K-WANG

Watlow Series 146 Temperature Regulator

Watlow Series 146 Temperature Regulator

Product basic information

Core positioning: A DIN rail mounted temperature regulation controller that supports thermocouple or RTD sensor input, with both DIN rail quick installation and embedded installation methods. Designed for various safety application scenarios, it can achieve high/low limit temperature control and is suitable for industrial heating equipment, commercial cooking equipment and other scenarios that require temperature safety protection, such as ovens, reactors, heaters, etc.

Core Features and Advantages

Flexible and convenient installation: Supports DIN EN50022 standard 35mm × 7.5mm rail installation, which can be completed with simple manual tools. Embedded installation can also be selected to adapt to different installation environment requirements.

Diverse control modes: The factory can preset high/low limit control modes, support manual or automatic reset after power failure, and meet different safety control logics; Equipped with temperature over limit latch alarm function, requiring manual reset to enhance safety and reliability.

Intuitive and easy to understand operation: equipped with output status LED indicator lights, providing real-time feedback on working status; Support built-in/remote adjustable or fixed setpoints, calibrated dial to compensate for sensor nonlinearity errors; Simultaneously compatible with both Celsius (° C) and Fahrenheit (° F) temperature scales, suitable for different usage habits.

Comprehensive safety protection: equipped with thermocouple and RTD disconnection protection function, automatically cutting off output in case of sensor failure to avoid equipment damage; Obtained multiple certifications such as CE and FM Class 3545, compliant with EN61010 safety standards, EN61326 industrial electromagnetic compatibility standards (Class B emission), installation category II, pollution level 2, suitable for specific scenarios such as commercial cooking.

Strong adaptability: Supports multiple thermocouple (E, J, K, T type, etc.) and RTD (100 Ω, 1000 Ω) inputs, with optional power supply voltages of 24VAC, 120VAC, 230-240VAC to meet different on-site power supply and sensing needs.

Product Technical Specifications

(1) Control and operation specifications

Control mode: The factory can choose high limit or low limit control; The power-off reset mode can be selected manually or automatically; When the temperature exceeds the limit (too high/too low), a latch alarm is triggered and manual reset is required; Support built-in reset switch or external reset switch provided by the user.

Operation interface: LED indicator light displays output status (power on/off); Adjustable set point (built-in/remote) equipped with calibration dial to compensate for sensor nonlinearity; Fixed set point factory calibration according to user specified values; Dual temperature scale (° C/° F) switching.

(2) Enter specifications

Sensor type: Supports thermocouples (E, J, K, T, etc.) or platinum resistance RTDs, thermocouples have automatic cold junction compensation function, and can choose isolation or grounding type; RTD supports 2-wire or 3-wire system, calibrated at 100 Ω @ 0 ° C, and conforms to the 0.003850 Ω/Ω·° C curve.

Input protection: thermocouple and RTD disconnection protection function, automatically cuts off the output when the sensor is disconnected, preventing equipment from losing control.

Measurement range: Depending on the sensor type and model configuration, for example, E-type thermocouple 0-799 ° C (32-1470 ° F), J-type thermocouple 0-315 ° C (32-600 ° F), T-type thermocouple -200-350 ° C (-328-662 ° F); RTD measurement range -73-600 ° C (-100-1112 ° F), etc., fixed set points can be customized according to user needs (such as 200 ° C, 350 ° C, etc.).

(3) Output specifications

Output type: 8A electromagnetic relay, Form C (single pole double throw, SPDT), rated load: 8A@240VAC (obstructive) 8A@28VDC (Resistive), with a rated load of 275VA, can directly drive small heating equipment, contactor coils, and other loads.

Load protection: When switching inductive loads (such as relay coils, solenoid valves, etc.), an RC suppressor (Watlow recommended model Quencharc, part number 0804-0147-0000) needs to be installed to avoid electromagnetic interference damaging the controller.

(4) Accuracy and stability

Calibration accuracy: The adjustable set point (built-in/remote) is within ± 1% of the range at an ambient temperature of 25 ° C ± 3 ° C (77 ° F ± 5 ° F) and a rated line voltage of ± 1%, with a minimum range of 540 ° C (1000 ° F); The fixed set point has an error of ± 6 ° C/± 10 ° F under the same environmental and voltage conditions.

Setpoint accuracy: The precision of the adjustable set point dial is ± 3%.

Temperature stability: When the thermocouple is input, for every 1 ° C change in ambient temperature, the input reference drift typical value is 9 µ V/° C (5 µ V/° F); When inputting RTD, for every 1 ° C change in ambient temperature, the typical drift value is 0.2 ° C/° C (0.2 ° F/° F).

Voltage stability: For every 1% change in rated line voltage, the range drift is ± 0.01% (minimum range 540 ° C or 1000 ° F).

(5) Power and environmental specifications

Power parameters: Supports 24VAC (+10%/-15%), 120VAC (+10%/-15%), 230-240VAC (+10%/-15%), frequency 50/60Hz, maximum power consumption 10VA, power type needs to be specified by model (such as 1=120VAC, 2=230-240VAC, 3=24VAC).

Environmental conditions: working temperature 0-55 ° C (32-131 ° F), storage temperature -20-85 ° C (-4-185 ° F); Relative humidity 0-90% (non condensing), suitable for most industrial and commercial environments.

(6) Physical and installation specifications

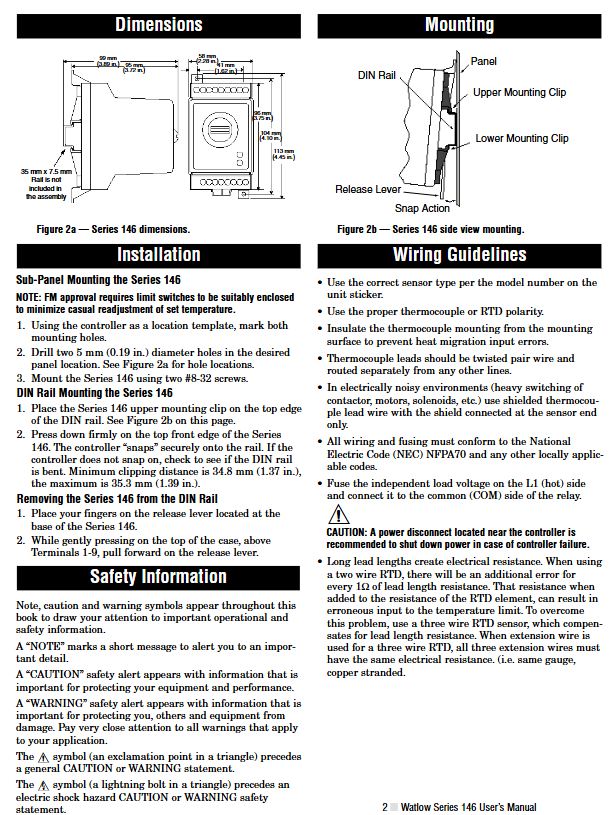

Dimensions: Width 60mm (2.28 inches), height 115mm (4.45 inches), depth 100mm (3.89 inches), weight 0.3kg (0.7 pounds).

Terminal specifications: Captive screw cage clamping connection, supports maximum 4mm (0.155 inch) screwdriver head operation, compatible with 14-30 gauge wires.

Installation method: DIN rail installation (compatible with 35mm × 7.5mm rails) or embedded installation. Embedded installation requires drilling two 5mm (0.19 inch) holes on the panel and fixing them with # 8-32 screws.

Installation and Wiring Guide

(1) Installation process

1. Sub Panel Mounting

Attention: FM certification requires that limit switches be appropriately closed to reduce arbitrary adjustments to the set temperature.

Step 1: Use the controller as a template and mark two installation hole positions on the panel (refer to the hole size in Figure 2a of the document).

Step 2: Drill two 5mm (0.19 inch) diameter holes at the marked location.

Step 3: Use two # 8-32 screws to secure Series 146 to the panel.

2. DIN Rail Mounting

Step 1: Align the upper mounting clip of the controller with the upper edge of the DIN rail (refer to Figure 2b in the document).

Step 2: Press firmly on the upper edge of the front part of the controller, and the controller will be firmly fixed on the guide rail in a "snap" manner; If it cannot be fastened, check if the guide rail is bent. The clamping distance range of the guide rail is 34.8mm (1.37 inches) to 35.3mm (1.39 inches).

3. Disassemble from DIN rail

Step 1: Use your fingers to hold down the release lever at the bottom of the controller.

Step 2: Gently press the top of the controller (above terminals 1-9) and pull the release lever forward to remove the controller.

(2) Wiring specifications

1. General wiring rules

Use sensor types that match the device label model to ensure correct polarity of thermocouples or RTDs.

Thermocouples should be insulated from the installation surface during installation to avoid input errors caused by thermal conduction; Thermocouple leads should be made of twisted pair wires, wired separately, and kept away from other circuits.

In environments with severe electromagnetic interference (such as frequent switching of contactors, motors, and solenoid valves), shielded thermocouple leads should be used, and the shielding layer should only be grounded at the sensor end.

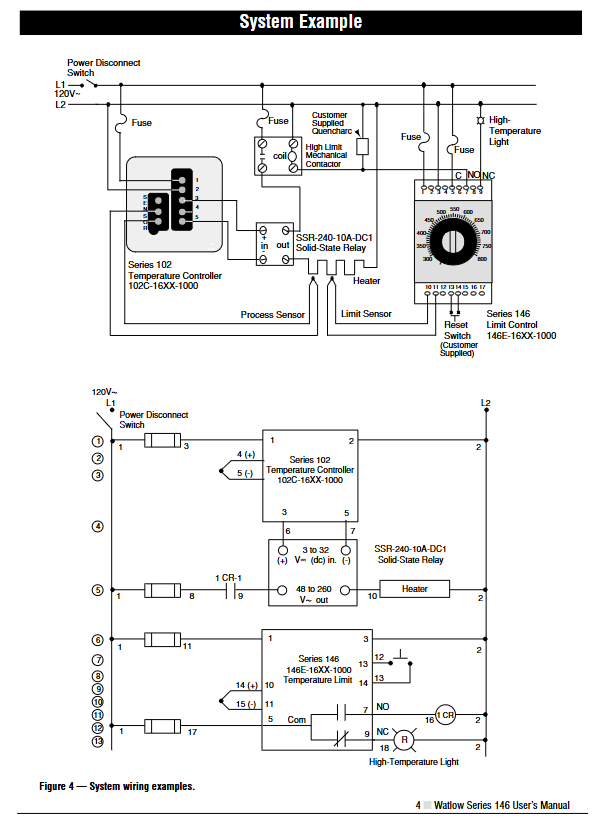

All wiring and fuse configurations must comply with the National Electrical Code (NEC NFPA70) and applicable local regulations; The independent load voltage needs to be fused on the L1 (live) side and connected to the common terminal (COM) of the relay.

It is recommended to install a power isolation switch near the controller to cut off the power supply in case of controller failure; The lead resistance of a 2-wire RTD can introduce errors (every 1 Ω lead resistance leads to additional errors). It is recommended to use a 3-wire RTD to compensate for lead resistance, and the three extension wires must have the same resistance (same wire gauge, copper stranded wire).

2. Power wiring

The power supply type is specified by the model: 120VAC corresponds to model 146_ -1_ -00000 230-240VAC corresponds to 146-2_ -0000, 24VAC corresponds to 146-3_ -0000.

Warning: To avoid the risk of electric shock, wiring must comply with national electrical safety standards. All wiring and fuses must comply with NEC and local regulations, otherwise it may cause equipment damage, property damage, or personal injury; The controller should be installed in an inconspicuous location to prevent unauthorized personnel from adjusting the set point. Only authorized personnel can operate the set point change, and unauthorized operation may cause safety risks; Applying incorrect voltage can cause irreversible damage to the controller.

3. Input wiring

Thermocouple wiring: Connect the positive and negative poles to the corresponding terminals as shown in Figure 3b of the document to ensure that the cold end compensation function is normal. Isolation and grounding thermocouples should be wired according to the model requirements.

RTD wiring: Refer to Figure 3c in the document for the wiring methods of 2-wire and 3-wire RTDs. The three leads of the 3-wire RTD need to have the same resistance. When wiring, pay attention to the correspondence between terminals S1 and S3 to ensure that the calibration curve matches (0.003850 Ω/Ω·° C).

4. Output wiring

The wiring of the electromagnetic relay (Form C type) should refer to Figure 3d in the document. The load should be connected in series between the normally open (NO) or normally closed (NC) terminal and the common terminal (COM). A fuse (recommended specification 1A) should be installed on the L1 side, and an RC suppressor should be connected in series for inductive loads.

5. Remote reset wiring

The remote reset switch is provided by the user, and the wiring method refers to Figure 3e in the document (terminals 13, 15, 16, 17, 14). Only the momentary switch meets FM certification requirements, and remote reset may affect the validity of FM certification.

6. System wiring example

Typical system wiring includes components such as power isolation switches, fuses, controllers, sensors, loads (heaters), contactors, solid-state relays, etc. Please refer to the two system wiring schemes in Figure 4 of the document to ensure that the power supply, input, output, and reset circuit wiring are complete and comply with safety regulations.

Model selection and order information

(1) Model Structure

The model format is 146E - (1/2/3) (100-999) - (1/2/3/4) (any three letters/numbers), and the meanings of each part are as follows:

146E: Product series and output type, E=8A electromagnetic relay (Form C type).

Line voltage code: 1=120VAC, 2=230-240VAC, 3=24VAC.

Input and Range Code: Represents sensor type and measurement range, for example:

E-type thermocouple: 619=0-799 ° C (32-1470 ° F).

J-type thermocouple: 601=0-315 ° C (32-600 ° F), 602=0-750 ° C (32-1382 ° F), 615=fixed 315 ° C (600 ° F), etc.

K-type thermocouple: 603=0-1250 ° C (32-2282 ° F), 611=0-600 ° C (32-1112 ° F), etc.

T-type thermocouple: 629=-200-350 ° C (-328-662 ° F), 632=fixed -75 ° C (-103 ° F), etc.

RTD: 101=-73-600 ° C (-100-1112 ° F, 100 Ω), 104=-73-600 ° C (-100-1112 ° F, 1000 Ω), 106=fixed 200 ° C (392 ° F), etc.

Limit mode code: 1=high limit+power-off manual reset, 2=low limit+power-off manual reset, 3=high limit+power-off automatic reset, 4=low limit+power-off automatic reset.

Remote option codes: 0=adjustable control+built-in setting potentiometer, N=adjustable control+no setting potentiometer (provided by the user), S=adjustable control+remote setting potentiometer+remote reset, P=adjustable control+remote setting potentiometer.

(2) Selection precautions

Confirm the on-site power supply voltage and select the corresponding line voltage code (1/2/3).

Select the sensor type (thermocouple/RTD) and corresponding range code based on the temperature measurement range and accuracy requirements, and specify the target temperature for the fixed set point.

Select the limit mode (high/low limit) and power-off reset mode (manual/automatic) according to safety control requirements.

Select remote options according to installation and operation requirements (built-in/remote setpoints, whether remote reset is required).

The warranty period for electromagnetic relays is usually 100000 closing operations, and the service life needs to be evaluated in conjunction with the load switching frequency.

Troubleshooting and Maintenance

(1) Common faults and solutions

Possible causes and solutions for the fault phenomenon

Load cannot start sensor open circuit maintenance or replacement of sensor

Check if the fuse, circuit breaker, load, and wiring of the load circuit are normal for an open circuit

Check the AC input connection according to the "Power Wiring" section (page 3) if it is not connected or connected incorrectly. If it is not connected, reconnect it

The load cannot be turned off. Connect the thermocouple correctly by reversing the thermocouple according to the "Input Wiring" section (page 4)

Controller failure cuts off the power supply of the controller and removes it from the system, only supplying power to the system; If the load is turned off, it indicates a controller malfunction and needs to be returned to the factory for repair; If the load is still running, it indicates that there are other faults in the system. Please contact the factory for consultation

(2) Maintenance

Regularly check whether the wiring terminals are loose, whether the sensors are damaged or aged, and ensure reliable connections.

Keep the controller clean, avoid dust and oil accumulation, and stay away from corrosive environments and severe vibrations.

Regularly verify the accuracy of set points and the reliability of output actions, and promptly troubleshoot sensor or wiring issues if any abnormalities are found.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923