K-WANG

ABB 3BSE000860R1 SB510 Backup Power Supply 110/230V AC

Description: Suitable for 110-230V AC (47-60Hz) or 110-230V DC input, designed for charging 12V, 4Ah nickel cadmium (NiCd) batteries.

Exemption Statement: This component is exempt from the scope of application of the 2011/65/EU (RoHS) directive, in accordance with Article 2 (4) (c), (e), (f), and (j) of the directive (refer to 3BSE088609- EU Declaration of Conformity for ABB Advant Master Process Control Systems).

ABB 3BSE000860R1 SB510 Backup Power Supply 110/230V AC

Basic information

Product identification: Product number 3BSE000860R1, model SB510, product type is Backup Power Supply.

Description: Suitable for 110-230V AC (47-60Hz) or 110-230V DC input, designed for charging 12V, 4Ah nickel cadmium (NiCd) batteries.

Exemption Statement: This component is exempt from the scope of application of the 2011/65/EU (RoHS) directive, in accordance with Article 2 (4) (c), (e), (f), and (j) of the directive (refer to 3BSE088609- EU Declaration of Conformity for ABB Advant Master Process Control Systems).

Size and weight

The net depth/length of the product is 291mm, the net height is 150mm, the net width is 60mm, and the net weight is 0.98kg.

Environmental and Classification Information

RoHS status: Compliant with EU Directive 2011/65/EU.

WEEE category: 5 categories (small equipment with no external dimensions exceeding 50cm).

SCIP: The identifier is 8a71de04-baf4-4395-9f39-8c98dd9bd6c1, and the associated country is Sweden (SE).

Customs code: HS code is 850440 (for electrical transformers, static converters (such as rectifiers), and inductors - static converters), and customs tax number is 85044082.

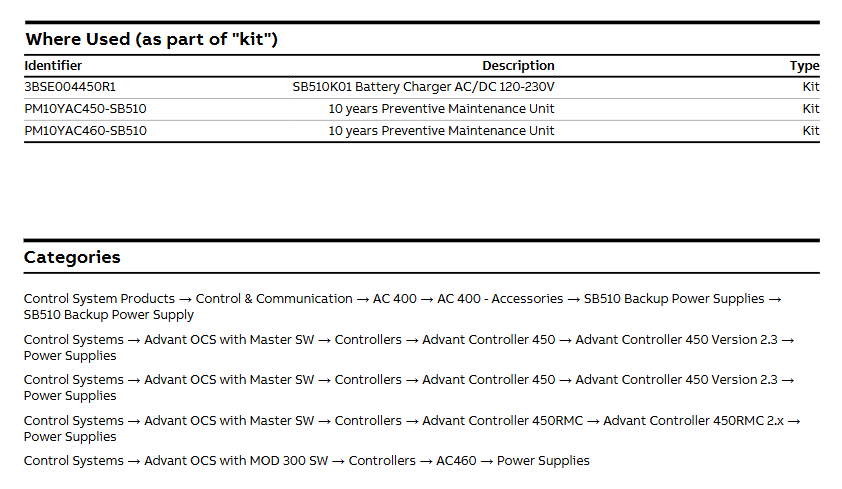

Related kits

The usage scenarios that are part of the suite include:

3BSE004450R1: SB510K01 Battery Charger (AC/DC 120-230V)

PM10YAC450-SB510: 10-year preventive maintenance unit

PM10YAC460-SB510: 10-year preventive maintenance unit

Category

Involving multiple categories of control systems, such as AC 400 accessories under Control System Products and power supply for Advant OCS related controllers.

Installation steps

1. Preparation before installation

Environmental inspection: Ensure that the installation location is well ventilated, away from heat sources, corrosive gases, and severe vibrations. The ambient temperature and humidity meet the requirements for equipment operation (referring to the general standards for industrial power supplies, usually -10~50 ℃, humidity ≤ 90%, no condensation).

Power matching: Confirm that the input power is 110-230V AC (47-60Hz) or 110-230V DC, consistent with the rated input of the device, to avoid damage caused by voltage mismatch.

Tools and accessories: Prepare suitable screwdrivers, wires, terminal blocks, etc. to ensure good insulation performance of the wiring tools.

2. Physical installation

Fixed method: According to the size of the equipment (width 60mm x height 150mm x depth 291mm), choose a suitable DIN rail or panel for installation, ensuring a firm installation and avoiding looseness.

Space reservation: Reserve at least 10cm of space around the device for heat dissipation and later maintenance.

3. Electrical connection

Input wiring: When connecting the input power supply, distinguish between the live wire (L), neutral wire (N), and ground wire (PE), ensure that the wiring is firm and insulated, and the grounding terminal should be reliably connected to the protective grounding system.

Battery connection: Connect 12V, 4Ah nickel cadmium (NiCd) batteries correctly according to the device identification, pay attention to positive and negative polarity, and avoid short circuits.

Wiring inspection: After the connection is completed, check whether the wiring is loose or short circuited. After confirming that there are no errors, turn on the power.

4. Power on test

When powering on for the first time, observe whether the device indicator light (such as the charging indicator light) lights up normally and confirm that the battery starts charging (if equipped with an indicator light).

Monitor whether the input voltage and output voltage are stable to ensure compliance with equipment operating parameters.

Maintenance points

1. Daily inspection (monthly)

Appearance inspection: Check whether the equipment casing is damaged or deformed, whether the wiring terminals are loose or oxidized, and whether the cables are aging.

Running status: Check if the charging is normal (such as measuring the battery voltage through the indicator light or multimeter, which should be around 13.5-14V after full charge), and there is no abnormal heating or noise.

2. Regular maintenance (every 6 months)

Cleaning and maintenance: After power off, use a dry brush or compressed air to clean the dust on the surface of the equipment and the heat dissipation holes to avoid dust accumulation that affects heat dissipation.

Battery inspection:

Measure the battery capacity. If the capacity drops below 70% of the rated value, it is necessary to replace the NiCd battery of the same model (12V, 4Ah) in a timely manner.

Check if the battery wiring is secure, and if there are any leaks, bulges, or other issues. If there are any abnormalities, replace them immediately.

Power performance test: Use a multimeter to check whether the input/output voltage is within the rated range, ensuring normal voltage regulation performance.

3. Long term storage and maintenance after discontinuation

If the device is not used for a long time, the input power should be disconnected, the battery should be removed and stored separately in a dry and cool place (temperature 0-25 ℃), and the battery should be recharged every 3 months to avoid damage caused by power loss.

Before re enabling, check the battery status and device wiring, confirm that there are no errors before powering on.

4. Fault handling

If the equipment cannot work properly, first check whether the input power supply is normal and whether the wiring is loose. After ruling out external problems, contact ABB's official after-sales or professional technical personnel for maintenance to avoid disassembling on your own.

Precautions

Be sure to cut off the power during operation, comply with electrical safety regulations, and wear protective equipment such as insulated gloves.

Batteries are classified as hazardous materials, and waste batteries that have been replaced must be properly disposed of in accordance with local environmental regulations and cannot be discarded at will.

Maintenance records: It is recommended to establish a maintenance ledger to record the content and time of each inspection and replacement, in order to facilitate the traceability of equipment status.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923