K-WANG

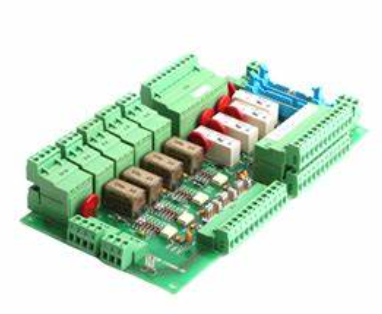

ABB SNAT602TAC circuit board

ABB SNAT602TAC circuit board

Product Overview

ABB SNAT602TAC Circuit Board is a circuit board that occupies a key position in the fields of industrial automation and power control. Its internal circuit design is precise and highly integrated with various advanced electronic components, aiming to efficiently process control signals and achieve stable data transmission, providing strong support for the smooth and precise operation of industrial equipment and systems. It is the core foundational component for building complex industrial control systems.

Specification parameters

Power specifications

Input voltage range: Suitable for 110-240V AC wide voltage input, can flexibly respond to power supply needs in different industrial environments, and reduce compatibility issues caused by voltage differences.

Frequency: Supports 50/60Hz standard frequency, meets common industrial power frequency requirements, and ensures stable operation.

Dimensions and physical characteristics

Dimensions: 200mm in length, 160mm in width, and 30mm in height. The compact size design facilitates installation in various control cabinets, equipment cases, and other space limited locations, effectively saving installation space.

Weight: Approximately 1.8kg. The moderate weight ensures the stability of the product structure while facilitating installation and handling, reducing the impact of vibration and other factors on circuit connections.

Interface type

Digital signal interface: equipped with multiple RS-485 interfaces, supporting half duplex communication mode, with a maximum transmission rate of 115.2kbps, it can achieve reliable connection with various digital devices such as sensors, actuators, controllers, etc., ensuring stable transmission of digital signals and collaborative work between devices.

Analog signal interface: It has a 4-20mA current loop input/output interface, which is used to connect analog sensors and actuators. It can accurately collect and output analog signals, and accurately adjust analog parameters such as temperature, pressure, and flow rate in industrial process control.

Working environment parameters

Temperature range: The working temperature ranges from -20 ℃ to+60 ℃, with excellent environmental adaptability. It can operate normally in harsh industrial environments such as high and low temperatures, reducing the impact of environmental temperature fluctuations on circuit board performance and ensuring production continuity.

Humidity range: Relative humidity of 5% -95% (without condensation), can work stably in humid environments, effectively preventing short circuits, corrosion and other faults caused by humidity issues, and improving product reliability.

Protection level: reaching IP20 protection level, it can effectively block solid foreign objects larger than 12mm from entering, providing basic protection for internal precision electronic components and reducing the risk of malfunction caused by foreign objects entering.

Core functions

Precise control signal processing: It can quickly analyze and process control instructions from the upper computer or other control sources, generate precise control signals, and output them to various connected industrial equipment such as motors, valves, etc., to achieve precise adjustment of equipment operating parameters (such as speed, opening, etc.), ensuring the accuracy and stability of the production process. In automated production lines, the movements of robotic arms can be precisely controlled to complete high-precision assembly tasks.

Efficient data collection and transmission: With powerful data collection capabilities, real-time device operation status data (such as temperature, pressure, position, etc.) is obtained through connected sensors, and the collected data is quickly processed and analyzed. At the same time, the processed data can be efficiently transmitted to the upper computer or other systems, providing data support for production decision-making and achieving information management and monitoring of the production process.

Communication protocol support: Supports multiple industrial communication protocols, such as Modbus RTU, Profibus DP, etc., which can seamlessly communicate with different manufacturers and types of devices, facilitating the construction of complex industrial automation systems, achieving high integration and collaborative work of the system, and meeting the diverse needs of industrial automation application scenarios.

Working principle

Instruction reception and parsing: Receive control instructions from upper level computers (such as PLCs, industrial control computers, etc.) through communication interfaces, which include key information such as equipment operation mode, target parameters, and action sequence. The microprocessor inside the circuit board decodes and parses the received instructions, converts them into executable control signals, and provides a basis for subsequent device control.

Data collection and processing: Various sensors connected to the circuit board collect real-time operational status data of the equipment, convert it into electrical signals, and transmit them to the circuit board. The analog-to-digital conversion circuit on the circuit board converts analog signals into digital signals. The microprocessor uses preset algorithms to analyze and calculate the collected data, determine whether the device is running normally, and compare it with preset standard parameters to determine the next control strategy.

Control signal output: Based on the data processing results, the microprocessor generates corresponding control signals, which are sent to connected actuators (such as motor drivers, solenoid valves, etc.) through output interfaces to drive actuator actions, achieve precise adjustment and control of equipment operating status, and ensure that the equipment operates according to predetermined requirements.

Feedback and adjustment: Continuously monitor the operating status of the equipment and receive feedback signals from the equipment. Compare the actual operation of the equipment with the expected target in real time. Once any deviation is found, adjust the control strategy and output signal immediately to form a closed-loop control system, continuously optimize the equipment operation performance, improve control accuracy and stability, and ensure the reliable production process.

Key advantages

High performance and stability: Adopting advanced manufacturing processes and high-quality electronic components, it has undergone strict quality inspection and aging testing, and has excellent anti-interference ability and stability. In complex electromagnetic environments, voltage fluctuations, and other harsh working conditions, it can still operate stably, ensuring precise and reliable equipment control, reducing the occurrence of failures and downtime, and improving production efficiency.

Flexible Scalability: Rich interface types and modular design enable it to have good scalability. Users can easily add functional modules and connect more devices according to their actual production needs, easily achieve system upgrades and expansions, and adapt to the constantly changing needs of industrial automation development.

Easy to maintain and diagnose faults: Equipped with comprehensive self diagnostic functions, it can monitor its own working status in real time. Once a fault is detected, an alarm signal is immediately issued and detailed fault information is recorded to help maintenance personnel quickly locate and troubleshoot the problem. The concise operation interface and intuitive parameter setting method reduce the difficulty of operation and maintenance personnel, and improve equipment maintenance efficiency.

Precautions

Installation environment requirements: It should be installed in a dry, well ventilated environment without severe vibration and electromagnetic interference. Avoid installation in damp, dusty, high-temperature, or corrosive gas environments to prevent affecting the performance and service life of circuit boards. The installation location should be away from strong electromagnetic interference sources such as large motors and transformers. If unavoidable, effective shielding and grounding measures should be taken.

Precautions for power connection: When connecting the power supply, it is necessary to strictly follow the product specifications and correctly connect the appropriate power supply voltage and phase sequence. Carefully check whether the power supply circuit is firm and reliable to prevent loosening, short circuits, and other situations from occurring. It is strictly prohibited to connect or disconnect the power supply while it is live, in order to avoid electric shock accidents or damage to the circuit board.

Key points of operation and maintenance: Operators need to undergo professional training and be familiar with the operation methods and parameter settings of circuit boards. When adjusting parameters, be cautious to avoid abnormal device operation caused by incorrect settings. Regularly clean and inspect the circuit board, remove surface dust and debris, check for loose interface connections, and inspect for signs of damage to components. If any abnormalities are found, the equipment should be shut down in a timely manner for handling, and it is strictly prohibited to operate the equipment with problems.

Software upgrade instructions: If a software upgrade is required, the original configuration data should be backed up first to prevent data loss during the upgrade process. Download officially recognized upgrade software and follow the correct upgrade steps. During the upgrade process, ensure stable power supply to the equipment to avoid upgrade failure and damage to the circuit board due to power outages or other reasons.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923