K-WANG

SIEMENS SIMOVERT MASTERDRIVES Vector Control Series

SIEMENS SIMOVERT MASTERDRIVES Vector Control Series

The comprehensive user manual for Siemens SIMOVERT MASTERDRIVES vector control series covers seven core modules: system overview, configuration connections, EMC design, functional parameters, parameterization steps, communication interfaces, and safety functions. It supports multiple control modes such as V/f control, encoder free vector control, and encoder vector control, and is compatible with a power range of 0.55kW-2300kW. It has multiple communication protocols such as PROFINET/PROFIBUS, STO/SS1 safety functions, and flexible parameterization methods. It can be configured through PMU/OP1S/DriveMonitor and is suitable for high-precision drive control in multiple scenarios of industrial automation.

Overview of System Core

1. Basic product information

Notes on Core Parameters of the Project

Product series SIMOVERT MASTERDRIVES Vector Control (VC) including Motion Control (MC) derivative models

Power range 0.55kW-2300kW Compact PLUS type 0.55-18.5kW, chassis type 45-2300kW

Control mode V/f control, vector control without encoder, vector control with encoder, torque control adapted for asynchronous/synchronous motors

Modular design of core components such as rectifier, inverter, CUVC control board, braking unit, and communication board (CBP/CBC), supporting multi axis expansion

Security level SIL2/SIL3, PL d/e, Cat.3/4 support STO/SS1 security function

Communication interface USS, PROFINET DP, PROFIBUS DP, SIMULINK, CAN optional communication board expansion

2. Core advantages

Multi mode adaptation: supports multiple modes such as V/f and vector control to meet different accuracy requirements

Security integration: Built in STO/SS1 security function, compliant with EN 61800-5-2 standard

Flexible expansion: Single axis/multi axis configuration is optional, supporting up to 3-axis collaborative drive

Precise control: With encoder vector control mode, it has fast dynamic response and high torque accuracy

Convenient debugging: supports PMU/OP1S/DriveMonitor three parameterization methods

Hardware configuration and connection

1. Equipment type and specifications

Equipment type, power range, installation method, core characteristics

Compact PLUS 0.55-18.5kW DIN rail installation integrated design, suitable for single axis/multi axis drive

Compact 2.2-37kW panel mounted independent power unit, supporting expansion

Chassis type 45-2300kW cabinet installation for high-power scenarios, supporting water cooling options

Water cooled on-demand matching cabinet installation suitable for high temperature environment, stable operation

2. Typical configuration scheme

Single axis drive: 1 rectifier+1 inverter, suitable for independent drive scenarios

Multi axis drive (≤ 3 axes): 1 rectifier+multiple inverters, sharing DC bus

Multi axis drive (>3-axis): common rectifier unit+multiple inverters, external 24V power supply

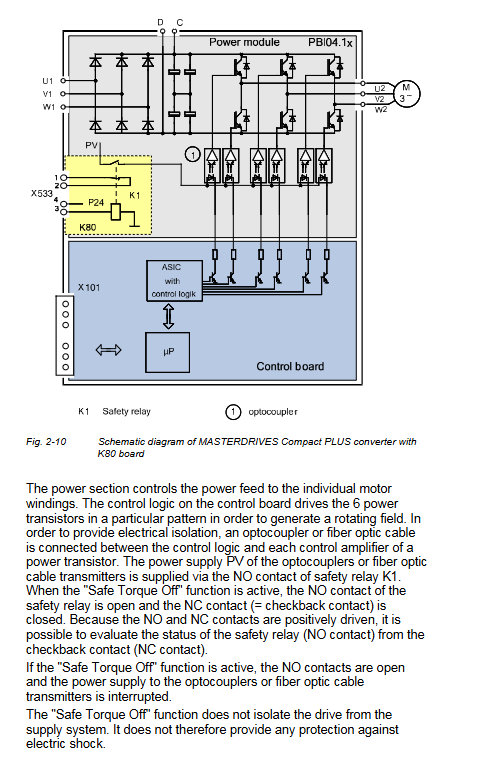

Safety configuration: Safety relay+STO/SS1 circuit, dual channel structure ensures safety

3. Wiring specifications

Power wiring: 3-phase AC 380-480V input, DC bus 510-650V, wire specifications 0.75-120mm ²

Signal wiring: Analog quantity (-10~+10V/0~20mA), digital quantity (24V DC), encoder signal (HTL/TTL)

Shielding requirements: Motor cables/signal cables need to be shielded, with both ends of the shielding layer grounded, and a minimum bending radius of 10 times the cable diameter

Safe wiring: The STO function requires dual channel wiring, and the emergency stop button is connected in series with the safety circuit

Detailed explanation of core functions

1. Control function

Functional Type Core Parameters Applicable Scenarios

V/f control voltage frequency curve, slip compensation, boost function fan, pump universal load

Without encoder vector control, the speed accuracy is ± 0.5%, the torque response is fast, and there is no need for high-precision speed measurement scenarios

Vector control speed accuracy with encoder ± 0.01%, 1024 line high-precision drive with pulse encoder (machine tool, conveyor belt)

Torque control with torque accuracy of ± 5%, adjustable torque limit and tension control (winding equipment)

2. Safety features

Standard basis for safety function description

STO (Safe Torque Off) cuts off the motor torque output to prevent accidental starting EN 61800-5-2, Stop Category 0

SS1 (Safe Stop 1) time controlled deceleration cuts off torque, controllable shutdown EN 61800-5-2, Stop Category 1

Dual channel design for safety circuit, diagnostic coverage rate of 90%+EN ISO 13849-1:2008

3. Auxiliary functions

Automatic motor recognition (P115): supports static/dynamic recognition, automatically matches motor parameters

Fly start (P130): Smooth start when the motor rotates to avoid surge current

Kinetic Energy Buffer (KIB): Utilizing the kinetic energy of the motor to maintain the DC bus voltage during power outages

DC braking: quick stop, adjustable braking time (0-100s)

Temperature adaptive: Adjust the output according to the motor temperature to protect the motor

Parameterized operation

1. Comparison of parameterization methods

Parameterized tool operation method, core advantages, applicable scenarios

PMU (panel) local button operation, 4-digit 7-segment display without additional equipment, quick setup, simple debugging, troubleshooting

OP1S (operation panel) displays in Chinese/English, supports parameter upload and download, has strong portability, and supports multi slave site and multi device debugging

DriveMonitor (software) PC operation, graphical interface for batch configuration, script editing for complex system configuration, offline debugging

2. Key parameterization process

Factory reset: P053=6 → P060=2 → P970=0, restore default parameters

Quick parameterization (P060=3): Input motor nameplate data → Select control mode → Set command source → Automatic parameterization

Detailed parameterization: power segment definition → board configuration → motor parameters → control parameters → communication parameters → safety parameters

Parameter backup: OP1S or DriveMonitor upload parameter set, supports batch download

3. Core parameter group

Function description of key parameters in parameter group

Motor parameters P101 (rated voltage), P102 (rated current), P107 (rated frequency), P108 (rated speed) match the motor nameplate data

Control parameters P100 (control mode), P235 (speed loop gain), P240 (speed loop integration time) to adjust and control dynamic performance

Instruction parameters P443 (main given source), P554 (ON/OFF 1 source), P573 (MOP rise) define the control instruction source

Configure safety loop signals for safety parameters P651 (digital output source) and P698 (SCI digital output)

Communication interface

1. Detailed explanation of communication protocol

Protocol type, transmission rate, number of connections, core usage

USS 9.6-19.2kBd up to 32 slave stations with simple bus control and parameterization

PROFIBUS DP 9.6kBd-12MBd up to 126 slave industrial automation network integration

PROFINET IO 100MBd real-time communication high-precision synchronous control

SIMOLINK 100MBd with up to 200 nodes for multi axis synchronization and high-speed data transmission

CAN 1Mbps up to 31 nodes low-cost distributed control

2. Key points of communication configuration

Address setting: USS/PROFIBUS addresses 1-247 to avoid conflicts

Baud rate matching: All slave stations must have the same baud rate as the master station

Bus terminal: Terminal resistors (120 Ω) need to be connected at both ends of the PROFIBUS/CAN bus

Protocol selection: Choose based on real-time requirements, prioritize high-precision synchronization PROFINET/SIMOLINK

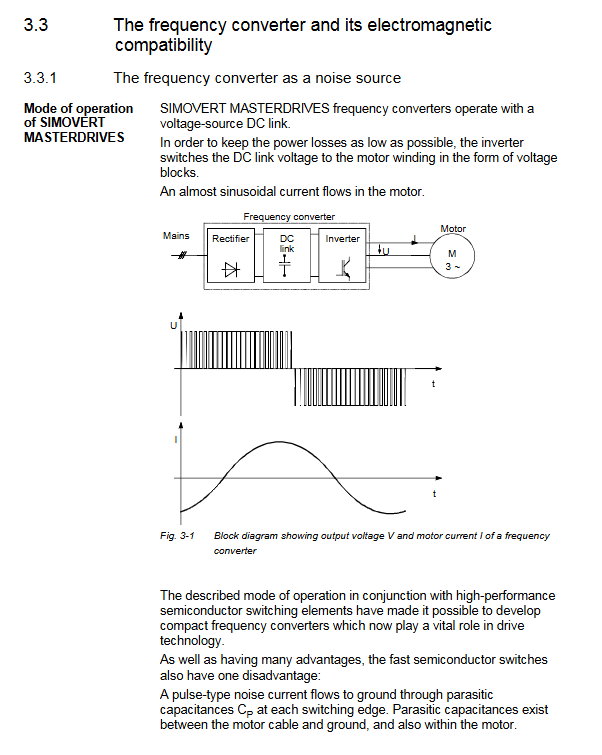

EMC Design Specification

1. Core EMC rules

Partition isolation: Install noise sources (inverters, braking units) and sensitive equipment (controllers, sensors) in different zones

Cable separation: The distance between power cables and signal cables should be ≥ 20cm, and cross wiring should be done vertically

Shielding treatment: The shielding layer of the motor cable/signal cable is grounded 360 ° without interruption

Grounding requirements: The grounding resistance of the cabinet should be ≤ 4 Ω, and all metal components should be reliably grounded

Filter configuration: Install EMC filter on the power side to reduce harmonic interference

2. Typical EMC configuration

Input side: EMC filter+incoming reactor to suppress conducted interference

Output side: dv/dt filter/sine filter, reducing motor cable radiation interference

Signal side: Use shielded twisted pair cables for analog signals, away from power cables

Safety and Compliance

1. Safety operation requirements

Qualification requirements: Only qualified personnel are allowed to operate, and familiarity with the safety manual is required

Power off operation: Before wiring/maintenance, disconnect all power sources and wait for the capacitor to discharge

Electromagnetic radiation: The device generates an electromagnetic field during operation, and pacemaker wearers should stay away from it

Environmental restrictions: It needs to be installed in a closed cabinet to avoid contact with high-temperature components

2. Compliance standards

International standards: IEC 61800-5-2 (safety), IEC 60947 (electrical safety) EN 55011(EMC)

Domestic standard: GB/T 12668 (Variable Speed Electrical Transmission System)

Certification qualifications: CE, UL, CSA, CCC

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923