K-WANG

SIEMENS SIMATIC TI545/TI555 Controller

SIEMENS SIMATIC TI545/TI555 Controller

Overview

The SIMATIC TI545/TI555 controller system manual focuses on the hardware installation, system wiring, program storage, startup, and troubleshooting of TI545-1102 and TI555-1101/1102 CPUs. It specifies that the system supports Series 505 local base (4/8/16 slots) and Series 500 remote base (requires PPX: 500-5114A RBC conversion), and hardware installation must follow the power budget (+5V 55W, -5V 3.75W), grounding specifications (grounding resistance ≤ 0.1 Ω), and anti-interference design (shielded twisted pair, noise suppression); The program can be stored in EEPROM/EPROM (128K/256K bytes), and startup requires completing memory configuration (TI545 maximum 192K bytes, TI555-1102 maximum 1920K bytes) and I/O registration; Troubleshooting relies on LED status indication, auxiliary functions (AUX 10/11/12/20/25/29), and RS-485 cable detection (line resistance 52-87 Ω), while providing Series 500 system upgrade solutions to adapt to discrete/analog control scenarios in industrial automation.

Core characteristics of the system

Control capability: Supports discrete/analog control, can execute relay ladder logic (RLL), PID loop, special function program (SFPGM), supports 256 SF modules;

Communication ability:

Local communication: 2 RS-232/422/485 ports (baud rate 300-19200), supporting programming devices/printers/modems;

Remote I/O: 1 RS-485 I/O port, maximum connection to 15 remote bases, distance 3300 feet (1km);

Storage capacity: Supports EEPROM/EPROM non-volatile storage (128K/256K bytes), RAM configurable (TI545 up to 192K bytes, TI555-1102 up to 1920K bytes);

Compatibility: Supports Series 505 local dock and Series 500 remote dock (requires RBC conversion), compatible with old system upgrades.

Hardware Installation Specification

1. Base and module installation

(1) Base type and installation

Key requirements for base model, slot number, installation method

PPX: 505-6504 4 panel installation requires NEMA enclosure with a spacing of ≥ 6 inches (heat dissipation)

PPX: 505-6508 8-panel installation screw hole size as shown in Figure 3-4, torque 2.6-5.22 in lb

PPX: 505-6516 16 16 rack/panel installation compatible with 19 inch rack, depth 7.99 inches

Series 500 6/8/12/14/16 panel installation requires PPX: 500-514A RBC conversion to remote base

(2) CPU installation

Installation location: Series 505 base second slot (adjacent to the power supply);

Battery configuration: 3V rechargeable lithium battery, switch 9 (DIP switch) control enable, backup for 6 months at 0-60 ℃, BATT GOOD light flashes when low battery level;

DIP switch settings:

Switch 1: Port2 mode (left=RS-422, right=RS-485);

Switch 2: Port1 function (left=programming port, right=printer port);

Switch 3-5: Port 1 baud rate (On=1, Off=019200=On/On/On);

Switch 6-8: Port 2 baud rate (same as Port 1);

Switch 9: Battery Enable (Left=On, Right=Off).

(3) Installation of Remote Base Controller (RBC)

Applicable scenarios: Series 505 remote base with PPX: 505-6851A, Series 500 remote base with PPX: 500-5114A;

Installation location: Remote base second slot;

Key settings:

Base number: Thumbwheel set 1-15 (0 is the local base, not available);

Baud rate: PPX: 505-6851A uses DIP switch 2 (Table 3-4), PPX: 500-5114A uses Thumbwheel (Table D-1);

Output hold: When the jumper selects communication interruption, output "hold" or "turn off".

2. Power installation and budget

(1) Power supply model and parameters

Power supply model Input voltage Output power Applicable scenarios

PPX: 505-6660A 110/220V AC (jumper selection)+5V 55W, -5V 3.75W AC power supply scenario

PPX: 505-6663 20-30VDC+5V 55W, -5V 3.75W DC power supply scenario

(2) Power budget calculation

Total power=sum of all modules+5V power+sum of all modules -5V power, must be ≤ 55W (+5V) and 3.75W (-5V);

Typical module power: CPU 4W, RBC 5W, analog module 4-5W, see Appendix B Table B-1 for details.

3. Anti interference and grounding design

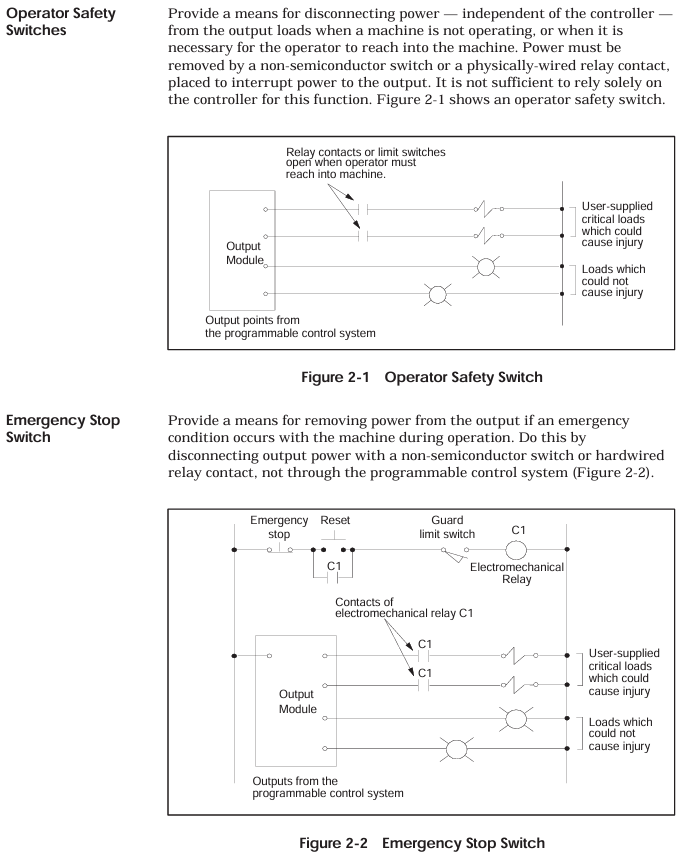

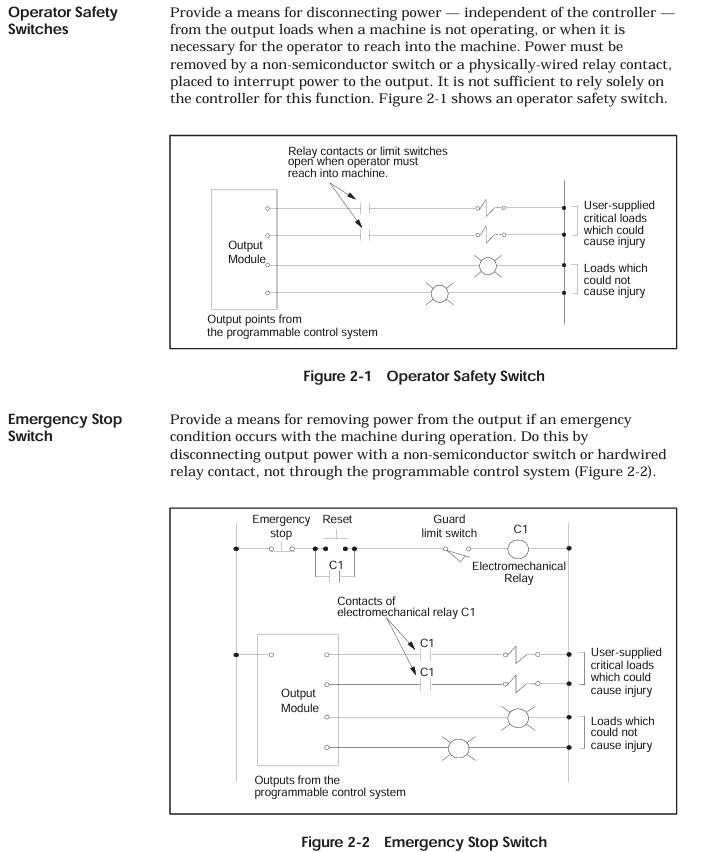

Noise suppression:

Noise source: motor, frequency converter, welding machine, with a spacing of ≥ 3 feet;

Suppression measures: Add RC/MOV buffer to inductive load (Figure 2-5/2-6), and use shielded twisted pair cable (12 twisted per foot) for signal;

Grounding specifications:

Grounding resistance ≤ 0.1 Ω, use # 8 copper wire to ground the electrode;

Controller grounding: base → cabinet → grounding electrode, remove the paint surface to ensure conductivity (Figure 2-9/2-10);

Shielded grounding: The input cable is shielded and grounded at the signal source end, and the output cable is shielded and grounded at the base end (single ended grounding).

System cabling and connections

1. Cable selection and wiring

(1) Key cable types

Recommended cable usage, key parameters, maximum length

RS-485 backbone Belden 9860 16AWG, impedance 124 Ω, capacitance 35.8pf/m 3300 feet (1006m)

RS-485 branch line Belden 9271 25AWG, impedance 124 Ω, capacitance 40pf/m 33 feet (10m)

RS-485 backup wire Belden 9182 22AWG, impedance 150 Ω, capacitance 28.9pf/m 2200 feet (670m)

Power connection wire 14AWG copper wire, temperature resistance ≥ 75 ℃, rated voltage ≥ 300V, short distance (≤ 10 meters)

(2) RS-485 wiring specification

Topology structure:

Main line: star (T-shaped) or bus type, avoiding multiple branches (Figure 4-8/4-9);

Terminal resistance: Add 120 Ω (9860/9271) or 150 Ω (9182) to both ends of the base, and do not add to the middle base;

Length limit:

2-5 terminal blocks: 9860 up to 3300 feet, 9182 up to 2200 feet;

16 terminal blocks: 9860 maximum 2200 feet, 9182 maximum 1467 feet (Table 4-2);

Wiring method: Underfloor/ceiling/surface trunking, avoid parallel connection with power cables (Figure 4-4/4-5).

2. Peripheral connection

Programming equipment: connected via Port1 (RS-232), distance ≤ 50 feet, using a 9-pin D-type connector (Figure 3-12);

Printer: Set Port1 as the printer port (switch 2 on the right), supporting XON/XOFF or READY/BUSY handshakes (Figure 4-13/4-14);

Modems: Port 1 connection, supports dedicated line (DCE interface, V.32 error correction) or dial-up (TIDIAL software required), unlimited distance (Figure 4-12).

Program Storage and System Startup

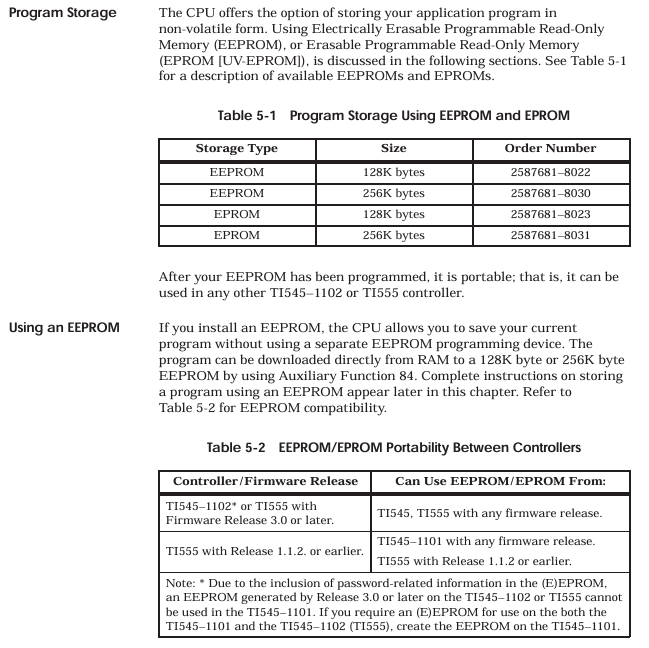

1. Program storage medium

Storage type, capacity, order number, key characteristics

EEPROM 128K bytes 2587681-8022 electrically erasable, supports RAM<->EEPROM replication, portable (Release 3.0+CPU universal)

EEPROM 256K bytes 2587681-8030 on the same left, with larger storage capacity

EPROM 128K byte 2587681-8023 UV erase, EEPROM copy required, not directly programmable

EPROM 256K bytes 2587681-8031 on the same left, with larger storage capacity

(2) EEPROM operation (AUX 84)

Copy RAM → EEPROM: The EEPROM needs to be erased first to ensure that the user program is ≤ 126K/254K bytes;

Copy EEPROM → RAM: If there is a program in EEPROM and the battery is damaged during power on, it will be automatically loaded into RAM;

Erase EEPROM: Select "Erase" for AUX 84, the program cannot be restored after erasing.

2. System startup process

(1) Initial startup steps

Initialize CPU:

Turn off the battery (switch 9 on the right), disconnect the power, and ensure that there is no EEPROM/EPROM;

Power on, CPU clears memory and enters Program mode;

Turn on the battery (left of switch 9), the BATT GOOD light will turn on (fully charged after 36 hours);

Configuration and Download:

Connect programming device (TISOFT 5.0+), configure memory (Table 6-1/6-2) and I/O base;

Download user program, JOG test actuator (motor/solenoid valve);

Switch to Run: Set the CPU to RUN mode and check that the CPU GOOD and RUN lights are on.

(2) Memory configuration (example)

CPU model, memory type, minimum capacity, maximum capacity, block size

TI545-1102 L (trapezoidal) 1K bytes 59K bytes 1K bytes (occupying 3K of system memory)

TI545-1102 V (variable) 1K bytes 177K bytes 1K bytes

TI555-1102 L (trapezoidal) 1K bytes 635K bytes 1K bytes (occupying 3K of system memory)

TI555-1102 V (variable) 1K bytes 1905K bytes 1K bytes

Troubleshooting and System Upgrade

1. Fault diagnosis tool

(1) LED status indication

LED name status meaning

CPU GOOD lights up. CPU has no fatal errors and is running normally

CPU GOOD extinguishes fatal errors (ROM failure, watchdog timeout, etc.)

RUN is on, CPU is in RUN mode

RUN flashing analog operation, discrete programming mode

BATT GOOD lights up, the battery is normal and enabled

BATT GOOD flashing battery charging or low battery level

BATT GOOD battery disabled or damaged

(2) Auxiliary functions (AUX)

Auxiliary Function Usage Key Operations

When the AUX 10 is powered on and the battery is restarted, it maintains V memory and clears memory when it is turned off

AUX 11 partially restarts to clear discrete I/O and maintain L/V/K/S memory

AUX 12 fully restarts and clears all I/O and timers/counters, downloads preset values

AUX 20 runs diagnostic tests on RAM/ROM/hardware, displaying the location of the fault

AUX 25 displays faulty I/O and lists unconfigured or faulty I/O modules

AUX 29 displays the diagnostic unit's scan time, mode, and battery status (Figure 7-1)

2. Common fault handling

Possible causes and solutions for the fault phenomenon

CPU GOOD ROM diagnostic failure, return to factory for repair

CPU GOOD extinguishes watchdog timeout check program scanning time, AUX 11 restarts

Communication failure RS-485 cable fault. Measure the inter line resistance (52-87 Ω) and check the terminal resistance

The battery light is flashing. If the battery is low after charging for 24 hours and still flashes, replace it

I/O unresponsive base unregistered AUX 25 check, reconfigure I/O

3. Series 500 system upgrade

(1) TI520/530 series upgrade

Hardware modification:

Remove the original controller/distributed base controller (DBC);

16/8 slot base with PPX: 500-5840 adapter, equipped with 24V power supply (PPX: 500-2151A);

Install PPX: 500-5114A RBC, with base numbers 1-15;

Wiring renovation:

RS-485 cable (Belden 9860) with a maximum backbone length of 3300 feet;

Add a 120 Ω resistor to the terminal block (base at both ends);

Software configuration:

Reconfigure I/O (base numbers 1-15) and download the program.

(2) TI560/565 series upgrade

RS-485 type: Remove the original CPU directly, connect the RS-485 cable to TI545/TI555 I/O ports, and change the base number to 1-15;

RF type: Add PPX: 505-6860 RF → RS-485 converter, then connect to TI545/TI555, change base number 1-15.

Appendix Key Information

1. Environmental Parameters (Appendix A)

Parameter indicators

Working temperature 0-60 ℃ (32-140 ℉)

Storage temperature -40-70 ℃ (-40-158 ℉)

Relative humidity 5% -95% (non condensing)

Vibration sine: 10-57Hz 0.15mm peak to peak value; Random: 57-150Hz 1.0g

Electrostatic discharge IEC 801-2 Level 4 (15kV)

Isolation Voltage Field - Controller 1500Vrms

2. Recommended spare parts (Appendix 7.9)

Base: PPX: 505-6504/6508/6516;

Power supply: PPX: 505-6660A/6663;

Fuse: 3A slow melting (6660A), 8A fast melting (6663);

Storage media: EEPROM 128K/256K, EPROM 128K/256K;

Cable: RS-232 programming cable (2601094-8001).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923