K-WANG

SIEMENS SIMATIC S5 S5-115U Programmable Controller

SIEMENS SIMATIC S5 S5-115U Programmable Controller

SIMATIC S5-115U is a programmable controller suitable for the mid to low end performance range. It adopts a modular design, with core components including power module, CPU (941/942/943/944 models), I/O module, etc. It supports both centralized and distributed configurations, and can expand up to 3 expansion units. In terms of communication, it is compatible with various systems such as SINEC L1. Programming relies on STEP 5 language and has functions such as interrupt handling and analog processing. It is suitable for multiple industries such as automotive, chemical, and food. Installation needs to follow mechanical fixation, standardized wiring, and electromagnetic compatibility requirements. Startup and testing need to complete steps such as overall reset, program transmission, parameter setting, and fault diagnosis.

Core hardware components

2.1 Power module (PS 951)

Input voltage: 120V AC, 230V AC, or 24V DC

Output current: 3A, 7A, 15A (7A and below do not require a fan)

Backup function: Lithium battery backup program memory and retention flag/timer/counter, battery life of about 2 years

Key features: Equipped with battery failure LED indicator, reset switch, voltage selection switch

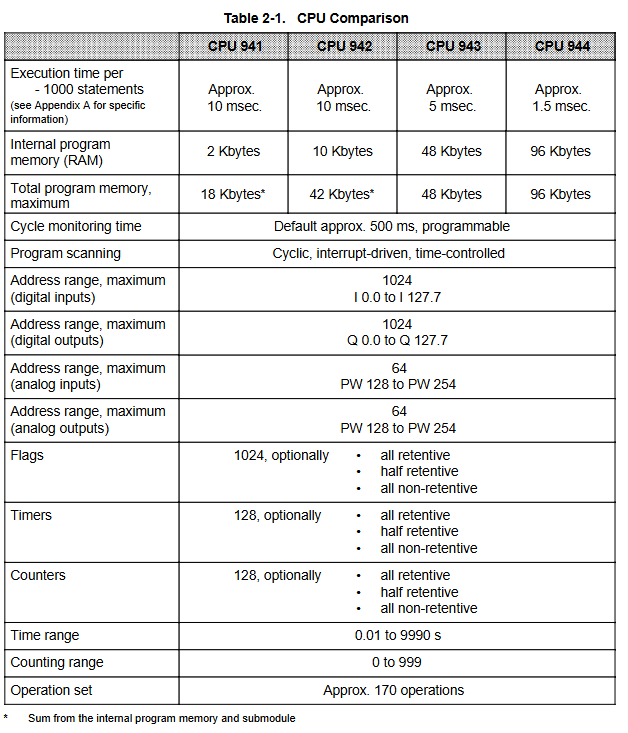

2.2 CPU module

CPU model, memory capacity, execution time (in thousands of instructions), core features

CPU 941 internal 2Kbytes, maximum 18Kbytes, approximately 10ms basic type, supports PID control

CPU 942 internal 10Kbytes, maximum 42Kbytes, approximately 10ms enhanced, supports PID control

CPU 943 internal 48Kbytes approximately 5ms dual serial ports, including real-time clock and ASCII driver

CPU 944 internal 96Kbytes, approximately 1.5ms dual serial port, supports 3964/3964R protocol, PID control

Common features: Supports 1024 flag bits, 128 timers/counters, time range 0.01-9990s, counting range 0-999

2.3 I/O modules

Digital module: adapted to machine voltage/current levels, supports screw or crimping connections

Simulation module: handles closed-loop control tasks, up to 4 measurement ranges per module, supports range card replacement

Intelligent I/O module: independent processor, parallel processing time critical tasks (counting, positioning, etc.)

2.4 Communication components

Communication system: Supports SINEC L1 LAN PROFIBUS、 Industrial Ethernet, point-to-point connection

Communication Processor (CP): divided into LAN type and link/signal/log type, adapted for human-machine and machine machine communication

System configuration

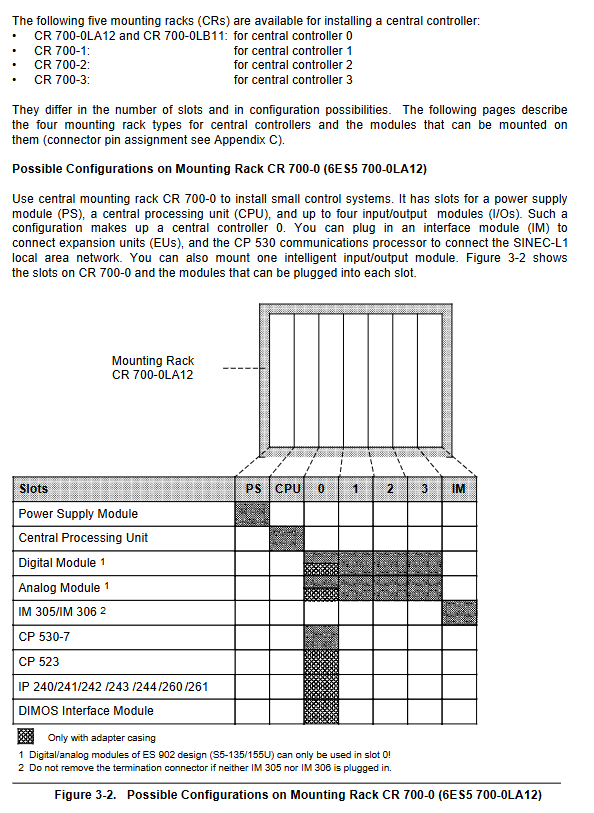

3.1 Centralized Configuration

Structure: 1 central controller (CC)+up to 3 expansion units (EU)

Interface modules: IM 305 (supporting 1 EU, cable ≤ 1.5m), IM 306 (supporting 3 EU, cable ≤ 2.5m)

Power supply: EU takes power from CC through interface module, with a maximum power supply current of 2A (IM 306)

3.2 Distributed Configuration

Maximum distance: Depending on the interface module, it can reach up to 3000m

Interface modules: AS 301/302, IM 304/314, etc., supporting multiple EU extensions

Advantages: Reduce sensor/actuator wiring costs and install closer to the site

Programming and Functionality

4.1 Programming Fundamentals

Programming language: STEP 5, supports 4 representation methods, structured/linear programming

Program block types: Program block (PB), Function block (FB), Sequential block (SB), Data block (DB), Organization block (OB)

Execution method: Loop execution (OB1), interrupt driven, time controlled

4.2 Core Functions

Interrupt handling: Supports process interrupts, time interrupts, and response time can be calculated

Analog processing: compatible with multiple sensors, supports wire breakage detection and sampling, including FB250/251 matching blocks

PID control: up to 8 control loops, sampling time ≥ 100ms

Real time clock: Built in CPU 943/944, supports time related program execution

Installation and Startup

5.1 Installation Requirements

Mechanical installation: The module is fixed on the mounting bracket (CR/ER series), allowing for a 15 ° tilt installation. High power modules require a fan

Wiring specifications: Distinguish between control circuits (5V/5.2V/24V) and load circuits, with different wiring for floating/non floating modules

Electromagnetic compatibility: Cable grouping and wiring, shielded cable double ended grounding, potential bonding conductor cross-section ≥ 16mm ² (≤ 200m)

5.2 Startup steps

Overall reset: Clear program memory, data, and error IDs, restore system data to default values

Program transfer: Directly transferred through memory submodules or programmers, automatically loaded into internal RAM by CPU 943/944

Parameter settings: Determine timer/counter/flag retention, set scan monitoring time (default 500ms, maximum 2.55s)

Program testing: Use functions such as STATUS/VAR, FORCE, etc. to check I/O signals and program logic

Fault diagnosis

Diagnostic tools: ISTACK (Interrupt Stack) analysis, LED indicator lights, BSTACK (Block Stack) program tracking

Common faults: battery failure (BAU signal), scan time timeout (ZYK), I/O not ready (PEU), memory error

Solution: Replace the faulty module, retransmit the program, check the wiring and terminal resistance

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

-

KEBA KeTop CB211 - Connection Box

-

KEBA HT4 / 20656 - Kammann Hand Held Keypad

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Y1-K1-Y2 PA9 - Engel Board Module

-

LTI MOTION CDA32.004C3.0 - Servo Drive 230V AC

-

KEBA E-CG-CONTROL - ECGCONTROL Module

-

KEBA Kemro K2-200 OP350/W 68334 - Engel EC200 Panel Membrane Touch Glass

-

KEBA i1075 - Membrane Keyboard

-

KEBA E-HSI-M - Interface Module

-

KEBA LQ10D321-ERSAT - ZTEILSET FNOB

-

KEBA E-16-DIGOUT/G - Circuit Board

-

KEBA HT4/Neutral/16846 - Mikron Handheld Terminal

-

KEBA KeTop CB310-000 - Connection Box

-

KEBA DC 161/IP20/17369 - Interface Card Module

-

KEBA E-16-DIGOUT-PLUS - Elektronik Bau Linz 262-1456-85-B

-

KEBA HT501 - Handheld Terminal

-

KEBA HT401-4X20 - Teach Pendant

-

KEBA E-3-ACU-10 D16738 - Controller Card Module

-

KEBA 240/A 068371 - Analog Output Module

-

KEBA E-7TEMP D1323E/F/G - Temperature Circuit Board

-

KEBA KeTop TT100-eaa - Communication Cable

-

KEBA E-16 DIGOUT-PLUS D1456D - Engel Output Board

-

KEBA Kemro K2-200 - Touch Panel Glass Digitizer

-

KEBA CC100A03/CAN/4 - PLC Chassis 16-Slot Rack Motherboard 1842E-0

-

KEBA CU 211 - PLC Power Supply

-

KEBA KeTOP CB310-S00 - Connection Box

-

KEBA I/O BUS KOPPLUNG D1547C - Engel Circuit Board

-

KEBA HCS01.1E-W0013-A-02 - Servo Drive

-

KEBA SMC1-Z30 - LTI Security Safety Control

-

KEBA E-PS88-M/C D1527C - Power Supply Board

-

KEBA D1678C / E-SEK - Control Board

-

KEBA 1.83E+02 - Circuit Board Module

-

LUST LTI/KEBA DSM4-05.4-20R.96-W1A - AC Servo Motor

-

Engel/KEBA OP 362-LD/W-5200 - Kemro Ke-200 Membrane Keypad Touch Screen

-

KEBA HT4 24V/0.2A - Kammann Hand Terminal C3052-R47

-

KEBA Kemro K2-200 BL210/B - Injection Molding Machine Controller Module

-

KEBA E-8-ANALOG D1432B - Analog Board

-

KEBA DM272 - Input Output Module

-

KEBA AR161 - PCB ML-EUMIG

-

KEBA E-PS-24V 1825E-1 - Power Supply Board

-

KEBA E-8-THERMO 1770B-1 - Engel Temperature Control Board

-

KEBA HT4-221-20556 - Kammann Hand Terminal

-

KEBA E-10-ANALOG-SUB D1458D - Circuit Board

-

KEBA AC 441 - Control Module 18-32 VDC

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA E-ANA-SUB2 D1690C - Analog Submodule Card

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad

-

KEBA OP 331/C-4400 - Keview V2 LCD Display Screen Panel

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923