K-WANG

Watlow Series 988 Controller

Watlow Series 988 Controller

The Watlow Series 988 controller is a 1/8 DIN microprocessor based temperature/process controller that integrates multiple functions, covering four models: 986, 987, 988, and 989. It has flexible configuration, compact size, and high durability, and can adapt to various temperature and process control scenarios. It supports multiple input/output options and complex control algorithms.

Core characteristics of controller

1. Hardware and functional highlights

Compact design: 1/8 DIN size, integrated with rich functions, balancing flexibility and durability

Control capability: Supports single unit cascade control, covering various process variables such as temperature, pressure, flow rate, etc

Featured features: including heater current monitoring, remote setpoint input, proportional control, and sliding line feedback valve control

Algorithm and Alarm: Equipped with extended self-tuning function, enhanced alarm function, and multiple unique control algorithms

2. Model coverage

When referring to "Series 988", it includes both horizontal and low-voltage versions (986, 987, 988, 989)

There are differences in power specifications and installation methods among different models (such as 986/988 for vertical installation and 987/989 for horizontal installation)

Installation and hardware settings

1. DIP switch configuration

Number of switches: Depending on the model, the controller contains 1-6 DIP switches inside

Core functions: Configure input sensor types, provide power for external signal conditioners, lock some functions of the front panel

Operation steps: Press the release tabs on both sides/top of the panel to remove the controller chassis. After setting the switch as shown in the diagram, reset the chassis and ensure that all four tabs are securely fastened

2. Panel installation

Installation preparation: Contact the back of the panel and cut the panel cut according to the size requirements (recommended to use Greenlee 1/8 DIN hydraulic kit)

Installation steps: Slide the controller housing into the panel cut, ensure that the sealing gasket is flat, install the bracket and tighten the screws (to avoid deformation of the housing due to over tightening), and finally insert the chassis and clamp it tightly

Sealing requirements: Strictly follow the installation process to ensure NEMA 4X sealing level and prevent equipment damage

3. Wiring specifications

Safety prerequisite: Follow the National Electrical Code (NEC) safety standards to avoid the risk of electric shock

Core wiring: including power wiring (100-240V AC/DC or 24-28V AC/DC), sensor wiring (thermocouples, RTDs, etc.), input/output wiring (supporting up to 4 inputs and 4 outputs)

Isolation requirement: Optical isolation (500V AC isolation barrier) is used between analog input and controller output/digital input to avoid grounding loops

Operation interface and menu navigation

1. Front panel buttons and display

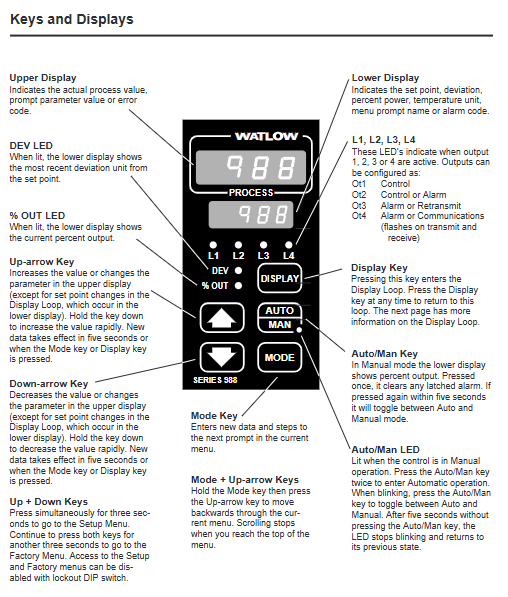

Core keys: Up arrow key (increase value), Down arrow key (decrease value), Mode key (confirm/switch menu), Display key (return to display loop), Auto/Manual key (mode switch/alarm reset)

Display function: upper displays actual process values, parameter values, or error codes; Lower displays set points, deviations, percentage outputs, etc; L1-L4 LED indicates whether the corresponding output is activated

Special operation: Press the up and down arrow keys simultaneously for 3 seconds to enter the settings menu, and press again for 3 seconds to enter the factory menu (which can be locked through DIP switch)

2. Core menu system

(1) Display Loop

Definition: The controller defaults to the "home" state and automatically returns after 1 minute of inactivity. Pressing the display button can return at any time

Display content: including input 1 reading, set point 1, input 2 reading (if equipped), deviation value, percentage output, temperature unit, etc

(2) Setup menus

Entry method: In the display loop state, press the up and down arrow keys simultaneously for 3 seconds

Includes menus: Input menu (InPt), Output menu (OtPt), Global menu (GLbL), Communication menu (COM, visible only for models equipped with communication function)

Operation rules: Output disabled during menu navigation. Use the up and down arrow keys to select the menu, and the mode key to step through the menu options

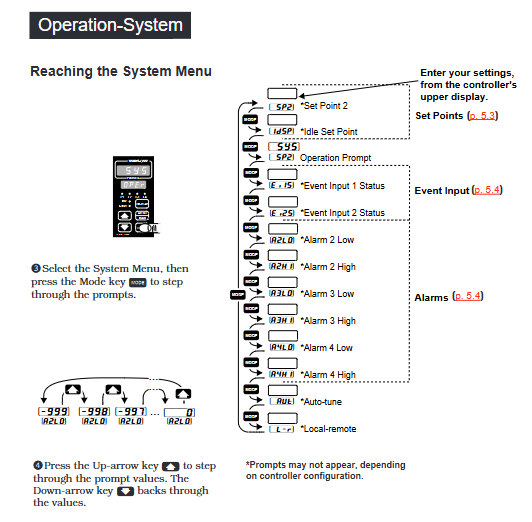

(3) Operation menus

Entry method: Press the mode key while displaying the loop state

Includes menus: System Menu (SYS), PID A Menu (PidA), PID B Menu (Pidb)

Core functions: Set second set point, idle set point, alarm trigger value, start self-tuning, etc

(4) Factory menus

Entry method: In the settings menu state, continue pressing the up and down arrow keys for 3 seconds

Includes menus: Panel Lock Menu (PLOC), Diagnostic Menu (diAg), Calibration Menu (CAL)

Restriction: When the hardware lock DIP switch is turned on, the menu cannot be accessed

Core functional configuration

1. Input/output configuration

Input settings: Select sensor type (thermocouple, RTD, 4-20mA, etc.), set decimal places, range upper and lower limits, calibration offset

Output settings: Configure output response mode (heating/cooling, alarm activation/deactivation), set lag value, alarm type (process alarm, deviation alarm, rate alarm)

2. Control mode and algorithm

Control type: supports normal control, cascade control, proportional control, differential control

Algorithm selection: Single group PID, proportional/differential control (with manual reset), dual group PID, duplex (heating/cooling) control can be selected

Self tuning function: supports automatic tuning of PID parameters, which needs to be started in the system menu. During the tuning process, the controller enters switch control mode

3. Alarm and error handling

Alarm function: Output 2-4 can be configured as an alarm, supporting lock type (manual reset required) and non lock type (automatic reset after fault relief)

Error code: including A/D conversion error, sensor over/under range error, ambient temperature error, etc. When an error occurs, the controller automatically switches to manual mode and maintains the preset output

Detailed explanation of software functions

1. General software functions

Core functions: including burst fire, communication function, dead zone control, digital events, heater current monitoring, input filtering, linearization, ramp to set point, remote set point, retransmission function, sliding line feedback, etc

Application scenario: Sudden ignition is suitable for zero crossing solid-state devices; Dead zone control prevents simultaneous activation of heating/cooling outputs; Sliding line feedback can control valve position

2. Enhanced software features (models equipped with enhanced software only)

Cascade control: precise control is achieved through two control loops (outer loop monitoring process values, inner loop monitoring heat source temperature) to reduce overshoot

Dual PID group: supports two independent PID parameters, which can be switched based on process values, setpoints, or event inputs

Proportional control: controlling the proportional value of one process variable to another, suitable for material mixing scenarios

Maintenance and Support

1. Calibration and Diagnosis

Calibration requirements: Factory calibrated. If regular calibration is required, please refer to the dedicated calibration manual

Diagnostic function: The software version, serial number, ambient temperature, A/D count, test display, and output functions can be viewed through the diagnostic menu

2. Warranty and Returns

Warranty period: 36 months warranty (from the date of first purchase and use), covering material and process defects

Return process: Contact customer service first to obtain a Return Merchandise Authorization (RMA) number. For returned products, prepaid shipping fees are required. For unused products, a 20% restocking fee may be charged

3. Technical support

Support time: 7am to 5pm Central Time in the United States

Support preparation: When contacting, please provide the controller model (12 digit number, located on the shell sticker and circuit board), user manual, configuration information, and diagnostic menu readings

Key Appendix Information

1. Specification parameters

Input type: Supports process signals such as J/K/T/N/R/S/B thermocouples, 100 Ω RTDs, 4-20mA, 0-10V, etc

Output options: Solid state relay (0.5A), electromechanical relay (5A), open collector, process output (4-20mA/0-10V), etc

Accuracy: ± 0.1% ± 1 LSD of full scale (ambient temperature 25 ℃± 3 ℃, rated voltage ± 10%)

2. Glossary of Terms

Core terms: including definitions of professional terms such as annunciator, burst fire, cascade control, PID (proportional integral derivative), dead band, etc

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923