K-WANG

Honeywell Satellite XT gas detection transmitter

Honeywell Satellite XT gas detection transmitter

Product overview

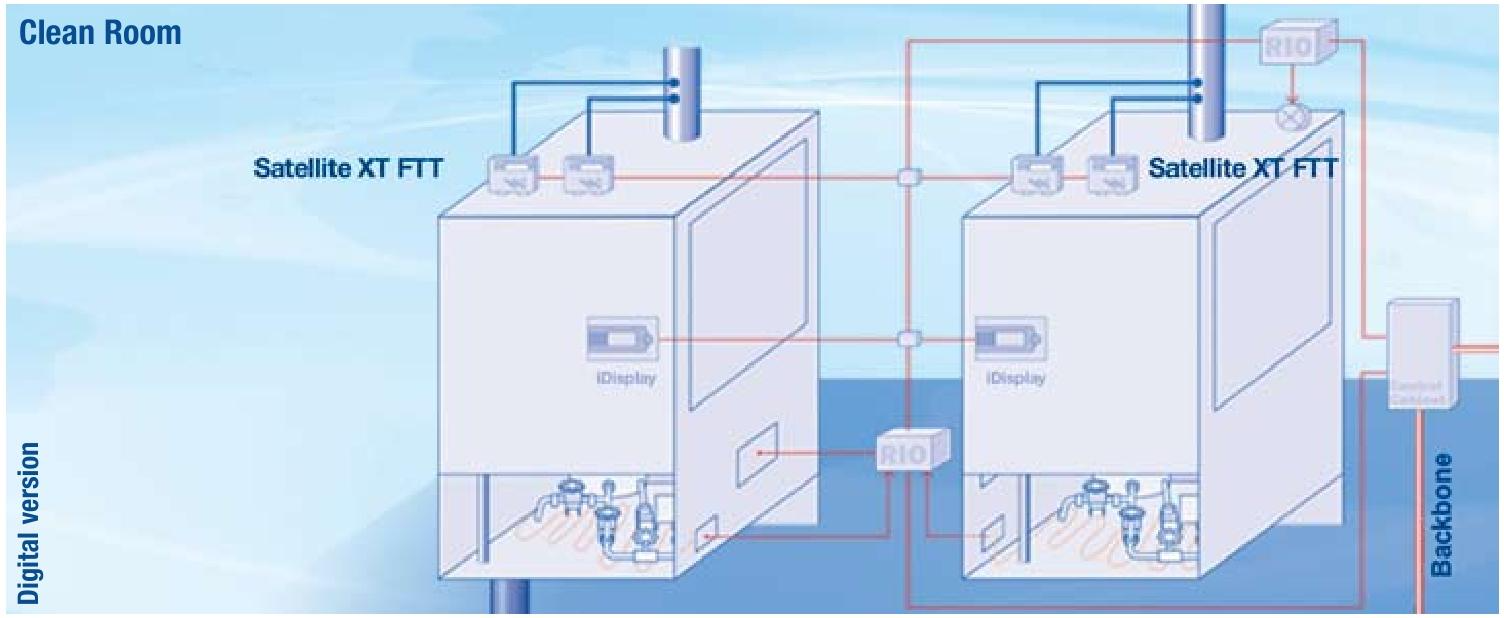

Satellite XT is an intelligent gas detection transmitter that uses a unique electrochemical sensor to detect toxic, corrosive, and flammable gases, making it a simple solution to meet all gas detection needs at any point of use. Based on the smallest and most reliable electrochemical cell technology on the market, it has the characteristics of flexibility, simplicity, and ease of application. It has two configurations to choose from, analog and digital, and can be integrated with new or existing facility control technologies. Among them, the digital version of Satellite XT is based on LonWorks ® Technology, based on LonWorks ® The life safety system built on the network platform allows users to utilize the cost-effectiveness of distributed control while maintaining the integrity and reliability required for compliant security applications.

Application scenarios

Suitable for gas detection in various scenarios, including:

Gas cabinet

Valve manifold box

Equipment casing

Environmental breathing zone

Gas storage room

Original Equipment Manufacturer (OEM) equipment

Typical installation scenarios include gas cabinet exhaust pipes, valve manifold boxes, equipment enclosures, and environmental breathing zones. On site attachments provide sampling options for various environments, including in-situ pipeline testing and extractive design for harsh or remote areas.

Product advantages

Fast, reliable, and specific gas detection

Continuous real-time monitoring

Interchangeable intelligent sensor units

No need for dynamic gas calibration

General sensor head electronic device

LOW COST OF OWNERSHIP

No easily worn or replaceable moving parts

Modular settings to meet current and future needs

DIN rail installation, easy to install (advantages of XT series)

The extraction module XT has the advantages of in-situ flow control, low maintenance, and easy installation

Series composition and options

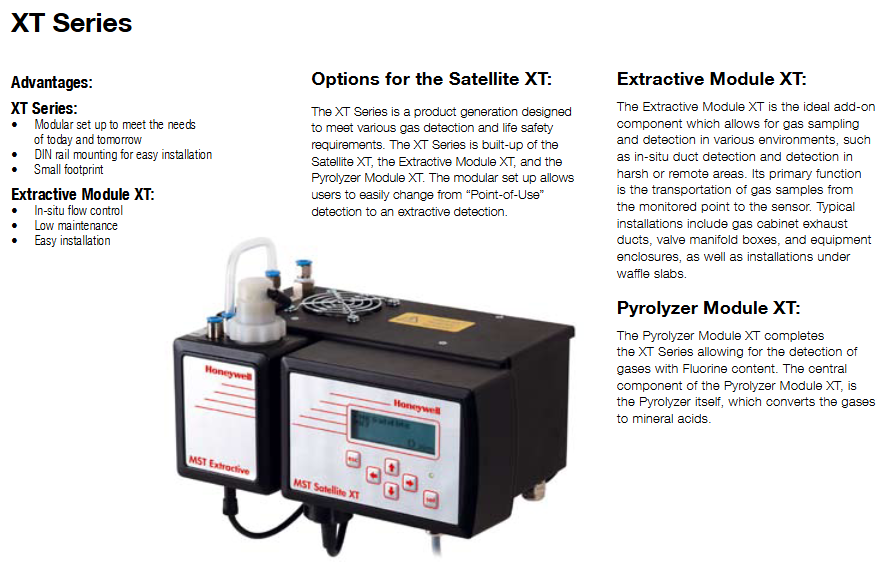

The XT series is a product line designed to meet various gas detection and life safety requirements, consisting of Satellite XT, Extraction Module XT, and Pyrolysis Module XT. Modular settings allow users to easily switch from "point of use" detection to extractive detection.

Extraction module XT: an ideal add-on component that allows gas sampling and detection in various environments, such as in-situ pipeline testing and detection in harsh or remote areas. Its main function is to transfer gas samples from monitoring points to sensors.

Pyrolysis module XT: The XT series has been improved to allow for the detection of fluorine-containing gases. Its core component is the pyrolyzer, which can convert gases into inorganic acids.

Sensor Expansion: Available in three lengths: 1 meter, 2 meters, and 3 meters.

Sensor related

Electrochemical cell gas detection sensor

It covers various substances, such as arsine (AsH ∝), diborane (B ₂ H ₆), bromine (Br ₂), chlorine (Cl ₂), etc. Each substance corresponds to different sensor models, nominal ranges, and related descriptions, and more gases and ranges can be provided upon request.

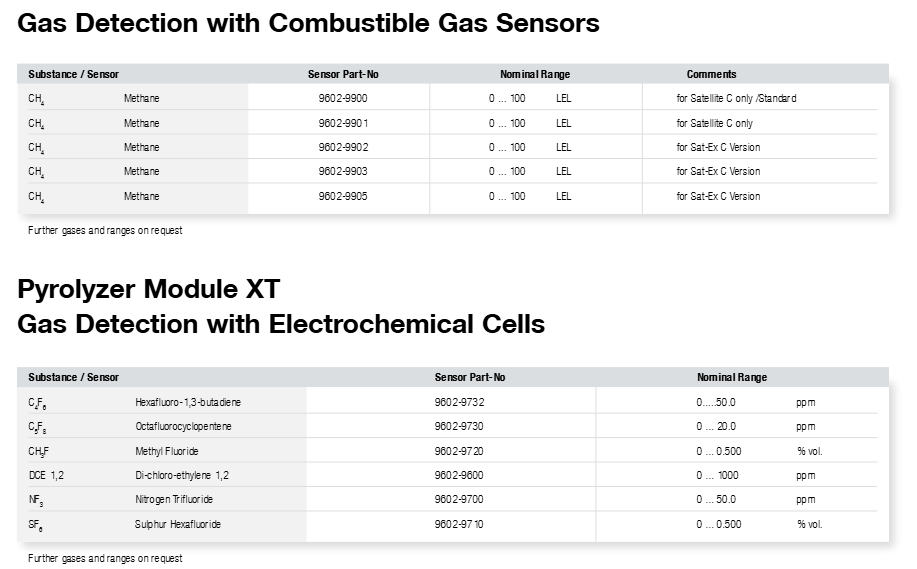

Combustible gas sensor

For methane (CH ₄), there are various sensor models with nominal ranges of 0... 100 LEL, suitable for different versions of equipment.

Pyrolysis module XT electrochemical cell gas detection sensor

Including hexafluoro-1,3-butadiene (C ₄ F ₆), octafluorocyclopentene (C ₅ F ₈), etc., each substance corresponds to a specific sensor model and nominal range.

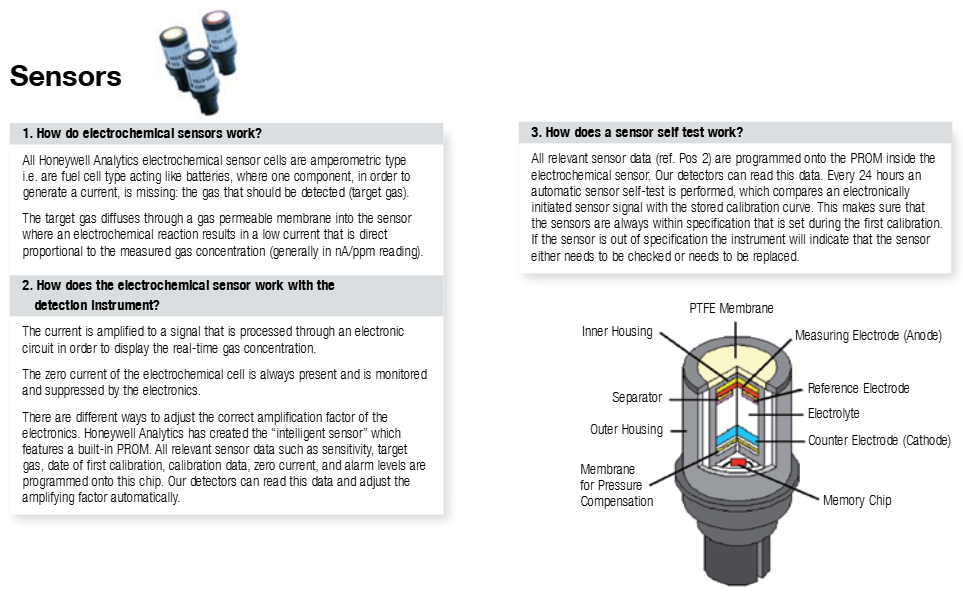

Working principle of sensors

Electrochemical sensors are all ampere type, similar to fuel cells. In order to generate current, they lack a component, which is the gas (target gas) that should be detected. The target gas diffuses through the breathable membrane into the sensor, where an electrochemical reaction occurs, producing a low current proportional to the measured gas concentration (usually read in nA/ppm).

The current is amplified into a signal and processed by electronic circuits to display real-time gas concentration. The zero current of electrochemical cells always exists and is monitored and suppressed by electronic devices.

Honeywell Analytical Instruments has created an "intelligent sensor" with a built-in PROM that programs all relevant sensor data (such as sensitivity, target gas, first calibration date, calibration data, zero current, and alarm level) onto the chip. The detector can read this data and automatically adjust the amplification factor.

Sensor self-test

All relevant sensor data is programmed into the PROM inside the electrochemical sensor, and the detector can read this data. Perform an automatic sensor self-test every 24 hours, comparing the electronically activated sensor signal with the stored calibration curve to ensure that the sensor remains within the specifications set during the initial calibration. If the sensor exceeds the specifications, the instrument will indicate that the sensor needs to be checked or replaced.

Technical specifications

Digital version (such as Satellite XT FTT, etc.)

Power requirements: Voltage ranging from 12 to 24 VDC, maximum power consumption varies for different models, such as FTT maximum 0.6W, FTT/R maximum 1.4W, etc.

Network data transmission: 78Kb/s.

Wiring topology: Free, such as bus, star, ring, or hybrid.

Wiring: The network uses 4-wire shielded cables, and relay contacts use 6-wire shielded cables.

Relay output: 3 single pole single throw (SPST) contacts, maximum rated 250 VAC/30 VDC, 2A.

Graphic display: 122 x 32 dots with backlight.

Status LED: Green.

Keyboard: 6 touch sensitive film function keys.

Physical dimensions: 145 x 95 x 50mm (length x width x height).

Weight: Different models have different weights, such as FTT at 480g (17oz) and FTT/R at 650g (23oz).

Installation: Special installation board (provided with the instrument).

Shell protection level: IP 52 (optional IP 65).

RF interference/electromagnetic compatibility: Complies with EN 55022 and EN 50082-2 standards.

Working conditions: temperature from -20 ° C to+40 ° C, pressure from 700 to 1300hPa, humidity from 20 to 90% relative humidity.

Part number: Different models correspond to different numbers, such as FTT 9602-0400, FTT/R 9602-0405, etc.

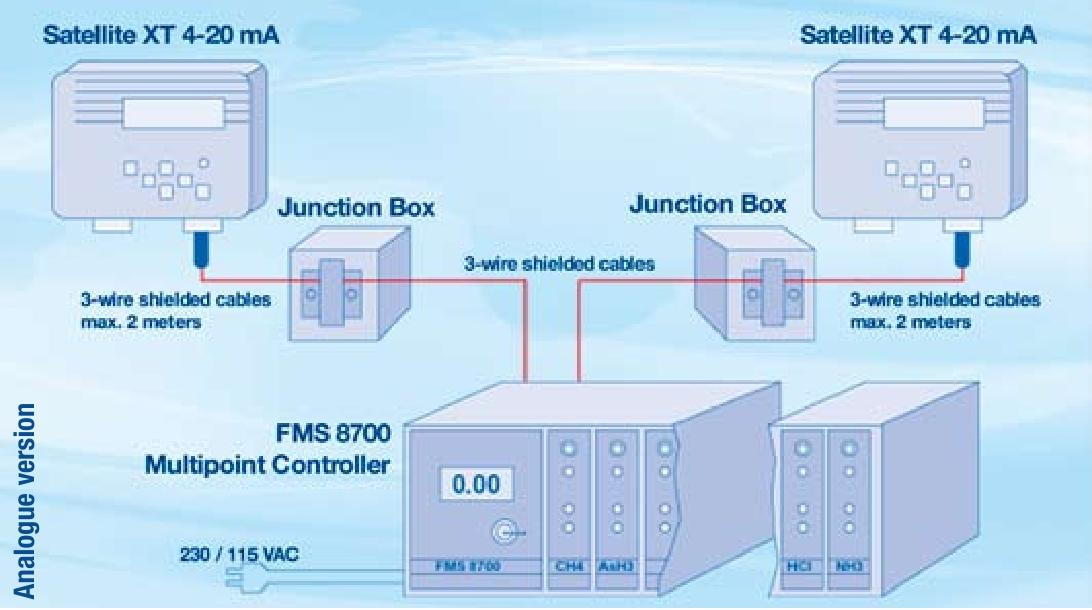

Simulated version (Satellite XT 4-20 mA, etc.)

Power requirements: Voltage 12 to 24 VDC, maximum power consumption varies for different models, such as 4-20 mA with a maximum of 1W, 4-20 mA/R with a maximum of 1.8W, etc.

Analog signal output: The monitoring mode is 2-20mA or 4-20mA, the warning state is 2.8-4 mA 0.1Hz, the maintenance mode is 2.4-4 mA 1Hz, and the fault range is 0-2mA.

Wiring: The analog interface uses 3-wire shielded cables, and the relay contacts use 6-wire shielded cables.

Relay output: 3 single pole single throw (SPST) contacts, maximum rated 250 VAC/30 VDC, 2A.

Graphic display: 122 x 32 dots with backlight.

Status LED: Green.

Keyboard: 6 touch sensitive film function keys.

Physical dimensions: 145 x 95 x 50mm (length x width x height).

Weight: Different models have different weights, such as 480g (17oz) for 4-20 mA and 650g (23oz) for 4-20 mA/R.

Installation: Special installation board (provided with the instrument).

Shell protection level: IP 52 (optional IP 65).

Radio frequency interference/electromagnetic compatibility: Complies with standards such as EN 55011 and EN 50082-2.

Working conditions: temperature from -20 ° C to+40 ° C, pressure from 700 to 1300hPa, humidity from 20 to 90% relative humidity.

Part number: Different models correspond to different numbers, for example, 4-20 mA is 9602-0200, 4-20 mA/R is 9602-0205, etc.

Honeywell related products and services

Range

Fixed gas monitoring: Honeywell Analytical Instruments provides a wide range of fixed gas detection solutions, suitable for various industries and applications, including commercial properties, industrial applications, semiconductor manufacturers, energy plants, and petrochemical plants. It can detect flammable, oxygen, and toxic gases (including foreign gases), with four core sensing technologies (paper tape, electrochemical cells, catalytic beads, and infrared), capable of detecting gases as low as one billionth (ppb) or volume percentage (% v/v), providing cost-effective solutions that comply with regulations, as well as customized preventive/corrective maintenance plans and extended product warranties.

Portable gas monitoring: Honeywell analytical instruments have a wide range of reliable solutions for personal protection against gas hazards, making them ideal for use in enclosed or confined spaces, including detecting flammable, oxygen, and toxic gases, single gas personal monitoring devices (worn by individuals), multi gas portable gas monitoring devices (for confined space entry and regulatory compliance), and multi gas transportable monitoring devices (for temporary protection of areas during on-site construction and maintenance activities).

Technical service

Honeywell Analytical Instruments values high-quality service and customer care, committed to providing complete and thorough customer satisfaction. The services provided include comprehensive technical support, well-equipped workshops to ensure quick repair turnover, a comprehensive network of service engineers, product usage and maintenance training, mobile calibration services, and more.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923