K-WANG

SIEMIENS SIMATIC 505 Analog I/O Module

SIEMIENS SIMATIC 505 Analog I/O Module

The complete user guide for SIMATIC 505 series analog I/O modules focuses on four single width modules (input module PPX: 505-6108A/6108B, output module PPX: 505-62088A/6208B), covering the entire process of module technology principles, installation and wiring, calibration and maintenance, and troubleshooting. All modules are compatible with the Series 505 controller, and the input module supports 8-channel ± 5V/± 10V voltage or 0-20mA current signal acquisition (12 bit resolution for version A and 13 bit resolution for version B). The output module synchronously provides 8-channel 0-10V voltage and 0-20mA current signals (12 bit resolution); Installation must follow shielded twisted pair wiring and terminal block wiring specifications. The input module does not require an external power supply, while the output module requires a 20-28VDC user power supply; Calibration needs to be carried out every 6-12 months to ensure measurement and control accuracy in industrial scenarios. At the same time, solutions such as LED status indication and fuse replacement are used to ensure stable operation of equipment, suitable for industrial analog signal processing scenarios such as pressure, temperature, and flow.

Overview of Core Framework and Modules

2.1 Basic Information

Applicable module analog input: PPX: 505-6108A, PPX: 505-6108B; Analog output: PPX: 505-6208A, PPX: 505-6208B

The core positioning is aimed at industrial automation engineers, providing a full process operation guide for module selection, installation, configuration, and maintenance

Certified compliance with UL (Industrial Control Equipment), CSA (Process Control Equipment), ATEX Class I Div.2 (Hazardous Areas), CE (Low Voltage/EMC Directive) and other standards

The supporting documents should be used in conjunction with the SIMATIC 505 System Manual, SIMATIC 500/505 TISOFT Release 6.3 User Manual, and other related documents

2.2 Module Core Positioning and Advantages

Design features: Single width structure, can directly replace dual width analog modules (without modifying the original wiring), saving controller slot space;

Function positioning: As a bridge between the Series 505 controller and industrial field equipment, the input module collects analog signals from sensors (such as temperature transmitters and pressure sensors) and converts them into digital signals. The output module converts the controller's digital signals into analog signals to drive actuators (such as regulating valves and frequency converters);

Core advantages: Supports multiple signal types, strong anti-interference ability (1500Vrms isolation), easy installation and maintenance, suitable for harsh industrial environments (0-60 ℃ working temperature, 5% -95% non condensing humidity).

Module technology principles and core parameters

3.1 Analog Input Module (PPX: 505-6108A/6108B)

3.1.1 Working principle

The module adopts analog-to-digital conversion (ADC) technology to convert continuously changing voltage/current signals into discrete digital quantities:

PPX: 505-6108A: Adopting dual slope integral conversion method, strong anti-interference ability, suitable for low-speed stable signal acquisition;

PPX: 505-6108B: Adopting the successive approximation conversion method, the conversion speed is faster and the resolution is higher, suitable for high-precision dynamic signal acquisition.

Both convert current signals into voltage signals through internal 250 Ω± 0.1% precision resistors, and then perform ADC conversion.

3.1.2 Key Technical Parameters

Parameter category PPX: 505-6108A PPX: 505-6108B

Number of channels: 8 channels, single ended input: 8 channels, single ended input:

Signal range voltage: ± 5V (default), ± 10V (jumper selection); Current: 0-20mA Same as left

Resolution of 12 bits+sign bit (± 5V range: 1.25mV/step; 0-20mA range: 5 μ A/step) 13 bits+sign bit (± 5V range: 0.625mV/step; 0-20mA range: 2.5 μ A/step

Conversion accuracy (25 ℃) Voltage: ± 0.5% of full scale; Current: ± 0.7% full-scale voltage: ± 0.25% full-scale; Current: ± 0.35% of full scale

Temperature coefficient voltage: 58ppm/℃; Current: 83ppm/℃ Voltage: 50ppm/℃; Current: 80ppm/℃

The maximum conversion time is 330ms (input system delay); Maximum update time 250ms (full channel), maximum sampling repetition time 25ms

Input protection overvoltage: ± 30VDC (clamp diode); Overcurrent: 30mA (optical isolation) same as left

Power requirement: Base only power supply (from controller): maximum 4W, typical 2.5W. Base only power supply: maximum 4W, typical 1.1W

3.1.3 Digital Format and Signal Conversion

The controller only receives 16 bit digital signals, and the module encapsulates the ADC conversion results into 16 bit words:

PPX: 505-6108A: bits 1-12 are valid data, bit 13 is the sign bit (1=negative, 0=positive), bit 14 is the over range bit (1=over range), bits 15-16 are invalid bits (fixed 0);

PPX: 505-6108B: bits 1-13 are valid data, bit 14 is the sign bit, bit 15 is the overrange bit, and bit 16 is the invalid bit (fixed 0);

Over range determination: When the input voltage exceeds ± 5.00125V (± 5V range) or ± 10.0025V (± 10V range), the over range position 1 and the digital quantity exceed ± 32000;

Conversion formula:

Voltage input (± 10V range): Digital quantity (WX)=(input voltage/10V) × 32000;

Current input (0-20mA range): Digital quantity (WX)=(input current/20mA) × 32000.

3.2 Analog Output Module (PPX: 505-6208A/6208B)

3.2.1 Working principle

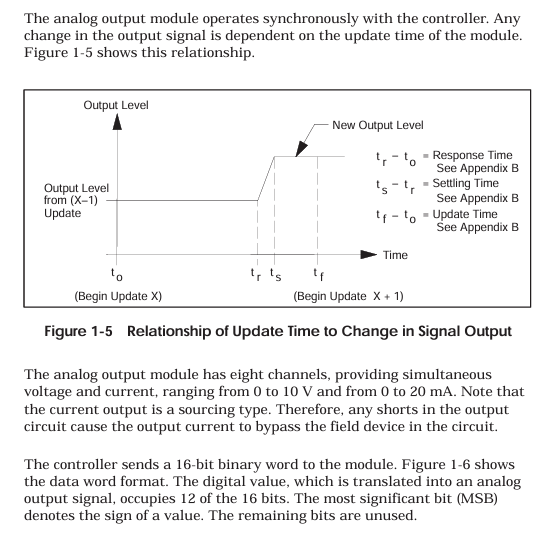

The module receives a 16 bit digital signal from the controller and converts it into a continuous analog signal through digital to analog conversion (DAC) technology. The voltage and current outputs are synchronized (the same channel can output two types of signals simultaneously without switching):

The current output is designed as a source type, and in the event of a short circuit, the current will bypass the on-site equipment. It is necessary to avoid short circuits in the output circuit;

If the digital sign bit (bit 1) is 1 (negative value), the module does not update the output and maintains the previous positive value output.

3.2.2 Key Technical Parameters

Parameter category PPX: 505-6208A PPX: 505-6208B

Number of channels: 8 channels, single ended output: 8 channels, single ended output:

Signal range voltage: 0-10VDC; Current: 0-20mA (source type) same as left

Resolution 12 bits (voltage: 2.5mV/step; Current: 5 μ A/step) Same as left

Conversion accuracy (25 ℃) Voltage: ± 0.5% of full scale; Current: ± 0.5% full range same as left

Full temperature range precision voltage: ± 1.45% of full range; Current: ± 1.83% full range same as left

Temperature coefficient voltage: 136ppm/℃; Current: 204ppm/℃ Voltage: 50ppm/℃; Current: 100ppm/℃

Response characteristic response time: 27ms (minimum) -54ms (maximum); Stability time: Voltage 0.2ms, Current 2.0ms Response time: Maximum 10ms Stability time: Same as left

Load requirement voltage: ≥ 5000 Ω, maximum capacitance 0.01 μ F; Current: 10-600 Ω (over 600 Ω requires 10V power supply, maximum 1000 Ω) Same as left

Power demand base power supply: maximum 2W (typical 1.0W); User Power Supply: 20-28VDC, 0.5A (Ripple ≤± 0.4VDC, UL Class 2) Same as Left

3.2.3 Digital Format and Signal Conversion

The controller outputs a 16 bit digital quantity: bits 1-12 are valid data, bits 13-16 are invalid bits (fixed to 0);

Conversion formula:

Voltage output: Digital quantity (WY)=(target voltage/10V) × 32000;

Current output: Digital quantity (WY)=(target current/20mA) × 32000.

Installation and wiring specifications

4.1 Wiring Core Requirements

4.1.1 Cable selection and protection

Cable specifications: 14-24 AWG (0.18-1.5mm ²) shielded twisted pair, supporting stranded (multi strand) or solid (single strand) wires;

Temperature and voltage resistance: The wire has a temperature resistance of ≥ 75 ℃ and a rated voltage of ≥ 300V, meeting the insulation requirements of industrial environments;

Anti interference measures:

Separate the wiring of signal cables and power cables (such as motor power lines) to avoid parallel laying, and form a 90 ° angle when crossing;

Avoid laying cables on vibrating surfaces, do not bend them into sharp angles, and use cable trays for standardized routing;

Shielding layer grounding: The shielding layer of the input cable is grounded at the signal source end, and the shielding layer of the output cable is grounded at the controller base end. It is strictly prohibited to ground both ends at the same time (to prevent noise caused by ground circulation).

4.1.2 Output module circuit calculation

Current circuit resistance: circuit cable equipment (L is the cable length, cable is the unit length resistance, equipment is the on-site equipment resistance); When the circuit is between 10-600 Ω, connect it directly; When the circuit is between 600-1000 Ω, a 10V DC power supply needs to be connected in series in the circuit; When the circuit is greater than 1000 Ω, it is necessary to replace the thick wire diameter cable or shorten the wiring distance, otherwise the output accuracy will decrease.

Fixed error of voltage circuit: The error equipment cables must ensure that the error is within the allowable range.

4.2 Terminal block wiring

4.2.1 Terminal block types and wiring steps

Terminal block model:

Standard configuration: PPX: 2587705-8006;

Optional: PPX: 2587705-8002 (wiring method consistent with standard, can replace old terminal blocks of double width modules);

Wiring steps:

Strip wire 0.25 inches (1.0cm), optional installation of fork/ring terminal blocks (Amp 321462/327891, compatible with # 4 studs);

Connect the wires according to the pin diagram (Figure 2-4), first connect the D terminal, then connect the C, B, and A terminals in sequence, and tighten the screws to ensure good contact;

After the wiring is completed, check the terminal definition to avoid misconnection (such as the "Return" terminal of the input module cannot be suspended, and the "24V common" output module needs to be reliably grounded).

4.2.2 Input module wiring differences

Key points to note for input type wiring method

Voltage input (± 5V/± 10V) signal+connected to voltage input terminal (such as channel 1 connected to A2 "V1 in"), signal - connected to return terminal (A3 "Return 1") does not need to be short circuited, ensuring that the internal resistance of the signal source is ≤ 1k Ω to avoid signal attenuation

Current input (0-20mA): First, short-circuit the current input terminal (A1 "I1 in") to the voltage input terminal (A2 "V1 in"). Connect the signal+to A1 and the signal - to A3. The short circuit should be directly connected with a wire and should not pass through high resistance components to ensure that the current flows through the internal 250 Ω resistor

4.2.3 Typical wiring scenarios

2-wire transmitter wiring (input module): transmitter+connected to input module current input terminal, transmitter - connected to return terminal, module provides power to transmitter through internal circuit;

4-wire transmitter wiring (input module): The transmitter is independently powered, with signal+connected to the current input terminal and signal - connected to the return terminal;

Output module wiring (4-channel example): Each channel simultaneously outputs voltage (such as A2 "V1 out") and current (A1 "I1 out"), which are connected to the corresponding actuators. The common terminal (Return) is grounded uniformly.

4.3 Module Installation and I/O Configuration

4.3.1 Module installation steps

Power off operation: Before installation, turn off the controller and all external power sources to avoid electric shock or component damage;

Slot selection: Insert the module into the idle single width I/O slot of the Series 505 controller, avoiding proximity to high-energy switch modules or EMI sources (such as frequency converters);

Fixed module: Tighten the module panel with screws and control the torque at 2.6-4.12 in lb (0.3-0.6N · m) to avoid damaging the module or base due to over tightening;

Static protection: Do not touch the module circuit board during installation, and wear an anti-static wristband if necessary.

4.3.2 I/O Configuration Process

Configuration tool: Use SIMATIC 500/505 TISOFT Release 6.3 software to connect the controller through programming devices;

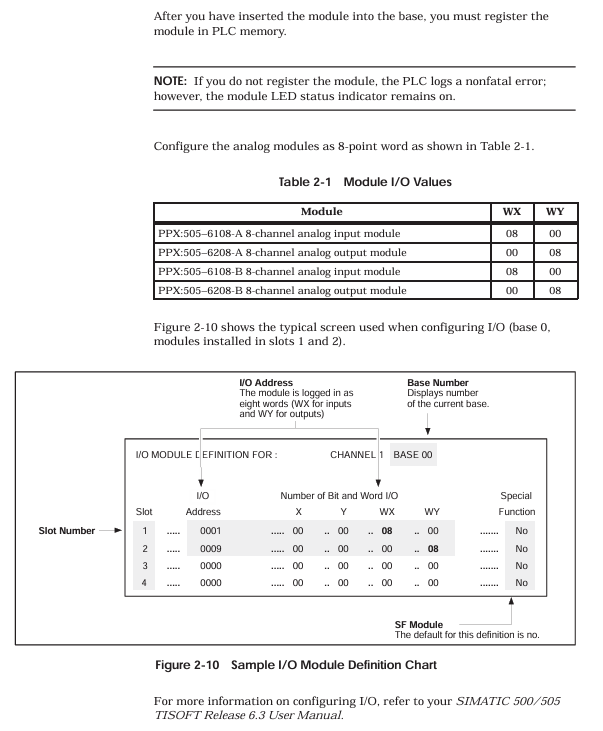

Module registration: Select the base number and slot number in the "I/O Module Definition Table", configure the module type and I/O parameters (Table 2-1):

|Module model | WX (number of input words) | WY (number of output words)|

| PPX:505–6108A | 08 | 00 |

| PPX:505–6108B | 08 | 00 |

| PPX:505–6208A | 00 | 08 |

| PPX:505–6208B | 00 | 08 |

Address allocation: The system automatically assigns I/O addresses (such as the input module address for slot 1 starting from WX0001), which are downloaded to the controller after configuration is complete;

Verify configuration: After powering on, observe the "Module Good LED" of the module. If the LED lights up, it indicates that the configuration is successful and the module has no faults.

Calibration and maintenance process

5.1 Basic Requirements for Calibration

5.1.1 Calibration cycle and conditions

Calibration cycle: It is recommended to calibrate every 6-12 months; If the module is used in high temperature and vibration environments for a long time, or if the measurement accuracy exceeds the tolerance, it needs to be calibrated immediately;

Environmental conditions: The calibration environment temperature is 25 ℃± 2 ℃, with no vibration or electromagnetic interference. The module reaches working temperature after being powered on for 30 minutes;

Tool preparation:

Calibration power supply: DC voltage source with an accuracy of ≥ 0.01% (used for input module calibration);

Measurement tool: a multimeter with an accuracy of ≥ 0.1% (for voltage/current measurement);

Load resistance: 5.1k Ω± 5% (voltage output calibration), 100 Ω± 5% (current output calibration);

Auxiliary tools: non-metallic screwdriver (to avoid short circuits), Euro extender card (optional, convenient for accessing potentiometers).

5.1.2 Calibration precautions

Disconnect the on-site wiring before calibration, leaving only the connections between the module, controller, and calibration equipment;

The controller needs to switch to "STOP mode" to avoid interference with calibration during operation;

The input module needs to first select the voltage range (jumper setting ± 5V or ± 10V) before calibration;

During the calibration process, avoid touching the module circuit board to prevent static damage or short circuits.

5.2 Input module calibration steps (PPX: 505-6108A/6108B)

Power off preparation: Turn off the controller power, disconnect the module field wiring. If using Euro extender card, remove the module first, insert the card, and then install the module onto the card;

Range selection: Select the calibration voltage range (± 5V or ± 10V) through the jumper on the module circuit board;

Power on preheating: Turn on the controller power and wait for 30 minutes for the module to reach operating temperature;

Device connection: Connect programming devices and controllers to ensure that module input data can be read; Connect the calibration voltage source to all input channels of the module;

Full range calibration (positive direction):

Input+5V (± 5V range) or+10V (± 10V range) to all channels;

Adjust the calibration potentiometer on the module circuit board with a non-metallic screwdriver until the programming device displays an average of+32000 for all channel numbers;

Full range calibration (negative direction):

Input -5V (± 5V range) or -10V (± 10V range) to all channels;

Adjust the potentiometer until the average digital value of all channels is -32000;

Accuracy verification: Enter+5V/+10V again to verify the numerical deviation:

PPX: 505-6108A: allowable deviation of ± 129/± 128;

PPX: 505-6108B: allowable deviation of ± 81/± 80;

Restore wiring: After calibration is complete, power off, remove the calibration equipment, restore on-site wiring and module installation positions, and reconfigure I/O addresses.

5.3 Calibration steps for output module (PPX: 505-6208A/6208B)

Power outage preparation: Turn off the controller and user power, disconnect the module load from the on-site wiring, and retain the user power wiring;

Load connection: Connect calibration loads to all output channels of the module (voltage channel connected to a 5.1k Ω resistor, current channel connected to a 100 Ω resistor);

Power on preheating: Turn on the controller and user power, wait for 30 minutes for the module to reach operating temperature;

Device connection: Connect programming devices and controllers to ensure that digital data can be written to the module;

Full range output: Write a digital quantity of 32000 to all channels (corresponding to 10V/20mA full range output);

Reference channel selection: Measure the current output values of all channels, calculate the average value, and select the channel with the output value closest to the average value as the reference;

Current calibration: Use a non-metallic screwdriver to adjust the calibration potentiometer so that the reference channel current output is 20.000mA (25 ℃);

Accuracy verification:

Voltage output: All channels must be 10.000V ± 50mV;

Current output: All channels must be 20.00mA ± 0.1mA;

If the deviation exceeds the tolerance, repeat steps 6-8;

Restore wiring: After calibration is completed, power off, remove the calibration load, and restore on-site wiring and module configuration.

5.4 Daily maintenance and troubleshooting

5.4.1 Key points of daily maintenance

Cleaning module: Clean the module panel and terminal block with a dry soft cloth every 3 months to avoid dust accumulation;

Wiring inspection: Check the tightening of terminal block screws every 6 months to prevent loose wiring caused by vibration;

Power inspection: Regularly check the user power supply (20-28VDC) of the output module to ensure that the ripple is ≤ ± 0.4VDC;

Fuse maintenance: When the output module fuse (0.5A fast melting, model PPX: 2587679-8009) burns out, it is necessary to first investigate the cause of overvoltage/overcurrent before replacing the fuse.

5.4.2 Common troubleshooting

Possible causes of malfunction, troubleshooting steps, and solutions

Module Good LED not lit (input module) Base power failure, module self diagnosis failure 1. Measure whether the base power supply voltage is normal; 2. Check if the module is correctly inserted into the slot; 3. Disconnect all wiring and reinstall. 1. Repair the power supply of the base; 2. Re plug and unplug the module; 3. Module self diagnosis failure requires return for repair

Module Good LED not lit (output module) Base power failure, user power failure, blown fuse, self diagnosis failure. 1. Measure the base and user power supply; 2. Check the status of the fuse; 3. Check if the module wiring is short circuited. 1. Repair the power supply; 2. Replace the fuse; 3. After eliminating the short circuit, power on again; 4. Self diagnosis failure requires return for repair

Input module reading error, wiring error, signal noise, calibration deviation, signal source out of range. 1. Check the wiring by referring to the pin diagram; 2. Check if the grounding of the shielding layer is correct; 3. Verify whether the output of the signal source is within ± 5V/± 10V or 0-20mA; 4. Recalibrate module 1. Correct wiring; 2. Optimize shielding and wiring; 3. Adjust the signal source to the effective range; 4. Complete calibration

The output module outputs abnormal loads beyond the range, digital input errors, calibration deviations, and unstable user power supply. 1. Measure whether the load resistance/capacitance meets the requirements; 2. Check if the digital output of the controller is correct; 3. Recalibrate the module; 4. Measure the user's power ripple. 1. Replace the load that meets the requirements; 2. Repair the digital output of the controller; 3. Complete calibration; 4. Replace the stable power supply

PLC reports non fatal module configuration error, module and controller communication failure. 1. Check the I/O configuration parameters (WX/WAY quantity); 2. Check if the module is in good contact with the base; 3. Restart the controller. 1. Correct the configuration parameters; 2. Re plug and unplug the module; 3. If the error persists after restarting, it needs to be returned for repair

Environmental and Safety Parameters (Appendix B)

6.1 Environmental adaptation parameters

Parameter indicators

Working temperature 0-60 ℃ (32-140 ℉)

Storage temperature -40-70 ℃ (-40-158 ℉)

Relative humidity 5% -95% (non condensing)

Vibration resistance sinusoidal vibration: 10-57Hz, 0.15mm peak to peak value; Random vibration: 57-150Hz, 1.0g

Impact resistance meets the IEC 68-2-27 Test Ea standard

Electrostatic Discharge (ESD) IEC 801-2 Level 4 (15kV)

Electromagnetic compatibility (EMC) conducted immunity: IEC 801-4 Level 3; Radiation immunity: IEC 801-3 Level 3

1500Vrms between the isolation voltage field and the controller

All components of corrosion protection are treated with corrosion-resistant materials, coatings, or spray paint

6.2 Safety Regulations

Overvoltage protection: Input module ± 30VDC, output module 30VDC;

Overcurrent protection: Input module 30mA, output module protected by fuse (0.5A);

Hazardous area use: Complies with ATEX Class I Div.2 standards and can be used in flammable dust environments (must meet dust explosion prevention requirements);

Wiring safety: The rated voltage of signal cables should be ≥ 300V, avoid mixing with power cables, and prevent insulation breakdown.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923