K-WANG

SIEMENS SIMOTICS L-1FN3 Linear Motor Operating Instructions

SIEMENS SIMOTICS L-1FN3 Linear Motor Operating Instructions

Overview

SIMOTICS L-1FN3 series permanent magnet synchronous linear motor operation guide, covering the entire life cycle process from receiving, installation to scrapping. The core information includes: the motor is a modular structure (including primary components, secondary components, and optional precision coolers/secondary coolers), with protection level of IP65 for primary components, minimum IP23 after installation, suitable medium temperature of * * -20... 220 ° C * * (special sealing letter needs to be replaced for low temperature), cooling method is water cooling (maximum pressure of cooling circuit is 10 bar), and needs to be used with SAX. electric actuators or SKD./SKB./SKC. electric hydraulic actuators; The manual emphasizes the safety risks of strong magnetic fields (the suction force of the secondary component permanent magnet can reach several kN, and those wearing pacemakers need to maintain a distance of ≥ 500mm), electrical connection specifications (must comply with SELV/PELV standards, and the shielding layer must be reliably grounded), and safe operation throughout the entire process. At the same time, it provides detailed guidance on mechanical installation dimensions, fault handling, maintenance, and waste disposal (secondary components need to be demagnetized at 300 ° C or above) to ensure the safe and stable operation of the motor.

Product Technical Characteristics

1. Basic parameter table

Parameter category specific specifications

Motor type: Permanent magnet synchronous linear motor

Modular structural form (primary components: including 3-phase winding+main cooler; secondary components: permanent magnet+steel base; optional precision cooler/secondary cooler)

Protection level for primary components: IP65 (compliant with DIN EN 60034-5); Motor after installation: minimum IP23 (determined by machine design)

Cooling method: Water cooling (maximum pressure of cooling circuit is 10 bar, interface is G1/8 pipe thread, in accordance with DIN ISO 228-1)

Thermal protection primary component with built-in 1 PTC thermistor (response threshold+120 ° C, compliant with DIN 44081/44082, Temp-S circuit)

Temperature monitoring Temp-F circuit (1FN3xxx-xxxx-xxx1 with KTY84 sensor, 1FN3xxx-xxxx-xxx3 with Pt1000 sensor)

Insulation Class Thermal Class 155 (F Class, compliant with EN 60034-1)

Electrical interface 1FN3050: Fixed cable (with/without connector); 1FN3100-1FN3900: Integrated connector+cover plate

2. Environmental and adaptation requirements

Temperature range:

Conventional: -5... 220 ° C; Low temperature: -20... 150 ° C (special sealing letter needs to be replaced: DN15... 50 is 428488060, DN65... 150 is 467956290)

Storage/transportation temperature: -5... 40 ° C (condensation and freezing are not allowed)

Rating reduction factor: When the installation height is greater than 2000m, the voltage needs to be reduced (such as 0.877 for 3000m and 0.656 for 5000m)

Adaptive actuator: It needs to be selected according to the driving force and stroke, as shown in the following table:

Applicable scenarios for actuator series driving force stroke

SAX. 800N 20mm DN ≤ 50 motor, light load

SKD. 1000N 20mm DN ≤ 50 motor, high load

SKB. 2800N 20mm DN ≥ 65 motor

SKC. 2800N 40mm DN ≥ 65 motor, large stroke requirement

Core safety requirements

1. Strong magnetic field safety (highest priority)

Risk point: The secondary component contains permanent magnets, and there is still a strong magnetic field in the power-off state. The suction force can reach several kN (equivalent to squeezing hundreds of kg of heavy objects), and the magnetic field strength can reach 3mT at a distance of 150mm (in accordance with Directive 2013/35/EU)

Safety measures:

Individuals wearing pacemakers/insulin pumps must maintain a distance of ≥ 500mm;

The installation of secondary components requires at least 2 people to work, wear gloves, prepare 3kg non-magnetic hammers and 10 ° -15 ° hardwood wedges (anti extrusion rescue);

Only remove the packaging of secondary components before installation, and it is forbidden to remove multiple packages at the same time. Do not place them side by side when they are not fixed;

It is prohibited to bring magnetic items (watches, steel tools) into the secondary component sensing area.

2. Electrical safety

Power requirements: Only allow connection to SELV (safe low voltage) or PELV (protective low voltage) power supply;

Induced voltage risk: When the primary and secondary components move relative to each other, the cable interface will generate induced voltage, which needs to be operated after power-off. It is forbidden to touch uninsulated interfaces;

Grounding and shielding:

Equipment with protection level I must be reliably grounded (to prevent contact voltage);

At least one side of the cable shielding layer is grounded through the grounding shell, and unused core wires need to be insulated or grounded;

The shielding layer of the power cable needs to be connected to the power module over a large area, and the protective grounding wire (PE) should be directly connected to the power module to prevent high discharge current from damaging the equipment.

3. Safe operation

Cooling system: No operation without cooling is allowed (overheating can cause the cooling water to vaporize and burst the pipes). The cooling circuit can only be connected after the motor has cooled down;

High temperature protection: The surface temperature of the motor during operation may exceed 100 ° C, and a "Hot Surface Warning" label should be affixed. During maintenance, it should be cooled down or protective gloves should be worn;

Unexpected operation: During debugging, it is necessary to limit the current and speed, ensure smooth travel, and keep personnel away from the operating/squeezing area.

Full process operation guide

1. Preparation for use (transportation and storage)

Transportation requirements:

Shipping/Highway: No additional magnetic field protection required;

Air freight: In accordance with IATA regulations, two secondary components must be stacked in opposite directions (offset<1cm), otherwise they must be transported as dangerous goods (magnetic field>0.418A/m at a distance of 2.1m);

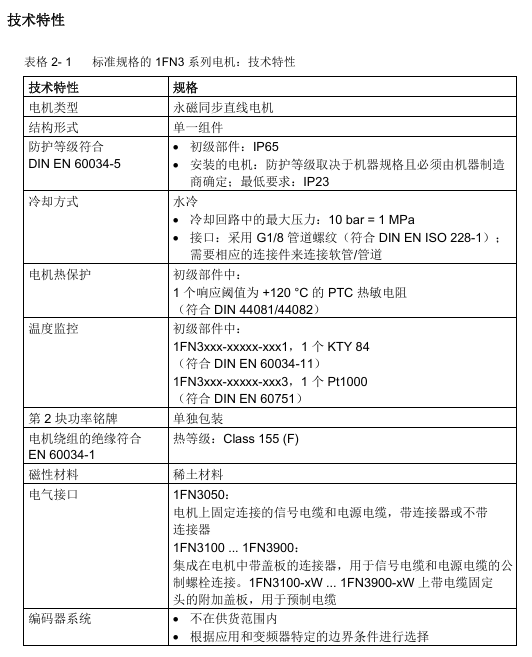

Lifting: Primary components require lifting eye bolts (in accordance with DIN 580), with a horizontal lifting angle of ≥ 50 ° and a center of gravity perpendicular to the hook.

Storage requirements:

Environment: 1K3 level (temperature -5... 40 ° C, humidity 5% -85%, no condensation/vibration);

Duration: Up to 2 years, exposed parts without anti-corrosion agents need to be coated with Tectyl, and the cooling system needs to be emptied and blown with dry compressed air.

2. Mechanical installation

Fixed specifications:

Screw: Grade 10.9 brand new screw, tightening torque must meet the standards (M5=7.6Nm, M6=13.2Nm, M8=31.8Nm);

Surface: The fixed surface needs to be free of oil/grease/paint, with a surface roughness Rz of 10-40 μ m;

Screw in depth: It must comply with the minimum (e.g. 1.8 × d for St 37 material) and maximum limit (calculated by the machine tool manufacturer).

Installation steps:

Check the installation dimensions (installation dimension error of ± 0.3mm for different configurations of heavy-duty/long-term motors);

Clean the installation surface and install secondary components (tighten the screws in the prescribed order, with all "N" markings facing the same direction);

Install primary components (note to align with the "N" mark on the secondary components, and ensure that the fixing screws are screwed in to the correct depth);

Inspection: The slider needs to move flexibly (force fluctuations caused by tooth groove force are normal), and the air gap (0.5mm film with cover plate and 1.0mm film without cover plate, which should be able to move easily).

3. Connection (cooling and electrical)

Cooling circuit connection:

Material: Brass/stainless steel is recommended for the coolant interface, and the hose should be resistant to coolant (Festo/Rectus brand is recommended);

Circuit: It is recommended to have an independent circuit, and ensure that the inlet temperature of each primary component is consistent when connected in parallel. Flexible hoses should be used for connection (to prevent rigid connection seal failure);

Coolant: Water containing anti-corrosion agent (chloride/sulfate<100mg/l, pH=6.5-9.5), recommended 25% -30% ethylene glycol mixture (freezing point ≤ -5 ° C).

Electrical connection:

Cable specifications: 4-core power cable (core wire cross-section ≥ 2.5mm ², 2.5mm ² corresponds to maximum rated current of 21A), 4-core signal cable (cross-section 0.5mm ²);

Pin layout: The power interface is U/V/W/PE, and the temperature sensor interface needs to distinguish between PTC (Temp-S) and KTY84/Pt1000 (Temp-F). The core wire color needs to match (such as - KTY/Pt1000 for white and+KTY/Pt1000 for black);

Shielding treatment: Signal/power cables need to be wired separately, and the shielding layer should be grounded extensively (using clamps/clamps).

4. Debugging

Prerequisite: Complete mechanical installation, electrical/cooling connections, and have drive system documentation;

Key steps:

Checklist confirmation (general: complete components/complete documentation; mechanical: smooth travel/compliant air gap; electrical: correct grounding/shielding);

Insulation resistance test: Test with 1000V DC for 60 seconds, insulation resistance ≥ 10M Ω (between winding and PE, temperature sensor and PE);

Cooling system inspection: Ensure that the coolant meets the requirements, the circuit is leak free, and the pressure is ≤ 10 bar;

Trial operation: Limit current and speed, check commutation (phase sequence U-V-W is positive direction), monitor temperature sensor signal.

5. Operation and maintenance

Operation monitoring: It is necessary to monitor abnormalities (such as noise, heat, current rise, vibration), and immediately stop the machine for troubleshooting (see the table below for fault codes and handling);

Fault Handling Table:

Possible causes (code) of the fault phenomenon and remedial measures

Motor lock A (overload), B (phase loss) to reduce load, check frequency converter and feeder line

Abnormal noise during operation D (reversing fault), K (foreign object) detection of reversing angle, cleaning of air gap foreign objects

Abnormal no-load heating F (cooling not connected), G (insufficient water volume), connect cooling, check cooling water volume/inflow temperature

Slow shaft response E (winding short circuit), L (poor alignment), check winding resistance, and re align machine guide rail

Maintenance requirements: There is no regular maintenance cycle, and the following situations require maintenance: foreign objects around the motor, machine abnormalities (visual/auditory), decreased positioning accuracy, and increased current; During maintenance, power off and cool down for 30 minutes, clean the air gap chips/dust, and check the cable shielding layer.

6. Scrapping and waste disposal

Dismantling steps: In reverse order of installation, power off and discharge first → cool for 30 minutes → disconnect cooling → clamp cable → drain coolant → remove primary components → remove secondary components;

Waste disposal:

Secondary components: Professional enterprises are required to use a furnace with a temperature of ≥ 300 ° C to demagnetize for at least 30 minutes, collect and treat exhaust gas;

Material classification: electronic waste (encoder/winding/cable), iron waste (iron core), aluminum, insulation materials;

Packaging: Recyclable materials (PE-HD/PE-LD/PP/PS) recycling, wood is combustible.

Appendix and Support

Manufacturer recommendations: corrosion inhibitors (Tyfocor, Antifrogen N), cooling connectors (Rectus), plastic hoses (Festo/Rectus), distance film (SAHLBERG);

Abbreviations: Temp-S (over temperature cut-off monitoring circuit), Temp-F (temperature observation circuit), HSB (Hall sensor box), PE (protective grounding);

Additional guidance: Installation size of Hall sensor box (fixed position and spacing for different motor models, such as 35mm distance between HSB and primary components of 1FN3050-150 motor).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923