K-WANG

Siemens SINAMICS DCM DC Converter and Control Module

Electronic module: Integrated control unit (CUD) with reserved rotatable bracket slots, supporting additional CUD expansion to enhance control flexibility and redundancy.

Power section: A fully controlled three-phase bridge circuit is constructed using thyristors, which are divided into two driving types - two quadrant driving (B6C structure) and four quadrant driving ((B6) A (B6) C structure), to meet the speed and braking requirements under different operating conditions.

Cooling system: Equipment with a rated DC current ≤ 125A adopts a self ventilated design, while equipment with a rated DC current ≥ 210A is equipped with an integrated fan for forced air cooling to ensure stable operation of power components.

Excitation power section: Standard single quadrant excitation power unit (including freewheeling circuit), optional non excitation version or two quadrant excitation version (suitable for high dynamic excitation current change scenarios), and integrated excitation overvoltage protection function.

Power supply and operation unit: including electronic device power supply; Standard BOP20 operation panel, AOP30 advanced operation panel requires additional purchase.

Siemens SINAMICS DCM DC Converter and Control Module

Core components of the product

The SINAMICS DC MASTER series DC converter consists of multiple key functional modules, which work together to achieve DC drive control. The specific components and functions are as follows:

Electronic module: Integrated control unit (CUD) with reserved rotatable bracket slots, supporting additional CUD expansion to enhance control flexibility and redundancy.

Power section: A fully controlled three-phase bridge circuit is constructed using thyristors, which are divided into two driving types - two quadrant driving (B6C structure) and four quadrant driving ((B6) A (B6) C structure), to meet the speed and braking requirements under different operating conditions.

Cooling system: Equipment with a rated DC current ≤ 125A adopts a self ventilated design, while equipment with a rated DC current ≥ 210A is equipped with an integrated fan for forced air cooling to ensure stable operation of power components.

Excitation power section: Standard single quadrant excitation power unit (including freewheeling circuit), optional non excitation version or two quadrant excitation version (suitable for high dynamic excitation current change scenarios), and integrated excitation overvoltage protection function.

Power supply and operation unit: including electronic device power supply; Standard BOP20 operation panel, AOP30 advanced operation panel requires additional purchase.

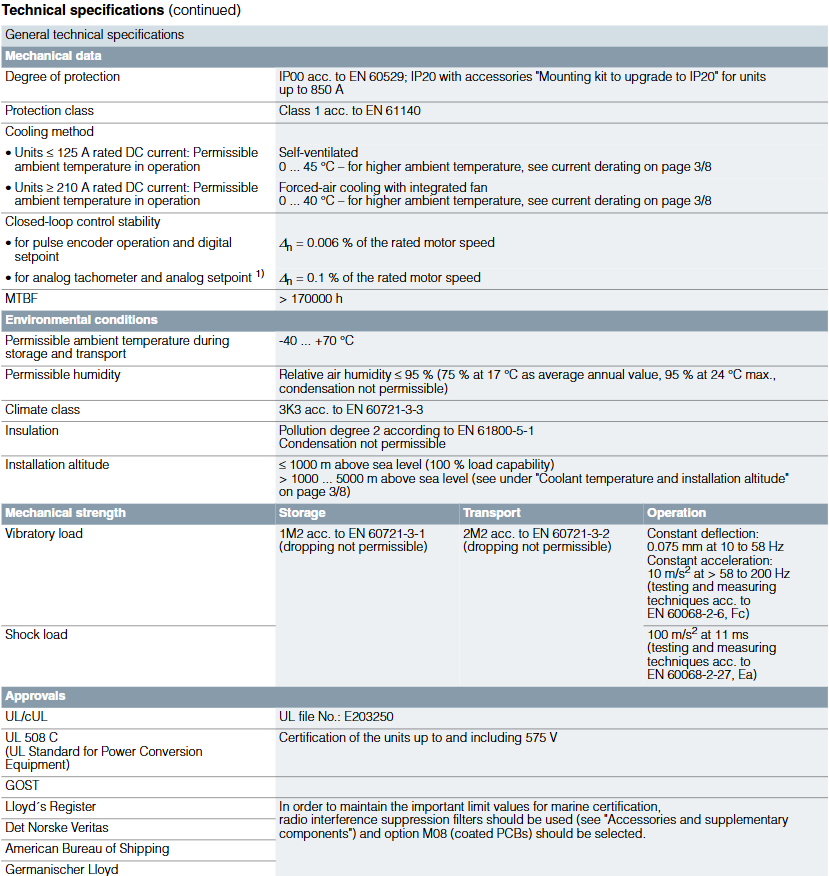

General Technical Specifications

1. Standard compliance

The product complies with multiple international and industry standards to ensure electrical safety, electromagnetic compatibility, and operational reliability. The core standards are listed in the table below:

Standard Number, Standard Name, and Scope of Application

EN 50178/IEC 62103 Electronic Equipment Standard for Power Facilities

EN 50274 Low voltage switchgear and control equipment components: Protection against electric shock (preventing accidental direct contact with hazardous live parts)

EN 60146-1-1 Semiconductor converters: General requirements and specifications for grid commutated converters

EN 61800-1 Adjustable Speed Electric Drive Systems Part 1: (DC Drive) General Requirements and Rating Specification for Low Voltage Adjustable Speed DC Drive Systems

EN 61800-3 Adjustable Speed Electric Drive Systems Part 3: Electromagnetic Compatibility (EMC) Product Standard with Specific Test Methods

EN 61800-5-1 Adjustable Speed Electric Drive Systems Part 5-1: Safety Requirements (Electrical, Thermal, and Energy Related)

UL 508 C Power Conversion Equipment UL Standard (575V and below equipment certified, UL file number E203250)

2. Electrical safety and performance

Overvoltage level and strength: The overvoltage level of the power supply circuit is EN 61800-5-1 Class II, which is Class III relative to the environment (other power supply circuits, enclosures, electronic devices); The overvoltage strength meets the EN 50178 Class 1 standard.

Short circuit current: Different combinations of supply voltage and rated DC current correspond to different maximum short-circuit currents. For example, in a 400/480V three-phase AC power supply, the maximum short-circuit current for equipment with a rated DC current of 15-1200A is 65kA, and for equipment with a rated DC current of 3000A, it can reach 100kA.

Radio interference suppression: The radio interference suppression function that complies with the EN 61800-3 standard is not configured. Additional accessories need to be purchased to meet the relevant requirements.

3. Stability of closed-loop control

Based on the thermal operation status of the equipment (rated motor speed), under specific premise conditions (ambient temperature ± 10 ℃, supply voltage ± 10%/-5%, temperature coefficient of the speed measuring generator with temperature compensation 0.15 ‰/10 ℃, constant given value), the control accuracy is as follows:

Pulse encoder operation+digital setpoint: speed deviation ∆ n=0.1% rated motor speed

Simulated speedometer+simulated setpoint: speed deviation ∆ n=0.006% rated motor speed

4. Environmental and mechanical parameters

Specific requirements for parameter categories

Basic protection level IP00 (EN 60529); Devices with ≤ 850A can be upgraded to IP20 through the "IP20 Upgrade Installation Kit"; Electrical safety level EN 61140 Class 1

Temperature range operation: ≤ 125A equipment 0-45 ℃, ≥ 210A equipment 0-40 ℃ (high temperature requires capacity reduction); Storage/transportation: -40-70 ℃

Relative humidity ≤ 95% (at 24 ℃), annual average ≤ 75% (at 17 ℃), condensation is strictly prohibited

Climate grade EN 60721-3-3 3K3

Insulation pollution level EN 61800-5-1 Class 2, condensation is strictly prohibited

Installation height ≤ 1000m altitude (100% load capacity); 1000-5000m altitude needs to refer to the derating specifications

Mechanical strength vibration: storage of 1M2 (EN 60721-3-1), transportation of 2M2 (EN 60721-3-2), constant deflection of 0.075mm during operation at 10-58Hz/constant acceleration of 10m/s ² during 58-200Hz; Impact: 100m/s ² (11ms, EN 60068-2-27 Ea) during operation

Mean Time Between Failures (MTBF)>170000 hours

5. Certification qualifications

In addition to UL/cUL certification, the product also complies with GOST standards and has been certified by Lloyd's Register, Det Norske Veritas, American Bureau of Shipping, and Germanischer Lloyd (ship certification requires radio interference suppression filters and M08 option - coated PCB).

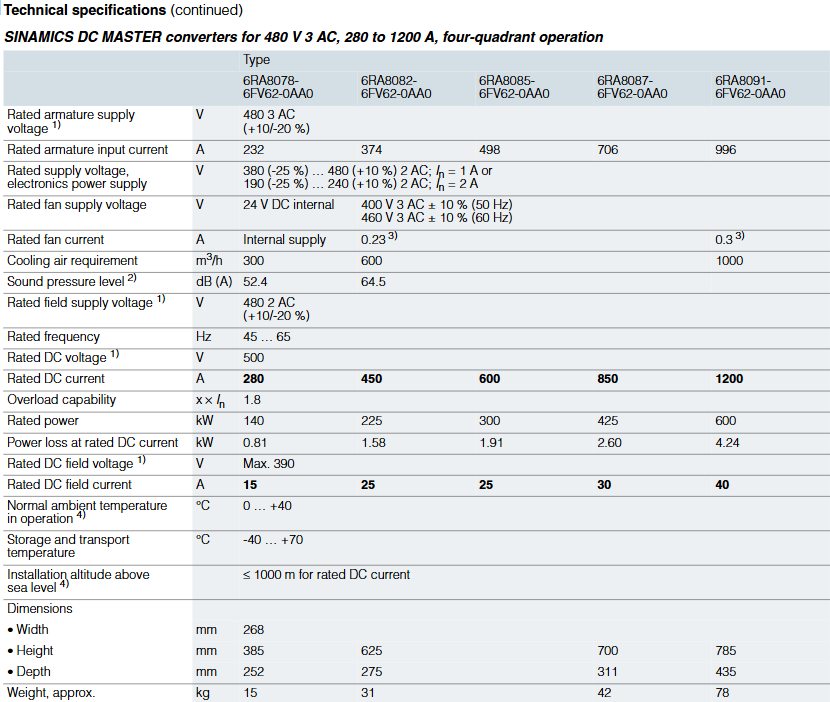

Typical model technical parameters (taking 480V three-phase AC and four quadrant operation as an example)

For the series models with rated armature supply voltage of 480V three-phase AC (± 10%/-20%) and four quadrant operation, the core parameters are shown in the following table (some key models):

Model Rated armature input current (A) Rated DC voltage (V) Rated DC current (A) Rated power (kW) Rated excitation voltage (V) Rated excitation current (A) Cooling air demand (m ³/h) Sound pressure level (dB (A)) Size (W × H × D, mm) Weight (kg)

6RA8078-6FV62-0AA0 232 500 280 140 480 two-phase AC 15 300 52.4 268 × 385 × 252 15

6RA8082-6FV62-0AA0 374 500 450 225 480 two-phase AC 25-268 × 625 × 275 31

6RA8085-6FV62-0AA0 498 500 600 300 480 two-phase AC 25 600-268 × 700 × 311 42

6RA8087-6FV62-0AA0 706 500 850 425 480 two-phase AC 30 1000 64.5 268 × 785 × 435 78

6RA8091-6FV62-0AA0 996 500 1200 600 480 two-phase AC 40-268 × 785 × 435-

Note: The armature/excitation supply voltage can be set to be lower than the rated value through parameter settings. The minimum input voltage for 400/480/575V rated voltage equipment is 50V, and for higher rated voltage equipment it is 85V. When the supply voltage undervoltage is ≤ 5%, the rated DC output voltage can be maintained.

Selection and ordering data

1. Core dimensions for selection

Selection should be based on armature circuit parameters (supply voltage, rated DC voltage/current), excitation circuit parameters (supply voltage, rated DC current), rated power, matched with corresponding models and matching fuses. Different supply voltages (400V/480V/575V/690V/830V/950V three-phase AC) correspond to different model sequences, for example:

400V three-phase AC: 6RA80xx-6DV62-0AA0 series

480V three-phase AC: 6RA80xx-6FV62-0AA0 series

575/690V three-phase AC: 6RA80xx-6GV62-0AA0 series

2. Rules for matching fuses

Different models require specific types and specifications of armature/excitation circuit fuses, such as:

6RA8013-6FV62-0AA0 (480V three-phase AC, 15A rated DC current): armature fuse 3NE1814-0 (2 pieces), excitation fuse 5SD420

6RA8087-6FV62-0AA0 (480V three-phase AC, 850A rated DC current): armature fuse 3NE3338-8+3NE3334-0B (parallel), excitation fuse 5SD480

High current models (such as 6RA8091-6FV62-0AA01200A rated DC current): Built in armature fuse, no external semiconductor fuse required, excitation fuse 3NE1802-0 (UL certified)

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923