dual fuel system ensures stable power supply

Transfield Pty Ltd 150MW single cycle power station in Townsville, Australia, with one new generation SGT5-2000E natural gas operating for over 35000 hours of peak shaving and emergency power supply, has started fast

Az Zour, Kuwait Ministry of Electricity and Water Resources 960MW single cycle power station, with 8 SGT5-2000E natural gas and fuel oil (dual fuel) units operating for over 170000 hours in a large-scale cluster configuration, suitable for areas with abundant oil and gas resources

Taiwan, China Xingda Taiwan Electric Power Company 2200MW combined cycle power plant (the world's largest 60Hz power plant), including multiple Siemens gas turbines with natural gas running more than 900000 hours in total, large-scale combined cycle application, efficient and stable power supply

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923