K-WANG

SIEMENS SIMATIC HMI Intelligent Panel

KP (button type) 4 "6AV2124-1DC01-0AX0 only has physical buttons

KP (button type) 7 "/9"/12 "/15" 6AV2124-1GC01-0AX0 (7 ") only has physical buttons

TP (Touch sensitive) 7 "/9"/12 "/15"/19 "/22" 6AV2124-0GC01-0AX0 (7 ") Touch screen only

KTP (composite) 4 "6AV2124-2DC01-0AX0 button+touch screen

SIEMENS SIMATIC HMI Intelligent Panel

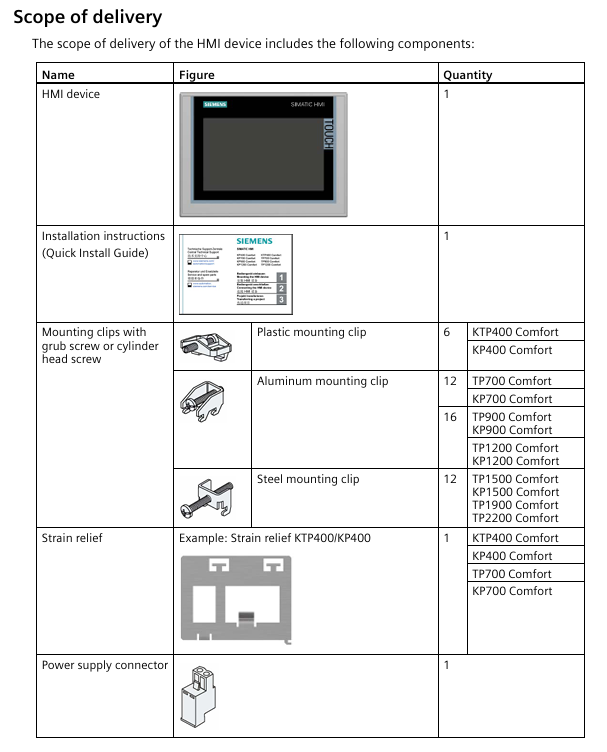

Product Overview and Classification

1. Equipment type and size

Equipment type, size specifications, representative model (part number example), operating method

KP (button type) 4 "6AV2124-1DC01-0AX0 only has physical buttons

KP (button type) 7 "/9"/12 "/15" 6AV2124-1GC01-0AX0 (7 ") only has physical buttons

TP (Touch sensitive) 7 "/9"/12 "/15"/19 "/22" 6AV2124-0GC01-0AX0 (7 ") Touch screen only

KTP (composite) 4 "6AV2124-2DC01-0AX0 button+touch screen

2. Differences in hardware versions

Version size range, operating system core differences

Comfort V1 4 "-22" Windows CE 6 with dual audio sockets and Mini-B USB interface

Comfort V1.1 7 "-12" Windows CE 6 with audio output only, Mini-B USB interface

Comfort V2 15 "-22" Windows Embedded Compact 2013 without Mini-B USB interface, performance improvement

3. Core hardware features

Display screen: 16 million color TFT widescreen, resolution 480 × 272 (4 ") -1920 × 1080 (22"), backlight life 30000-80000 hours

Communication interface:

PROFINET:10/100Mbps(4"-12")、10/100/1000Mbps(15"-22"), Support circular topology

PROFIBUS DP: Maximum transmission rate of 12Mbps, RS422/485 interface

USB: Type A (peripheral devices), Mini-B (debugging, V2 not available)

Protection level: IP65 on the front (after installation), IP20 on the back

Safety regulations and usage restrictions

1. Warning level and meaning

Example scenario of warning sign meaning

Danger (DANGER) Failure to take measures may result in death/serious personal injury. When the cabinet is electrified, it may open and come into contact with lethal voltage

Warning: Failure to take measures may result in death/serious personal injury. In explosion-proof areas, live plug and unplug connectors may cause explosions

Caution (CAUTION) Failure to take measures may result in minor personal injury, sharp objects scratching the touch screen

Caution: Failure to take measures may result in property damage, failure to follow the connection sequence, and equipment damage

2. Key safety requirements

Electrical safety: Only supports 24VDC power supply (voltage range 19.2V-28.8V) and must comply with SELV/PELV circuit requirements (IEC/EN 61131)

Use in explosion-proof areas:

Only Ex certified models are available for Zone 2/22 zones

Do not plug or unplug connectors or memory cards with power on

Ensure that the plug is secure against loosening (such as fixing the USB interface with a cable tie)

Environmental restrictions:

Only for indoor industrial use, prohibited for use in residential areas

Avoid high radio frequency interference (such as mobile phones), corrosive gases, and strong electromagnetic radiation

Equipment installation and connection

1. Key parameters for installation preparation

Prepare project requirements remarks

Installation opening size 4 "(KTP400): 122 × 98mm; 7" (TP700): 197 × 141mm, etc. Vertical installation requires exchanging width and height

Material thickness of 2mm-6mm ensures protection level of IP65

The heat dissipation gap should be ≥ 15mm on both sides, ≥ 50mm on the top and bottom, and ≥ 10mm on the back to avoid equipment overheating

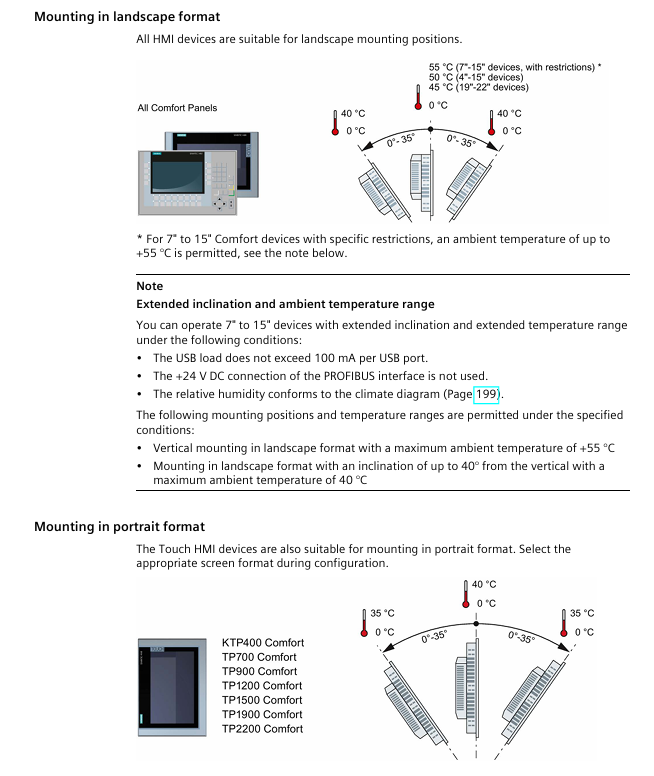

Installation tilt angle: horizontal ± 35 °, vertical ± 35 ° (touch only). The 7 "-15" model can be extended to 40 ° under specific conditions

2. Connection sequence and specifications

Equipotential bonding: Use copper/galvanized steel wires with a cross-sectional area of ≥ 16mm ², and the wire between the grounding bar and the equipment should be ≥ 4mm ²

Power connection:

The power plug supports a maximum of 1.5mm ² wire and a torque of 0.5-0.6Nm

Equipped with reverse polarity protection to prevent damage to equipment caused by reverse connection

Controller connection:

Support SIMATIC S7-200/300/400/1200/1500 and third-party controllers (such as Allen Bradley)

PROFINET requires a unique device name to be configured, and PROFIBUS requires a bus address (1-126) to be set

Peripheral device connection:

USB devices (mouse/keyboard/printer): wire length ≤ 1.5m, USB 2.0 or above certification

Audio equipment: Connected through Line Out interface, production environment requires shielded cables

Equipment debugging and configuration

1. Core debugging function

Memory management:

Memory: stores OS, project files, licenses, prohibits circular write access

SD/MMC card: Recommended SIMATIC HMI storage card (≥ 2GB) for data archiving and backup

System memory card: only SIMATIC HMI card (≥ 2GB), supports automatic backup, quick fault recovery

Control panel settings:

Display settings: brightness (25% -100%), screen orientation (horizontal/vertical), touch screen calibration

Network settings: IP address (static/DHCP), PROFINET device name, NTP time synchronization

Security mode: Password protected control panel to prevent unauthorized modifications

2. Service and maintenance functions

Key points of functional operation

Backup/restore supports WinCC or ProSave tools, backup file format *. psb, including project, recipe, license

OS updates require external storage media or configuration PC, and automatic backup must be disabled before updating to avoid data loss

Automatic backup activated after inserting the system storage card, real-time synchronization of device data, and can be restored by inserting a replacement device in case of failure

Touch screen calibration uses a touch pen to calibrate 5 points, confirm and save within 30 seconds to ensure precise operation

Project commissioning and operation

1. Project transmission and testing

Transmission method:

Manual transmission: Select "Download to device" through WinCC and configure PROFINET/Ethernet channels

Automatic transmission: Used during debugging phase, it is recommended to disable it after commissioning to avoid accidental triggering

Test type:

Offline testing: Communication without controller, verifying interface layout and operational logic

Online testing: Connect the controller to verify measurement value updates, alarm triggering, and communication stability

2. Core operational functions

Numerical input:

Touch sensitive: Pop up on-screen keyboard (alphanumeric/pure numeric), supports range verification

Key press: System key press the phone keyboard logic input, long press to enter numbers

Function key operation:

Global function key: Effective for all projects (such as alarm confirmation)

Local function keys: only effective for the current screen (such as switching between sub screens)

Language switching: Supports up to 32 languages, requires configuration of corresponding operating components, and takes effect immediately after switching

Maintenance and Technical Specifications

1. Daily maintenance requirements

Cleaning: Turn off the power or lock the touch screen, wipe with a cloth dipped in neutral cleaner, and avoid solvents such as compressed air and alcohol

Spare parts replacement: Only use Siemens certified spare parts (such as assembly clips, memory cards), and contact official technical support for any malfunctions

Recycling and disposal: processed by compliant electronic waste recycling enterprises, in compliance with local environmental regulations

2. Key technical parameters (taking TP1500 Comfort V2 as an example)

Project specifications

Display screen with 15 "TFT, 1280 × 800 resolution, 16 million colors, backlight life of 50000 hours

Communication interface 2 x PROFINET (1 x 10/100Mbps, 1 x 10/100/1000Mbps), 1 x PROFIBUS DP

Power supply 24VDC, current 1.7A (load related 1.45-2.1A), power 41W

Working temperature 0-50 ℃ (horizontal), 0-40 ℃ (inclined at 35 ° C)

Protection level: IP65 on the front and IP20 on the back

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923