K-WANG

SIEMENS SENTRON Circuit Protection Equipment with Communication and Measurement Functions

SIEMENS SENTRON Circuit Protection Equipment with Communication and Measurement Functions

SENTRON's circuit protection equipment with communication and measurement functions is the core product of Siemens' intelligent infrastructure series. With SENTRON Powercenter 1000 as the data transmission and reception core, it is compatible with 7 types of terminal devices (including small circuit breakers, arc fault detection devices, fuses, etc.), supports wireless+Bluetooth+Ethernet multi interface communication, and achieves data transmission through Modbus TCP protocol. It can collect electrical parameters and equipment status such as current, voltage, temperature, etc. It has functions such as alarm threshold setting, trip reason recording, remote control, etc. The protection level reaches IP20-IP68, and the working temperature covers -40 ° C to+60 ° C (some models can withstand 200 ° C cyclic high temperature). It is suitable for scenarios such as main distribution panels and sub distribution panels, and can improve the system. Availability and operational transparency, only qualified professionals are allowed to install and debug.

Core Component Details

2.1 Data transmission and reception core: SENTRON Powercenter 1000

Specific specifications of parameters

Order number 7KN1110-0MC00

Interface type Ethernet (Cat5 F/UTP and above), Bluetooth 5.1, wireless

The connection capability can pair up to 24 terminal devices and support parallel operation of 4 devices

Power supply requirement: 24V DC SELV (19.2~28.8V), maximum power consumption of 100mA

Data storage, measurement trend storage for 1 hour to 30 days, with a maximum of 50 message records

Protection level IP20

Environmental temperature operation: -25~+60 ° C; Storage: -40~+85 ° C

Physical dimensions: width 18mm, height 90mm, depth 70mm, net weight 52g

2.2 Terminal devices (7 core models)

Equipment type, core functions, key parameters, protection level

5SL6 COM miniature circuit breaker overload/short circuit protection, power measurement, RCM version supports residual current monitoring rated current 2-32A, trip characteristics B/C, measurement accuracy ± 0.5% IP20 (rear side)/IP40 (front side)

5SV6 COM arc fault detection equipment overload/short circuit/arc fault protection, electrical parameter acquisition rated current 6-32A, breaking capacity 6kA, working temperature -25~+45 ° C IP20 (connection end)/IP40 (front side)

3NA COM fuse short circuit protection, current/temperature monitoring, advance warning rated current 80~315A, size NH2, operation category gG/gFF IP20

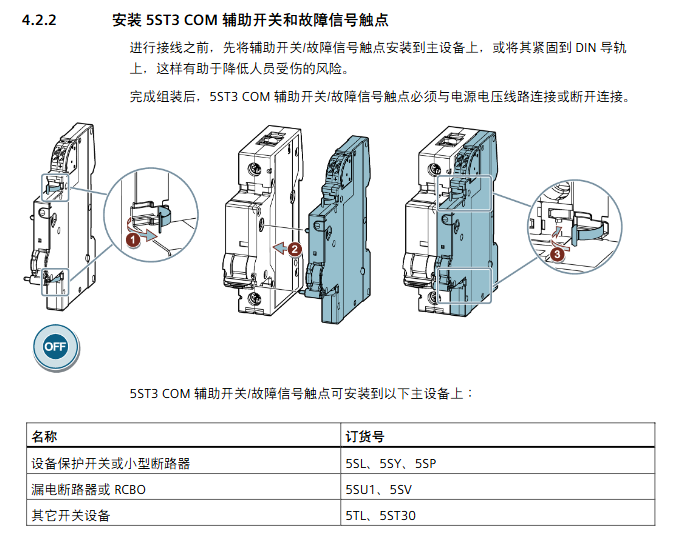

5ST3 COM auxiliary switch/fault signal contact status monitoring (switch position/trip), temperature measurement modular width 0.5TE, power supply 24V DC, current consumption 20mA IP20

3RV2 COM wireless auxiliary switch motor starter protector status monitoring, overload/short circuit trip record width 18mm, working temperature -20~+60 ° C IP20

5ST3 COM RCA remote control auxiliary remote switch, automatic reclosing (ARD), RCD/IR test power supply 100~240V AC, supports 3+3 reclosing attempts IP20

2.3 Supporting software

Mobile: SENTRON Powerconfig mobile (iOS/Android)

Function: Device scanning, pairing debugging, parameter setting, data visualization

Connection methods: Bluetooth (5m~10m), WLAN (same network)

PC end: SENTRON Powerconfig

Function: Project import and export, firmware update, batch parameter configuration

Compatibility: Supports Modbus TCP protocol docking with third-party systems

Installation and commissioning specifications

3.1 Installation Preparation

Delivery inspection: Confirm that the packaging is undamaged, the equipment model is consistent with the order, and the original packaging is retained

Identification requirements: including manufacturer identification (order number/serial number/RF code) and user identification (equipment/location ID+installation date)

Environmental conditions:

Pollution level: Level 2 (conventional)/Level 3 (only 3NA COM)

Temperature: -25~+60 ° C for operation (-10~+55 ° C for 3NA COM), -40~+75 ° C for storage

Humidity: ≤ 93% at 40 ° C (no condensation)

Installation spacing:

The maximum distance between the terminal and Powercenter is ≤ 3m (standard transmission power 0dBm)

When multiple Powercenters are running in parallel, channels need to be distinguished (automatic/manual selection) to avoid interference

3.2 Equipment Installation and Wiring

Installation method: DIN rail card mounting (compliant with EN 60715 standard)

Wiring requirements:

Power supply line: 24V DC SELV adopts screw free plug-in terminals, with a conductor cross-section of 0.2~1.5mm ²

Signal line: 5SL6/5SV6 COM needs to be connected with phase+neutral wire (230V AC)

Shielding requirement: Both ends of the cable should be grounded to avoid parallel laying with the power line

Special requirements:

3NA COM needs to be installed vertically, and electronic modules must not be located above fuses

The installation location of Powercenter should be away from metal surfaces to ensure antenna efficiency

3.3 Debugging Process

Device addition: Add Powercenter 1000 through Bluetooth/WLAN search or manually enter IP address

Terminal pairing: Scan the device RF code (including MAC/installation code) and assign device addresses (1-24)

Parameter configuration:

Communication parameters: IP address (static/DHCP), Bluetooth PIN code, radio transmission power

Measurement parameters: alarm threshold, energy flow direction, RCM measurement range

Control parameters: ARD delay time, RCD test cycle

Function verification: Check LED status (green light is always on as normal), measurement value transmission, alarm response

Core functions and technical features

4.1 Data collection function

Collection parameters:

Electrical parameters: current (0.02~2In), voltage (50~400V), power, electrical energy, power frequency (45~65Hz)

Equipment status: temperature (-25~120 ° C), operating hours, switch cycles, number of trips, residual current (RCM version)

Collection accuracy:

Current/Voltage: ± 0.5%

Power/Electric Energy: ± 1%

Temperature: ± 2~2.5 ° C

Transmission frequency: Key parameters (current/temperature) are transmitted every 2 seconds, and electrical energy/voltage is transmitted every 60 seconds

4.2 Monitoring and alarm functions

Alarm type:

Threshold alarm: overcurrent/undercurrent, overvoltage/undervoltage, overtemperature

Status alarm: tripping operation (overload/short circuit/arc fault), service life warning (operating hours/operating cycle)

Diagnostic alarm: communication error, self-test failure, RCM warning

Alarm settings:

Can turn on/off alarms, adjust threshold and lag values (0-10%)

RCM alarm supports automatic reset or manual confirmation

LED indication: green light (normal), yellow/red light (warning/fault), flashing frequency to distinguish status

4.3 Communication and Control Functions

Communication protocol: Modbus TCP, supports 3 concurrent connections, port 502

Control function:

Remote control: Device switching is achieved through software or wired interfaces

Automatic Recloser (ARD): 3+3 attempts, delay time 10-1800 seconds can be set

Testing functions: RCD testing (compliant with IEC 63024), insulation resistance (IR) testing

Data synchronization: Supports SNTP time synchronization to ensure the accuracy of event timestamps

4.4 Data Storage and Visualization

Trend storage:

Short term: average temperature/current (1 hour, interval of 10 seconds)

Long term: Extreme values of electrical energy/temperature (30 days, with an interval of 1 day)

Visualization method:

Mobile: real-time data, trend charts, alarm message lists

PC end: Project data export (. splx format), batch device management

Upper system docking: supports SENTRON Powermanager, Powercenter 3000, and cloud platform (Insights Hub)

Maintenance and troubleshooting

5.1 Daily Maintenance

Firmware update: executed through PC side Powerconfig, updating Powercenter takes 2 minutes, and terminal devices take 5-15 minutes

Disposal: Comply with local environmental regulations and do not dispose of as household waste

Regular inspection: confirm LED status, wiring tightness, and clear alarm messages

5.2 Common troubleshooting

Solution to Fault Phenomena

Bluetooth cannot find Powercenter 1. Activate device Bluetooth mode (short press button<3 seconds); 2. Check the Bluetooth/GPS on the mobile device; 3. Confirm that the PIN code is entered correctly

Pairing timeout 1. Check device power supply; 2. The backend is still pairing, please be patient and wait; 3. Press and hold the device button for ≥ 10 seconds to reset and retry

Modbus connection failure: 1. Confirm that the device address and register address are correct; 2. Check the Ethernet wiring; 3. Verify function code (read 0x03/0x04, write 0x06/0x10)

The device flashes red light. Press the button briefly to confirm the trip operation; 2. Check the cause of circuit overload/short circuit; 3. Reset the device and then close it again

Firmware update failed 1. Ensure continuous power supply to the device; 2. Check that there is no interference in communication; 3. Confirm that the firmware version matches the device type

Summary of Key Technical Parameters

Category Core Indicators

Protection level IP20 (Powercenter/auxiliary switch)~IP68 (some terminal devices)

Rated voltage 230V AC (single-phase), 400V AC (3NA COM)

Rated current 2~32A (miniature circuit breaker/AFDD), 80~315A (fuse)

Breaking capacity 6kA (5SL6/5SV6 COM), 100kA (3NA COM)

Communication interface Ethernet (Modbus TCP), Bluetooth 5.1, wireless (2400~2483.5MHz)

Storage capacity for up to 30 days of trend data and 50 event messages

Response time switch command response ≥ 1 second, interval between two commands ≥ 10 seconds

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

-

KEBA KeTop CB211 - Connection Box

-

KEBA HT4 / 20656 - Kammann Hand Held Keypad

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Y1-K1-Y2 PA9 - Engel Board Module

-

LTI MOTION CDA32.004C3.0 - Servo Drive 230V AC

-

KEBA E-CG-CONTROL - ECGCONTROL Module

-

KEBA Kemro K2-200 OP350/W 68334 - Engel EC200 Panel Membrane Touch Glass

-

KEBA i1075 - Membrane Keyboard

-

KEBA E-HSI-M - Interface Module

-

KEBA LQ10D321-ERSAT - ZTEILSET FNOB

-

KEBA E-16-DIGOUT/G - Circuit Board

-

KEBA HT4/Neutral/16846 - Mikron Handheld Terminal

-

KEBA KeTop CB310-000 - Connection Box

-

KEBA DC 161/IP20/17369 - Interface Card Module

-

KEBA E-16-DIGOUT-PLUS - Elektronik Bau Linz 262-1456-85-B

-

KEBA HT501 - Handheld Terminal

-

KEBA HT401-4X20 - Teach Pendant

-

KEBA E-3-ACU-10 D16738 - Controller Card Module

-

KEBA 240/A 068371 - Analog Output Module

-

KEBA E-7TEMP D1323E/F/G - Temperature Circuit Board

-

KEBA KeTop TT100-eaa - Communication Cable

-

KEBA E-16 DIGOUT-PLUS D1456D - Engel Output Board

-

KEBA Kemro K2-200 - Touch Panel Glass Digitizer

-

KEBA CC100A03/CAN/4 - PLC Chassis 16-Slot Rack Motherboard 1842E-0

-

KEBA CU 211 - PLC Power Supply

-

KEBA KeTOP CB310-S00 - Connection Box

-

KEBA I/O BUS KOPPLUNG D1547C - Engel Circuit Board

-

KEBA HCS01.1E-W0013-A-02 - Servo Drive

-

KEBA SMC1-Z30 - LTI Security Safety Control

-

KEBA E-PS88-M/C D1527C - Power Supply Board

-

KEBA D1678C / E-SEK - Control Board

-

KEBA 1.83E+02 - Circuit Board Module

-

LUST LTI/KEBA DSM4-05.4-20R.96-W1A - AC Servo Motor

-

Engel/KEBA OP 362-LD/W-5200 - Kemro Ke-200 Membrane Keypad Touch Screen

-

KEBA HT4 24V/0.2A - Kammann Hand Terminal C3052-R47

-

KEBA Kemro K2-200 BL210/B - Injection Molding Machine Controller Module

-

KEBA E-8-ANALOG D1432B - Analog Board

-

KEBA DM272 - Input Output Module

-

KEBA AR161 - PCB ML-EUMIG

-

KEBA E-PS-24V 1825E-1 - Power Supply Board

-

KEBA E-8-THERMO 1770B-1 - Engel Temperature Control Board

-

KEBA HT4-221-20556 - Kammann Hand Terminal

-

KEBA E-10-ANALOG-SUB D1458D - Circuit Board

-

KEBA AC 441 - Control Module 18-32 VDC

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA E-ANA-SUB2 D1690C - Analog Submodule Card

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad

-

KEBA OP 331/C-4400 - Keview V2 LCD Display Screen Panel

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923