K-WANG

SIEMENS VVF53./VXF53. series flange valves

SIEMENS VVF53./VXF53. series flange valves

Product Overview

Siemens VVF53. (two-way flange valve) and VXF53. (three-way flange valve) series, belonging to ACVATIX ™ The long stroke valve family is designed specifically for fluid control in industrial and building automation. Its core positioning is control or shut-off valves, compatible with PN 25 pressure rating, and can operate stably in the temperature range of -20... 220 ° C. It covers nominal diameters from DN15 to DN250, meeting different flow and diameter requirements.

Core technical parameters

1. Basic parameter table

Parameter categories, specific specifications, and key explanations

Rated pressure PN 25 (DN15... 50 compatible with PN16) DN65... 250 only compatible with PN25

Nominal diameter (DN) 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200, 250 DN15... 150 is ductile iron valve body, DN200... 250 is carbon steel valve body

Flow coefficient (kvs) 0.16... 630 m ³/h VVF53. K model (pressure compensation) kvs value optimization, adapted to higher pressure differentials

Normal temperature range for medium: -5... 220 ° C; low temperature: -20... 150 ° C (special sealing box needs to be replaced). The maximum temperature for steam medium is 220 ° C, and a low-temperature sealing box is required for antifreeze/saltwater

Rated travel DN ≤ 50:20mm; DN ≥ 65:40mm stroke length matched with actuator driving force (e.g. SAX. compatible with 20mm stroke)

Leakage rate straight through: DN15... 150 is 0... 0.01% kvs (Class IV), DN200... 250 is 0... 0.02% kvs; Bypass: 0.5... 2% KVS complies with EN 60534-4/EN 1349 standards

2. Pressure compensation characteristics (VVF53. K model)

Exclusive design: Using pressure compensation valve core, the same actuator can be used to control flow with greater pressure difference;

Suitable media: liquid and steam (DN65... 150 for closed flow direction, DN200... 250 for open flow direction);

Applicable actuators: Only compatible with electric hydraulic actuators (SKD../SKB../SKC..), not suitable for electric actuators (SAX..).

Executive matching scheme

Executive Parameters and Adaptation Table

Actuator series driving force stroke working voltage control signal operating time (on/off) adapted to valve scenarios

SAX. 800N 20mm AC/DC 24V, AC230V 3-digit, 0... 10V, 4... 20mA, etc. 120s (conventional), 30s (fast) DN ≤ 50 two-way/three-way valve, light load scenario

SKD. 1000N 20mm AC24V, AC230V 3-digit, 0... 10V, 4... 20mA, etc. Open for 30s/Close for 10-15 seconds DN ≤ 50 High load scenarios

SKB. 2800N 20mm AC24V, AC230V 3-position, 0... 10V, 4... 20mA, etc. Open for 120s/Close for 10s DN ≥ 65 two-way/three-way valve

SKC. 2800N 40mm AC24V, AC230V 3-position, 0... 10V, 4... 20mA, etc. Open for 120s/Close for 20s DN ≥ 65 large stroke valve

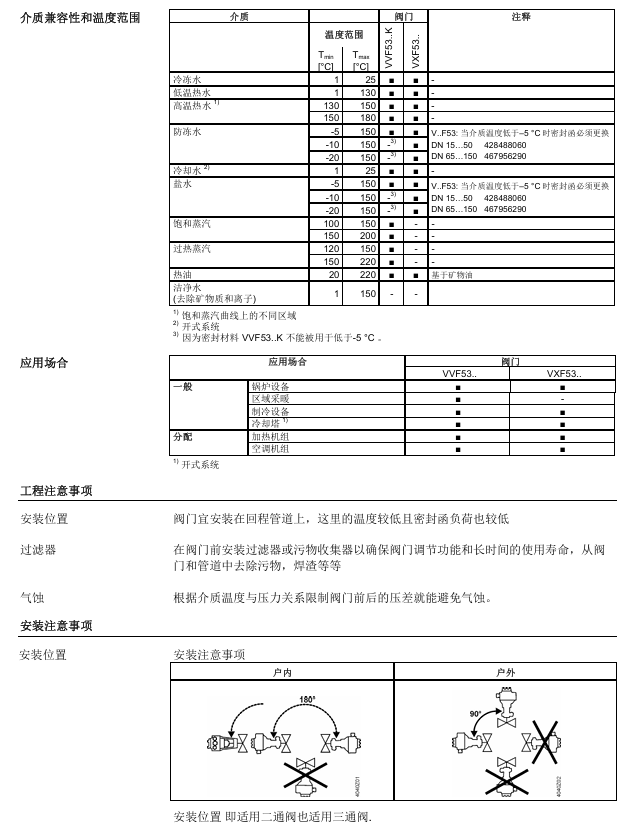

Media compatibility and application scenarios

1. Media adaptation table

Medium type, temperature range (° C), key requirements for valve series adaptation

Frozen water/cooling water 1... 25 VVF53., VXF53. Open systems require attention to impurity filtration

Low/high temperature hot water 1... 180 VVF53., VXF53. 130... 180 ° C is high temperature hot water, and the temperature resistance of the actuator needs to be confirmed

Antifreeze water/saltwater -20... 150 VVF53., VXF53. If the temperature is less than -5 ° C, a special sealing box (DN15... 50:428488060; DN65... 150:467956290) needs to be replaced

Saturated/superheated steam 100... 220 VVF53. (including K-type) VXF53. does not support steam, avoid wet steam (which can easily cause cavitation)

Hot oil 20... 220 VVF53., VXF53. Only suitable for mineral oil hot oil

2. Distribution of application scenarios

Application Fields VVF53. (Two way valve) VXF53. (Three way valve) Core Function

Boiler equipment ✅ ✅ Medium flow control, pressure regulation

Regional heating system ✅ ❌ Hot water delivery cut-off and flow regulation

refrigeration equipment ✅ ✅ Control of chilled water/saltwater circuit

cooling tower ✅ ✅ Cooling water circulation flow regulation (open system)

Heating unit/air conditioner ✅ ✅ Switching between hot and cold media, temperature control

Key points for installation and maintenance

1. Installation requirements

Location selection: Priority installation in the return pipeline (low temperature, low sealing load);

Pre installed accessories: A filter or dirt collector must be installed in front of the valve to prevent impurities from jamming the valve core;

Cavitation prevention: Limit the pressure difference before and after the valve according to the temperature pressure curve of the medium to avoid cavitation (special attention should be paid to steam medium);

Flange connection: Following ISO 7005 standard, pipeline flanges, bolts, and gaskets need to be provided on site.

2. Maintenance and Accessories

Routine maintenance: There is no special maintenance requirement for the valve. Before maintenance, the pump should be stopped, the power should be cut off, and the pressure should be released for cooling;

Low temperature accessories: If the medium temperature is less than 0 ° C, a valve stem heating element (ASZ6.6, material number S55845-Z108) needs to be installed;

Sealing letter replacement: When the temperature is below -5 ° C, a dedicated low-temperature sealing letter (DN15... 50:428488060; DN65... 150:467956290) needs to be replaced;

Replacement parts: VXF53. Replace VXF41. Series requires specialized matching parts (such as ALF41B15, compatible with DN15).

Compliance and Standards

Pressure Vessel Directive: Compliant with PED 2014/68/EU, DN65... 125 is classified as Class I (Module A), DN150... 250 is classified as Class II (Module A2);

Basic standards: comply with ISO 7005 (flange), EN 1092 (flange connection), VDI 2173 (valve characteristics), EN 60534-4 (leakage rate);

CE marking: DN65... 150 notified body number 0036, DN200... 250 notified body number 0035, compliance documents can be downloaded from Siemens official website.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923