K-WANG

Allen-Bradley SLC 500 ™ 32 channel digital I/O module

Core restriction: Live replacement of components or wiring is prohibited in hazardous environments. Component replacement must use original factory accessories, otherwise it may damage the explosion-proof characteristics.

Allen-Bradley SLC 500 ™ 32 channel digital I/O module

Product scope of application and requirements for hazardous environments

(1) Applicable scenarios

Environmental classification: Only applicable to Class I, Division 2 hazardous environments (Groups A, B, C, D) or non hazardous environments, prohibited for use in higher-level hazardous areas (such as Class I, Division 1).

Core restriction: Live replacement of components or wiring is prohibited in hazardous environments. Component replacement must use original factory accessories, otherwise it may damage the explosion-proof characteristics.

(2) Multi language support

The document contains bilingual hazardous environment warnings in English and French, with the French version emphasizing component replacement risks and power outage operation requirements, adapting to the compliance needs of the European market.

Module overview and installation process

(1) Module positioning

The 1746 series 32 channel digital I/O module is a dedicated module for SLC 500 chassis, which is divided into input modules (IB32, IV32) and output modules (OB32, OB32E, OV32). Its core function is to achieve bidirectional interaction between industrial field digital signals (such as sensors and actuators) and PLC, supporting 24V DC mainstream industrial voltage. It is designed according to "group isolation" (input 4 groups/8 points, output 2 groups/16 points) to reduce signal interference.

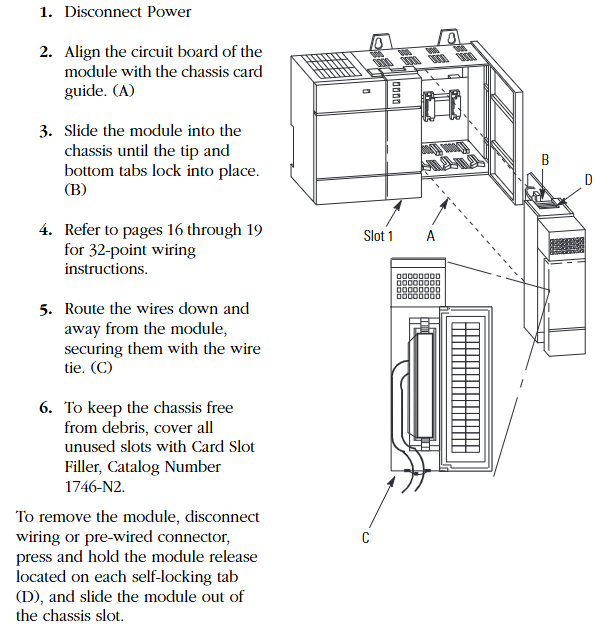

(2) Standard installation steps (power-off operation)

Power off preparation: Disconnect the chassis power supply to ensure no voltage input.

Module alignment: Align the module circuit board with the chassis card slot to avoid touching the backplane pins (to prevent static damage).

Insertion fixation: Slowly push the module into the upper and lower self-locking tabs to tighten, without the need for additional screws.

Wiring arrangement: After wiring, comb down the wires and fix them in the module slot with cable ties to avoid blocking heat dissipation or loosening.

Idle slot handling: Cover the idle slots with 1746-N2 slot filling plates to prevent dust from entering the chassis.

(3) Module disassembly

First, disconnect the external wiring or pre wired connector, press the release tabs up and down on the module, and pull out the module horizontally. Do not forcefully pull or pull it.

Core technical specifications

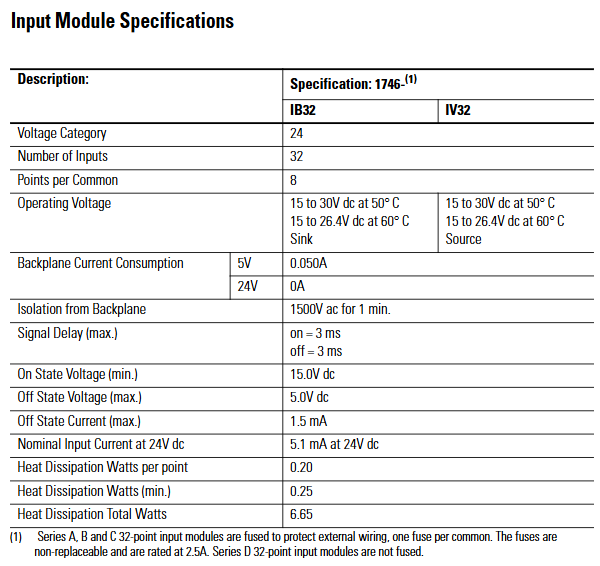

(1) Input module specifications (IB32, IV32)

Specification category 1746-IB32 (24V DC sinking input) 1746-IV32 (24V DC sourcing input)

Number of channels: 32 channels, 32 channels

8 points per group/public end (4 groups in total, isolated between groups) 8 points per public end (4 groups in total, isolated between groups)

Working voltage 15-30V DC (50 ℃), 15-26.4V DC (60 ℃) 15-30V DC (50 ℃), 15-26.4V DC (60 ℃)

Backplane current consumption 5V DC 0.050A, 24V DC 0A, 5V DC 0.050A, 24V DC 0A

Backboard isolation voltage 1500V AC (1 minute) 1500V AC (1 minute)

Signal delay (maximum) 3ms for both on/off and 3ms for both on/off

Conducting voltage (minimum) 15.0V DC 15.0V DC

Turn off voltage (maximum) 5.0V DC 5.0V DC

Turn off current (maximum) 1.5mA 1.5mA

24V DC nominal input current 5.1mA 5.1mA

Total heat dissipation power 6.65W (0.20W per point, minimum 0.25W) Total 6.65W (0.20W per point, minimum 0.25W)

Fuse protection (Series A/B/C) with 1 non replaceable 2.5A fuse per group, Series D without 1 non replaceable 2.5A fuse per group, Series D without

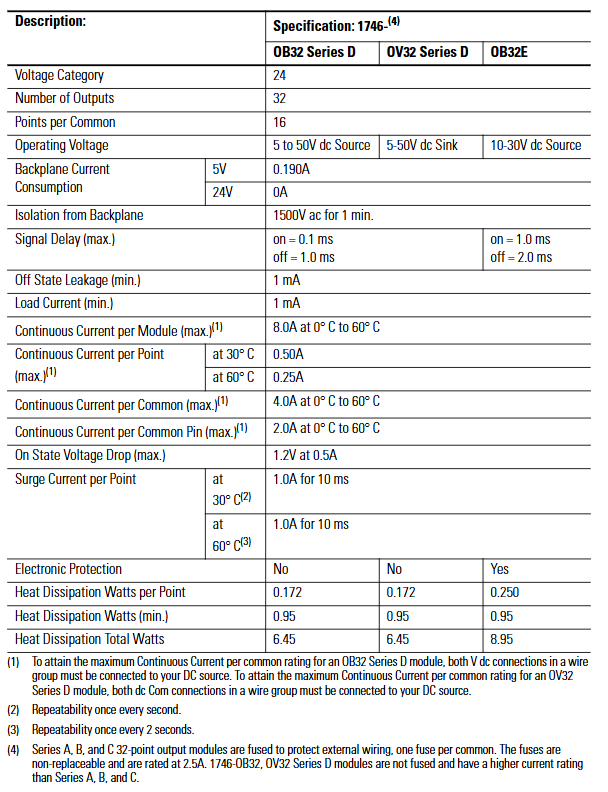

(2) Output module specifications (OB32, OB32E, OV32)

Specification category 1746-OB32 (Series D, 24V DC sourcing output) 1746-OB32E (24V DC sourcing with electronic protection) 1746-OV32 (Series D, 24V DC sinking output)

Number of channels: 32 channels, 32 channels, 32 channels

16 points per group/common end (2 groups in total, isolated between groups) 16 points per common end (2 groups in total, isolated between groups) 16 points per common end (2 groups in total, isolated between groups)

Working voltage 5-50V DC 10-30V DC 5-50V DC

Backplane current consumption 5V DC 0.190A, 24V DC 0A 5V DC 0.190A, 24V DC 0A 5V DC 0.190A, 24V DC 0A

Backboard isolation voltage 1500V AC (1 minute) 1500V AC (1 minute) 1500V AC (1 minute)

Signal delay (maximum) conducts 0.1ms, turns off 1.0ms conducts 0.1ms, turns off 1.0ms conducts 1.0ms, turns off 2.0ms

Turn off leakage current (maximum) 1mA 1mA 1mA 1mA

Minimum load current 1mA 1mA 1mA

Module total continuous current (maximum) 8.0A (0-60 ℃) 8.0A (0-60 ℃) 8.0A (0-60 ℃)

Single channel continuous current (maximum) 0.50A at 30 ℃, 0.25A at 60 ℃, 0.50A at 30 ℃, 0.25A at 60 ℃, 0.50A at 30 ℃, and 0.25A at 60 ℃

Continuous current per group (maximum) 4.0A (0-60 ℃) 4.0A (0-60 ℃) 4.0A (0-60 ℃)

Continuous current per pin (maximum) 2.0A (0-60 ℃) 2.0A (0-60 ℃) 2.0A (0-60 ℃) 2.0A (0-60 ℃)

Voltage drop during conduction (maximum) 1.2V (at 0.5A) 1.2V (at 0.5A) 1.2V (at 0.5A)

Surge current (per point) 1.0A/10ms at 30 ℃ (once per second), 1.0A/10ms at 60 ℃ (once every 2 seconds), 1.0A/10ms at 30 ℃ (once per second), 1.0A/10ms at 60 ℃ (once every 2 seconds), 1.0A/10ms at 30 ℃ (once per second), 1.0A/10ms at 60 ℃ (once every 2 seconds)

Electronic protection None (short circuit, overload thermal cut-off protection) None

The total heat dissipation power is 6.45W (0.172W per point, minimum 0.95W), 8.95W (0.250W per point, minimum 0.95W), and 6.45W (0.172W per point, minimum 0.95W)

Fuse protection (Series A/B/C): 1 non replaceable 2.5A fuse per group, Series D: None (relying on electronic protection): 1 non replaceable 2.5A fuse per group, Series D: None

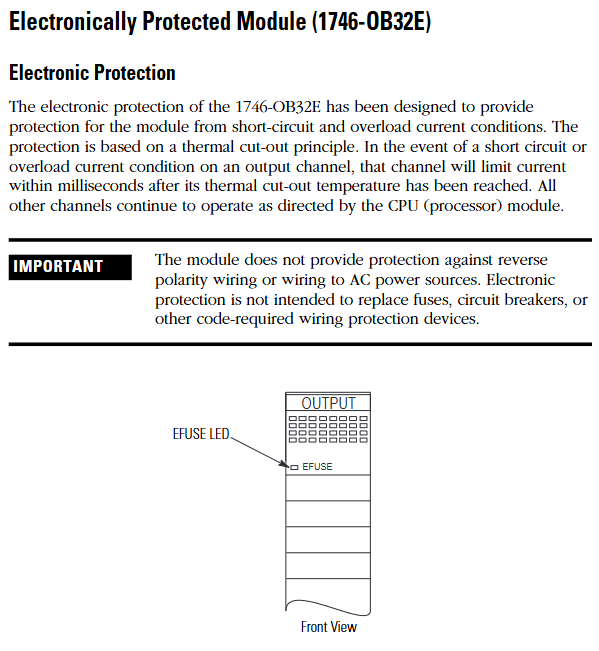

Key supplement (OB32E electronic protection features)

Protection principle: Based on thermal cut-out technology, in the event of a short circuit or overload, the faulty channel limits current within milliseconds, while other channels operate normally, and the E-Fuse LED lights up to sound an alarm.

Automatic reset: After the fault is removed, the channel cools down below the threshold and automatically recovers; Or power off and restart the module to reset, without the need to manually replace the fuse.

Limitations: It does not protect against reverse polarity wiring or AC power connection, and requires external circuit breakers to meet safety regulations.

Octal Label Kit Installation (PLC Processor Only)

(1) Composition and purpose of the kit

Contains components: octal filter label, octal door label, used to replace the default decimal label of the module and adapt to the octal addressing requirements of the PLC system.

Acquisition method: It is necessary to order separately from Allen Bradley dealers, and the model must match the I/O module catalog number (refer to manual 1747-UM011 or ACIG-PL001 price list).

(2) Installation steps

Filter label: Peel off the label from the carrier paper, align the module color bar horizontally, cover decimal numbers, and press to fix.

Door label: After peeling off, directly cover the decimal label on the inside of the chassis door to ensure consistent addressing identification.

Wiring scheme and operating specifications

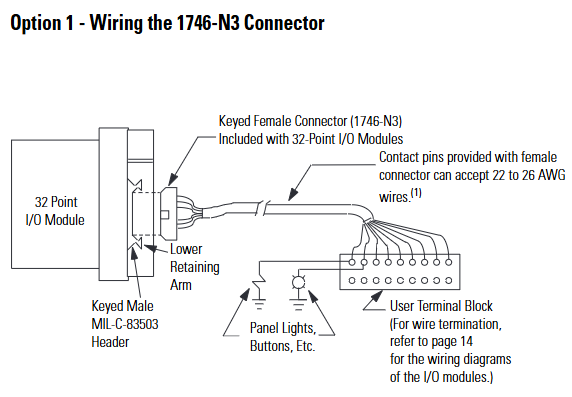

(1) Comes with connector wiring (Option 1:1746-N3 connector)

The components include: the module comes standard with a 40 pin female connector with keys (1746-N3) and crimping pins, supporting 22-26 AWG wires.

Pin assembly steps:

Stripping: Strip off the insulation layer of 4mm (5/32 inch) wire to expose the conductor.

Plug in: Insert the wire into the pin to the "wire stop" position.

Crimping: Use DDK 357J-5538 crimping tool (or Amp 90418-1 equivalent tool) for crimping; When there are no tools available, use sharp nose pliers to press the wire barrel and insulation barrel together, and then weld and fix them with 60% tin/40% lead rosin solder.

Fixed: Insert the pin into the connector, gently pull the wire to confirm that the "tang" is locked to prevent detachment.

Connector installation: Align the keyway of the module male connector (MIL-C-83503 standard) and lock it by pressing the upper and lower retaining arms.

(2) 1492 Wiring System (Option 2: Pre wiring Scheme)

1. System composition and advantages

Core components: 1492-CABLExx pre wired cable (with four lengths of 0.5m/1.0m/2.5m/5.0m), 1492-IFM40xx DIN rail terminal block (with/without LED status light), no need for on-site crimping, improving wiring efficiency.

Voltage drop reference (30 ℃/60 ℃):

Cable model: Voltage drop of power/common terminal wire (2A), voltage drop of output channel wire (0.5A), voltage drop of power/common terminal wire (2A), voltage drop of output channel wire (0.5A)

1492-CABLE005H 127mV 34mV 144mV 38mV

1492-CABLE10H 173mV 45mV 196mV 51mV

1492-CABLE25H 334mV 83mV 388mV 95mV

1492-CABLE50H 574mV 147mV 686mV 169mV

2. Terminal block label specifications

Label kit: The 1492 terminal block comes with multiple sets of sticker labels, indicating the module model (such as 1746-IB32) and the position of the "upper/lower" terminal block, distinguishing SLC (decimal) and PLC (octal) addressing.

Paste requirements: Select the corresponding label according to the module model and paste it on the outside of the terminal block. For example, label the "+V3" and "IN16" on the "upper" terminal block of module 1746-IV32 to ensure that the wiring corresponds.

(3) General Wiring Guidelines

Group isolation maintenance: When using the 1492 terminal block, it is necessary to choose a model that supports "group isolation" (such as with grouping partitions) to avoid signal crosstalk between different groups.

Voltage drop control: Calculate the total voltage drop (wire resistance x current x length) to ensure that the output module load terminal voltage is not lower than the minimum conduction voltage (such as 1.2V for OB32).

Public end connection:

Input module (IB32): Each group has 2 interconnected DC Com pins, which can be connected to only 1 pin; When it needs to exceed 2A, 2 should be connected.

Output module (OB32/OV32): Each group has 2+V DC (or DC Com) pins internally connected. When the current exceeds 2A, 2 pins must be connected to avoid pin overload.

Wiring diagrams and addressing instructions

(1) Core identification of diagrams

Double digit labeling: Each wiring diagram is labeled with both decimal (SLC system) and octal (PLC system) addresses, such as "IN 14" for SLC corresponding to "16 (octal)" for PLC.

Grouping division: Use "Wire Group 1-4" (input) or "Wire Group 1-2" (output) to clarify the wiring grouping, and the correspondence between the common terminal (COM1-4) and the signal terminal (IN/OUT 0-31) is clear.

(2) Typical module wiring example

1746-IB32 (sinking input):

The common terminal (DC Com 1-4) is connected to the negative terminal of 24V DC, the signal terminal (IN 0-31) is connected to the sensor output, and the+V DC 1-4 is connected to the positive terminal of 24V DC.

1746-OB32E (sourcing output with protection):

The common terminal (DC Com 1-2) is connected to the negative terminal of the load, the signal terminal (OUT 0-31) is connected to the positive terminal of the load, and the+V DC 1-2 is connected to the positive terminal of 24V DC. The E-Fuse LED corresponds to the fault channel.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Automation Module

-

HIMA K9203 PLC Module | Safety Control System Module

-

HIMA F60AI801 PLC Module | Analog Input Module

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Module

-

HIMA K9203 PLC Module | Safety Automation Module

-

X-DO1201 HIMA Control Pulse Card | Digital Output Module

-

F6705 HIMA Analog Output Module | Safety Control Output Module

-

HIMA B9361 PLC Module | Safety Automation System Module

-

HIMA H41Q-HRS / H41QX PLC Module | Safety Automation Module

-

HIMA F3003 Controller Unit | HIMAtrix Compact Safety Controller

-

HIMA HIMatrix F1DI1601 PLC Module | Digital Input Module for Safety Systems

-

HIMA X-DI 64 51 PLC Module | Digital Input Module for Safety Automation

-

HIMA F30 Controller Unit HIMAtrix 01 OPEN | Safety PLC Controller

-

HIMA K9202B PLC Module | Safety-Oriented Control Module

-

HIMA F3DIO20802 Controller PLC Module | Digital I/O Control for Safety Automation

-

HIMA F8627-1 F8627X Communication Module | Safety System Communication Interface

-

HIMA B4237-2 PLC Module | Safety Control and Logic Processing Module

-

HIMA X-DO2401 PLC Module | Digital Output Module for Safety Automation

-

HIMA 22100 PLC Module | Industrial Safety Control and Logic Processing

-

HIMA 90100 PLC Module | Safety-Oriented Industrial Control Module

-

HIMA 895210001 PLC Module | Industrial Safety Control and Processing Module

-

HIMA 157528-0 PLC Module | Industrial Safety Control and Processing Module

-

HIMA B5322 PLC Module | Industrial Safety Control and Processing Module

-

HIMA BV7032 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F3300 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7105A PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7150 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7508 PLC Module | Industrial Safety Control Processing Module

-

HIMA F8627 984862765 PLC Module | Industrial Safety Control Module

-

HIMA M3410 PLC Module | Industrial Safety Control Processing Module

-

HIMA Z7308 PLC Module | Safety Control System Processing Module

-

F8640 HIMA Central Module | Safety System Core Controller

-

HIMA F8630 Module | Safety System Functional Module

-

F8651X HIMA Central Module | Safety System Core Controller

-

F3236 Digital Input Module | HIMA Safety System Input Interface

-

F7131 HIMA Power Monitoring Module | Safety System Power Supervision

-

F8627X HIMA Communication Module | Safety System Network Interface

-

HIMA F8560X PLC Module | Safety-Related Control System Component

-

HIMA P8403 PLC Module – Industrial Safety Control Processor

-

HIMA F8628X Communication Module – Industrial Safety System Interface

-

HIMA F8621A Communication Module – Safety System Communication Interface

-

HIMA 984865066 PLC Module – Safety Control Processing Unit

-

HIMA F60CPU01 PLC Module – Safety Control Processing Unit

-

HIMA F8650E PLC Module – Safety Control Processing Unit

-

HIMA F8652E Central Module – Safety Control Processing Unit

-

HIMA F8650X Card – Safety Central Processing Module

-

F8652X HIMA Central Module – Safety Control Central Processing Unit

-

HIMA 99-7105233 B5233-1 Safety Module – Industrial Safety Control Component

-

KEBA KeTop T70-rqa-AK0-LK Teaching Device – Industrial Robot Teach Pendant

-

KEBA KETOP T50-T41-CPU 2495D-0 – Industrial CPU Module

-

KEBA E-CON-CC100/A/ 22178 – Industrial Controller Module

-

KEBA Kemro K2-200 CP 250/X 71580 CPU-MODULE – Industrial Control CPU Module

-

KEBA D3‑DA 330/A‑1211‑00 Drive – KeDrive D3 Axis Controller Industrial Servo Drive

-

KEBA KETOP O70‑bra‑A0a‑F Demonstrator – Industrial Automation Control Module

-

KEBA KETOP O70-BRA-A0A-F Demonstrator | Industrial HMI Operating Terminal

-

KEBA SO84.012.0083.0101.2 Servo Drive | Industrial Motion Control Solution

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

XYCOM 1546 - Proface Industrial Workstation 1546-102031013

-

XYCOM 86864-002-E - Processor Board Module

-

XYCOM 3112T - Pro-face Operator Interface

-

XYCOM 3712 KPM - Pro-face Operator Panel

-

XYCOM 4615KPMT - Proface Industrial PC Display Panel PM-070007

-

XYCOM 5015T - Pro-Face Touch Monitor 100-240 VAC

-

XYCOM 5015T/R2 - Industrial Flat Panel Touch Monitor 5015R2-0100000

-

XYCOM 1341 - Proface Embedded Computer TF-AEC-6920-C2

-

XYCOM GLC150-BG41-DN - Graphic Logic Controller M-24V

-

XYCOM GP2301H-SC41-24V - Pro-face Operator Interface 5.7" w/ Cable

-

XYCOM 1547 - Pro-face Industrial PC Model 1547-00113101

-

XYCOM ST401-AG41-24V - Graphic Touchscreen Operator Interface

-

XYCOM 3310T - Pro-face Operator Panel 3310-001101001

-

XYCOM 5015 KPMT - Proface Operator Panel Display

-

XYCOM XVME-684 - PC Module VME Bus Processor 70684-201

-

XYCOM 3300 MT - Screen Monitor Display

-

XYCOM SXT1811T - Touch Panel Monitor 100/240VAC

-

XYCOM XT-1502 - Touch Screen Monitor Flat Panel Display Interface

-

XYCOM SXT1811 - Viewtronix SXGA Flat Panel Monitor 18.1" Display

-

XYCOM VT1040T - ViewTronix Touch Screen Monitor

-

XYCOM WS2786291 - Industrial Workstation PC

-

XYCOM XCME-540 - Analog I/O Module VMEbus 70540-001

-

XYCOM XVME-682 - CPU PCB Processor Module 70682-101

-

XYCOM CU040103500 - VME Rack System Module 4200401

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923