K-WANG

SIEMENS SIMATIC Drive Controller System

SIEMENS SIMATIC Drive Controller System

Basic Framework and Security Standards

1. Positioning and safety warning

Scope: Covering the entire range of SIMATIC Drive Controllers, including CPU 1504D TF/1507D TF and SINAMICS Integrated, providing full process guidance from planning to maintenance, suitable for Motion Control scenarios such as multi axis machine tools, packaging machinery, printing equipment, etc.

Security level classification:

Warning type risk description example scenario

DANGER Fatal/Serious Personal Injury Contact with Live Parts, Undischarged Capacitors

Warning: May cause fatal/serious injury. Equipment damage may lead to electrical leakage, and wireless devices may interfere with safety functions

CAUTION Minor personal injury, electrostatic discharge damage to components

NOTICE property loss, wiring error leading to module failure

Qualification requirements: Only personnel with "industrial automation qualification" are allowed to operate, and they must be familiar with standards such as IEC 61131-2 and EN 60204.

2. Industrial network security (new core chapter added)

Protection strategy: Adopting the "Defense in Depth" framework, divided into 3 layers of protection:

Physical security: Lock the control cabinet door and manage access permissions (password/fingerprint)

Network security: network segmentation, firewall VPN、 Disable unused ports (such as NTP/PUT/GET)

System integrity: firmware updates, configuration verification, data backup

Key measures:

Regular firmware updates (via TIA Portal/memory card/web server)

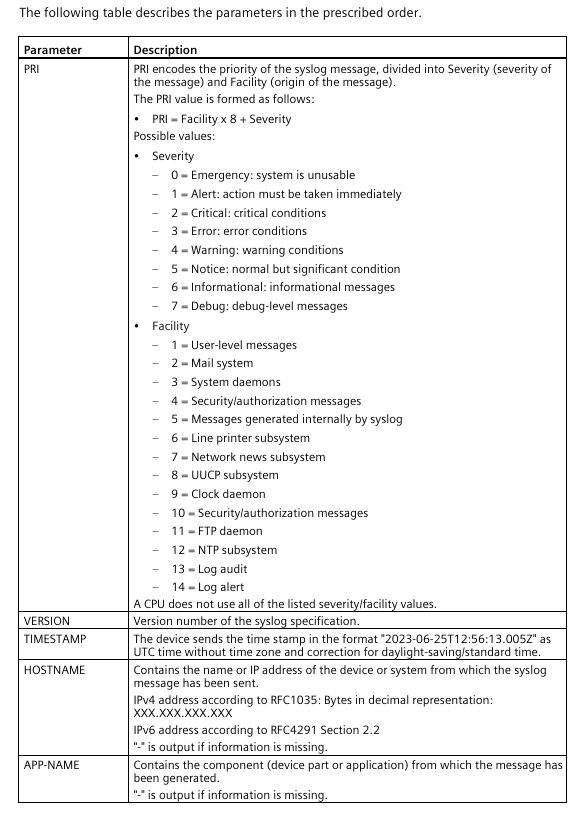

Syslog log: CPU local cache security events (such as password errors, configuration tampering) can be forwarded to the server (UDP port 514/TLS port 6514)

Data destruction: Before retiring the device, a "factory reset" (SINAMICS first, CPU later) must be performed to format the storage card or physically destroy it

System Overview and Core Components

1. Comparison of Core Parameters of Controllers

Component model: CPU 1504D TF (for small and medium-sized applications) CPU 1507D TF (for high-end applications) Key differences

Code working memory 4 MB 15 MB 1507D supports more complex programs

Data working memory 6 MB 40 MB 1507D can store more real-time data

Number of positioning axes (maximum) 40 160 1507D Supports multi axis synchronization

Motion Control resources 3200 12800 1507D handle higher loads

Minimum cycle 500 μ s 250 μ s 1507D supports higher real-time performance

Integrated I/O 8 DI/DQ (X142) 8 DI/DQ (X142) Consistent

2. SINAMICS Integrated Function

Control mode:

Servo control: Maximum dynamic response, supports Dynamic Servo Control (DSC, 125 μ s cycle)

Vector control: maximum torque accuracy, 250 μ s current controller cycle

U/f control: suitable for fan/pump loads, 500 μ s cycle

Security function:

Basic functions: STO (Safe Torque Shutdown), SS1 (Safe Stop 1)

Extended functions: SS2 (Safety Stop 2), SBC (Safety Braking Control)

Advanced features: SLS (Safety Speed Limit), SLA (Safety Distance Limit), requiring 1 license per axis

Restrictions: Free Function Blocks (FBLOCKS) and SIMOTION CX32-2 extensions are not supported, only partial technical extensions (such as POLYGON/SETPGEN) are supported

Application planning and installation wiring

1. Hardware configuration rules

Power configuration:

System power supply: 24V DC PELV (such as SITOP smart), no-load current 1.7A, maximum load 13.1A

Drive power supply: SINAMICS Line Module (generates DC link voltage), Motor Module takes power from the DC link

Communication configuration:

PROFINET IO IRT (X150): Supports isochronous mode, IRT level, synchronous multi drive

PROFIBUS DP (X126): Maximum of 12 I/O modules, does not support isochronous coupling

DRIVE CLiQ: 4 interfaces, each with 450mA power supply, connected to Motor Module/Encoder/Sensor Module (SMC)

2. Installation and wiring specifications

Installation requirements:

Guide rail: TH 35 standard guide rail (length 160-2000mm), fixed with M6 screws (torque 6Nm)

Gap: Top/bottom ≥ 80mm (heat dissipation), vertical installation (only allowed in the vertical direction)

Wiring rules:

Interface type wiring requirements, wire specifications

24V DC power supply 4-pin connector, distinguishing L+/M, stripping length 7-8mm 0.25-2.5mm ² (multi strand without sleeve)

PROFINET uses FastConnect cable, requires 8-core wire for 1000Mbps, and the 145 ° connector only supports 100Mbps CAT5e and above

DRIVE CLiQ shielded cable, the shielding layer is grounded through a metal bracket, with a maximum length of 100m Siemens specific DRIVE CLiQ cable

Digital I/O (X142) 24V DC, DI input delay 1 μ s/125 μ s, DQ high speed output (0.4A) Stripping length 10-11mm 0.25-1.5mm ²

Configuration and Debugging Process

1. Software configuration (TIA Portal+Startdrive)

Basic steps:

Create a project and add a Drive Controller (automatically generating CPU and SINAMICS Integrated devices)

Hardware configuration: Assign PROFINET device name/IP, configure SINAMICS driver object (Line Module/Motor Module)

Message configuration: default PROFIdrive message 393 (X122/X132 I/O), 105 (drive shaft)

Technical object configuration: Create positioning axis/synchronization axis/output cam, bind Drive Controller I/O (such as X142 Timer DI/DQ)

Isochronous mode configuration:

Coupling objects: PROFINET X150+X142 I/O+SINAMICS Integrated

Cycle setting: minimum 250 μ s (1507D TF), requiring allocation of OB 91 (MC Servo)

Synchronization mechanism: IRT clock synchronization ensures driver/IO/CPU cycle consistency

2. Key debugging steps

First power on:

Check wiring (power/ground/DRIVE CLiQ), insert SIMATIC memory card (24MB-2GB)

After power on, the CPU performs a self-test (LED flashing → STOP yellow light on), and the SINAMICS Integrated RDY light turns green

Download project: First download the CPU hardware configuration, then download the SINAMICS driver configuration (requires CPU STOP mode)

IO testing:

Scan PROFINET network using PRONETA tool and test I/O wiring

Monitor variables through STEP 7 "Watch&Force Tables" or force peripheral I/O through CPU web server

Program Execution and Security Protection

1. Fundamentals of Program Processing

Organizational Block (OB):

Description of OB Number Triggering Event Priority Function

OB 1 loop program 1 main loop executes user program

OB 91 MC Servo Interrupt 26 Processing Motion Control Task (Equal Time Mode)

OB 80 time error 22 triggered when cycle time exceeds the limit

OB 121 programming error 7 triggered when there is a syntax error in the program

Asynchronous instruction:

Representative instructions: MC_SoveAbsolute (absolute positioning), MC_GearIn (gear synchronization)

Resource limitations: CPU 1504D TF supports 6400 asynchronous instructions to be executed simultaneously, 1507D TF has no explicit restrictions

2. Security protection mechanism

Access control:

Level 4 permissions: Full access (no password), Read access (read configuration only), HMI access (HMI operation only), No access (fully protected)

Local User Management (TIA V19+): Create users/roles, assign CPU functional permissions (such as web server access/OPC UA permissions)

Data Protection:

Know how protection: Set password for OB/FB/DB, only display interfaces and comments

Copy protection: Bind programs to CPU/storage card serial numbers to prevent piracy

Integrity protection: Verify firmware/configuration data, detect tampering (such as storage card data corruption)

Maintenance and Diagnosis

1. Daily maintenance

Module replacement:

CPU: Replace after power failure, need to download configuration again (keep IP address)

Memory card: Only allows insertion and removal when CPU STOP/POWER is OFF, and memory reset is required after replacement

DRIVE CLiQ component: topology detection needs to be performed again after replacement (SINAMICS Integrated automatic recognition)

Firmware update:

CPU: via TIA Portal/memory card/web server (with correct FW file format)

SINAMICS Integrated: Matching FW version (such as V5.2 SP3 HF10+) through CPU web server

2. Fault diagnosis

Diagnostic tool:

Diagnostic buffer: records CPU/SINAMICS faults (such as power overload, topology errors), which can be read through STEP 7/Web server

Trace function: Record CPU tags (16 signals), SINAMICS parameters (8 signals), support triggering conditions (such as value exceeding threshold)

Service data: Export DUMP.S7S file for Siemens technical support analysis

Technical Parameters and Appendices

1. Core technical parameters

Environmental parameters:

Parameter Type Range Remarks

When the operating temperature exceeds 0-60 ℃ (horizontal)/0-40 ℃ (vertical), the display screen will automatically turn off

Storage temperature -40-80 ℃ under original packaging conditions

EMC performance EN 61000-6-2/4 electrostatic discharge ± 8kV (air)/± 6kV (contact)

Electrical parameters:

Parameter Type Range Remarks

24V DC power supply 19.2-28.8V DC PELV rating

Insulation voltage 600V in accordance with IEC 60664-1

Digital I/O (X142) 24V DC, DI input current 2.5mA, DQ output current 0.4A (high speed)

2. Appendix Resources

Accessories list: including DRIVE CLiQ cable (6SL3060 series), front connector (6ES7592 series), shielding bracket (6ES7590 series)

Migration Guide: Steps for migrating from SIMOTION D4x5-2 to Drive Controller (such as replacing technical objects, adjusting messages)

Open source software information: Open source software licenses (such as GPL license) can be read through CPU QR codes or memory cards

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923